Patents

Literature

60results about How to "Increase toughness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Fiber cement composite materials using cellulose fibers loaded with inorganic and/or organic substances

InactiveUS6872246B2Reduction of it pore volumeIncrease toughnessNatural cellulose pulp/paperSpecial paperFreeze thaw resistanceChemical dissolution

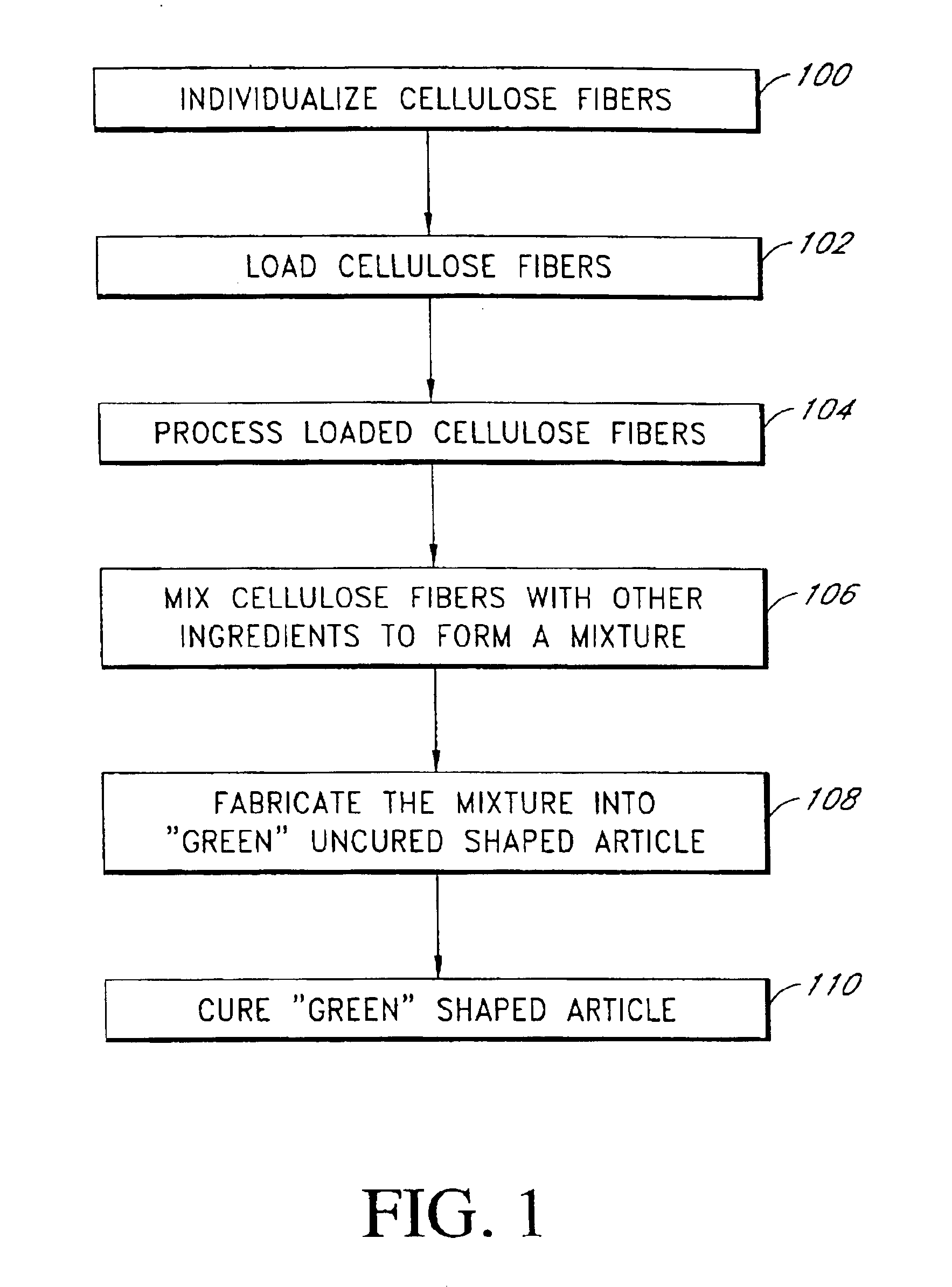

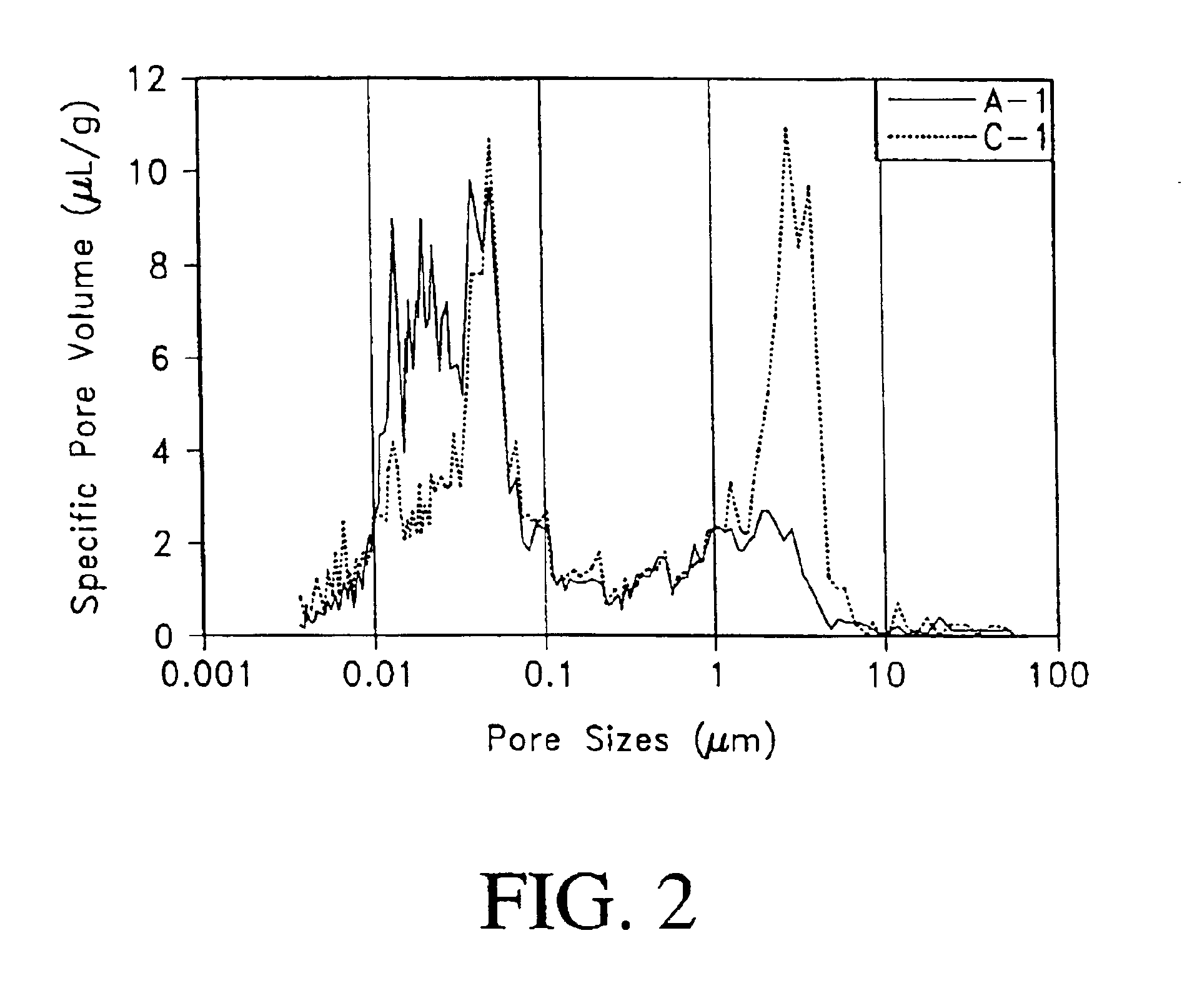

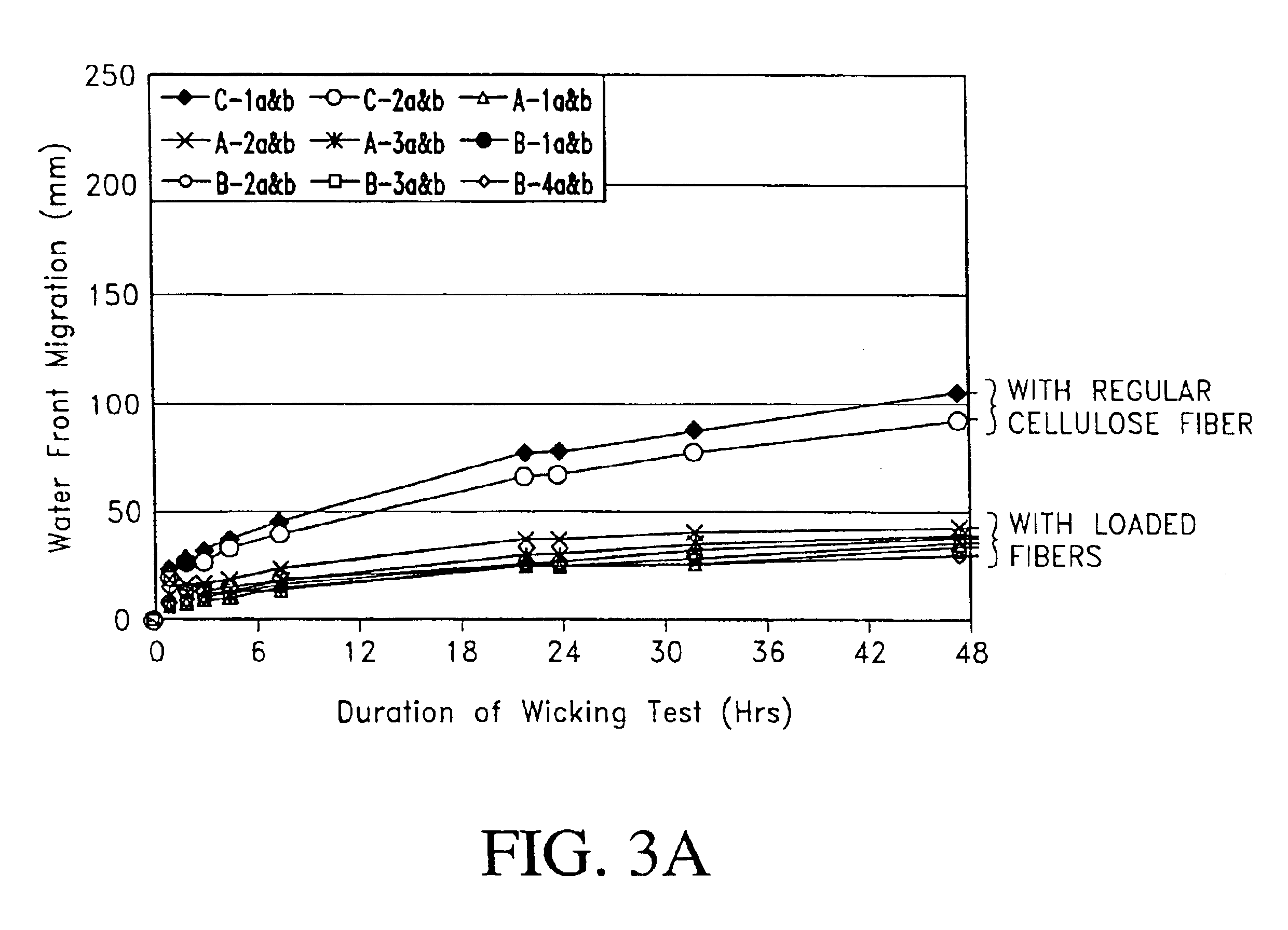

This invention discloses a new technology related to cellulose fiber reinforced cement composite materials using the loaded cellulose fibers. This invention discloses four aspects of the technology: fiber treatment, formulation, method and final product. This technology advantageously provides fiber cement building materials with the desirable characteristics of reduced water absorption, reduced rate of water absorption, lower water migration, and lower water permeability. This invention also impart the final products improved freeze-thaw resistance, reduced efflorescence, reduced chemical dissolution and re-deposition, and improved rot and fire resistances, compared to conventional fiber cement products. These improved attributes are gained without loss in dimensional stability, strength, strain or toughness.

Owner:JAMES HARDIE TECH

Series flux cord welding rod used for pile-up welding reparing and remanufacturing large type medium high carbon steel parts

InactiveCN100999041AImprove crack resistanceHigh carbon contentArc welding apparatusWelding/cutting media/materialsHigh carbonRare earth

The present invention discloses a series flux-cored wire for reparation and refabrication of large-size medium-high carbon steel components and parts. Its chemical composition includes (wt%) 5-10 of fluorite, 25-45% of high-carbon ferrochrome, 2-10% of high-carbon manganese iron, 5-8% of tantiron, 10-15% of ferro-molybdenum, 8-14% of rare earth oxide, 5-15% of metal nickel, 2-5% of ferrovanadium, 0.5-2% of graphite, 2-4% of chloride and 1-2.5% of aluminium-magnesium alloy. Its external covering adopts low-carbon steel tape.

Owner:QINHUANGDAO WEIERDE SPECIAL WELDING IND

Special flux-cored wire for carrying out preheating-free and heat treatment-free surfacing repair and reproducing on shaft and gear parts

InactiveCN102019520AImprove wear resistanceImprove thermal fatigue resistanceWelding/cutting media/materialsSoldering mediaCrack resistanceNiobium

The invention belongs to the field of material science and engineering and relates to a special flux-cored wire for carrying out preheating-free and heat treatment-free surfacing repair and reproducing on shaft and gear parts. The special flux-cored wire comprises the following chemical compositions in percentage by weight: 5 to 10 percent of fluorite, 20 to 40 percent of high-carbon ferrochrome, 5 to 10 percent of high carbon ferromanganese, 5 to 10 percent of ferrosilicon, 5 to 10 percent of ferromolybdenum, 10 to 15 percent of rare earth oxide, 15 to 20 percent of metallic nickel, 2 to 5 percent of ferrovanadium, 2 to 5 percent of ferrocolumbium, 2 to 5 percent of ferrotitanium, 0.1 to 0.5 percent of graphite, 5 to 15 percent of iron powder, 0.5 to 2 percent of nitride and 1 to 3 percent of aluminum magnesium alloy. A sheath of the special flux-cored wire is a low-carbon steel strip. The special flux-cored wire can be suitable for open arc welding or submerged arc welding. The series flux-core wire for surfacing can carry out surfacing repair and reproducing on the shaft and gear parts under the conditions that preheating is free before surfacing and heat treatment is free after surfacing. The surfacing metal has high crack resistance. The performance of the repaired parts is equal to or even superior to that of the original parts. The special flux-cored wire is convenient to use on site. The hardness range is between HRC20 and HRC45. The service life of the repaired parts is about 3 times longer than that of the original parts.

Owner:YANSHAN UNIV

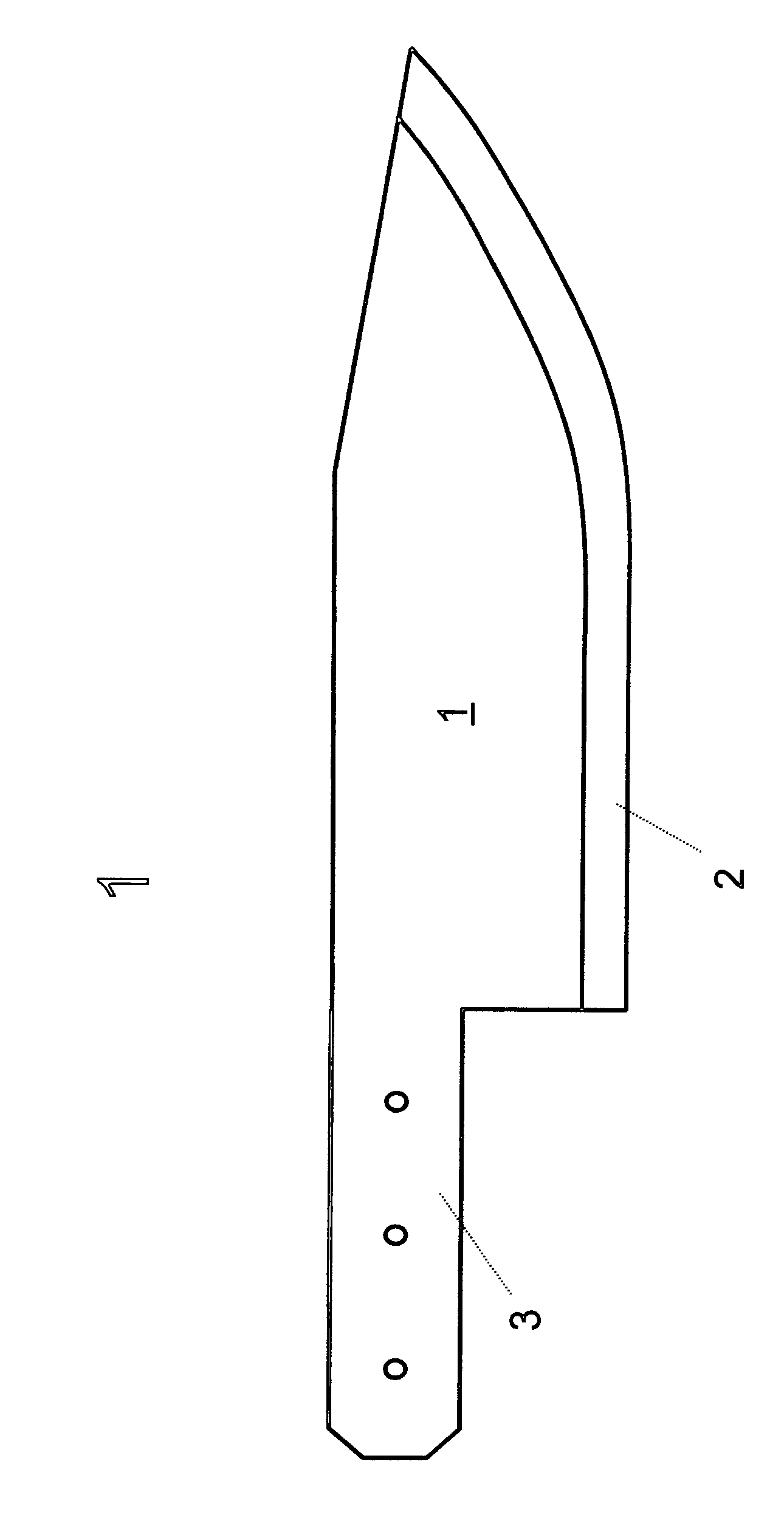

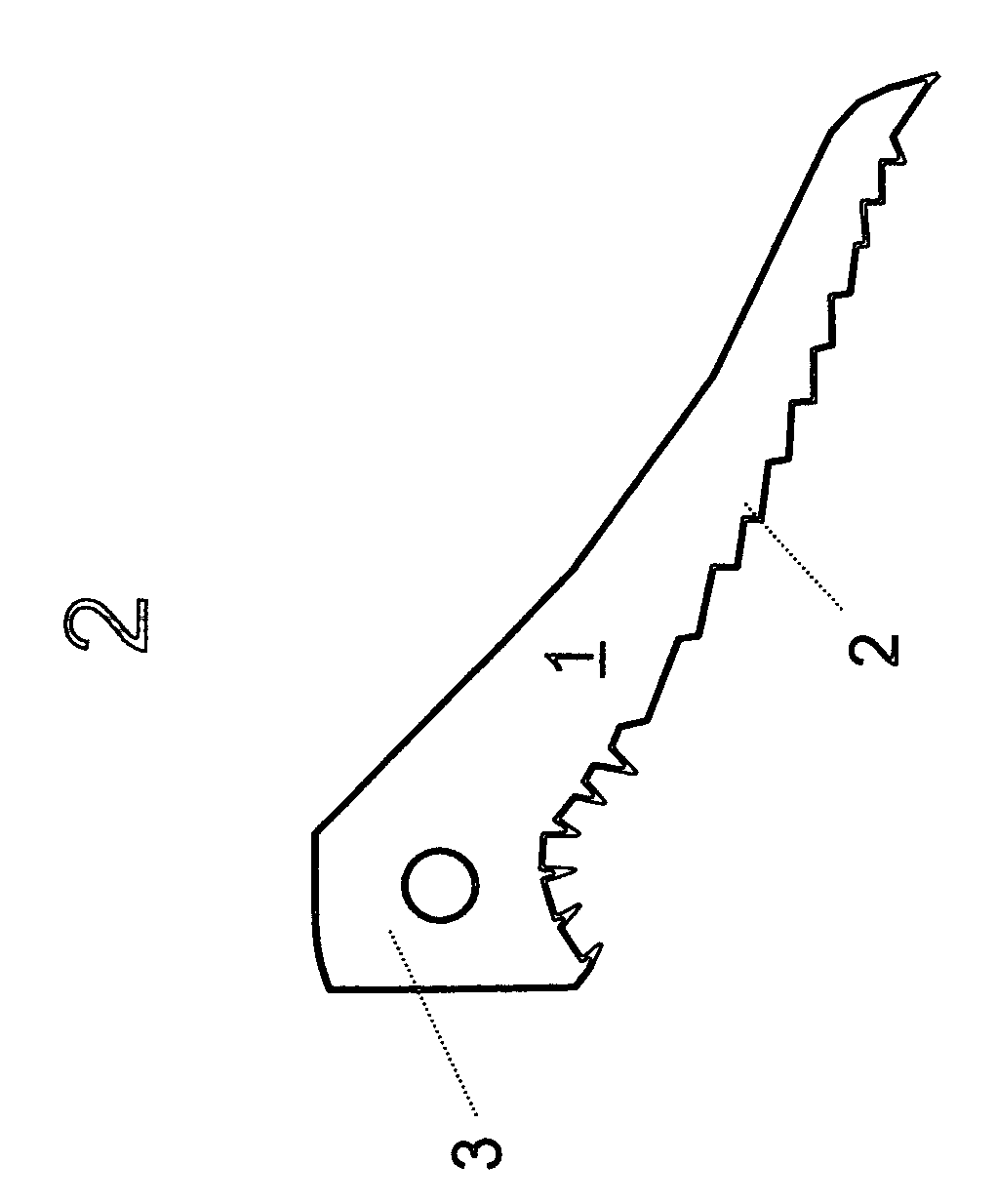

Novel advanced materials blades and cutting tools

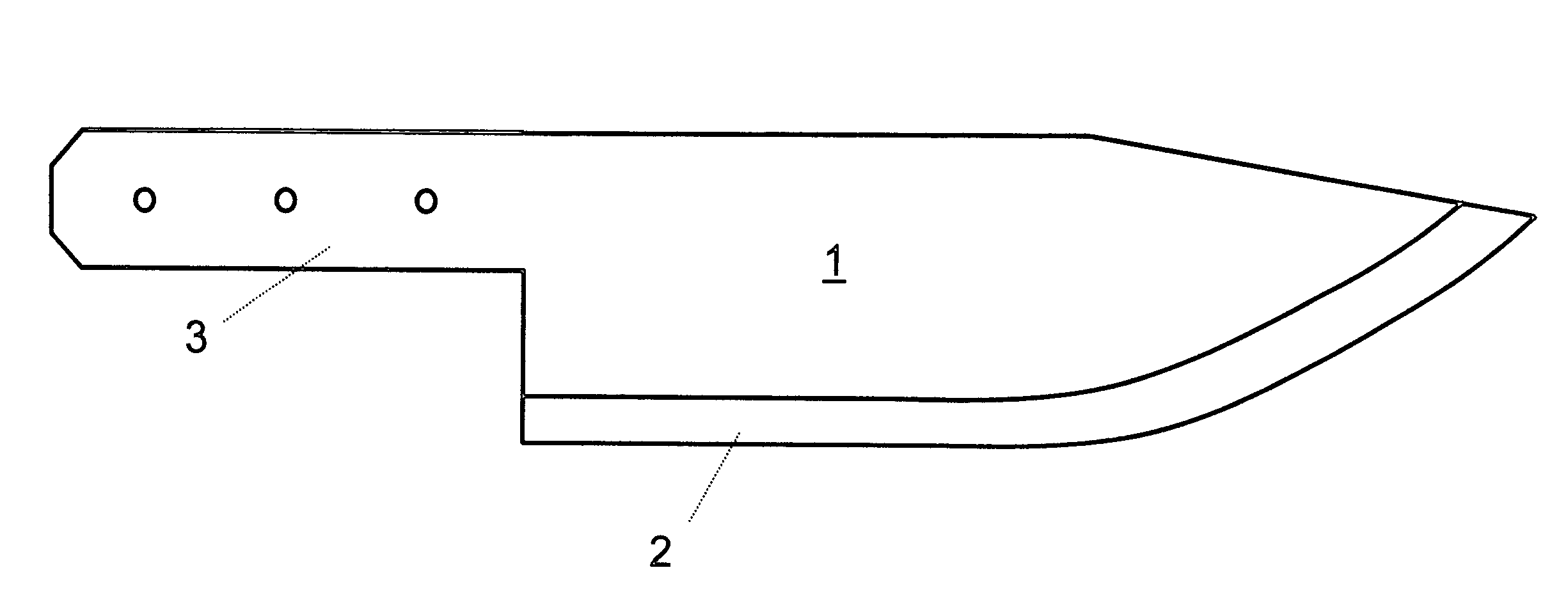

InactiveUS20090217537A1High hardnessIncrease toughnessMountaineeringMetal sawing toolsLong lastingCermet

A novel advanced materials blade has been invented. It is intended for use by professionals and other people who desire a high quality blade or other cutting tool. It offers many advantages, having an extraordinarily durable and long lasting edge and being tarnish free. The blade is composed of a superalloy from the cobalt-chrome-nickel ternary phase diagram; said blade having a body, and edge, and a tang. In an embodiment the blade edge is transmuted into a metallo-ceramic graded material using carbon to form carbides (-MC). These carbides are diffusion integrated into the superalloy, making this blade a graded material. In an additional embodiment the blase edge is atomically modified causing the excess carbon to form tetrahedral carbon (diamond). Applications of this novel advanced materials blade include professional chefs knifes, ice axe tools, and wood cutting axes.

Owner:MACDONALD LEO SPITZ +1

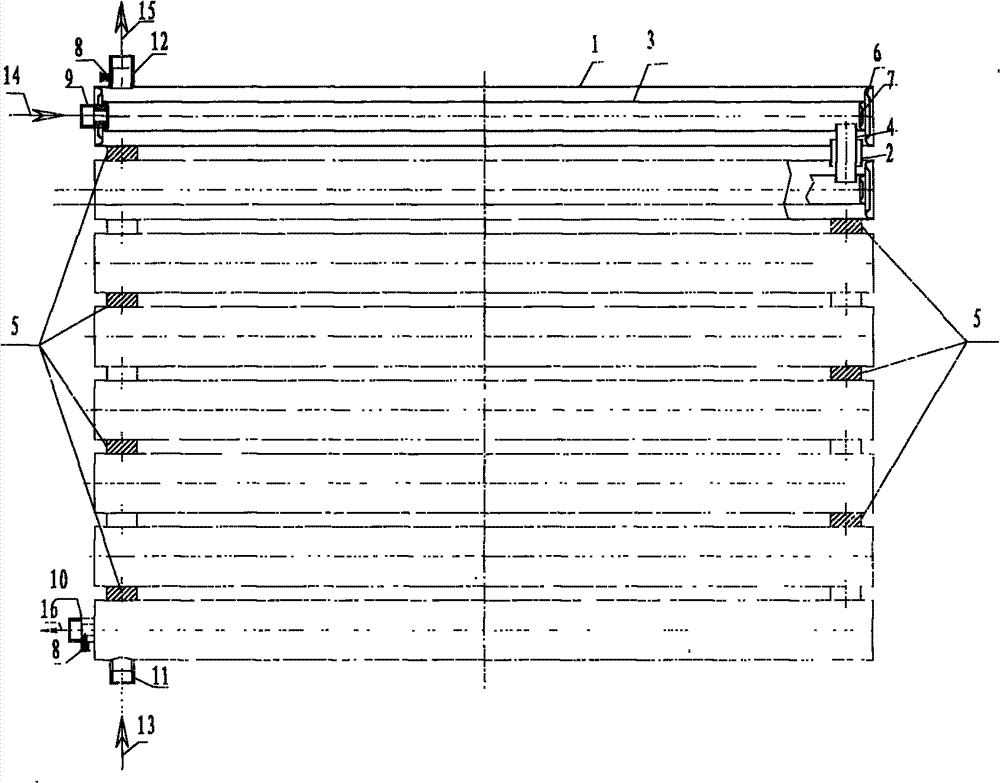

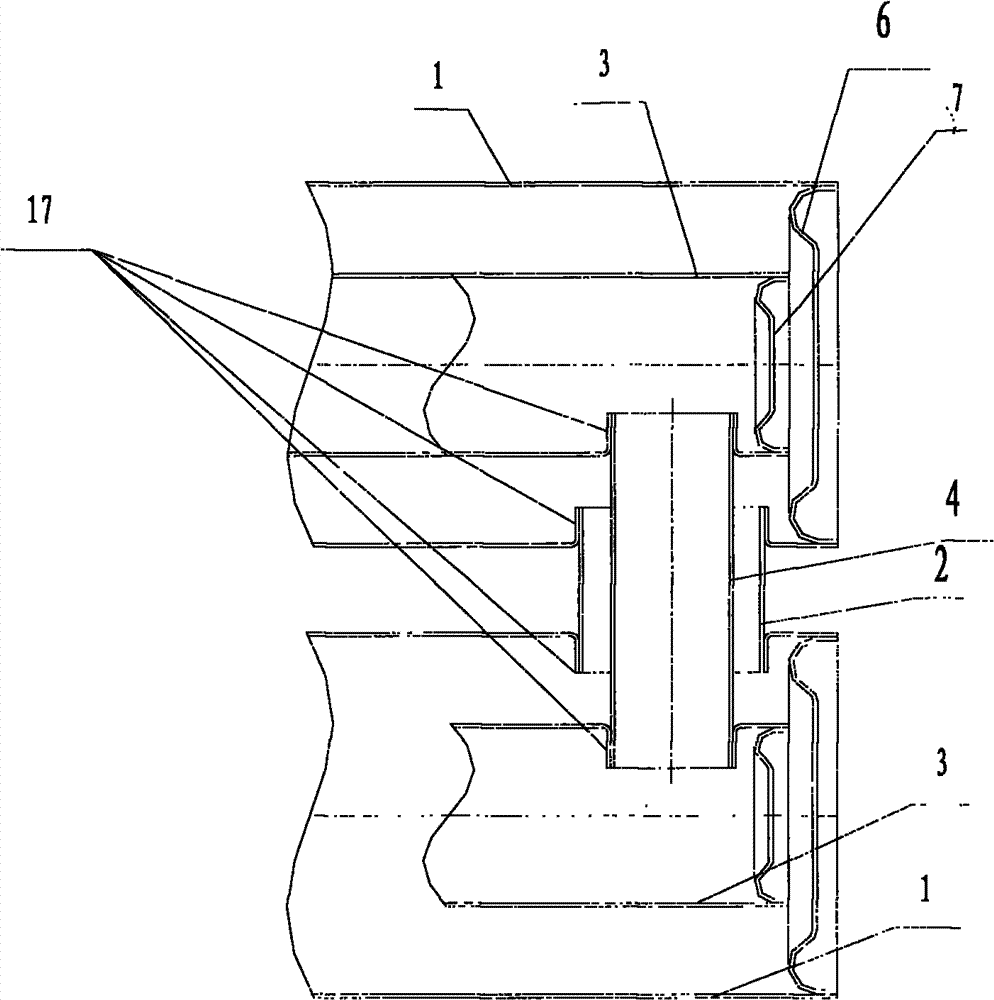

Pipeline heat-exchange water heater capable of reducing internal pressure by adverse flow

ActiveCN102735082AImprove heat exchange efficiencyIncreased Anti-Aging StrengthHeat exchanger casingsStationary tubular conduit assembliesEngineeringInternal pressure

The invention relates to a liquid-state heat exchanger, and particularly relates to a household heat-exchange water heater which takes heat supply type water heat or gas heat as a heat source, and belongs to a water heating device. The heat-exchange water heater comprises a plurality of tap water heat conduction pipes 1 which are connected and communicated with one another in series, tap water heat conduction pipe communicating pieces 2, steam heating pipes 3, internal pipe communicating pieces 4, internal circular chamfering end covers 6, air-release valves 8, inner-screw steam inlet connectors 9 and inner-screw tap water inlet connectors 11. The heat-exchange water heater is characterized in that the two ends of the plurality of tap water heat conduction pipes 1 are serially connected and communicated with the tap water heat conduction pipe communicating pieces 2, the internal pipe communicating pieces 4 and connecting pieces 5 in a welding manner so as to form a rectangle; the plurality of internal circular chamfering end covers 6 are welded at the two ends of the tap water heat conduction pipes 1; each two adjacent steam heating pipes 3 are fixedly connected with the internal pipe communicating pieces 4 in a mode that the inner walls of the pipes are welded; before the steam heating pipes 3 are fixedly connected with the internal pipe communicating pieces 4 in a welding manner, round holes are punched firstly, and subsequently, turnup round-hole bosses 17 are stretched to be fixedly connected with the internal pipe communicating pieces 4 in a welding manner.

Owner:ZAOZHUANG FUYUAN ENVIRONMENTAL PROTECTION & ENERGY SAVING MACHINERY MFG CO LTD

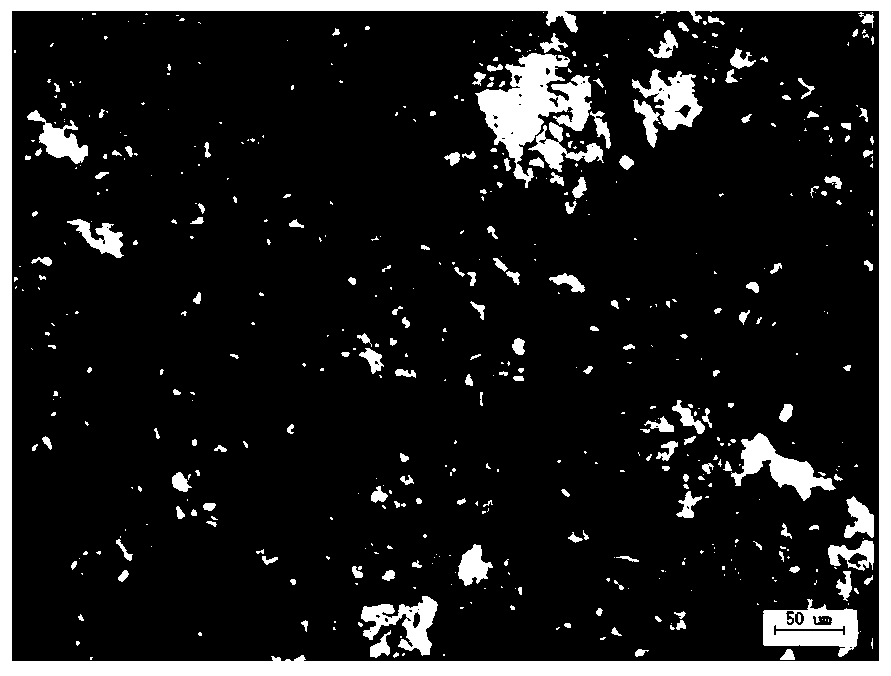

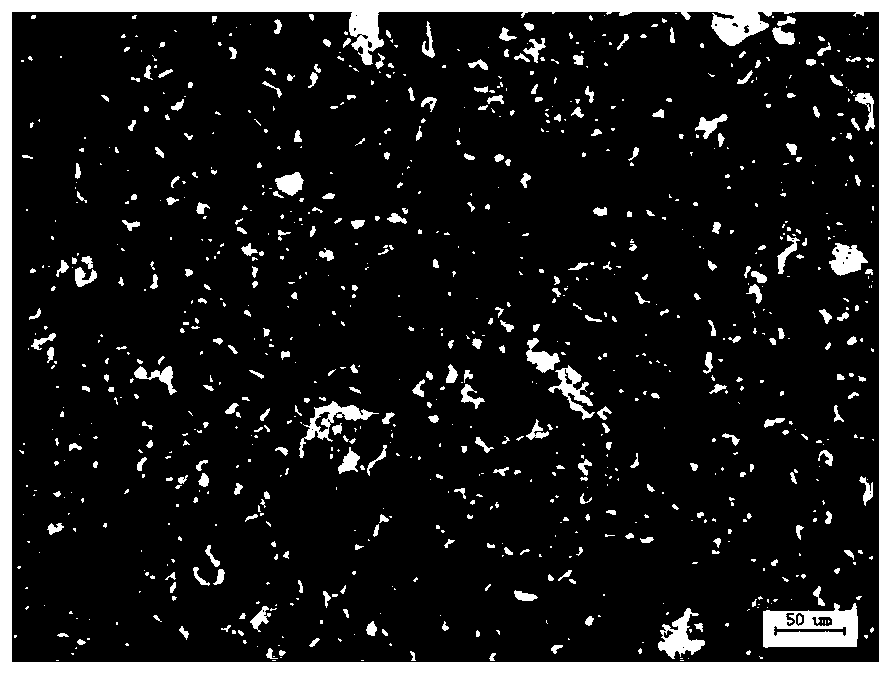

Chromium-tungsten-rare earth-boron series air cooling medium-high carbon bainite steel and preparation method thereof

The invention relates to chromium-tungsten-rare earth-boron series air cooling medium-high carbon bainite steel and a preparation method thereof, and belongs to the technical field of alloy steel. The components in the bainite steel comprise C, Mn, Si, Cr, W, Mo, Ni, V, Re, B, Al, P, S and the balance of Fe, wherein P and S are less than 0.035. The bainite steel is normally melted by an electric furnace to raise temperature, then aluminum is added into the melted bainite steel, the heat is preserved, the steel is discharged, rare-earth and boron are added into the steel by using a ladle flushing method, and then the mixture is cast into a cast product conventionally By setting the category and content matching of alloying elements and micro-alloying elements, the number of carbides is increased, the dispersion distribution is even, the tissue is thinned, and the prepared bainite steel has high strong hardness, high toughness and high abrasion resistance; the preparation method shortens the thermal treatment time, reduces the production cost, protects the environment, and lessens the work intensity of workers; the using amount of expensive elements is little; and the product has low cost and is convenient for popularization.

Owner:谢新佑 +1

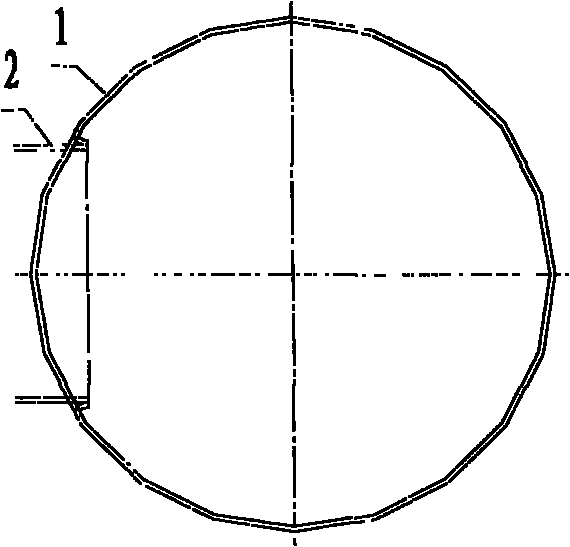

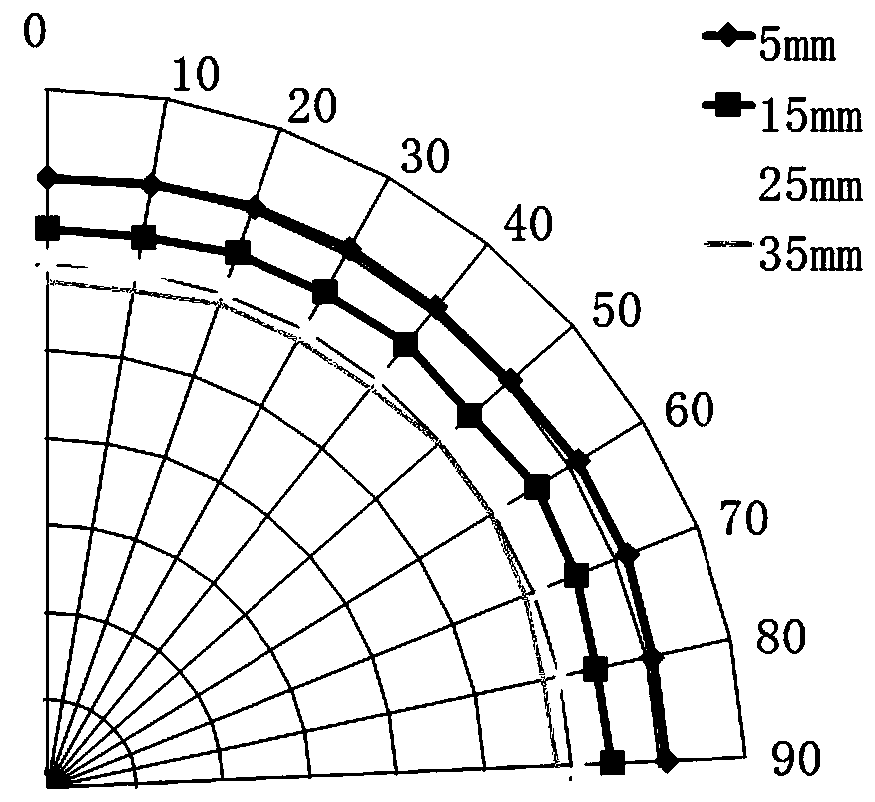

Wheel steel capable of resisting out-of-round, wheels and preparation method of wheels

ActiveCN110904311AImprove hardenabilityIncrease toughnessRail-engaging wheelsFurnace typesMechanical engineeringRail transit

The invention discloses a wheel steel capable of resisting out-of-round, wheels and a preparation method of the wheels, and belongs to the technical field of rail transit wheels and a preparation method thereof. The wheel steel capable of resisting out-of-round comprises the following components of, in percentage by weight, 0.56%-0.60% of C, 0.25%-0.35% of Si, 0.70%-0.80% of Mn, 0.20%-0.25% of Cr,0.10%-0.20% of Ni, less than or equal to 0.008% of P, less than or equal to 0.008% of S, and the balance Fe and inevitable impurity elements. The wheel steel capable of resisting out-of-round, the wheels and the preparation method of the wheels aim to overcome the defects that in the prior art, the rail transit wheels are prone to out-of-round problems, and the wheel steel capable of resisting out-of-round, the wheels and the preparation method of the wheels are provided, the wheel steel capable of resisting out-of-round, the wheels and the preparation method of the wheels can remarkably improve the hardness and the circumferential hardness uniformity of the wheels, are favorable for reducing the out-of-round probability of the wheels, and can prolong the turning mileage and service lifeof the wheels.

Owner:MAANSHAN IRON & STEEL CO LTD

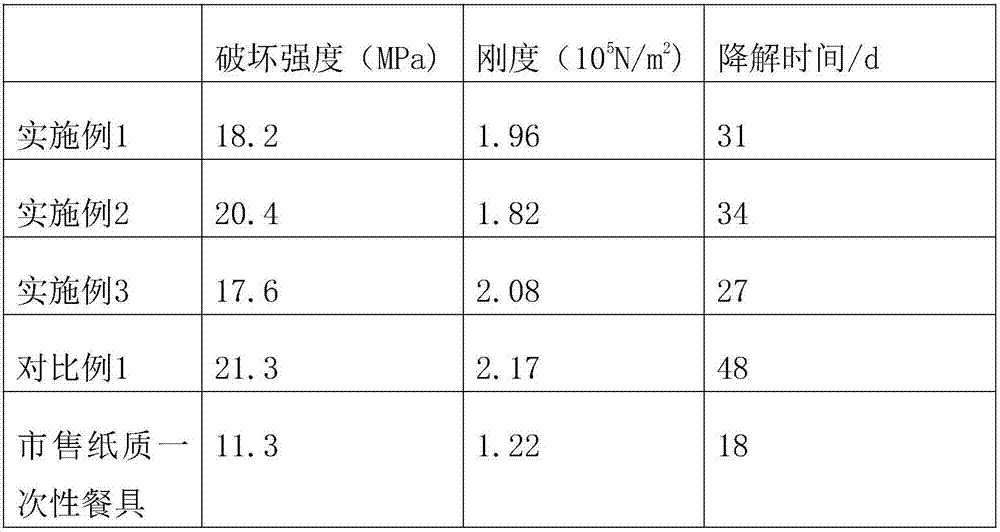

Degradable disposable tableware and preparation method thereof

The invention belongs to the field of disposable tableware, and particularly relates to a degradable disposable tableware and a preparation method thereof. The invention uses purely natural green materials, such as composite straw powder, shell powder, composite starch and composite fiber pulp, peach gum is adopted as binder, bamboo outer skin is added to increase the toughness of the tableware, kelp extract is sprayed on the surface of the tableware to isolate oil and water, so that the tableware is more durable, and ultimately, the degradable disposable tableware which uses the purely natural materials, does not contain chemical ingredients and is tough and durable is obtained.

Owner:贵州省玉态康环保餐具有限公司

Degradable disposable tableware and preparation method thereof

The invention belongs to the field of disposable tableware and especially relates to degradable disposable tableware and a preparation method thereof. According to the invention, pure natural green raw materials such as wheat straw powder, reed pulp, wheat starch, peach gum, etc. are used, composite bioplastic is added to raise the integral strength, bamboo fiber is added to increase toughness oftableware, and then strength and toughness of the tableware are greatly enhanced. Thus, the degradable disposable tableware which is easy to degrade and has high strength and high toughness is finallyobtained.

Owner:贵州省玉态康环保餐具有限公司

Asphalt concrete pavement material composition capable of absorbing microwaves

The invention discloses an asphalt concrete pavement material composition capable of absorbing microwaves. The composition is prepared from the following raw materials in parts by weight: 10-15 partsof pyrite slag powder, 5-10 parts of carbon fiber powder, 2-6 parts of taconite powder, 1-2 parts of magnetite ore powder, 2-5 parts of quartz sand powder, 0.2-0.5 part of manganese dioxide, 30-40 parts of asphalt, 5-8 parts of limestone ore powder, 0.2-0.3 part of aluminum oxide, 0.1-0.2 part of nickel oxide, 0.2-0.4 part of cobalt oxide and 4-6 parts of copper ore powder; the carbon fibers, thecopper ore powder and iron ore substances such as the pyrite slag powder in the component materials have stronger thermal conductivity and microwave absorption capacity, wherein the carbon fibers cannot only improve the mechanical property parameters of the asphalt concrete pavement materials and improve the tensile strength, but also have higher microwave absorption capacity, so that the absorption capacity of the pavement material to the microwaves can be effectively improved after the carbon fibers are added into the asphalt concrete pavement material composition.

Owner:和县祥龙沥青混凝土有限公司

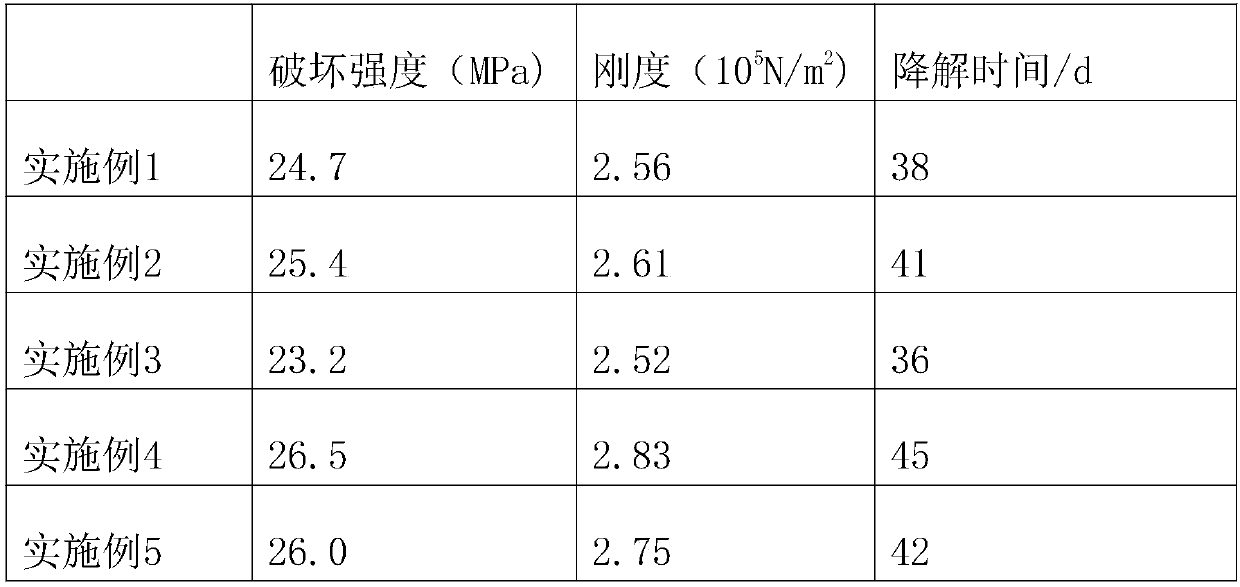

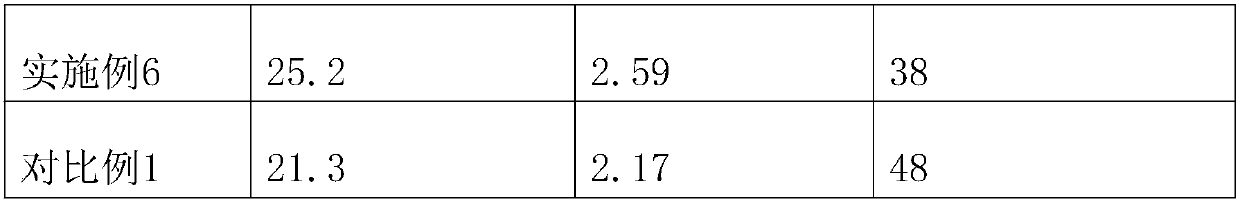

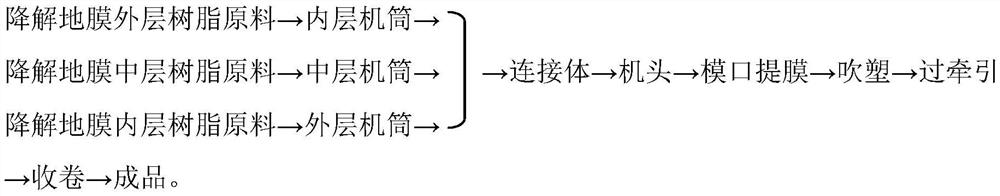

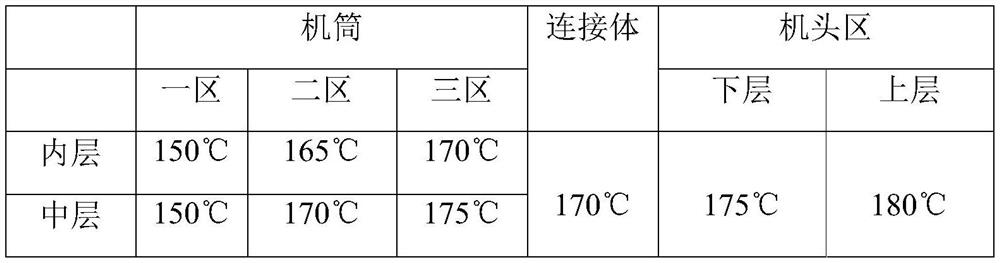

Three-layer composite high-barrier controllable full-biodegradable mulching film and preparation method thereof

ActiveCN112262695ABiodegradableWith mechanical propertiesAgricultural articlesClimate change adaptationAgricultural engineeringPlastic mulch

The invention belongs to the technical field of agricultural film preparation, and particularly relates to a three-layer composite high-barrier controllable full-biodegradable mulching film and a preparation method thereof. The mulching film comprises an inner layer, namely a mulching film slow release layer, a middle layer, namely a mulching film barrier layer, and an outer layer, namely a mulching film service life control layer; the mulching film slow release layer comprises PBAT and PLA; the mulching film barrier layer comprises PBAT, PLA and TPU; and the mulching film service life controllayer comprises PBAT and PLA. The three-layer composite high-barrier controllable full-biodegradable mulching film meets the requirements of farmers for original heat preservation and soil moisture conservation functions of the mulching film, the degradation effect of the mulching film can be controlled within a certain period of time according to the growth requirements of crops, the mulching film can be completely degraded when the crops are harvested, and no pollution is caused to the land environment and soil. The secondary labor cost of the farmers is reduced, and the social secondary pollution is reduced. The preparation method is scientific, reasonable, simple and feasible.

Owner:SHANDONG QINGTIAN PLASTIC IND

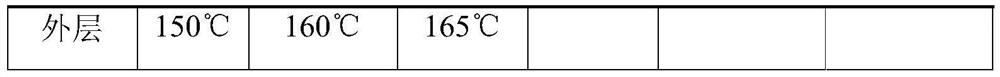

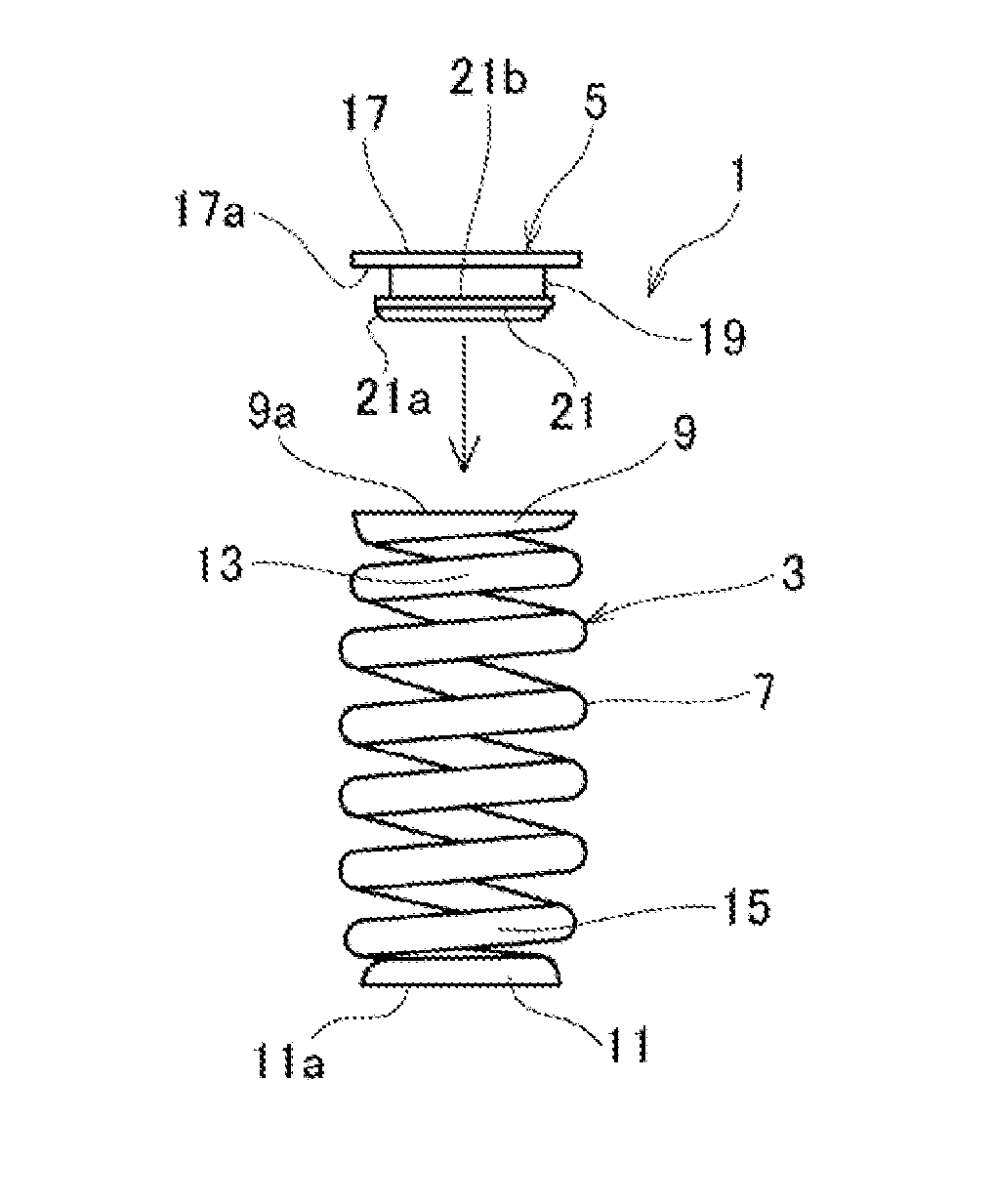

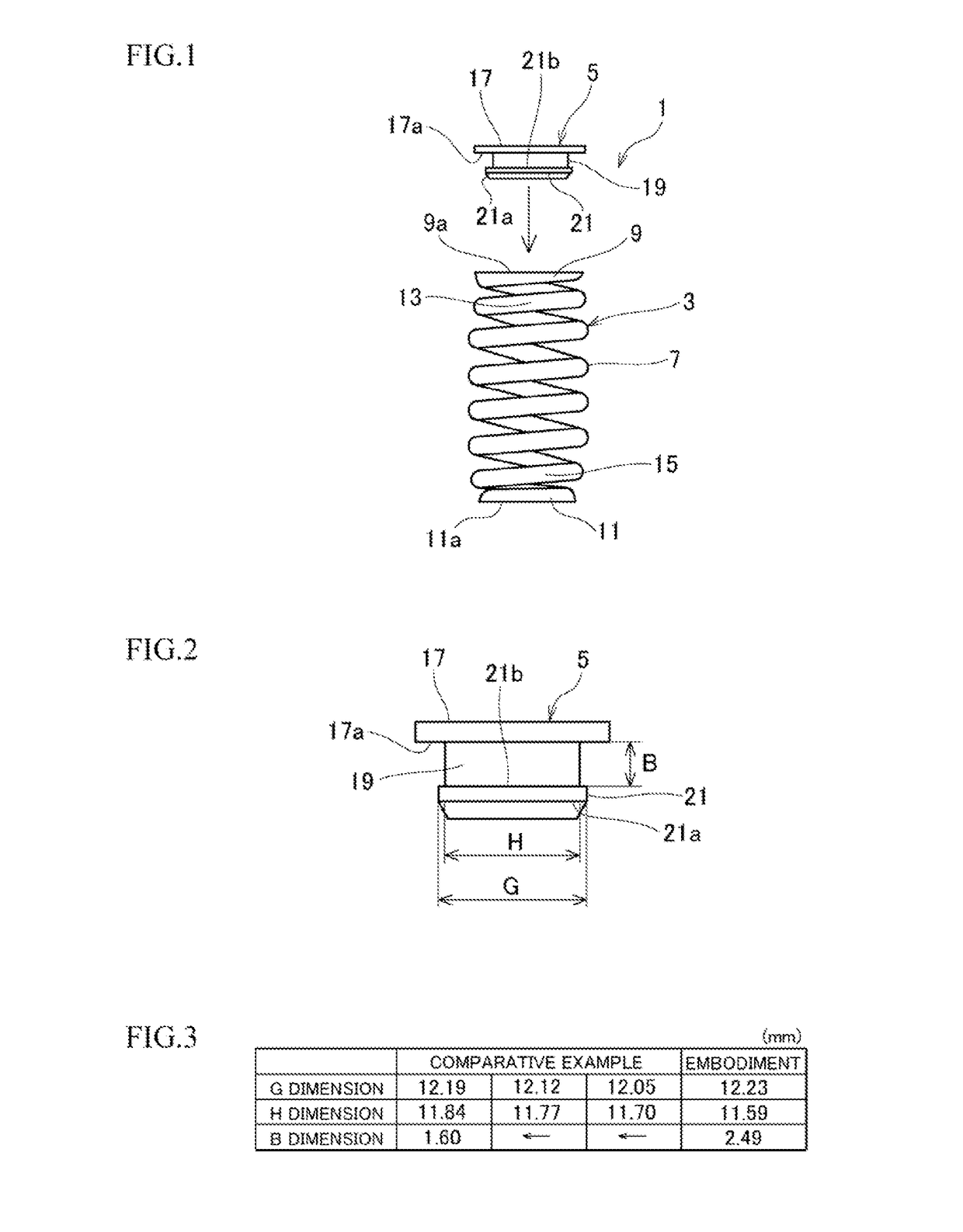

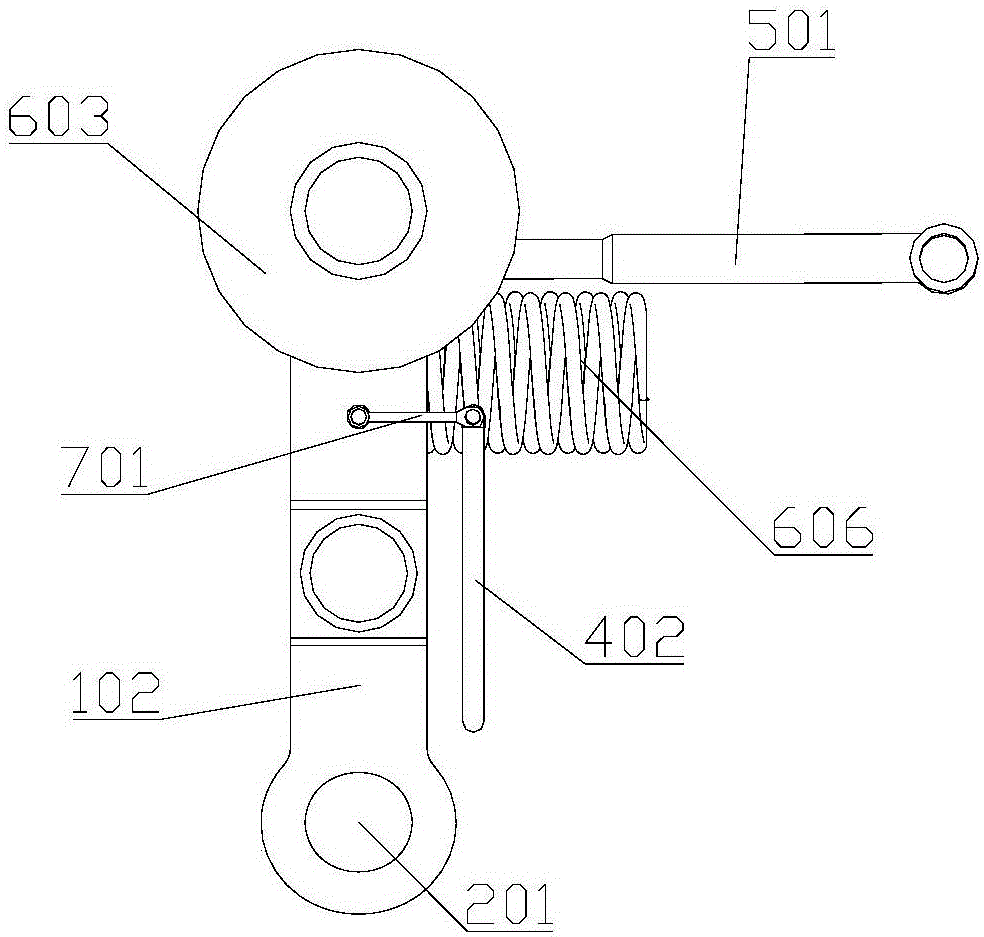

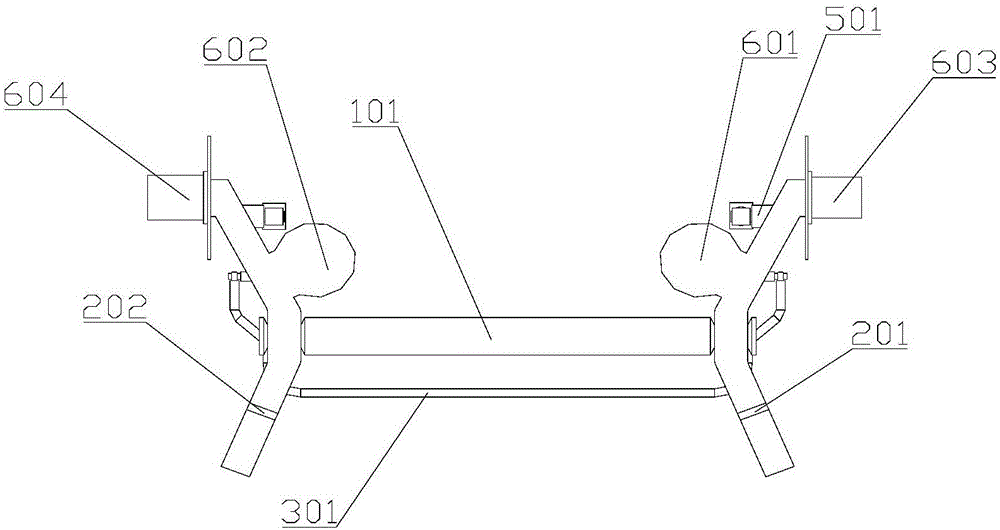

Coiled spring assembly

Provided is a coiled spring assembly having a coiled spring and a seat for the coiled spring, in which the coiled spring has an end turn formed up to a first turn with a reduced diameter and a transition portion with a diameter gradually increasing from the end turn to a body portion, the seat has a seat portion, a mounting shaft portion, and an enlarged diameter portion, the mounting shaft portion has an axial length defining a gap or a zero-gap between the enlarged diameter portion and the end turn in a free state in which the end turn is fitted to the mounting shaft portion and the bearing surface of the end turn is in contact with the receiving surface of the seat portion, and the transition portion circumvents the enlarged diameter portion while the bearing surface is in contact with the receiving surface.

Owner:NHK SPRING CO LTD

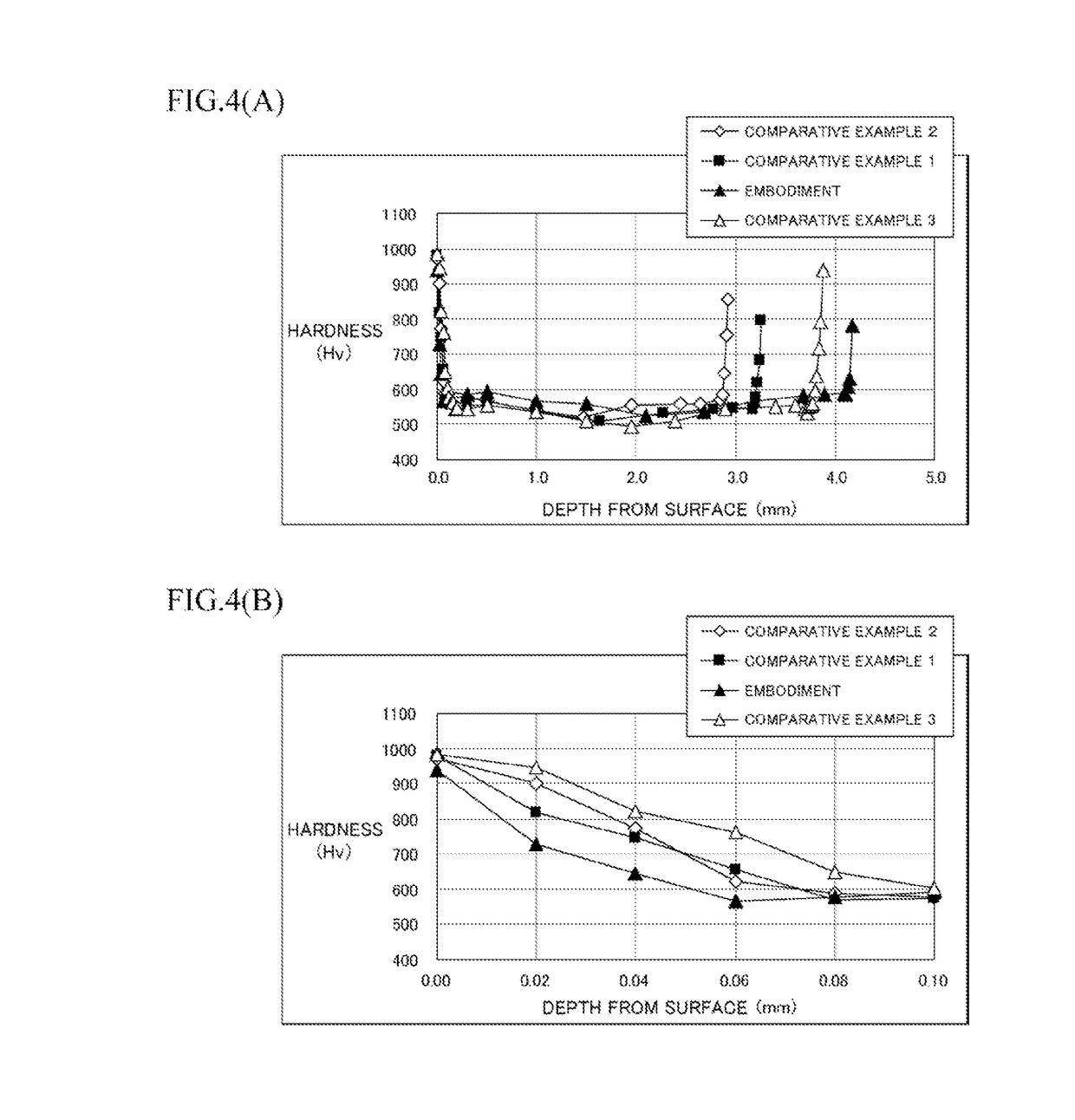

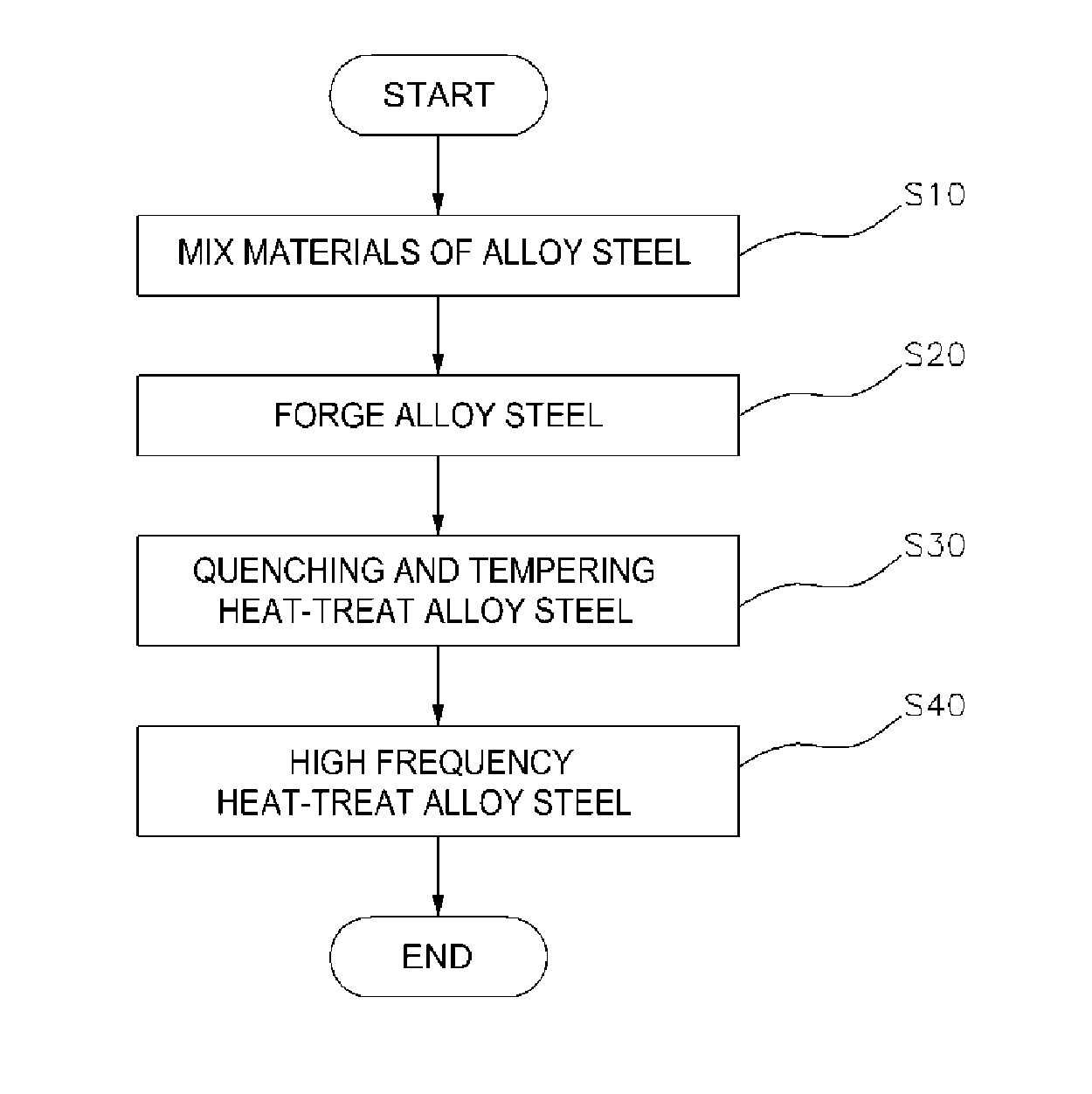

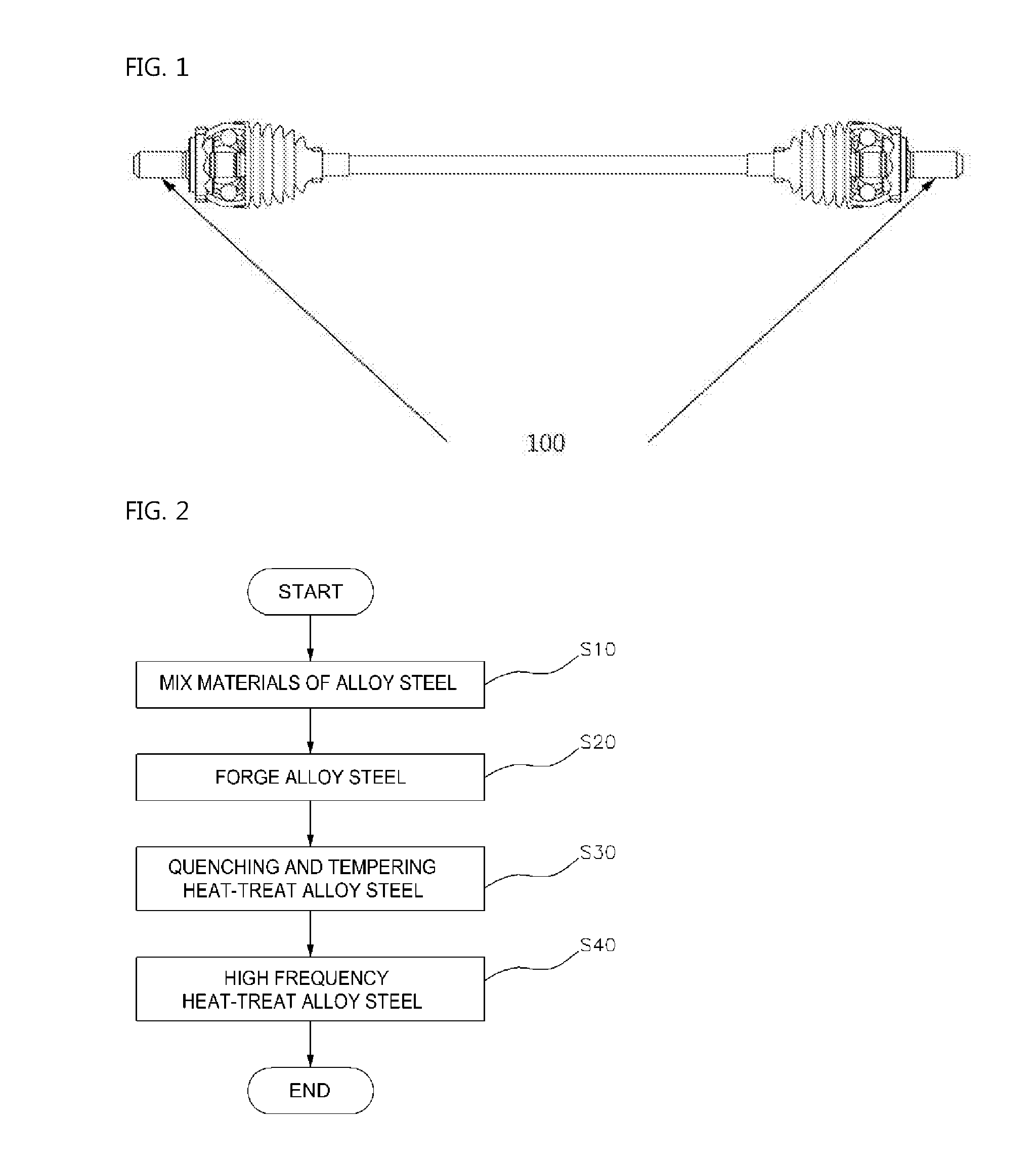

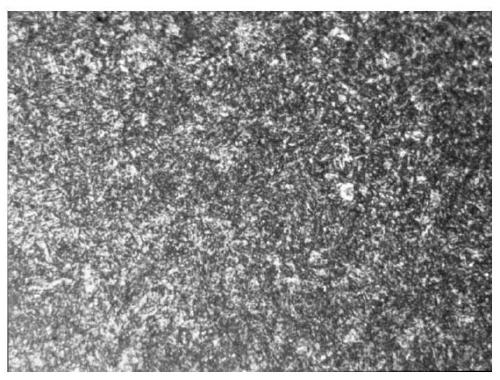

Alloy steel for high toughness constant velocity joint outer wheel and method of manufacturing the same

InactiveUS20160369363A1Increase toughnessImprove durabilityYielding couplingFurnace typesConstant-velocity jointAlloy steel

Alloy steel for a constant velocity joint outer wheel includes, based on a total weight of the alloy steel, 0.50 to 0.60 wt % C (carbon), 0.15 to 0.35 wt % Si (silicon), 0.4 to 0.8 wt % Mn (manganese), more than 0 to 0.03 wt % P (phosphorus), more than 0 to 0.035 wt % S (sulfur), more than 0 to 0.3 wt % Cu (copper), more than 0 to 0.00002 wt % O (oxygen), and a balance of Fe (iron).

Owner:HYUNDAI MOTOR CO LTD

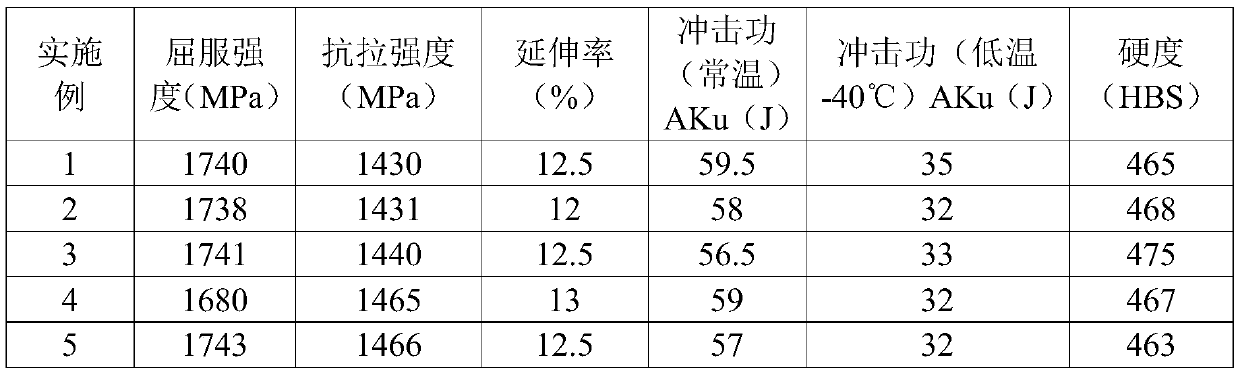

Thermal treatment method for civil bulletproof steel

The invention discloses a thermal treatment method for civil bulletproof steel. The thermal treatment method comprises the following steps: carrying out composition according to chemical element components of the above bulletproof steel in mass percent, smelting molten steel by adopting a vacuum smelting furnace so as to manufacture a steel billet, heating the steel billet to 1250 DEG C to 1300 DEG C, carrying out heat preservation for 6 h to 8 h, and carrying out hammer forging till the set thickness is reached; and heating the steel billet subjected to hammer forging to 1280 DEG C to 1330 DEG C, carrying out heat preservation for 1 h to 2 h, carrying out rolling after discharging from the furnace, carrying out air cooling to the room temperature after rolling, and then carrying out the thermal treatment process which comprises the procedures of quenching, two-phase region quenching and tempering. A civil bulletproof steel plate prepared through the thermal treatment method has the advantages that the yield strength reaches 1350 MPa to 1480 MPa, the tensile strength reaches 1550 MPa to 1750 MPa, the elongation reaches 12% to 14%, the normal-temperature impact property (a u-shapednotch) reaches 55 J to 60 J, the low-temperature impact property (negative 40 DEG C and a u-shaped notch) reaches 30 J to 38 J, the Brinell hardness HBS reaches 450 to 550, and the anti-bullet property reaches the grade C of a box body or a bulletproof steel plate involved in the People's Republic of China Public Safety Industry Standard GA 164-2005. The protective requirements of current light-duty vehicles such as bulletproof cash trucks as well as anti-terrorist, anti-explosion and peacekeeping vehicles can be met.

Owner:INNER MONGOLIA METAL MATERIAL RES INST

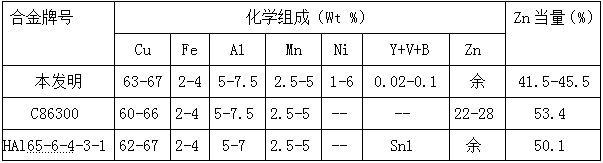

High-strength toughness aluminum brass alloy and manufacturing method thereof

The invention relates to a high-strength toughness aluminum brass alloy and a manufacturing method of the high-strength toughness aluminum brass alloy. The chemical composition of the alloy comprises,by weight, 63-68% of copper, 2-4% of iron, 5-7.5% of aluminum, 2.5-5% of manganese, 1-6% of nickel 0.02-0.1% of yttrium, vanadium and boron, and the balance zinc (containing other inevitable impurities with the content smaller than or equal to 0.5%). Aluminum and copper are added in sequence for alloy smelting, it is ensured that the amount ratio of copper to aluminum is smaller than or equal to2, heating smelting is carried out, the density of the alloy liquid formed by copper and aluminum is smaller than or equal to 7g / cm<3>, in this way, aluminum film covering protection is achieved, manganese can be conveniently immersed in the alloy melt for melting, copper-manganese alloy is formed at first, iron dissolving is added after the temperature is increased, and hard brittle iron-rich particles are reduced or eliminated. An alloy casting has high hardness, has high strength, high hardness, high ductility and good wear resistance, and is widely applied to parts such as bearings, shaftsleeves, thrust nuts and the like which are difficult to lubricate and replace.

Owner:TIANJIN SANTIAOSHI NONFERROUS METAL FOUNDRY

Rapid preparation method and product of uranium dioxide/nano-diamond nuclear fuel pellet

ActiveCN108538409AEnhance macro thermal conductivityGuaranteed high temperature stability and radiation stabilityNuclear energy generationReactors manufacturePowder metallurgyThermal conductivity

The invention discloses a rapid preparation method and a product of a uranium dioxide / nano-diamond nuclear fuel pellet, and belongs to the field of energy and composite materials, particularly belongsto the field of powder metallurgy, and aims to solve the problems that safety requirements of a nuclear power station are difficultly met as heat conductivity of an existing ceramic uranium dioxide (UO2) pellet is poor. According to the method, the uranium dioxide / nano-diamond nuclear fuel pellet with a three-dimensional network structure is prepared by a powder metallurgy technique, the heat conductivity of uranium dioxide nuclear fuel is improved, high-temperature stability and radiation stability of the fuel pellet are improved, the method can effectively solves the problems, safety of theuranium dioxide nuclear fuel pellet is greatly improved, industrial large-scale production application requirements can be met, the method has high application value and good application prospect andis worthy of large-scale popularization and application.

Owner:MATERIAL INST OF CHINA ACADEMY OF ENG PHYSICS

Composite wear-resistant material and preparation method thereof

The invention discloses a composite wear-resistant material and a preparation method thereof. The composite wear-resistant material is prepared from the following raw materials in parts by weight: 40to 60 parts of glass-ceramic powder, 10 to 15 parts of tabular corundum, 8 to 12 parts of silicon carbide, 5 to 12 parts of quartz sand, 3 to 8 parts of titanium carbide, 15 to 20 parts of fly ash floating beads, 9 to 12 parts of carboxymethylcellulose, 1 to 3 parts of ricinate and 5 to 12 parts of flexibilizer. The preparation method comprises the following steps: adding a wetting dispersant intoinorganic materials for grinding and carrying out diluted hydrochloric acid activating treatment; then uniformly stirring a mixture with the carboxymethylcellulose and the flexibilizer, carrying outcompression-moulding and hot pressed sintering; finally, obtaining the composite wear-resistant material which has the advantages of low cost, controllable and uniform micropores, uniform tissues, high strength and hardness and good wear resistance.

Owner:NANYANG INST OF TECH

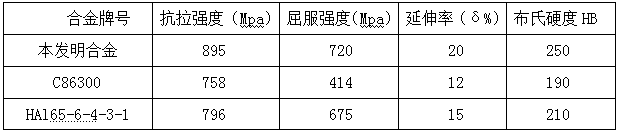

Semi-independent automobile rear suspension

InactiveCN105034743AIncrease toughnessReduce the degree of deformationInterconnection systemsPivoted suspension armsRoad surfaceAdaptive capacity

The invention provides a semi-independent automobile rear suspension and belongs to the technical field of vehicles. The semi-independent automobile rear suspension comprises a left dragging arm, a right dragging arm, a beam and movable connecting pieces. The two ends of the beam are movably connected with the left dragging arm and the right dragging arm through the movable connecting pieces respectively. Due to the fact that the left dragging arm and the right dragging arm are movably connected with the beam, the dragging arms on the two sides can move within a certain degree in a relatively-independent mode, in the driving process of an automobile, the deformation degree of the beam is reduced, the beam only bears the axial acting force of the beam, the overall suspension is more flexible, the adaptive capacity of the suspension to complex road surfaces is improved, and the overall comfort degree of the automobile with the semi-independent automobile rear suspension is greatly improved.

Owner:李海龙

High-temperature refractory material and manufacturing process method

The invention relates to the technical field of high-temperature refractory materials, and discloses a high-temperature refractory material and a manufacturing process method. The refractory brick comprises the following raw materials in parts by weight: 10-25 parts of a silicon oxide material, 10-15 parts of quartz sand, 5-6 parts of magnesium carbonate, 15-20 parts of corundum, 0.3-1.2 parts ofa rare earth-containing raw material, 7-8 parts of chromium dioxide, 0.7-1.2 parts of methylcellulose, 10-20 parts of mullite, 30-40 parts of dolomite, 0.5-0.7 part of sodium silicate, 20-30 parts ofa carbonic acid solution, 0.4-0.7 part of an expanding agent and 5-15 parts of a binder. According to the high-temperature refractory material, the silicon oxide material is added, and the bonding strength of the high-temperature refractory material is greatly improved, so that the high-temperature refractory material is prevented from caking and sagging, collapsing and sinking in the curing period, and meanwhile, the high wear resistance and corrosion resistance of the material can be enhanced, by adding corundum and dolomite raw materials, the strength and anti-pressure ability of the material body is increased, the body toughness degree of the high-temperature refractory material is improved by adding methyl cellulose, the production is simple, the raw material cost is low, and the quality effect is good.

Owner:德清县钢友耐火材料有限公司

Edible tableware and preparation method thereof

InactiveCN107494752AIncrease toughnessTable equipmentsOther dairy technologyFiberChemical composition

The invention belongs to the field of tableware and particularly relates to edible tableware and a preparation method thereof. The preparation method comprises the following steps: by taking bean dregs as raw materials, processing the bean dregs to enable the properties of the bean dregs to be suitable for preparing the edible tableware; adding condiments and a natural adhesive, and adding bamboo fibers to improve the toughness of the tableware; and spraying the surface of the tableware with a pasty solution prepared by mixing kelp extract, peach gum and acetylated potato starch to isolate oil from water so as to enable the tableware to be more durable, thereby finally obtaining the edible tableware which is firm and durable, free of chemical components and harmless to the human body.

Owner:贵州省玉态康环保餐具有限公司

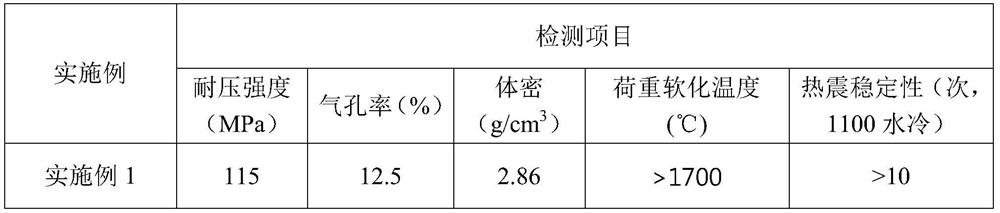

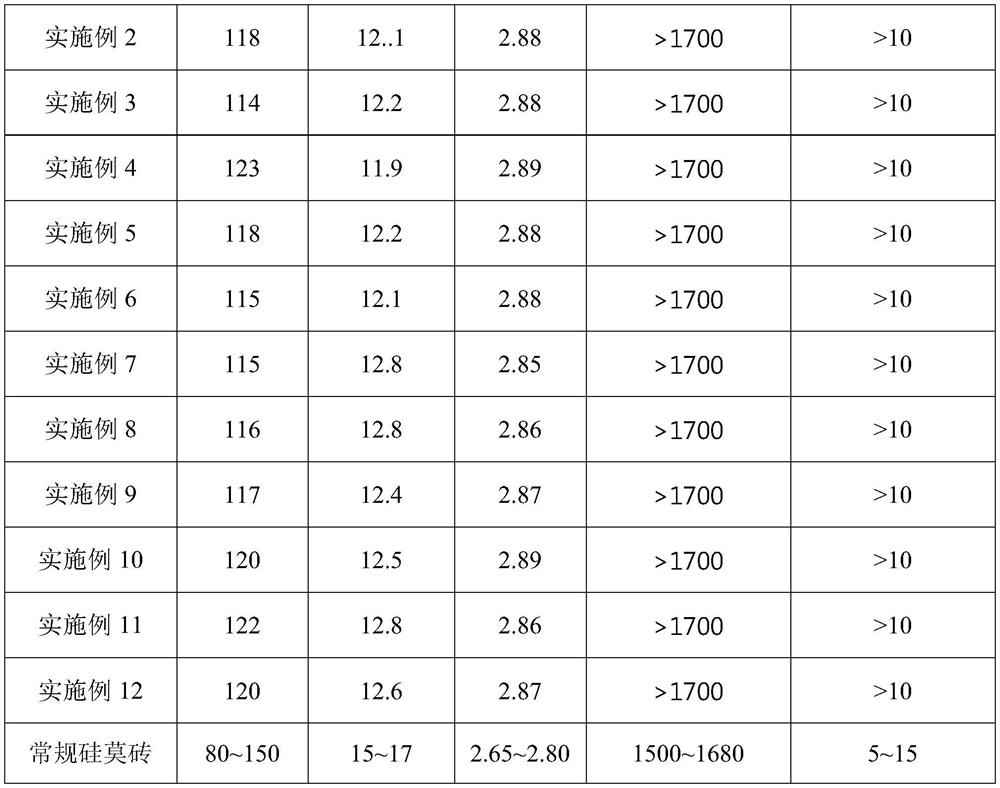

Solid-melting Ti(C,N) unfired silicon mullite brick and preparation method thereof

The invention provides a solid-melting Ti(C,N) unfired silicon mullite brick and a preparation method thereof. The unfired silicon mullite brick is prepared from the following components in percentageby weight: 72-85% of solid-solution Ti(C,N) fused mullite, 1-5% of silicon carbide, 5-15% of calcined alumina powder and 3-8% of binding clay. and a binding agent accounting for 3-5% of the total weight of the components is added. According to the baking-free silicon mullite brick, fused mullite of solid solution Ti(C,N) is used as a main raw material and is produced and prepared from low-grade bauxite, so that consumption of high-grade bauxite resources is avoided, the low-grade bauxite resources rich in resources can be fully utilized, and the produced silicon mullite brick is outstanding in performance; in the preparation process of the silicon mullite brick, low-temperature treatment is adopted, high-temperature firing is not needed, compared with traditional silicon mullite brick preparation, the production period is shortened, the production cost is reduced, pollutant emission in the high-temperature process is avoided, environmental protection and comprehensive utilization of bauxite are facilitated, and obvious social and economic benefits are achieved.

Owner:TONGDA REFRACTORY TECH CO LTD +1

Method for preparing unglazed stair brick from vanadium-titanium magnet tailings

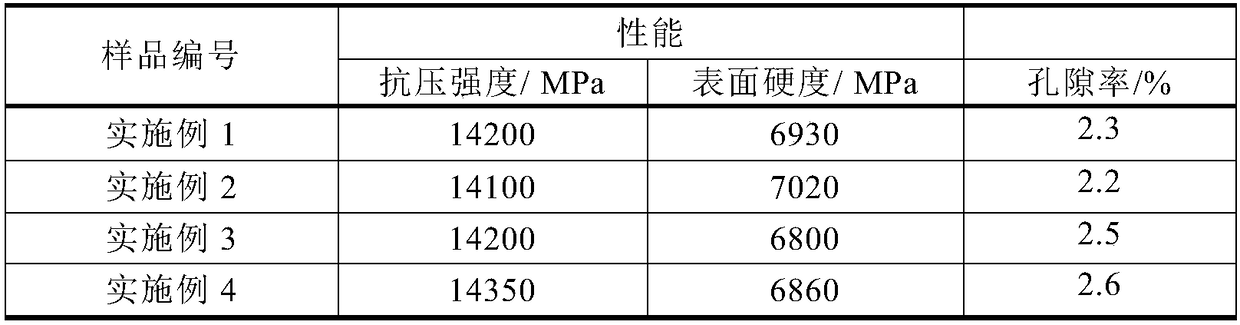

The invention discloses a method for preparing an unglazed stair brick from vanadium-titanium magnet tailings. The method comprises the following steps: firstly, performing refining treatment to obtain micron-sized active vanadium-titanium magnet tailings, mixing the micron-sized active vanadium-titanium magnet tailings with a correcting raw material, an oxidant and a cosolvent, mounding, finallysintering in a pushed slab kiln, and performing surface wear resisting treatment to finally obtain an unglazed stair brick material. By the method, with the vanadium-titanium magnet tailings as a mainraw material, through addition of the correcting raw material, the oxidant and the cosolvent and by a surface wear resisting technology, preparation of the unglazed stair brick is achieved, the costof the raw materials is greatly reduced and the wear resistance of the surface of the brick is improved. The unglazed stair brick prepared by the method provided by the invention has the compressive strength being higher than or equal to 14100 MPa, the surface hardness being higher than or equal to 6800 MPa and the porosity being lower than or equal to 2.6%.

Owner:SHAANXI SCI TECH UNIV

No-magnetic casting iron and application thereof

The non-magnetic cast iron is a product having no defined form, its production belongs to the field of alloy addition of cast iron and quenching process, and its application belongs to the field of antimagnetic magnetism-isolating component in the power equipment. It can be substituted for stainless steel, copper and aluminium alloy components which are used for resisting magnetism and isolating magnetism in power equipment. Its production method is characterized by utilizing two measures of alloy addition and quenching process to obtain and retain austenic base body so as to atain non-magnetic effect. The magnetic conductibility of said material is less than 1.1.

Owner:陈培山

Beaded glass and method of manufacture

The invention provides a glass bead with a bead billet and a coating contained the pearl essence and / or metal powder on the billet. This invention can present different colors, enhances its decoration effect, and is resistant well to attrition and high-temperature. The opposite preparation method is simple and short period, and has low cost for new-product exploit and variable requests.

Owner:庄旭钦

Regulation and control method for strengthening and toughening of rare earth magnesium alloy

ActiveCN114381677AIncrease supersaturationIncrease toughnessMetal-working apparatusIncreasing energy efficiencySolution treatmentMechanical property

The invention discloses a rare earth magnesium alloy strengthening and toughening regulation and control method. The method comprises the following steps: (1) carrying out high-temperature solution treatment of an external pressure field on a target rare earth magnesium alloy; (2) the rare earth magnesium alloy component obtained after solution treatment is completed is subjected to cooling multi-pass multi-axis forging treatment; after each pass of forging is finished, the magnesium alloy is subjected to quenching treatment, and then electromagnetic induction heating is conducted to reheat the magnesium alloy to the temperature required by subsequent pass of forging; and (3) finally, the alloy is subjected to external stress and electrostatic field assisted aging heat treatment. Through regulation and control of the method, the strengthening and toughening degree of the rare earth magnesium alloy is improved, the tensile strength and the ductility are improved, the comprehensive performance is more excellent, and the use requirements are better met. Compared with a traditional treatment process (T5 and the like), the process is more detailed and comprehensive, and the mechanical property improvement effect of the rare earth magnesium alloy is more remarkable.

Owner:GRIMAT ENG INST CO LTD

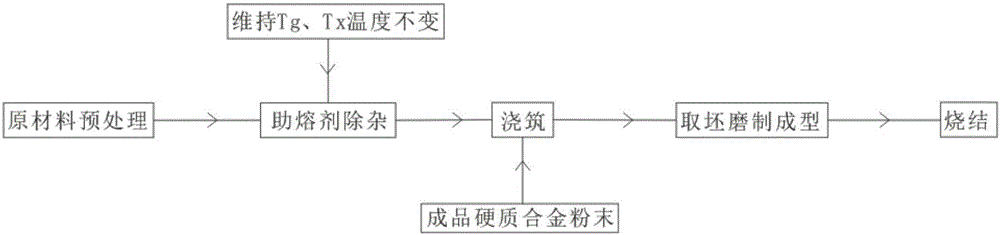

Hard alloy ultra-low temp. treatment process

InactiveCN1250751CDimensionally stableNot bentFurnace typesHeat treatment furnacesAlloyCryogenic treatment

Owner:胡明

Blow molding and foam combining technique, and its product

Owner:GUANGDONG LESHAN INTELLIGENT EQUIP CORP LTD

Series flux cord welding rod used for pile-up welding reparing and remanufacturing large type medium high carbon steel parts

InactiveCN100999041BImprove crack resistanceHigh carbon contentArc welding apparatusWelding/cutting media/materialsHigh carbonRare earth

The present invention discloses a series flux-cored wire for reparation and refabrication of large-size medium-high carbon steel components and parts. Its chemical composition includes (wt%) 5-10 of fluorite, 25-45% of high-carbon ferrochrome, 2-10% of high-carbon manganese iron, 5-8% of tantiron, 10-15% of ferro-molybdenum, 8-14% of rare earth oxide, 5-15% of metal nickel, 2-5% of ferrovanadium,0.5-2% of graphite, 2-4% of chloride and 1-2.5% of aluminium-magnesium alloy. Its external covering adopts low-carbon steel tape.

Owner:QINHUANGDAO WEIERDE SPECIAL WELDING IND

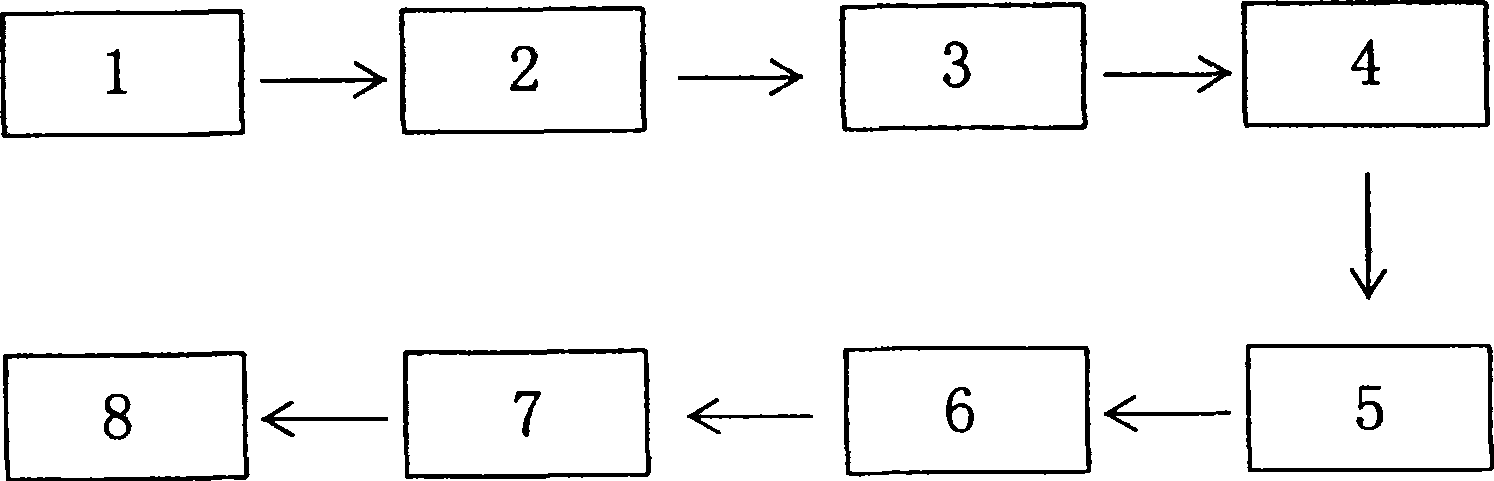

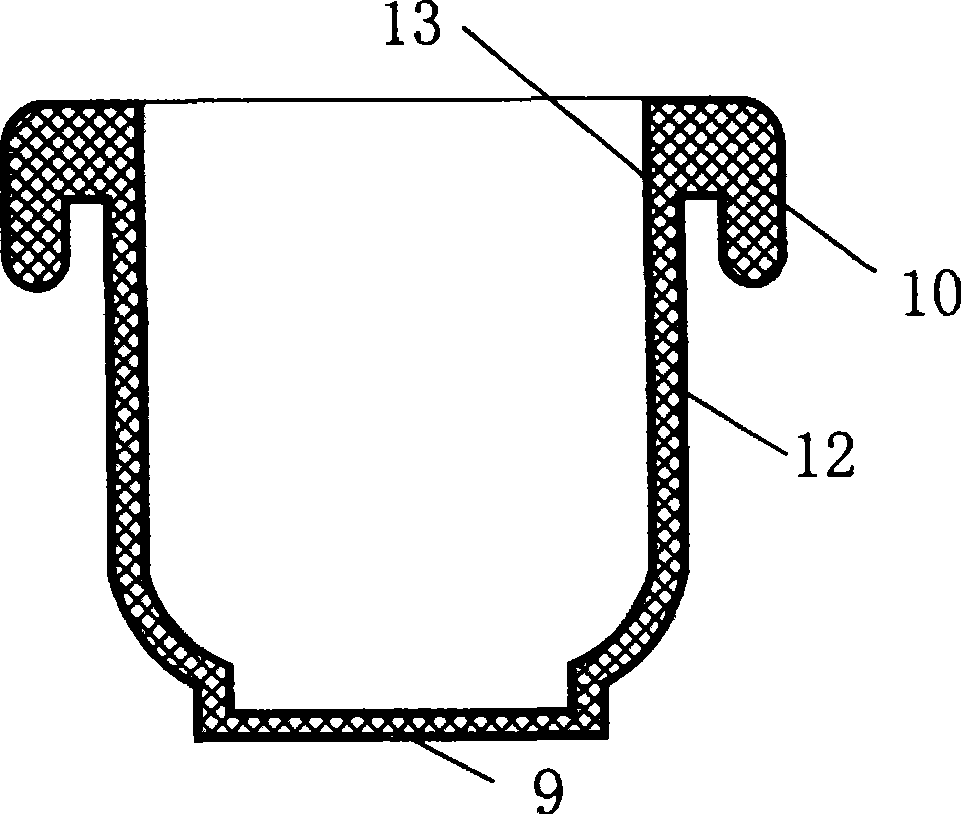

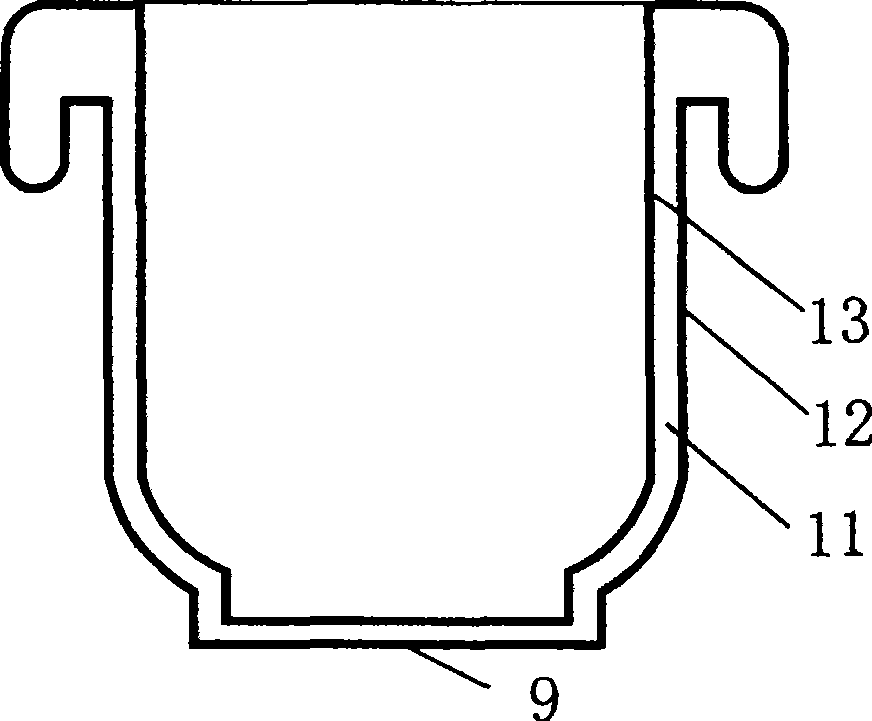

Preparation method for large-size hard alloy

The invention discloses a preparation method for a large-size hard alloy. The preparation method includes the following steps that S1, raw material preprocessing is conducted so that surface sundries and oxide can be removed; S2, fluxing agent impurity removal is conducted so that impurities in internal melt can be extracted out; S3, pouring is conducted, the melt is placed in a water-cooled copper mold, and after pouring is completed, the water-cooled copper mold enters a water tank to be suddenly cooled, and a blank is obtained; S4, the blank is taken, ground and formed, the blank is taken out and ground, a rough blank is obtained, and the rough blank is pressed; and S5, sintering is conducted, wherein secondary vacuum sintering is conducted on the rough blank, temperature and pressure are regulated in the secondary vacuum sintering process, a large-size hard alloy finished product is obtained, raw materials are purified, other nodules are prevented from appearing in the forming process, grinding is conducted after the blank is obtained, secondary sintering and die pressing are conducted after grinding is conducted, holes are further removed, and on the premise that the large size is ensured, the predicted rigid degree of the hard alloy is reached, the production period is shortened, the die occupation time is shortened, and the production efficiency is improved.

Owner:河源富马硬质合金股份有限公司

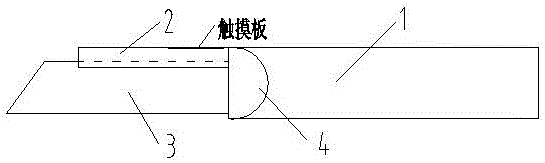

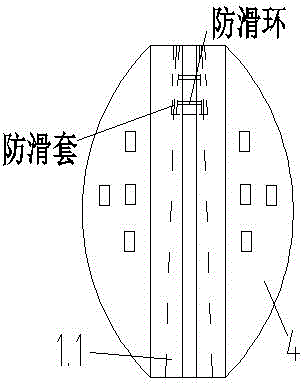

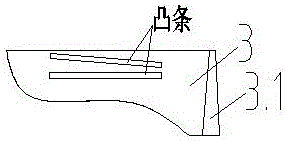

Ceramic lighting scalpel

ActiveCN105935306AHigh strengthIncrease toughnessIncision instrumentsSurgical field illuminationSurgical knifeKnife blades

The present invention discloses a ceramic lighting scalpel which comprises a holder, a blade clip and a blade; the front end surface of the holder is provided with an installing groove; the front of the holder is provided with the blade clip; the blade is fixedly installed on the holder through the installing groove and the blade clip; two sides of the front of the holder are provided with lighting devices which are LED lighting devices or laser lighting devices; and the blade is prepared by ceramic materials. The purpose of the technology is to provide the ceramic lighting scalpel which is provided with the lighting devices, the blade of the scalpel is installed more reliably, and the blade of the scalpel is prepared by the ceramic materials. The blade of the scalpel is installed more reliably, sharpness of the scalpel can be increased due to the adopted ceramic blade, and doctors can perform the operation in some dark corners conveniently due to the fact that the scalpel is equipped with the lighting devices.

Owner:常州市佳杰医疗器械有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com