Method for preparing unglazed stair brick from vanadium-titanium magnet tailings

A vanadium-titanium magnet and stair brick technology, which is applied in the field of green building materials preparation, can solve the problems such as the difficulty in increasing the industrial added value of vanadium-titanium magnet tailings, so as to improve the actual utilization rate, reduce the cost of raw materials, and improve the wear resistance of the brick surface Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] (1) After washing, sieving, and drying the vanadium-titanium magnet tailings, it is placed in a linked powder activation device for refinement. The refinement medium is zirconium dioxide prisms, the spindle speed is 480 rpm, and the refinement time is 8 Hours to obtain micron-sized active vanadium-titanium magnetite tailings;

[0027] (2) Mix the active vanadium-titanium magnetite tailings, alumina powder, manganese dioxide powder, iron powder, and potassium carbonate powder at a ratio of 67:10.7:9.5:10.2:2.6 for 2.1 hours, and then add a polymer with a mass concentration of 10%. The spheroidizing agent of vinyl alcohol aqueous solution is placed in a high-pressure mold for compression molding, and the molding pressure is 87MPa;

[0028] (3) Put the cold pressed body into a pusher kiln for preheating, sintering and cooling. The time of each step is 3 hours, 5 hours and 7 hours respectively, and the maximum sintering temperature is 1170℃; finally, the surface high-energy heat...

Embodiment 2

[0030] (1) After washing, sieving and drying the vanadium-titanium magnet tailings, it is placed in a linked powder activation device for refinement. The refinement medium is zirconia prism, the spindle speed is 400 revolutions / min, and the refinement time is 9 Hours to obtain micron-sized active vanadium-titanium magnetite tailings;

[0031] (2) Mix the active vanadium-titanium magnetite tailings, alumina powder, manganese dioxide powder, iron powder, and potassium carbonate powder in a ratio of 64:11.7:10.5:11.2:2.6 for 3.1 hours, and then add 10% polymer with a mass concentration of The spheroidizing agent of vinyl alcohol aqueous solution is placed in a high-pressure mold and pressed into a shape with a molding pressure of 58MPa;

[0032] (3) Put the cold-pressed body into a pusher kiln for preheating, sintering and cooling. The time for each step is 3 hours, 5 hours and 7 hours respectively, and the maximum sintering temperature is 1270℃; finally, the surface high-energy heat ...

Embodiment 3

[0034] (1) After washing, sieving and drying the vanadium-titanium magnet tailings, it is placed in a linked powder activation device for refinement. The refinement medium is zirconium dioxide prism, the spindle speed is 500 rpm, and the refinement time is 8 Hours to obtain micron-sized active vanadium-titanium magnetite tailings;

[0035] (2) Mix the active vanadium-titanium magnetite tailings, alumina powder, manganese dioxide powder, iron powder, and potassium carbonate powder at a ratio of 65:9.9:10.7:12.3:2.1 for 2.8 hours, and then add a polymer with a mass concentration of 10%. The spheroidizing agent of vinyl alcohol aqueous solution is placed in a high-pressure mold for compression molding, and the molding pressure is 88MPa;

[0036] (3) Put the cold-pressed body into the pusher kiln for preheating, sintering and cooling. The time of each step is 3 hours, 5 hours and 7 hours respectively, and the maximum sintering temperature is 1250℃; finally, the surface high-energy heat...

PUM

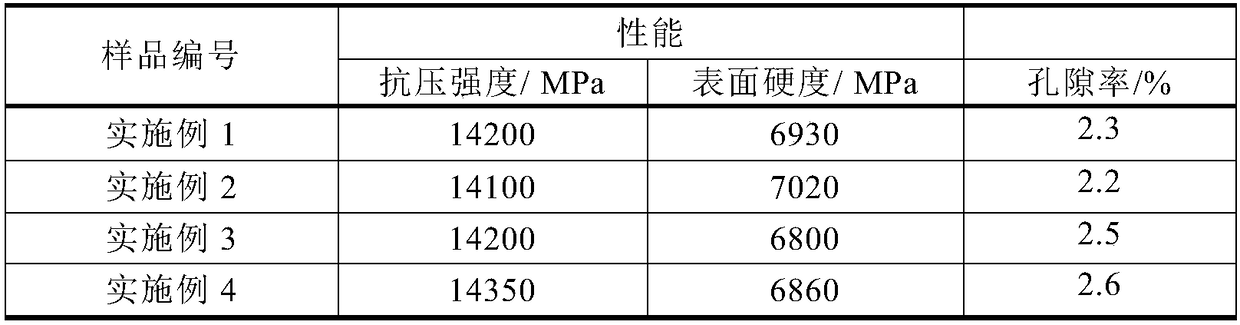

| Property | Measurement | Unit |

|---|---|---|

| Compressive strength | aaaaa | aaaaa |

| Surface hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com