A kind of extrusion casting magnesium alloy material and preparation method thereof

A technology of squeeze casting and magnesium alloy, which is applied in the field of squeeze casting magnesium alloy material and its preparation to achieve the effects of structure refinement, improvement of alloy strength and toughness, and improvement of mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

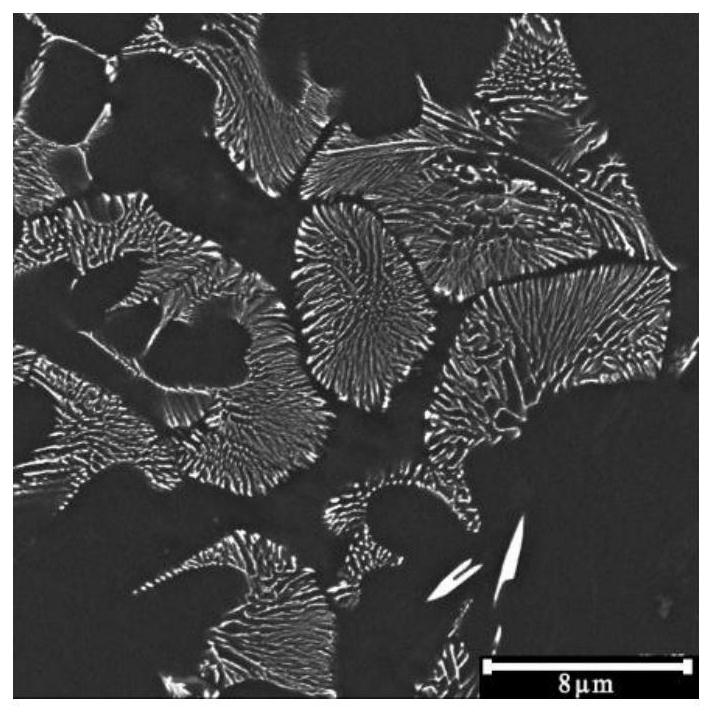

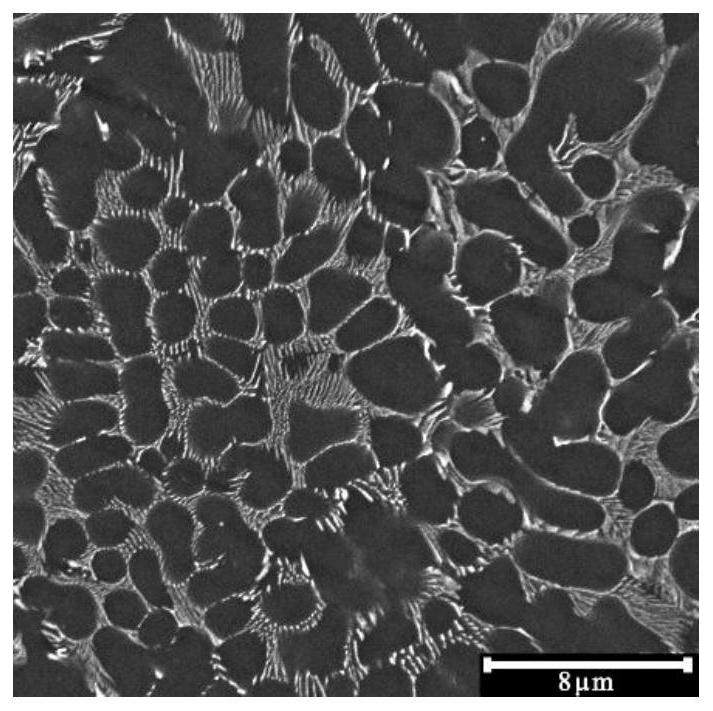

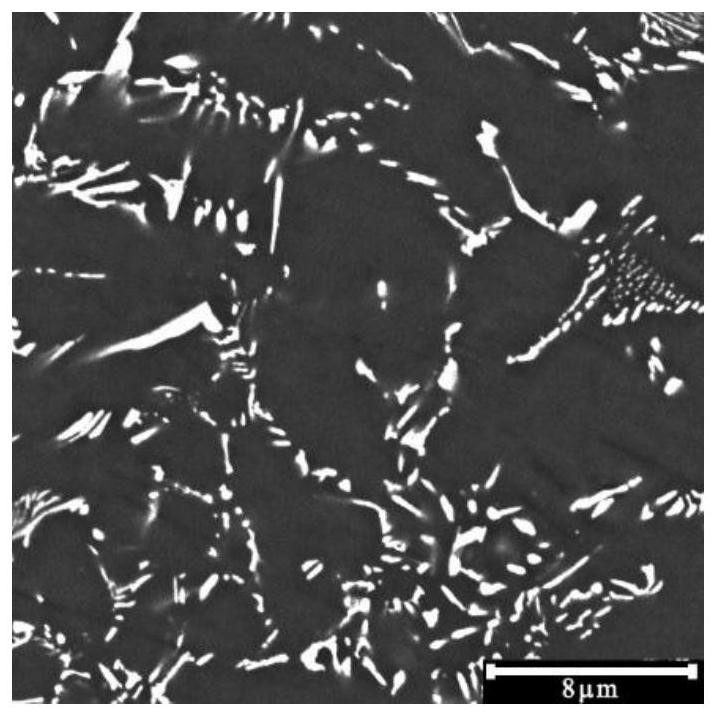

Image

Examples

Embodiment 1

[0045] Alloy composition (mass percentage) of squeeze cast magnesium alloy: 3.82% Al, 2.11% Ce, 1.08% La, 0.98% Pr, 0.01% Sm, 0.32% Mn, other unavoidable impurities are less than 0.2%, and the rest is Mg.

[0046] This embodiment relates to the smelting method of conventional rare earth magnesium alloy and the alloy squeeze casting method among the present invention:

[0047] Among them, the smelting process is in SF 6 and CO 2 Under the condition of mixed gas protection, the steps are as follows:

[0048] (1) Baking material: Preheat the smelting raw material at 200°C for 3 hours;

[0049] (2) Molten magnesium: Put the dried pure magnesium into the SF 6 / CO 2 Melting in a gas shielded crucible resistance furnace;

[0050] (3) Adding pure aluminum and magnesium-manganese master alloy: when the pure magnesium is completely melted and the temperature reaches 670°C, add the preheated pure aluminum and magnesium-manganese master alloy;

[0051] (4) Magnesium rare earth maste...

Embodiment 2

[0057] Alloy composition (mass percentage) of squeeze cast magnesium alloy: 3.74% Al, 2.06% Ce, 1.04% La, 1.01% Pr, 0.44% Sm, 0.12% Nd, 0.03% Er, 0.30% Mn, other unavoidable impurities Less than 0.2%, the rest is Mg.

[0058] This embodiment relates to the smelting method of conventional rare earth magnesium alloy and the alloy squeeze casting method among the present invention:

[0059] Among them, the smelting process is in SF 6 and CO 2 Under the condition of mixed gas protection, the steps are as follows:

[0060] (1) Baking material: Preheat the smelting raw material at 250°C for 2 hours;

[0061] (2) Molten magnesium: Put the dried pure magnesium into the SF 6 / CO 2 Melting in a gas shielded crucible resistance furnace;

[0062] (3) Add pure aluminum and magnesium-manganese master alloy: when the pure magnesium is completely melted and the temperature reaches 680°C, add the preheated pure aluminum and magnesium-manganese master alloy;

[0063] (4) Magnesium rare e...

Embodiment 3

[0069] Alloy composition (mass percentage) of squeeze casting magnesium alloy: 3.94% Al, 4.09% La, 1.09% Sm, 0.19% Nd, 0.04% Er, 0.30% Mn, other unavoidable impurities are less than 0.2%, and the rest is Mg.

[0070] This embodiment relates to the smelting method of conventional rare earth magnesium alloy and the alloy squeeze casting method among the present invention:

[0071] Among them, the smelting process is in SF 6 and CO 2 Under the condition of mixed gas protection, the steps are as follows:

[0072] (1) Baking material: Preheat the smelting raw material at 200°C for 6 hours;

[0073] (2) Molten magnesium: Put the dried pure magnesium into the SF 6 / CO 2 Melting in a gas shielded crucible resistance furnace;

[0074] (3) Add pure aluminum and magnesium-manganese master alloy: when the pure magnesium is completely melted and the temperature reaches 690°C, add the preheated pure aluminum and magnesium-manganese master alloy;

[0075] (4) Magnesium rare earth maste...

PUM

| Property | Measurement | Unit |

|---|---|---|

| breaking strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com