Degradable disposable tableware and preparation method thereof

A disposable and tableware technology, applied in the field of degradable disposable tableware and its preparation, can solve the problems that hinder the rapid popularization of such materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

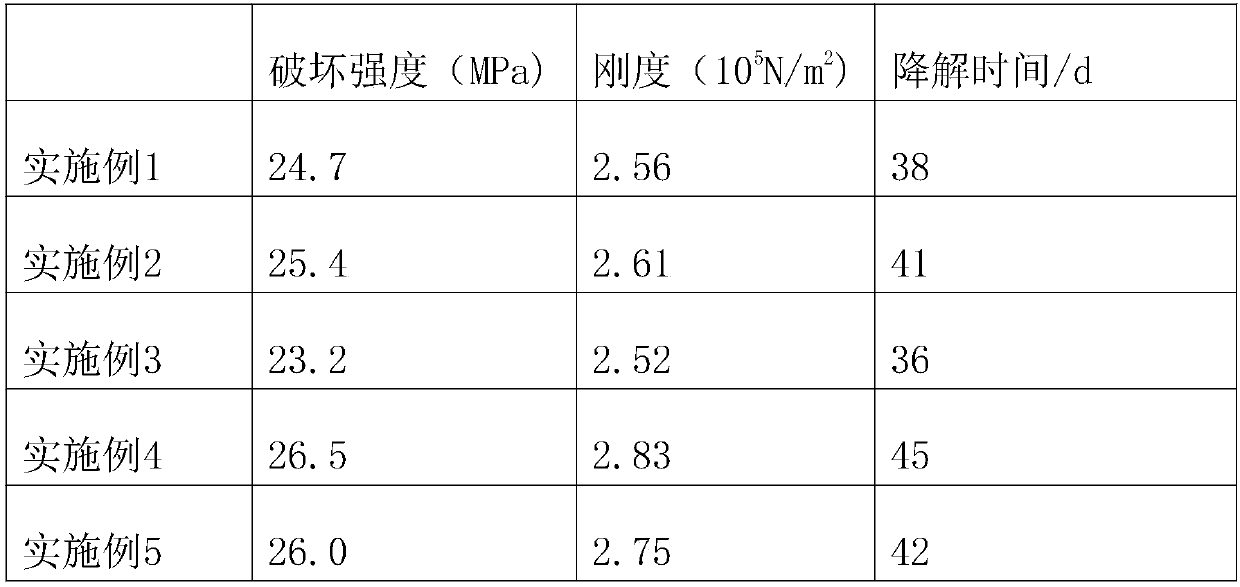

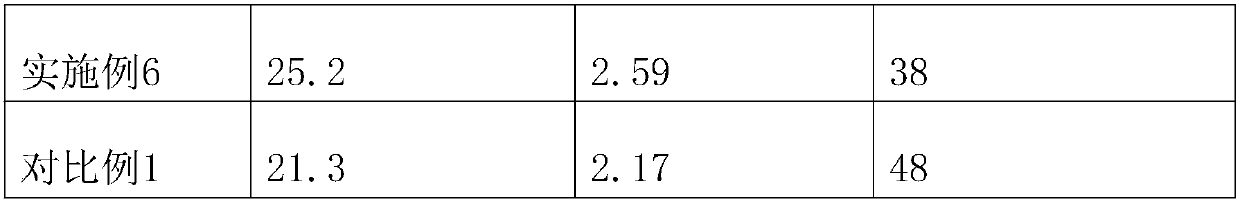

Examples

Embodiment 1

[0032] (1) Weigh 70kg of wheat straw powder, 37.5kg of reed pulp, 30kg of wheat starch, 20kg of peach gum, 12.33kg of PHA, 24.66kg of PHBV, and 11kg of bamboo fiber

[0033] (2) Grinding wheat straw powder, wheat starch and peach gum respectively, and passing through an 80-mesh sieve;

[0034] (3) Put the wheat straw powder into a high-temperature high-speed mixer, add peach gum powder, after mixing evenly, slowly add wheat starch, and obtain viscous wheat mixed powder after cooling;

[0035] (4) Bamboo fiber is soaked and softened with lye, cleaned and dried;

[0036] (5) Add equal amount of water to the wheat mixed flour, stir evenly, and form a paste;

[0037] (6) Add reed pulp, PHA, PHBV to the paste of step (6), stir evenly, add bamboo fiber, stir again, obtain raw material mixture;

[0038] (7) The raw material mixture is molded with a molding machine, and taken out after molding. The molding temperature is 160° C., and the molding pressure is 230 MPa.

[0039] The re...

Embodiment 2

[0041] (1) Weigh 65kg of wheat straw powder, 35kg of reed pulp, 23kg of wheat starch, 18kg of peach gum, 11.66kg of PHA, 23.33kg of PHBV, and 10kg of bamboo fiber

[0042] (2) Grinding wheat straw powder, wheat starch and peach gum respectively, and passing through an 80-mesh sieve;

[0043] (3) Put the wheat straw powder into a high-temperature high-speed mixer, add peach gum powder, after mixing evenly, slowly add wheat starch, and obtain viscous wheat mixed powder after cooling;

[0044] (4) Bamboo fiber is soaked and softened with lye, cleaned and dried;

[0045] (5) Add 0.5 times the amount of water to the wheat mixed flour, stir evenly, and form a paste;

[0046] (6) Add reed pulp, PHA, PHBV to the paste of step (6), stir evenly, add bamboo fiber, stir again, obtain raw material mixture;

[0047] (7) The raw material mixture is molded with a molding machine, and taken out after molding. The molding temperature is 140° C., and the molding pressure is 220 MPa.

[0048] ...

Embodiment 3

[0050] (1) Weigh 75kg of wheat straw powder, 40kg of reed pulp, 32kg of wheat starch, 22kg of peach gum, 13kg of PHA, 26kg of PHBV, and 12kg of bamboo fiber

[0051] (2) Grinding wheat straw powder, wheat starch and peach gum respectively, and passing through an 80-mesh sieve;

[0052] (3) Put the wheat straw powder into a high-temperature high-speed mixer, add peach gum powder, after mixing evenly, slowly add wheat starch, and obtain viscous wheat mixed powder after cooling;

[0053] (4) Bamboo fiber is soaked and softened with lye, cleaned and dried;

[0054] (5) Add 1.5 times the amount of water to the wheat mixed flour, stir evenly, and form a paste;

[0055] (6) Add reed pulp, PHA, PHBV to the paste of step (6), stir evenly, add bamboo fiber, stir again, obtain raw material mixture;

[0056] (7) The raw material mixture is molded with a molding machine, and taken out after molding. The molding temperature is 180° C., and the molding pressure is 240 MPa.

[0057] The re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com