Solid-melting Ti(C,N) unfired silicon mullite brick and preparation method thereof

A technology of silica brick and fused mullite, which is applied in the field of solid-melt Ti non-fired silica brick and its preparation, can solve the problems of increasing energy consumption and environmental impact, and achieve shortened production cycle, reduced consumption, good thermal The effect of shock stability and wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

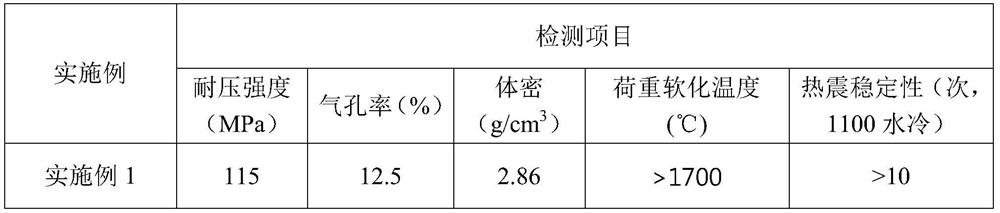

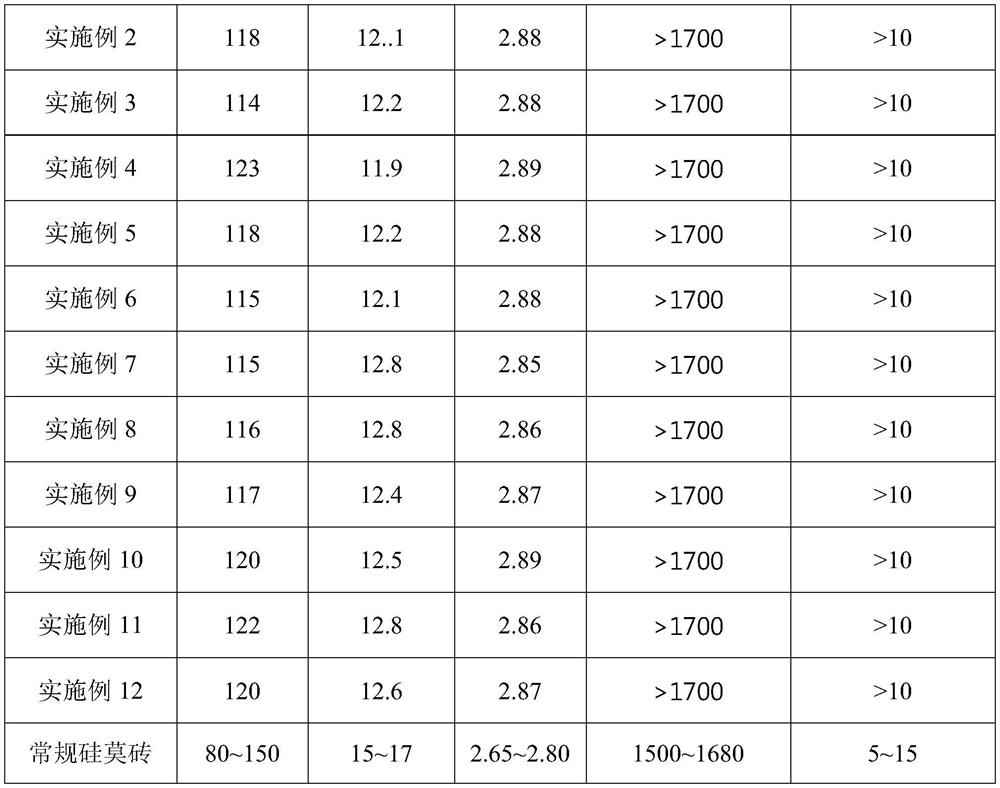

Examples

Embodiment 1

[0032] A solid solution Ti(C,N) unfired silica brick, prepared from the following components in weight percentage: solid solution Ti(C,N) fused mullite 80%, 90% silicon carbide 2% , calcined alumina powder 10%, bonded clay 8%; of which 3-5mm fused mullite 10%, 1-3mm fused mullite 35%, 0-1mm fused mullite 20%, 200 mesh Fused mullite 15%. Add 3.2% of aluminum dihydrogen phosphate (specific gravity 1.38) accounting for the total weight of the above components.

[0033] Among them, the solid solution Ti(C,N) fused mullite index is: Al 2 o 3 71.32%, SiO 2 20.02%, Fe 2 o 3 0.49%, TiO 2 6.09%, bulk density is 3.15g / m 3 ;

[0034] The preparation method of above-mentioned solid solution Ti (C, N) unfired silica brick, comprises the following steps:

[0035] (1) Weigh the raw materials according to the above ratio, put the fine powder raw materials 15kg fused mullite, 2kg silicon carbide, 8kg bonded clay and 10kg calcined alumina powder into the double-screw premixer for pr...

Embodiment 2

[0040] A solid solution Ti(C,N) unfired silica brick, prepared from the following components in weight percentage: solid solution Ti(C,N) fused mullite 80%, 93 silicon carbide 2% , calcined alumina powder 10%, bonded clay 8%; of which 3-5mm fused mullite 10%, 1-3mm fused mullite 35%, 0-1mm fused mullite 20%, 200 mesh Fused mullite 15%. Add 3.2% of aluminum dihydrogen phosphate (specific gravity 1.38) accounting for the total weight of the above components.

[0041] Among them, the solid solution Ti(C,N) fused mullite index is: Al 2 o 3 71.32%, SiO 2 20.02%, Fe 2 o 3 0.49%, TiO 2 6.09%, bulk density is 3.15g / m 3 .

[0042]The preparation method of above-mentioned solid solution Ti (C, N) unfired silica brick, comprises the following steps:

[0043] (1) Weigh the raw materials according to the above ratio, put the fine powder raw materials 15kg fused mullite, 2kg silicon carbide, 8kg bonded clay and 10kg calcined alumina powder into the double-screw premixer for prem...

Embodiment 3

[0048] A solid solution Ti(C,N) unfired silica brick prepared from the following components in weight percentage: Al 2 o 3 80% of fused mullite with a content of 70%, 2% of 97 silicon carbide, 10% of calcined alumina powder, and 8% of bonded clay; 10% of 3-5mm fused mullite, 1-3mm fused mullite 35%, 0-1mm fused mullite 20%, 200 mesh fused mullite 15%. Add 3.2% of aluminum dihydrogen phosphate (specific gravity 1.38) accounting for the total weight of the above components.

[0049] Among them, the solid solution Ti(C,N) fused mullite index is: Al 2 o 3 71.32%, SiO 2 20.02%, Fe 2 o 3 0.49%, TiO 2 6.09%, bulk density is 3.15g / m 3 .

[0050] The preparation method of above-mentioned solid solution Ti (C, N) unfired silica brick, comprises the following steps:

[0051] (1) Weigh the raw materials according to the above ratio, put the fine powder raw materials 15kg fused mullite, 2kg silicon carbide, 8kg bonded clay and 10kg calcined alumina powder into the double-screw...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com