Method for producing ethylene carbonate from ethylene oxide and CO2

A technology of ethylene carbonate and ethylene oxide, which is applied in the field of preparing ethylene carbonate from ethylene oxide and carbon dioxide, can solve the problem of low activity of heterogeneous catalysts, and achieve the characteristics of not easy to lose, good technical effect, and stable catalyst properties Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

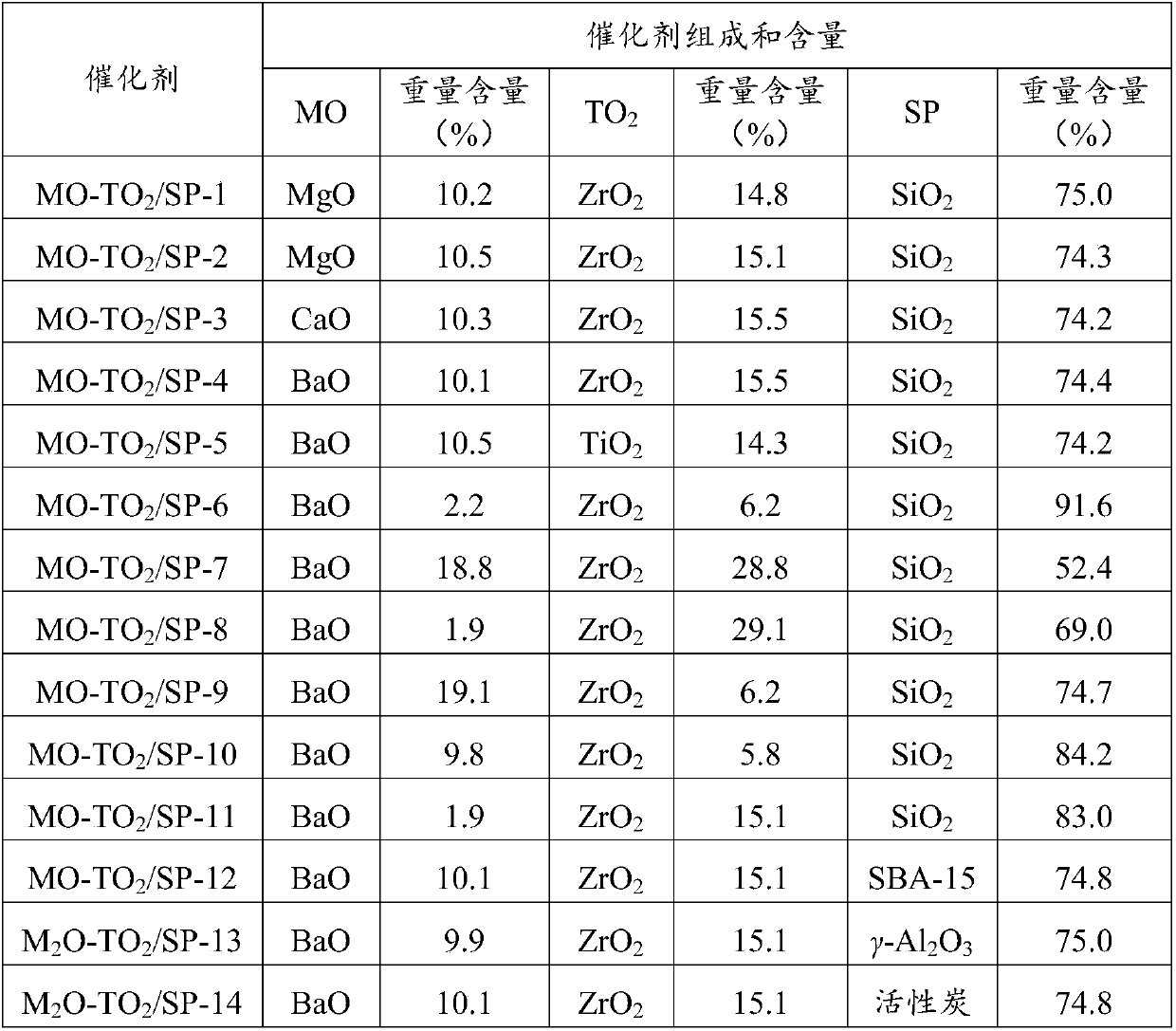

[0020] Weigh 8.5g of magnesium nitrate hexahydrate and 7.0g of zirconium nitrate pentahydrate and dissolve them in 100ml of water, and dissolve 10g of porous SiO 2 (Degussa Aerosil 200) was added to it, heated to 90°C and evaporated to dryness, dried overnight in an oven at 120°C, and then roasted in a muffle furnace at 550°C for 4 hours to obtain the supported mixed metal oxide catalyst MO-TO 2 / SP-1, wherein the weight content of MO is 10.2%, TO 2 The weight content of the carrier SP is 14.8%, and the weight content of the carrier SP is 75.0%.

Embodiment 2

[0022] The catalyst preparation steps are the same as in [Example 1], except that the M metal salt used is 7.1g magnesium acetate tetrahydrate, and the catalyst obtained is MO-TO 2 / SP-2.

Embodiment 3

[0024] The catalyst preparation steps are the same as in [Example 1], except that the M metal salt used is 5.1 g calcium nitrate tetrahydrate, and the obtained catalyst is MO-TO 2 / SP-3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com