Wheel steel capable of resisting out-of-round, wheels and preparation method of wheels

A wheel steel and wheel technology is applied in the field of rail transit wheels and their preparation, which can solve the problems that plague the operation and wear of subway vehicles, and achieve the effects of prolonging the repair mileage, improving the hardenability and improving the wear and tear.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] An anti-lost-round wheel steel in this embodiment includes the following components in weight percentage: C: 0.56%, Si: 0.25%, Mn: 0.70%, Cr: 0.20%, Ni: 0.10%, P: 0.008%, S: 0.008%, the rest is Fe and unavoidable impurity elements. From the perspective of the influence of alloying elements on properties, in order to obtain high strength and hardness properties and high plastic properties, composite microalloying should be implemented. Therefore, the present invention focuses on designing the contents of Si, Mn, Cr and Ni in the wheel steel. The metallographic structure of the wheel steel in this embodiment is ferrite+pearlite.

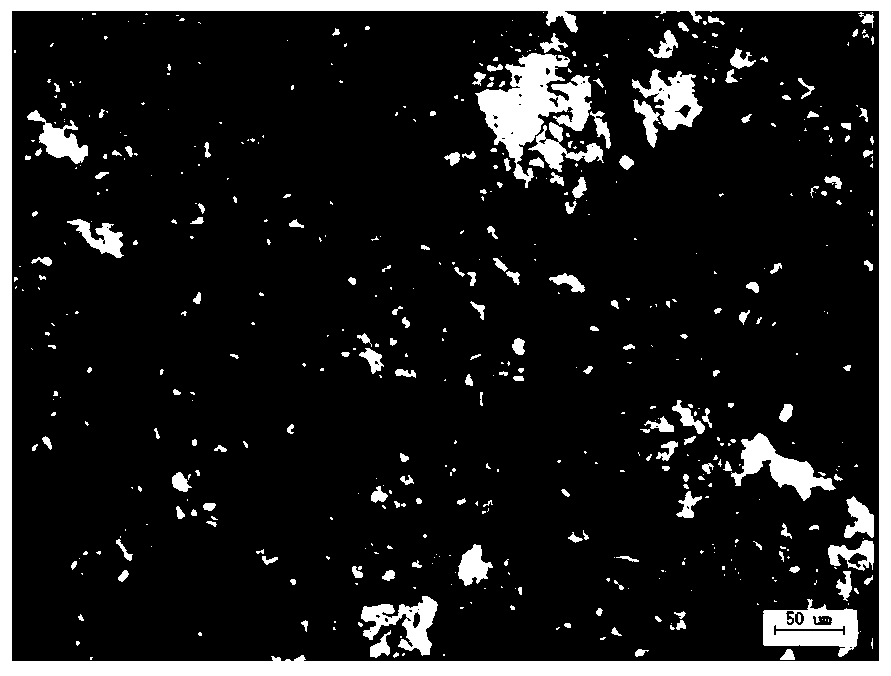

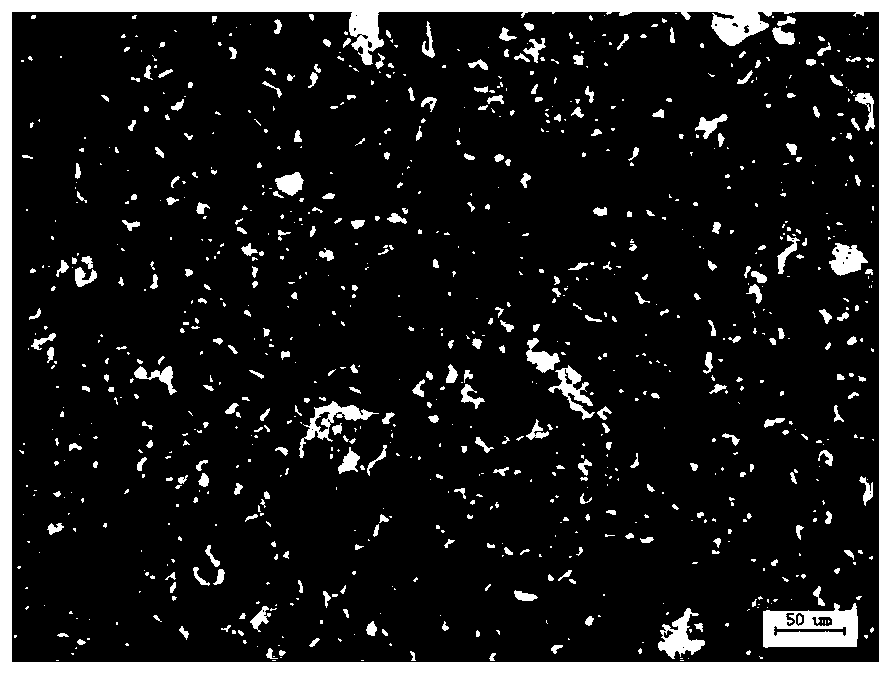

[0046] The anti-lost-round wheel of this embodiment is prepared by using the above-mentioned anti-lost-round wheel steel. Such as figure 1 , 2 As shown, the metallographic structure of the wheel prepared in this embodiment is basically the same as that of the comparative example (ER9 wheel), both of which are fine pearlite + a small amount o...

Embodiment 2

[0068] A kind of anti-lost round wheel steel of this embodiment is basically the same as that of Embodiment 1, the differences are: C: 0.60%, Si: 0.35%, Mn: 0.80%, Cr: 0.25%, Ni: 0.20% , P: 0.007%, S: 0.002%, and the rest are Fe and unavoidable impurity elements.

[0069]The anti-lost-round wheel of this embodiment is prepared by using the above-mentioned anti-lost-round wheel steel. Such as figure 1 , 2 As shown, the metallographic structure of the wheel prepared in this embodiment is basically the same as that of the comparative example (ER9 wheel), both of which are fine pearlite + a small amount of ferrite. For comparative ER9 wheels.

[0070] The preparation method of an anti-lost-round wheel in this embodiment, its preparation process is basically the same as that of Embodiment 1, the difference is that the electric furnace steelmaking process in this embodiment refers to adding raw materials into an electric furnace for smelting, when molten steel When the temperatu...

Embodiment 3

[0076] A kind of anti-lost round wheel steel of this embodiment is basically the same as that of Embodiment 1, the difference is: C: 0.58%, Si: 0.30%, Mn: 0.75%, Cr: 0.23%, Ni: 0.15% , P: 0.006%, S: 0.006%, and the rest are Fe and unavoidable impurity elements.

[0077] The anti-lost-round wheel of this embodiment is prepared by using the above-mentioned anti-lost-round wheel steel. Such as figure 1 , 2 As shown, the metallographic structure of the wheel prepared in this embodiment is basically the same as that of the comparative example (ER9 wheel), both of which are fine pearlite + a small amount of ferrite. For comparative ER9 wheels.

[0078] The preparation method of an anti-lost-round wheel in this embodiment, its preparation process is basically the same as that of Embodiment 1, the difference is that the electric furnace steelmaking process in this embodiment refers to adding raw materials into an electric furnace for smelting, when molten steel When the temperatur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com