Degradable disposable tableware and preparation method thereof

A one-time, tableware technology, applied in the direction of coating, which can solve the problems of complex processing technology, insufficient toughness, brittleness, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

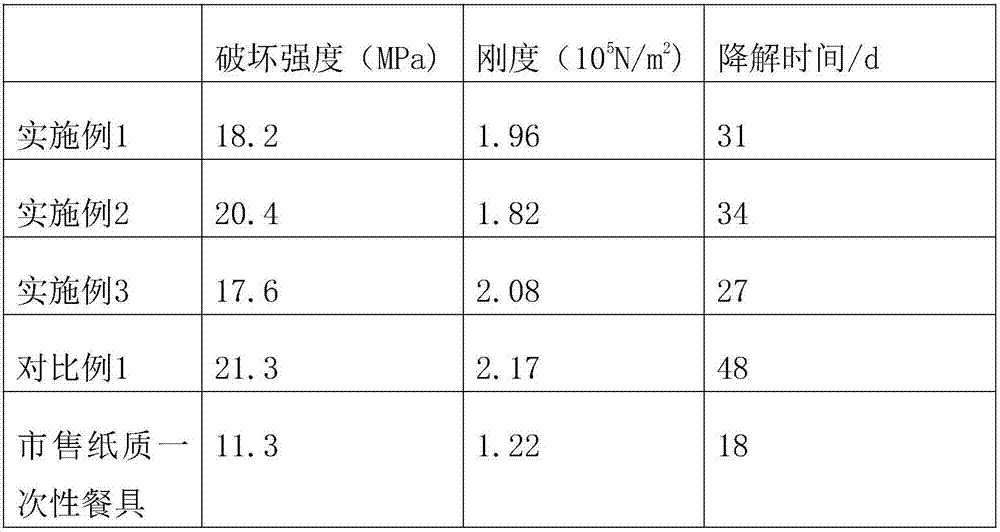

Examples

Embodiment 1

[0024] (1) Weigh 40kg of compound straw powder, 12.5kg of shell powder, 27.5kg of compound starch, 22.5kg of compound fiber pulp, 9kg of kelp extract, 22.5kg of peach gum, and 2.5kg of green bamboo

[0025] (2) Grinding the compound straw powder, shell powder and compound starch respectively, and passing through an 80-mesh sieve;

[0026] (3) Put the composite straw powder into a high-temperature high-speed mixer, add shell powder, and mix evenly, divide the composite starch and composite fiber pulp into three parts on average, add one part each time, and add the two alternately until the mixture is mixed. After cooling, mixed fiber powder is obtained;

[0027] (4) the bamboo green hammer pine, shredded into filaments, rinsed repeatedly with 0.1mol / L NaOH solution and then dried;

[0028] (5) Fully soak the peach gum with 5 times the amount of water, heat to 95°C, and fully stir until it forms a jelly;

[0029] (6) Add the mixed fiber powder and bamboo green after rinsing to...

Embodiment 2

[0036] (1) Weigh 35kg of compound straw powder, 10kg of shell powder, 25kg of compound starch, 20kg of compound fiber pulp, 8kg of kelp extract, 20kg of peach gum, and 2kg of green bamboo

[0037] (2) Grinding the compound straw powder, shell powder and compound starch respectively, and passing through an 80-mesh sieve;

[0038] (3) Put the composite straw powder into a high-temperature high-speed mixer, add shell powder, and mix evenly, divide the composite starch and composite fiber pulp into three parts on average, add one part each time, and add the two alternately until the mixture is mixed. After cooling, mixed fiber powder is obtained;

[0039] (4) the bamboo green hammer pine, shredded into filaments, rinsed repeatedly with 0.1mol / L NaOH solution and then dried;

[0040] (5) Fully soak the peach gum with 5 times the amount of water, heat to 90°C, and fully stir until it forms a jelly;

[0041] (6) adding the mixed fiber powder and bamboo green after rinsing to the pe...

Embodiment 3

[0048] (1) Weigh 45kg of compound straw powder, 15kg of shell powder, 30kg of compound starch, 25kg of compound fiber pulp, 10kg of kelp extract, 25kg of peach gum, and 3kg of bamboo green

[0049] (2) Grinding the compound straw powder, shell powder and compound starch respectively, and passing through an 80-mesh sieve;

[0050] (3) Put the composite straw powder into a high-temperature high-speed mixer, add shell powder, and mix evenly, divide the composite starch and composite fiber pulp into three parts on average, add one part each time, and add the two alternately until the mixture is mixed. After cooling, mixed fiber powder is obtained;

[0051] (4) the bamboo green hammer pine, shredded into filaments, rinsed repeatedly with 0.1mol / L NaOH solution and then dried;

[0052](5) Fully soak the peach gum with 5 times the amount of water, heat to 95°C, and fully stir until it forms a jelly;

[0053] (6) Add the mixed fiber powder and bamboo green after rinsing to the peach...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com