Brush Alloy with Age Hardening Effect and Its Application

A technology of aging hardening and brush, which is applied in the direction of circuits, current collectors, electrical components, etc., can solve the problems of intensified arc erosion, accelerated brush wear, and difficulty in meeting the use requirements, achieving less burning loss, easy technology, and significant aging The effect of enhancing the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

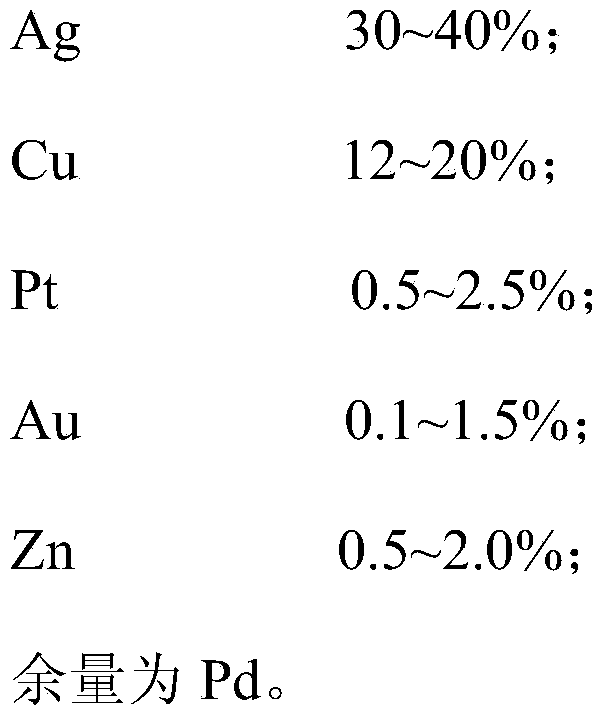

Method used

Image

Examples

Embodiment Construction

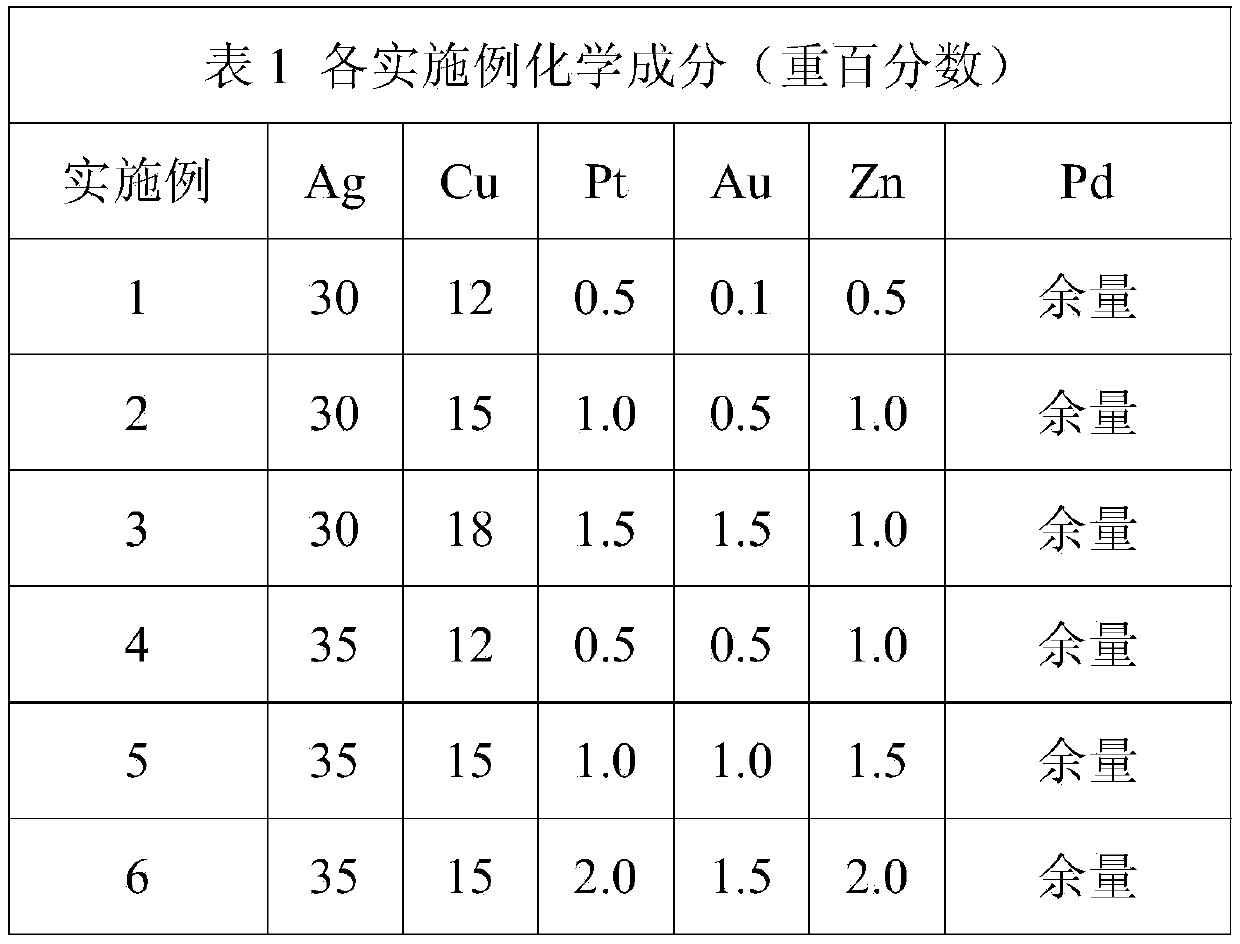

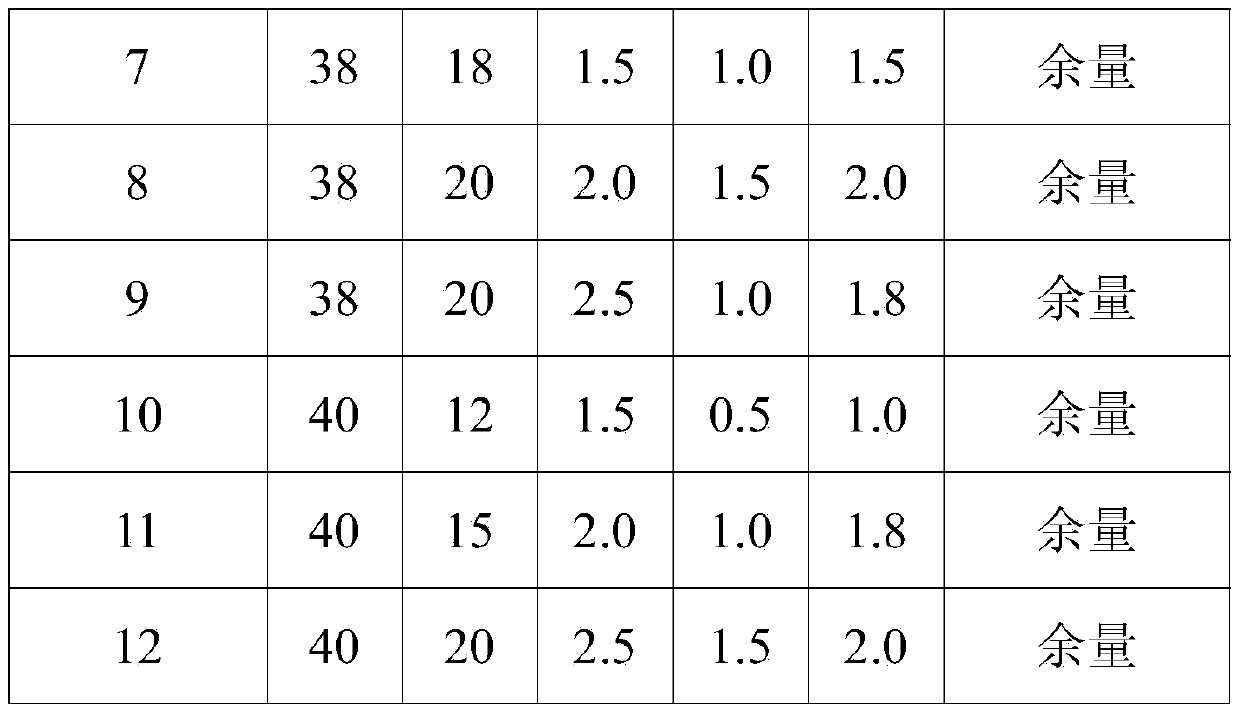

[0027] The alloy compositions of Examples 1 to 12 are shown in Table 1.

[0028]

[0029]

[0030] The preparation and processing technology of above-mentioned alloy are:

[0031] 1) The alloy is prepared by melting in a vacuum induction furnace, in which each element can be added in the form of an intermediate alloy or in the form of pure metal; scraps discarded in the production process and qualified in composition can also be used as raw materials for preparing new alloys;

[0032] 2) Prepare the prepared alloy ingots into strips or wires through blanking, rolling, intermediate annealing, drawing and other processes.

[0033] 3) Using hot rolling, warm rolling or cold rolling composite technology, the above-mentioned strip or wire material is composited with copper alloy to make a layered composite material.

[0034] In order to ensure that the alloy contains Cu 3 Pt and Cu 3 The Au ordered phase, the alloy prepared according to the ratio in Table 1 needs solution ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com