Spectrometer with validation cell

A verification unit and measurement unit technology, which is applied in color/spectral characteristic measurement, absorption/scintillation/reflection spectroscopy, instruments, etc., can solve the problem of not being able to reliably provide trace gas concentrations, not suitable for providing reliable verification results, Can not support accurate measurement and other issues at the same time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

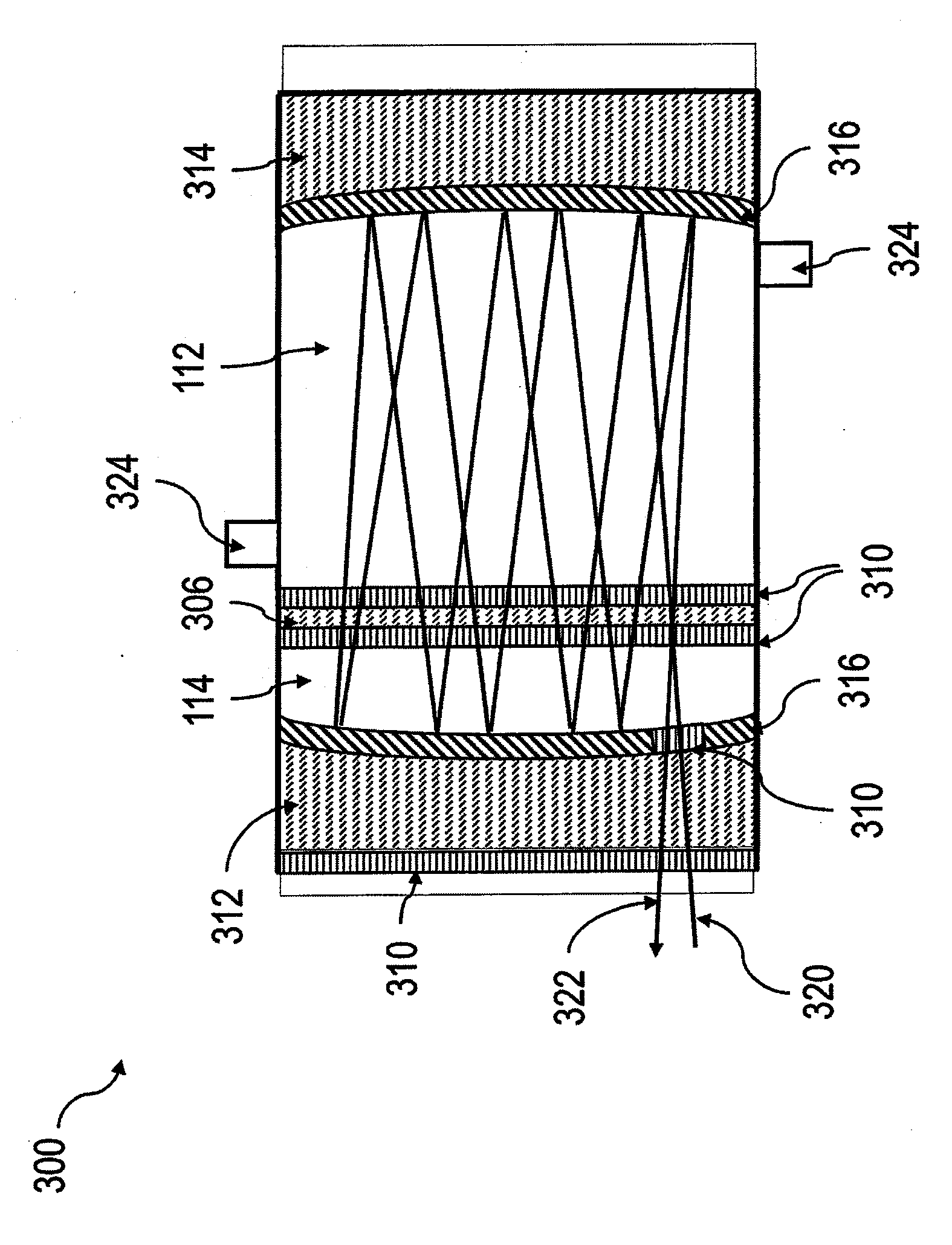

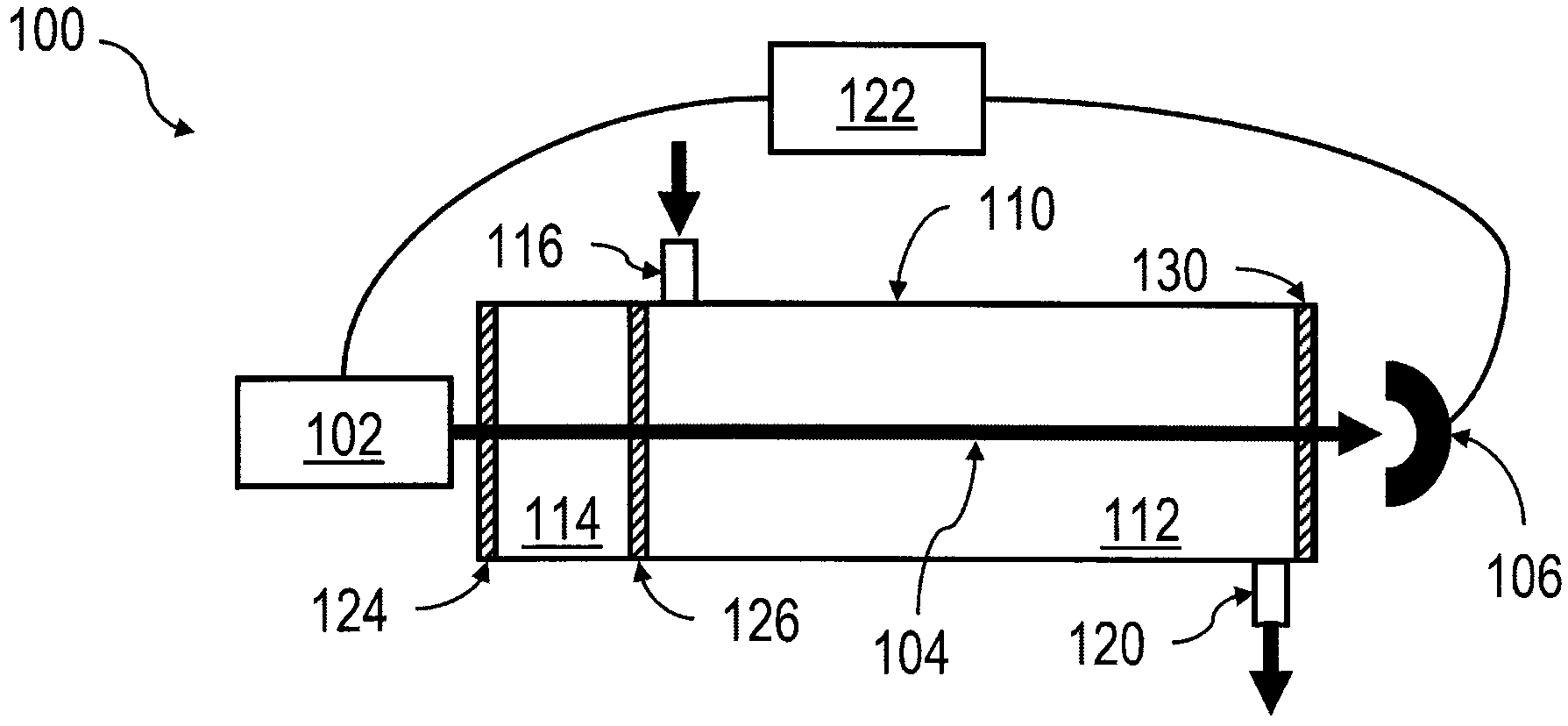

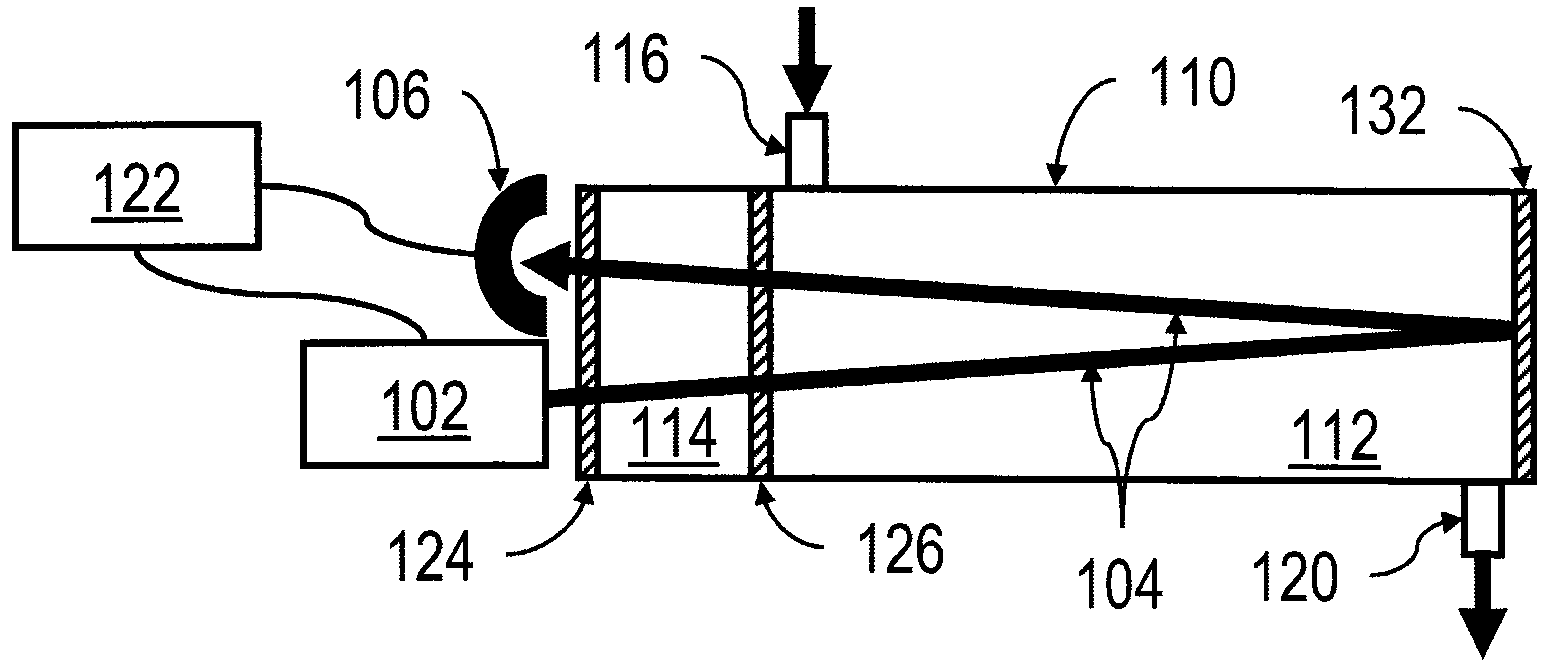

[0046] To address the above notable problems, and potentially others, of currently available solutions, one or more implementations of the subject matter provide a system capable of providing complete measurement fidelity accuracy verification capability in the optical absorption cell of a spectrometer, among other possible advantages. Methods, systems, products of manufacture, etc. The only gas required for field validation is an appropriate, readily available, low-cost zero gas. As used herein, the term "zero gas" refers to a composition of a sample measurement cell that has negligible or well-characterized light absorbance covering the target spectral signature of one or more target analytes to be detected in the sample gas mixture . The embedded verification unit includes a reference gas and is positioned such that light from the light source passes through the verification unit and the sample measurement unit on its way to the detector, which quantifies the received ligh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com