Blow molding and foam combining technique, and its product

A technology for finished products and foams, applied in the field of blow molding and foam, can solve the problems of insufficient mechanical strength, insufficient toughness, easy deformation, etc., and achieve the effects of saving energy, saving foaming molds, and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

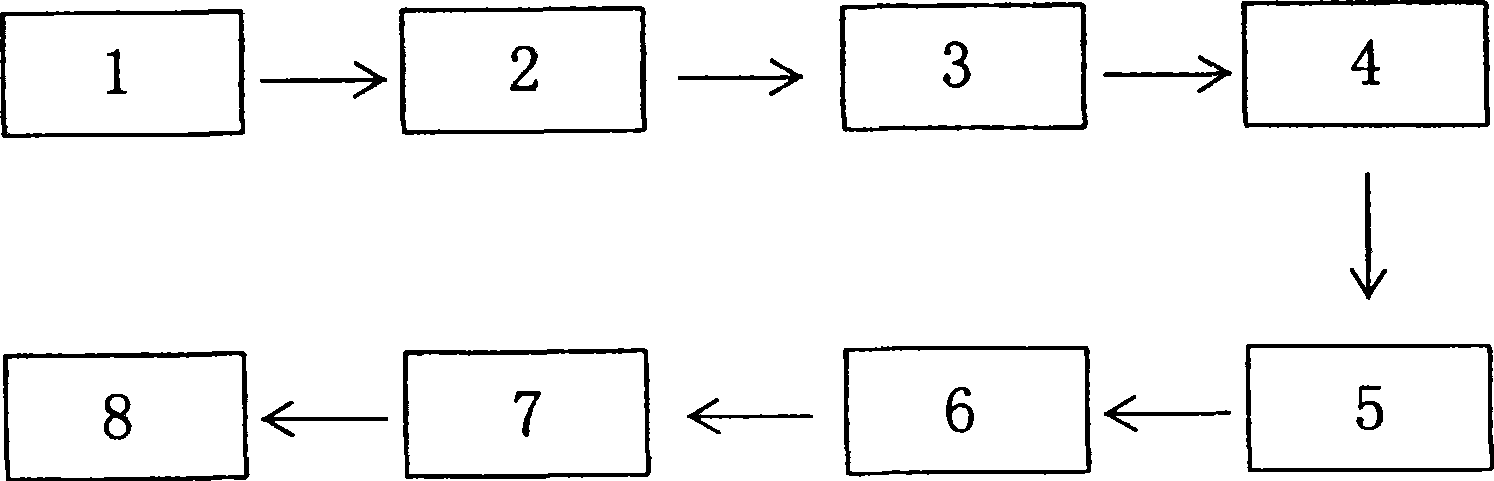

[0017] Such as figure 1 Shown is a method of blow molding and foaming. During the process of blowing plastic hollow products by a blow molding machine, foam is injected into the cavity from the blowing port when the mold is not opened after the plastic hollow product is hot-blown. The foam utilizes the waste heat of the plastic Foam molding, a method of making a finished product by opening a mold after setting the shape.

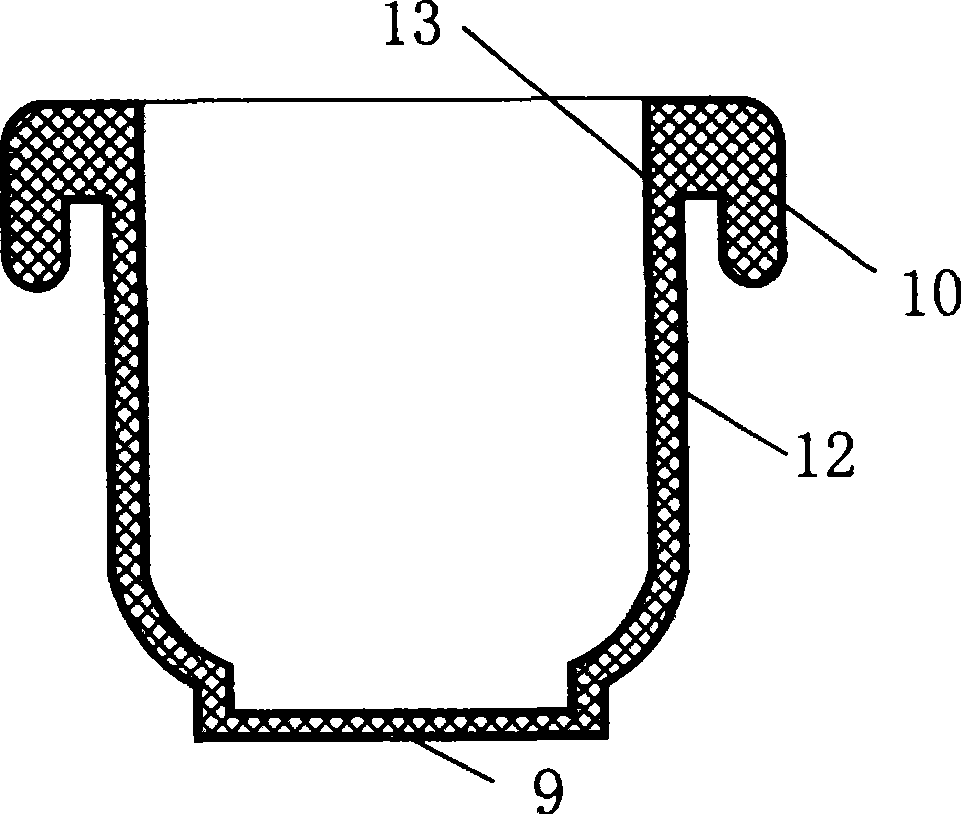

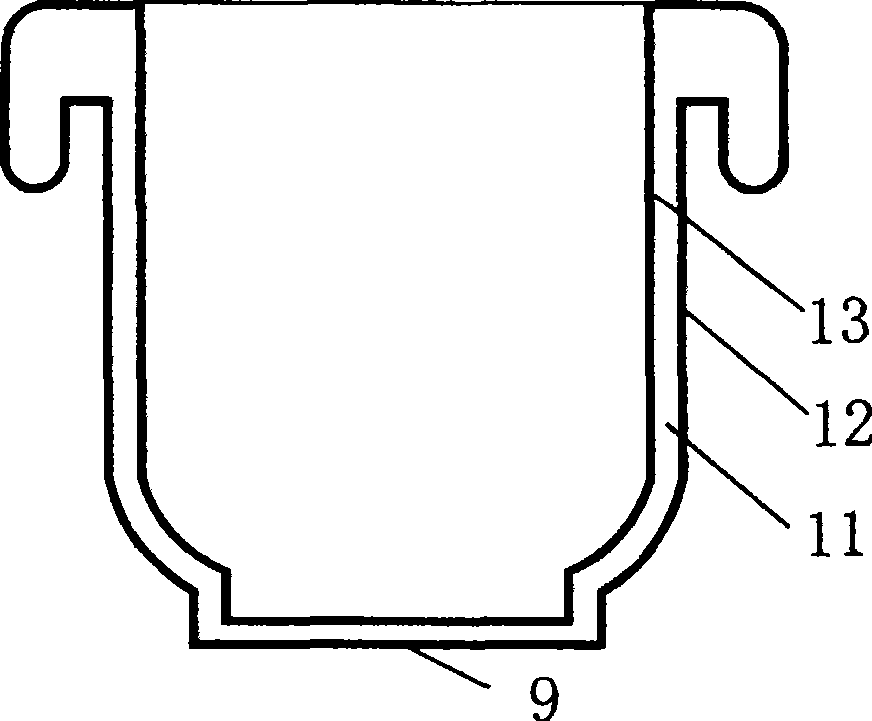

[0018] The process of making finished products by this method is embryo making 1 mold closing 2 air blowing 3 deflation and foam injection 5 foaming and setting 6 mold opening 7 finished product 8 embryo making 1 When the embryo is made, the temperature of the embryo is controlled between 120 degrees and 190 degrees. Mold closing 2 again, successively through air blowing 3 and deflation 4, then inject foam from air blowing port 9, when injecting foam, treat the plastic in the mold to cool down naturally or artificially control it between 80 degrees to 120 de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com