Zirconium-loaded impregnated carbon for protecting HCN and CNCL poisons and its preparation method

A technology of impregnated carbon and poison, which is applied in the direction of catalyst activation/preparation, chemical instruments and methods, physical/chemical process catalysts, etc. It can solve the problems of poor protection ability of small molecule poisons, poor stability of impregnated carbon, and occupancy, reaching a large market and practical application value, the effect of simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

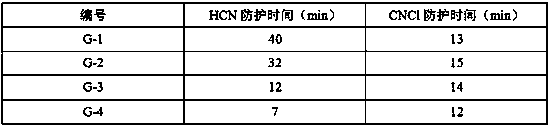

Examples

Embodiment 1

[0014] A zirconium-loaded impregnated carbon for protection against HCN and CNCl poisons, using coconut shell crushed activated carbon as the carrier skeleton material, based on the weight of activated carbon, loaded with 15% Cu, 2% Cl - , 0.5% W, 5% V, 2% Ce, 4% Zr, and the balance is activated carbon.

[0015] The preparation method is as follows:

[0016] Weigh 13g basic copper carbonate, 1.5g ammonium chloride, 0.3g ammonium metatungstate, 5.7g ammonium metavanadate, 3.2g cerium nitrate, 7.7g zirconium sulfate, gradually add 50mL ammonia water and 5mL deionized water in order In the mixed liquid, fully stir and dissolve at 60-80°C to obtain the impregnating liquid. Pour the prepared impregnating liquid into a beaker containing 50g of activated carbon and keep stirring. After the impregnation is fully complete, put the mixed material into a sealed In the bag, after standing for 4 hours, put the mixture in the hot air flow to dry and activate for 24 hours to prepare sample ...

Embodiment 2

[0018] A zirconium-loaded impregnated carbon for protection against HCN and CNCl poisons, using coconut shell crushed activated carbon as the carrier skeleton material, based on the weight of activated carbon, loaded with 18% Cu, 6% Cl - , 1% W, 4% V, 0.1% Ce, 2% Zr, and the balance is activated carbon.

[0019] The preparation method is as follows:

[0020] Weigh 15.5g basic copper carbonate, 4.5g ammonium chloride, 0.7g ammonium metatungstate, 4.5g ammonium metavanadate, 0.15g cerium nitrate, 3.8g zirconium sulfate, gradually add 50mL ammonia water and 5mL deionized water in order In the mixed solution, fully stir and dissolve at 60-80°C to obtain the impregnation solution, pour the prepared impregnation solution into a beaker containing 50g of activated carbon, and keep stirring. After the impregnation is fully complete, put the mixture into In a sealed bag, after standing for 4 hours, place the mixture in a hot air stream to dry and activate for 24 hours to prepare sample...

Embodiment 3

[0022] A zirconium-loaded impregnated carbon for protection against HCN and CNCl poisons, using coconut shell crushed activated carbon as the carrier skeleton material, based on the weight of activated carbon, loaded with 20% Cu, 1% Cl - , 5% W, 1.5% V, 1% Ce, 6% Zr, and the balance is activated carbon.

[0023] The preparation method is as follows:

[0024] Weigh 17g basic copper carbonate, 0.75g ammonium chloride, 3.3g ammonium metatungstate, 1.7g ammonium metavanadate, 0.6g cerium oxide, 11.5g zirconium sulfate, gradually add 50mL ammonia water and 5mL deionized water in order In the mixed liquid, fully stir and dissolve at 60-80°C to obtain the impregnating liquid. Pour the prepared impregnating liquid into a beaker containing 50g of activated carbon and keep stirring. After the impregnation is fully complete, put the mixed material into a sealed In the bag, after standing for 4 hours, place the mixture in the hot air flow to dry and activate for 24 hours to prepare sampl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com