Patents

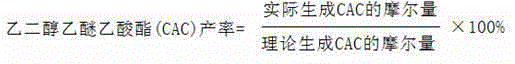

Literature

59 results about "Reactive synthesis" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Reactive synthesis (or temporal synthesis) is the field of computer science that studies automatic generation of state machines (e.g. Moore machines) from high-level specifications (e.g. formulas in linear temporal logic). "Reactivity" highlights the fact that the synthesized machine interacts with the user, reading an input and producing an output, and never stops its operation.

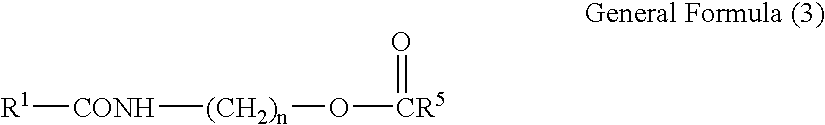

Carboxamide derivative, processes for producing the same, and detergent composition

InactiveUS20070010680A1Reduced amide ester contentGood low temperature stabilityCosmetic preparationsHair cosmeticsBetaineFormamide

To provide: a carboxamide derivative having reduced content of amide ester; a method for producing thereof; and a detergent composition containing the carboxamide derivative and having excellent low-temperature stability. One method for producing a carboxamide derivative is to react carboxamide, produced with a manufacturing method of carboxamide including 0.02% by weight to 0.18% by weight of amide ester, with hydrogen peroxide, wherein the method includes a carboxamide synthesis process to synthesize carboxamide by reacting diamine with fatty acid ester at a molar rate of 1.20 to 1.60. Another method for producing a carboxamide derivative is to react the carboxamide with monohaloalkylcarboxylic acid or a salt thereof. A carboxamide derivative is produced by the method for producing a carboxamide derivative. A detergent composition includes the carboxamide derivative. The carboxamide derivative is preferably amidoamine oxide or amide betaine.

Owner:LION AKZO

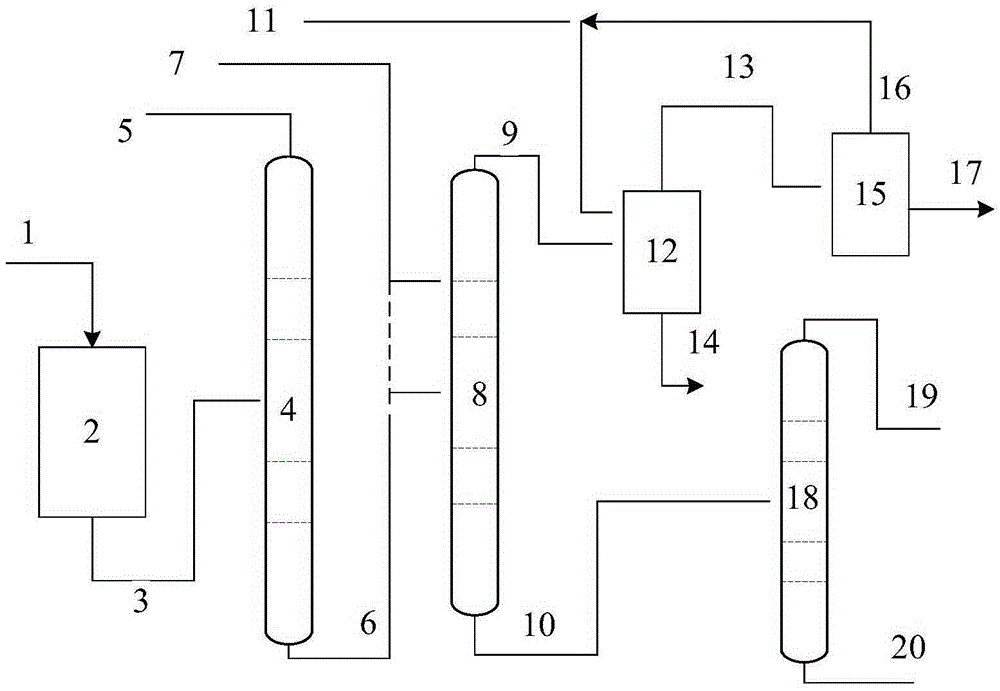

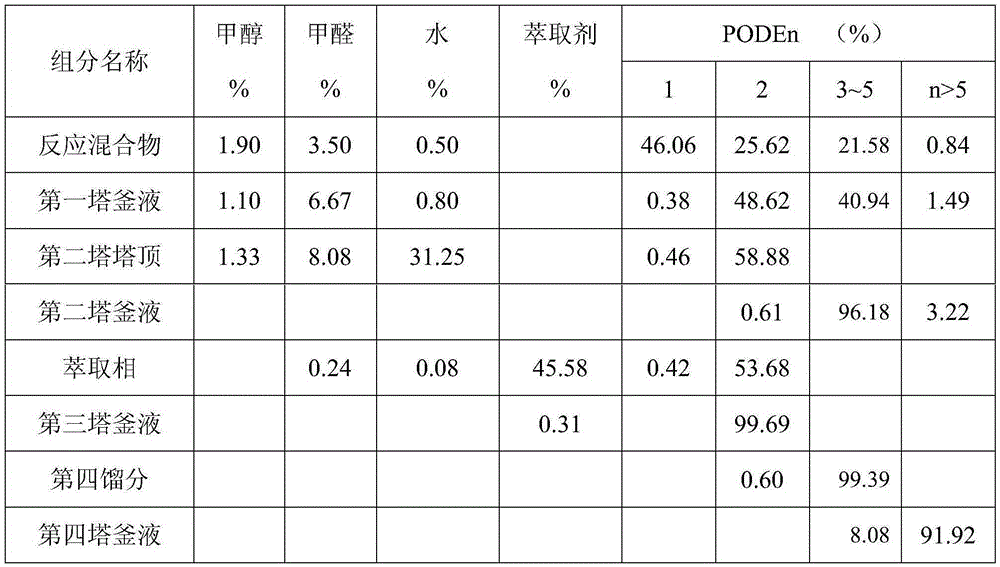

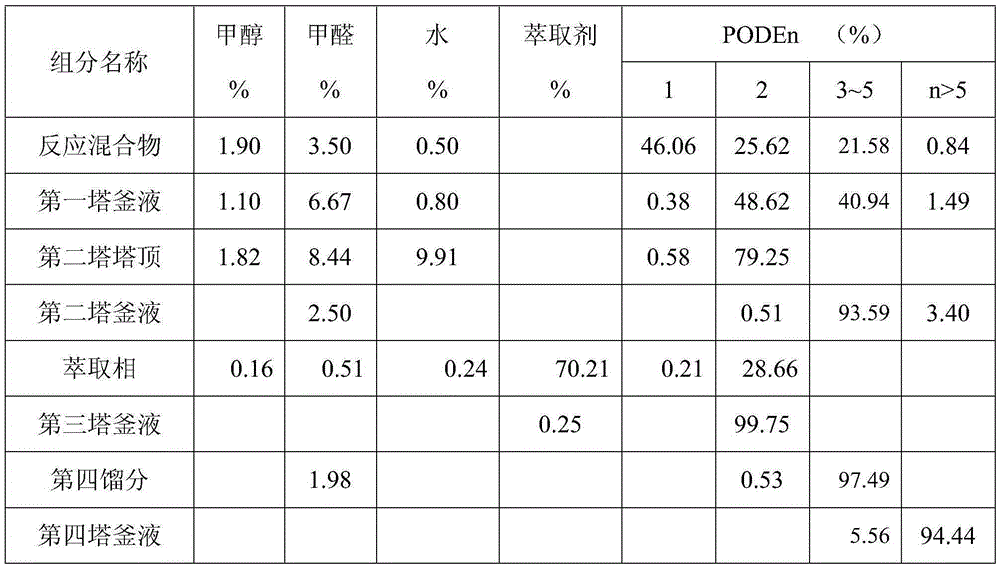

Purification method for polyoxymethylene dimethyl ether(PODE)

ActiveCN106588589AGuaranteed separation and recoveryEasy to removeOrganic chemistryOrganic compound preparationPurification methodsDistillation

The invention needs to solve a technical problem of being hard to operate continuously in long-term when materials block an overhead of rectifying column in the process of purifying the PODE by distillation. An adopted technical scheme includes following steps: (a) a reaction mixture, produced through a reactive synthesis unit, enters into a first rectifying column. A first fraction, mainly including Methylal, is separated and a first column residue is produced; (b) the first column residue and make-up water enter into a second rectifying column, and a second column residue and a second overhead of rectifying column light ends including PODE2 raw material are produced by separation; (c) after adding extraction agent in the second overhead of rectifying column light ends, raffinate is separated and extract phase is produced; (d) a second column residue enters into a fourth rectifying column. Production fraction containing PODE 3-5 is separated by the overhead of rectifying column.

Owner:CHINA PETROLEUM & CHEM CORP +1

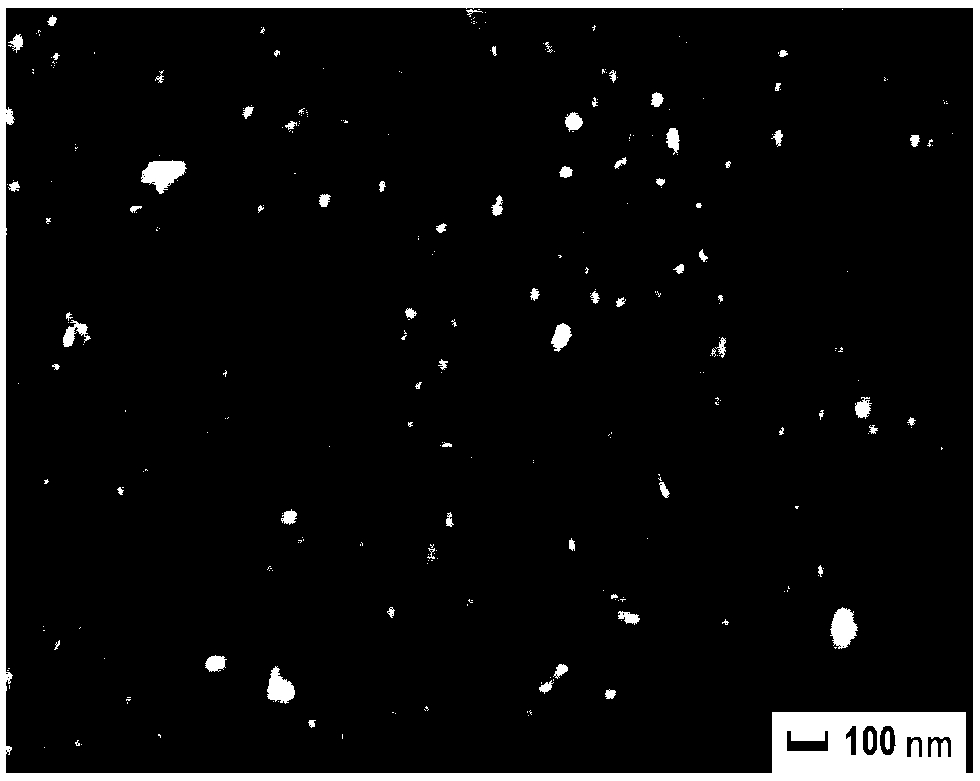

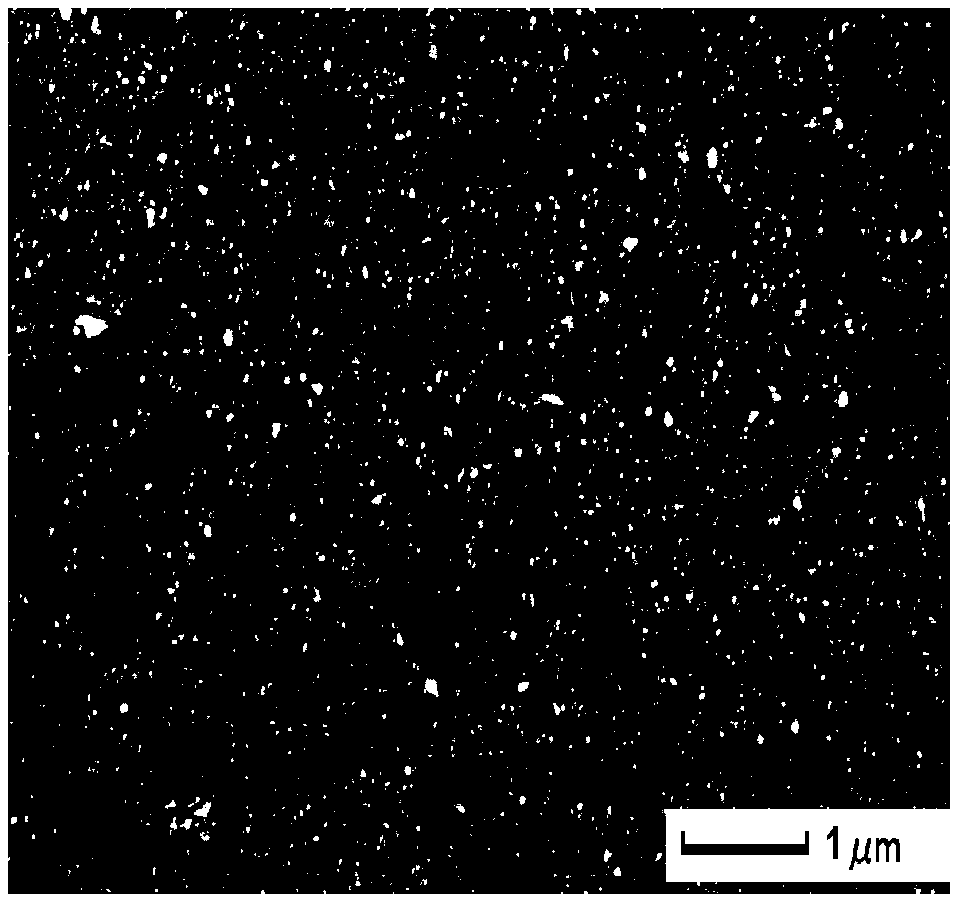

Preparation method for nano precious metal particle modified tin dioxide gas sensitive material

InactiveCN102041474AAdjustable dispersionEffective dispersionVacuum evaporation coatingSputtering coatingTin dioxideNanoparticle

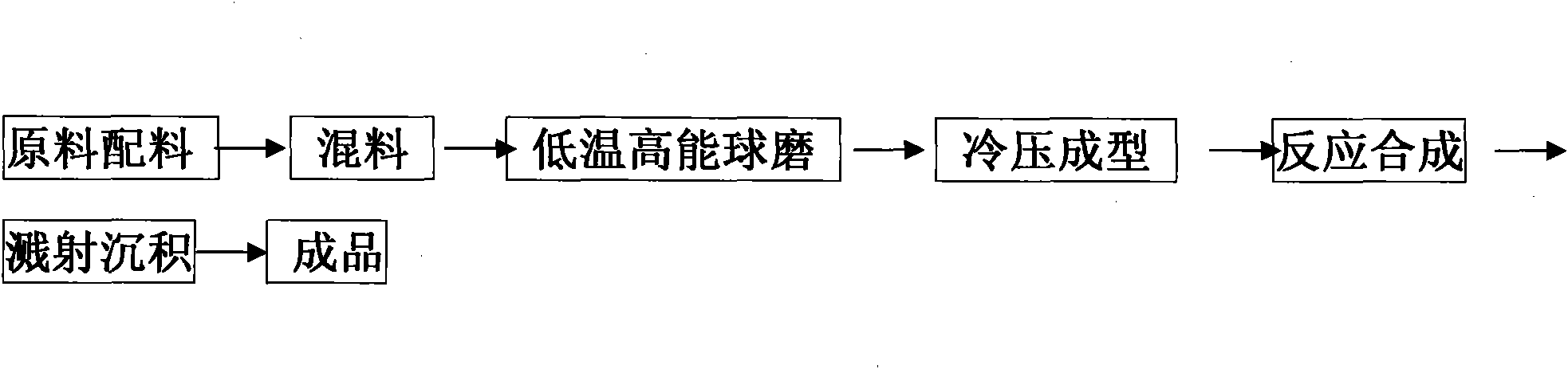

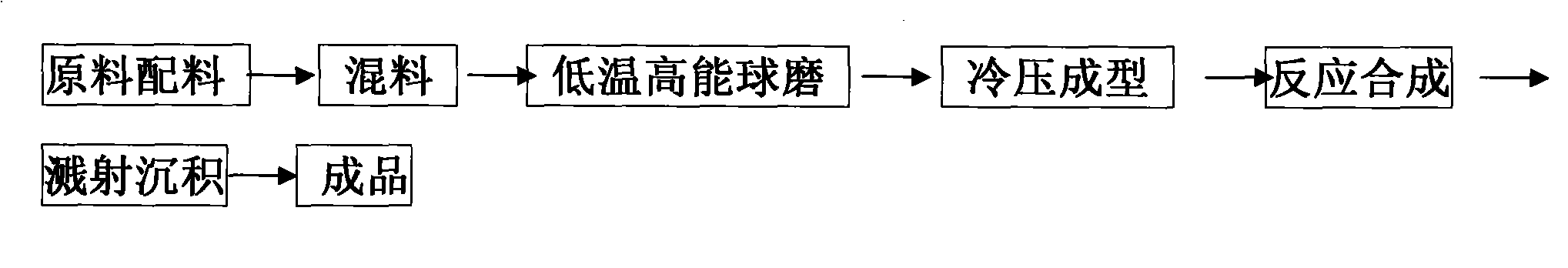

The invention discloses a method for a novel nano precious metal particle modified tin dioxide gas sensitive material. The preparation method for the nano precious metal particle modified tin dioxide gas sensitive material comprises the following steps of: adding a small quantity of other elements serving as performance tuning elements into raw materials of precious metal powder (two or more types of Ag, Au, Pt, Ru, Rh, Pd, Ir and Re), tin powder or alloy powder of the precious metals and tin, wherein the mass fraction ratio of the precious metals to the tin is controlled to be between 2 and 10 percent; performing mechanical alloying in a low-temperature ball mill, wherein the prepared precious metals are enwrapped by the tin powder, and formed nano-clusters are uniformly distributed in powder; pressing the prepared compound powder; performing oxygen atmosphere sintering at a certain temperature; and finishing reactive synthesis of oxides by controlling the process condition. The prepared precious metals are distributed in a tin dioxide target material in the form of nano particles, and the previous metal nano particles prepared by sputtering or depositing are uniformly distributed on a tin dioxide gas sensitive thin film. The novel gas sensitive material prepared by the method has high gas sensitive comprehensive performance, low cost, wide detection of harmful gases and long service life.

Owner:KUNMING UNIV OF SCI & TECH

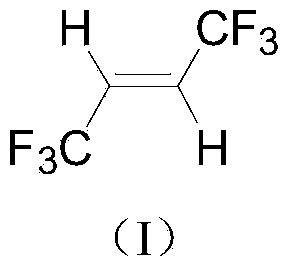

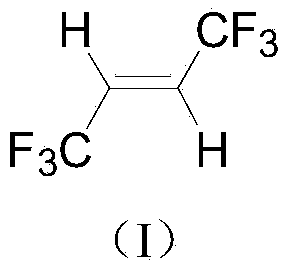

Synthetic method of trans-1, 1, 1, 4, 4, 4-hexafluoro-2-butene

ActiveCN104370690ALow costWide variety of sourcesPreparation by hydrogen halide split-offPreparation by halogen replacementGas phase2-Butene

The invention provides a method for synthesizing trans-1, 1, 1, 4, 4, 4-hexafluoro-2-butene by three steps by taking 1, 1, 1-triflluoro-2, 2-dichloroethane and chloroethylene CH2=CX2 as raw materials. The method comprises the following steps: (a) in the presence of a telomerization catalyst and a catalytic addictive, carrying out reactive synthesis on 1, 1, 1-triflluoro-2, 2-dichloroethane and CH2=CX2 to obtain CF3CHClCH2CClX2; (b) carrying out photochlorination on CF3CHClCH2CClX2 to synthesize CF3CHClCH2CCl3; and (c) in the presence of a fluorination catalyst, carrying out gas phase fluorination on CF3CHClCH2CCl3 to synthesize trans-1, 1, 1, 4, 4, 4-hexafluoro-2-butene, wherein CH2=CX2 is ethylene, chloroethylene and 1, 1-dichloroethylene. The method provided by the invention has the characteristics of high trans-selectivity and low price of raw materials.

Owner:XIAN MODERN CHEM RES INST

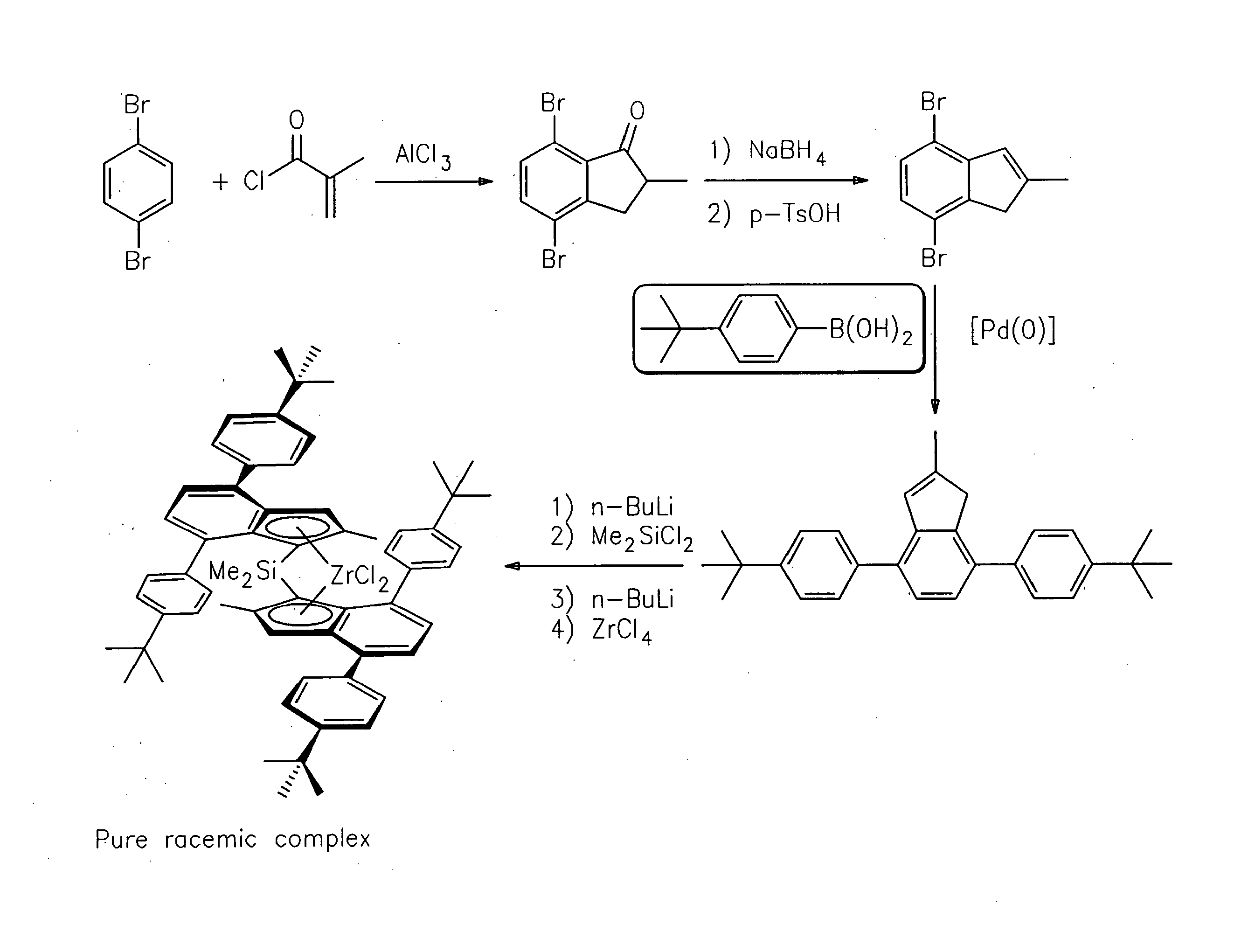

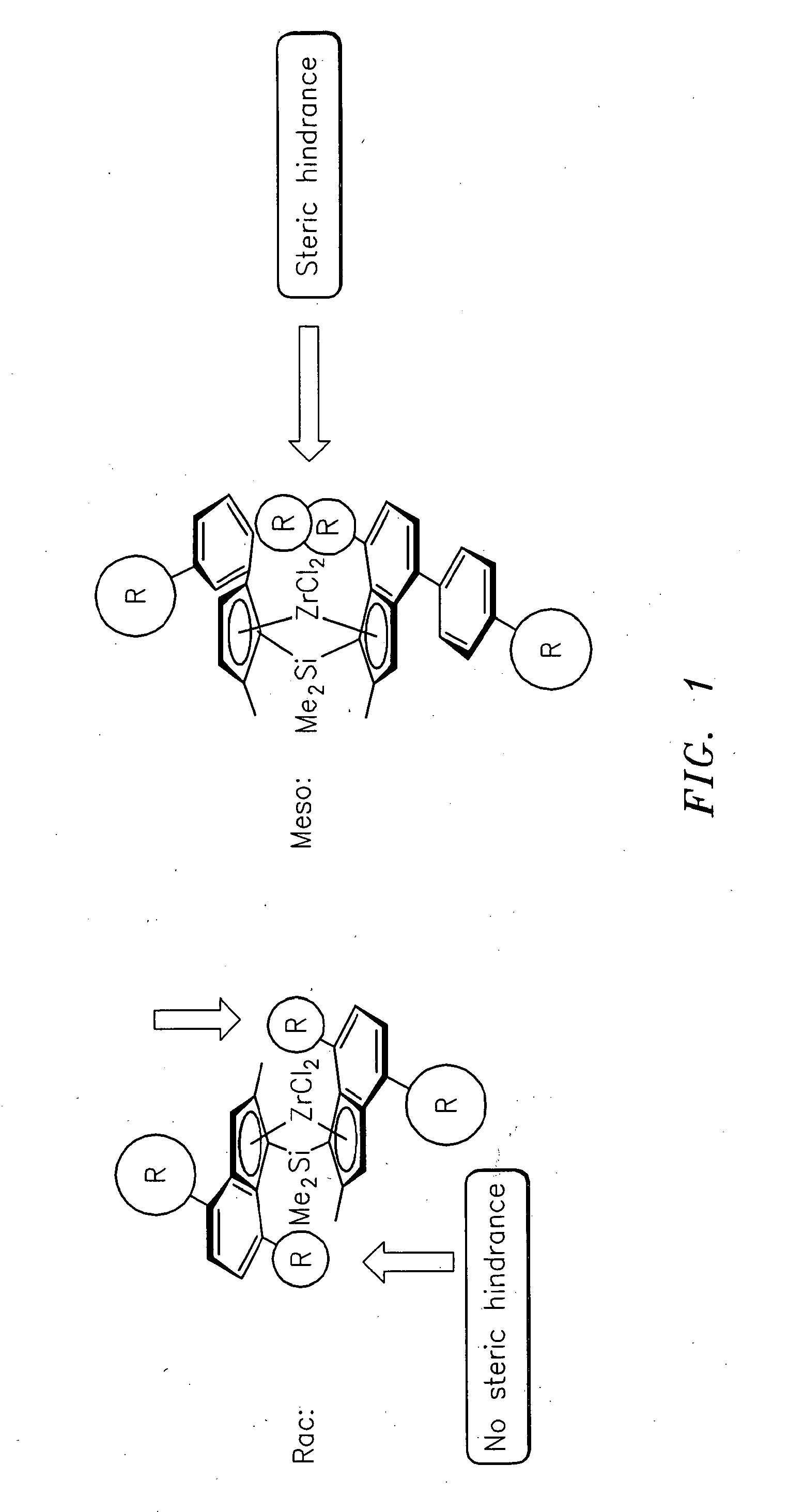

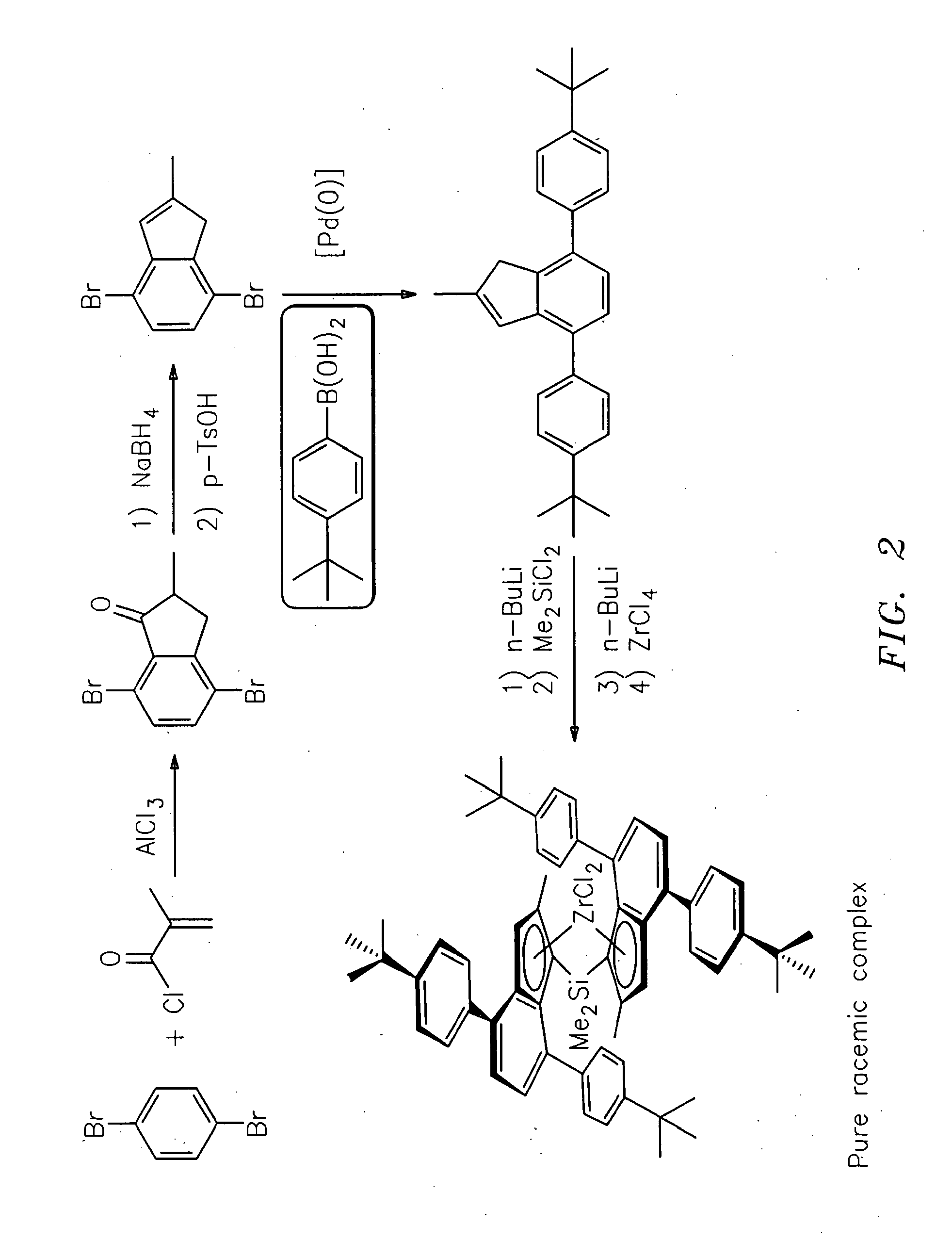

Racemoselective synthesis of ansa-metallocene compounds, ansa-metallocene compounds, catalysts comprising them, process for producing an olefin polymer by use of the catalysts, and olefin homo- and copolymers

InactiveUS20100261860A1Promote resultsOrganic-compounds/hydrides/coordination-complexes catalystsCatalyst activation/preparationAnsa-metalloceneOlefin polymerization

A metallocene compound with the 4- and 7-positions on the indenyl moiety possessing large aromatic substituents is prepared in accordance with a method which produces substantially 100 percent racemic isomer. Advantageously, polymerisation catalysts including the metallocene of the invention provide superior olefin polymerisation results.

Owner:LUMMUS NOVOLEN TECH

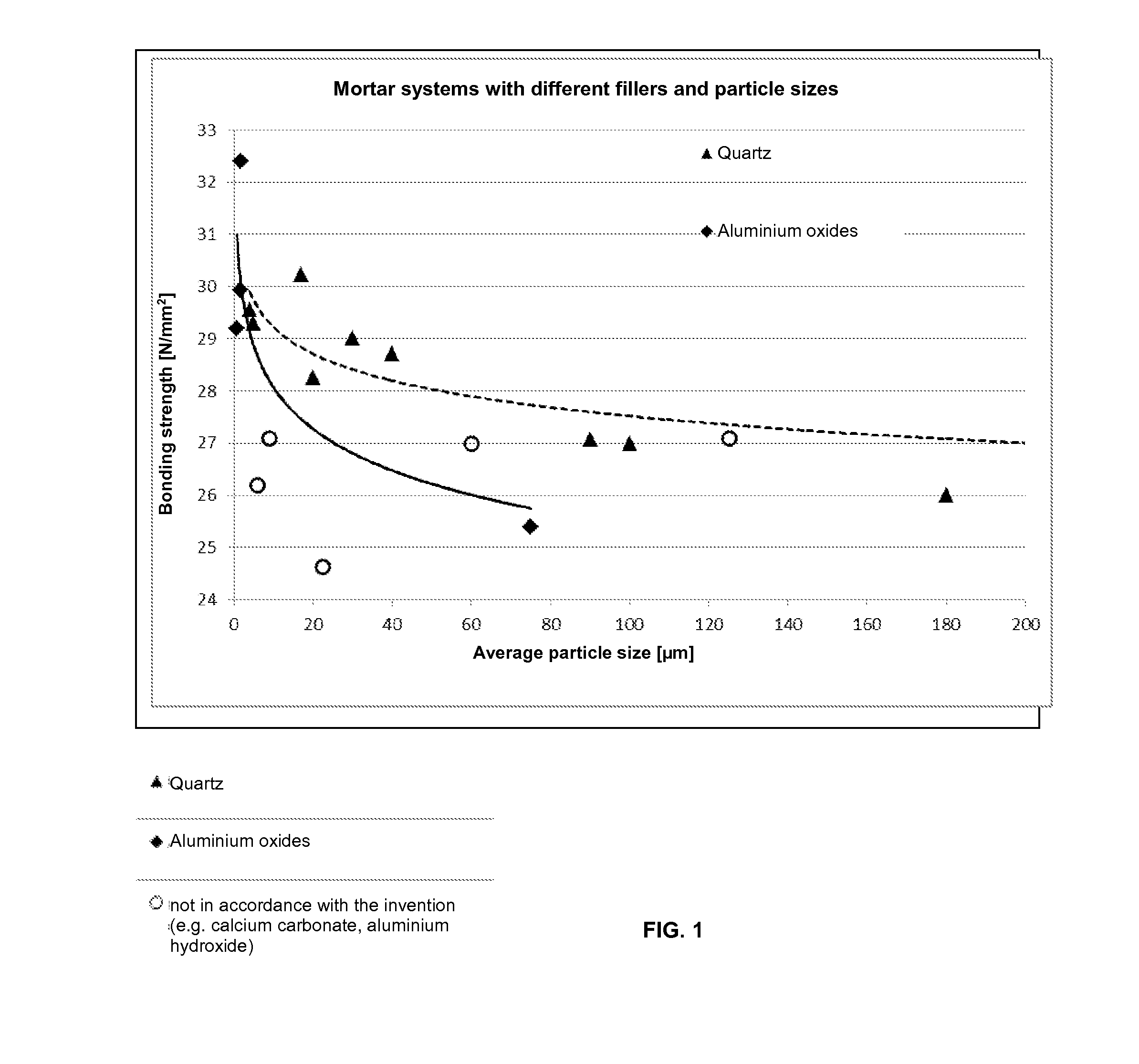

Fixing systems having fine-particle fillers

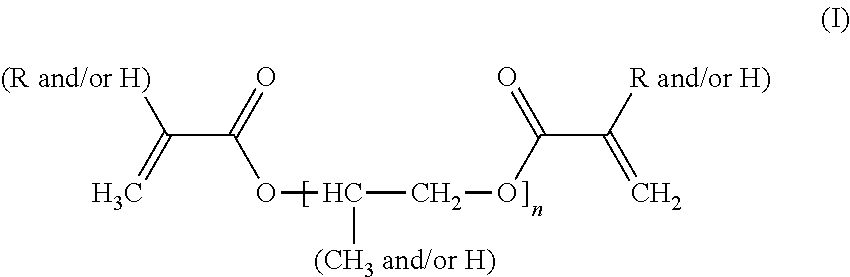

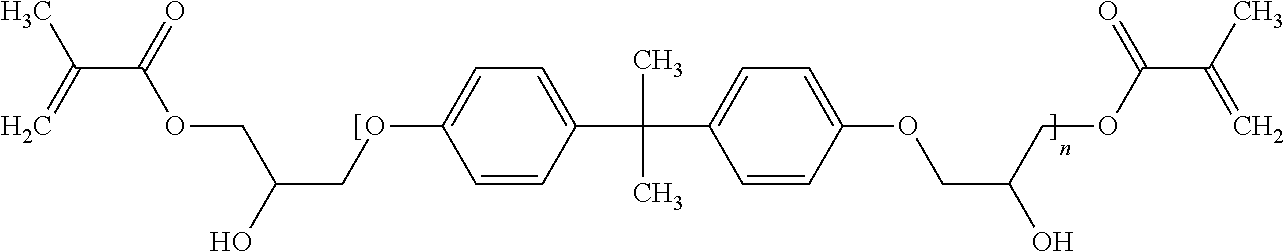

ActiveUS20160083563A1High bonding strengthBuilding repairsOrganic non-macromolecular adhesiveEpoxyMeth-

Multi-component synthetic mortar fixing system, especially for fixing anchoring elements in building substrates, which comprises in one component reactive synthetic resins (i) based on urethane (meth)acrylate, (ii) based on epoxy resin or (iii) based on free-radical-hardening (or -hardenable) unsaturated reactive resins, in a further component hardener, and at least one filler selected from oxides of silicon and aluminium, or mixed oxides in the presence of further cations, the d50 average particle size of which is 50 μm or less, and also especially a silane having at least one hydrolysable group, and also its use, methods including its use in fixing anchoring elements in building substrates and related subject-matter of the invention.

Owner:FISCHERWERKE ARTUR FISCHER GMBH & CO KG

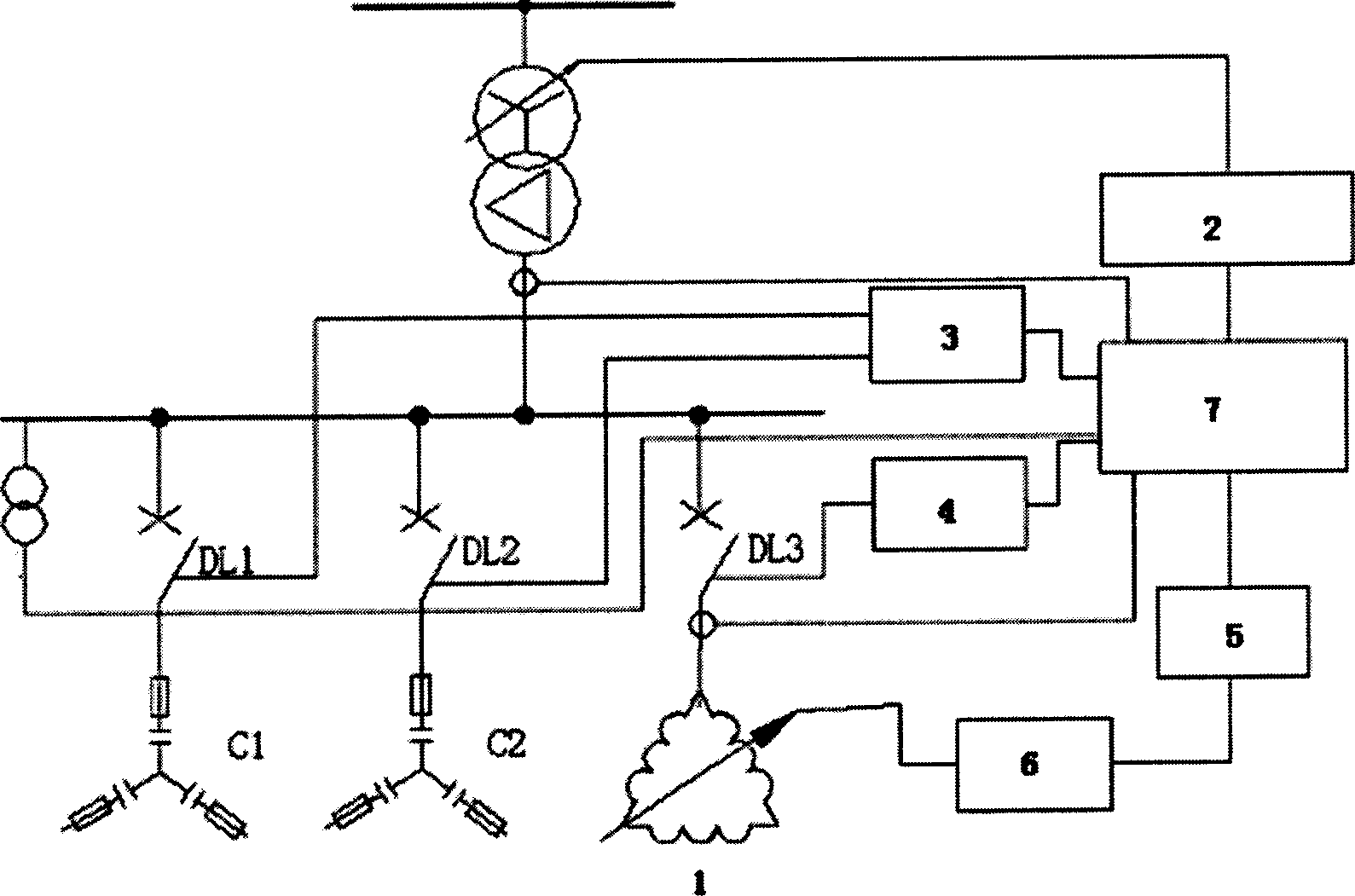

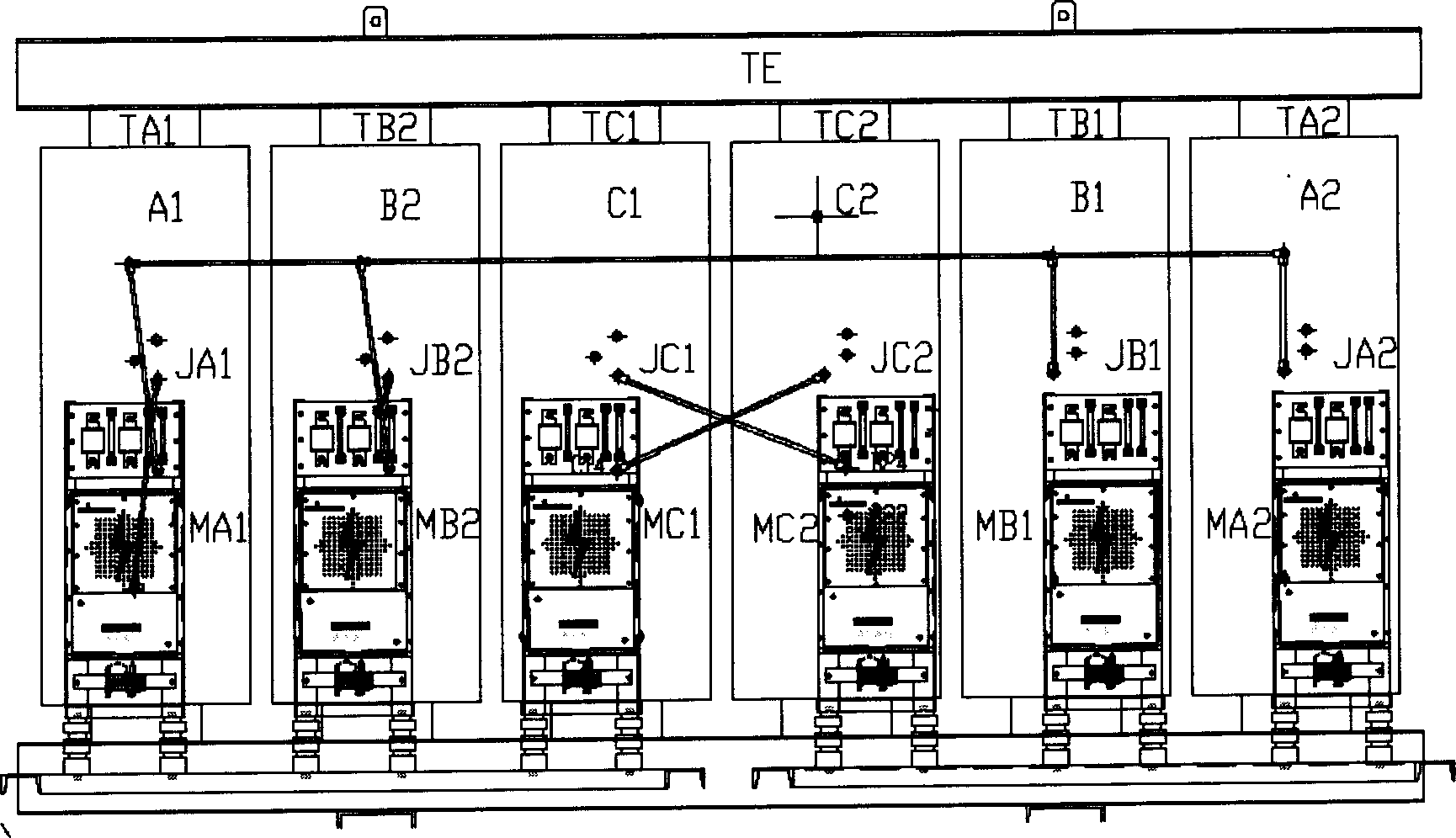

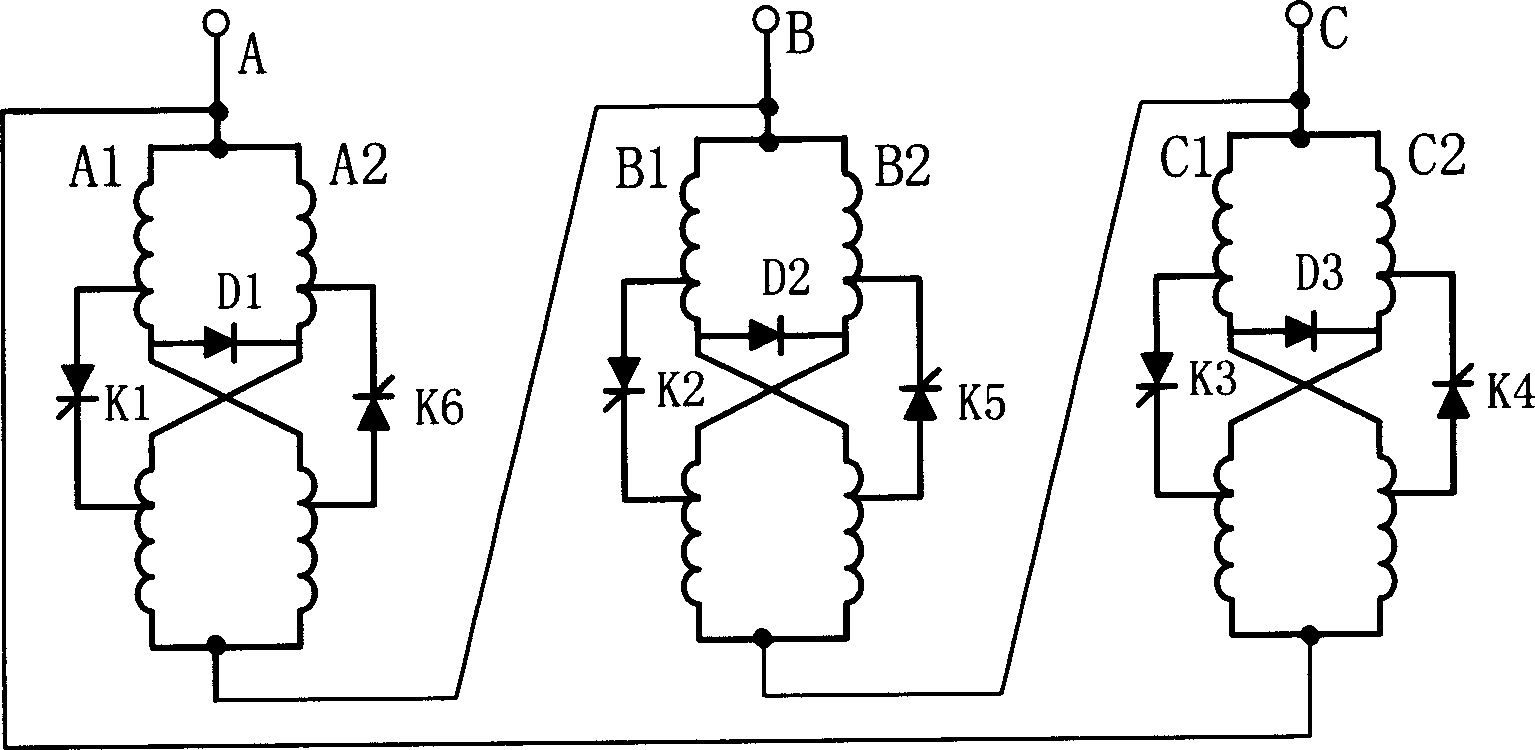

Voltage reactive power integrated control device based on magnetic control reactor

ActiveCN1790860AReduce harmonic currentSolve the problem of not being able to absorb excess reactive powerReactive power adjustment/elimination/compensationReactive power compensationEpoxyElectric power system

The voltage reactive synthesis control device based on magnetic control reactor in power system field comprises: connecting a trigger control module to the three-phase six-column epoxy resincast dry reactor, an impulse electric-to-optical transformation circuit between said trigger control module and intelligent control module, a capacitor switch module to breaker coil on an extra capacitor, and a reactor protection module to breaker coil on an extra magnetic control reactor; when detecting abnormal of the said dry reactor, automatic cutting off the reactor, and connecting the main on-load tap switch control module, capacitor switch module and reactor protection module to intelligent control module. This invention realizes intelligent control for power voltage stabilization and reactive power dynamic balance on precondition of high reliability.

Owner:SIEYUAN ELECTRIC CO LTD

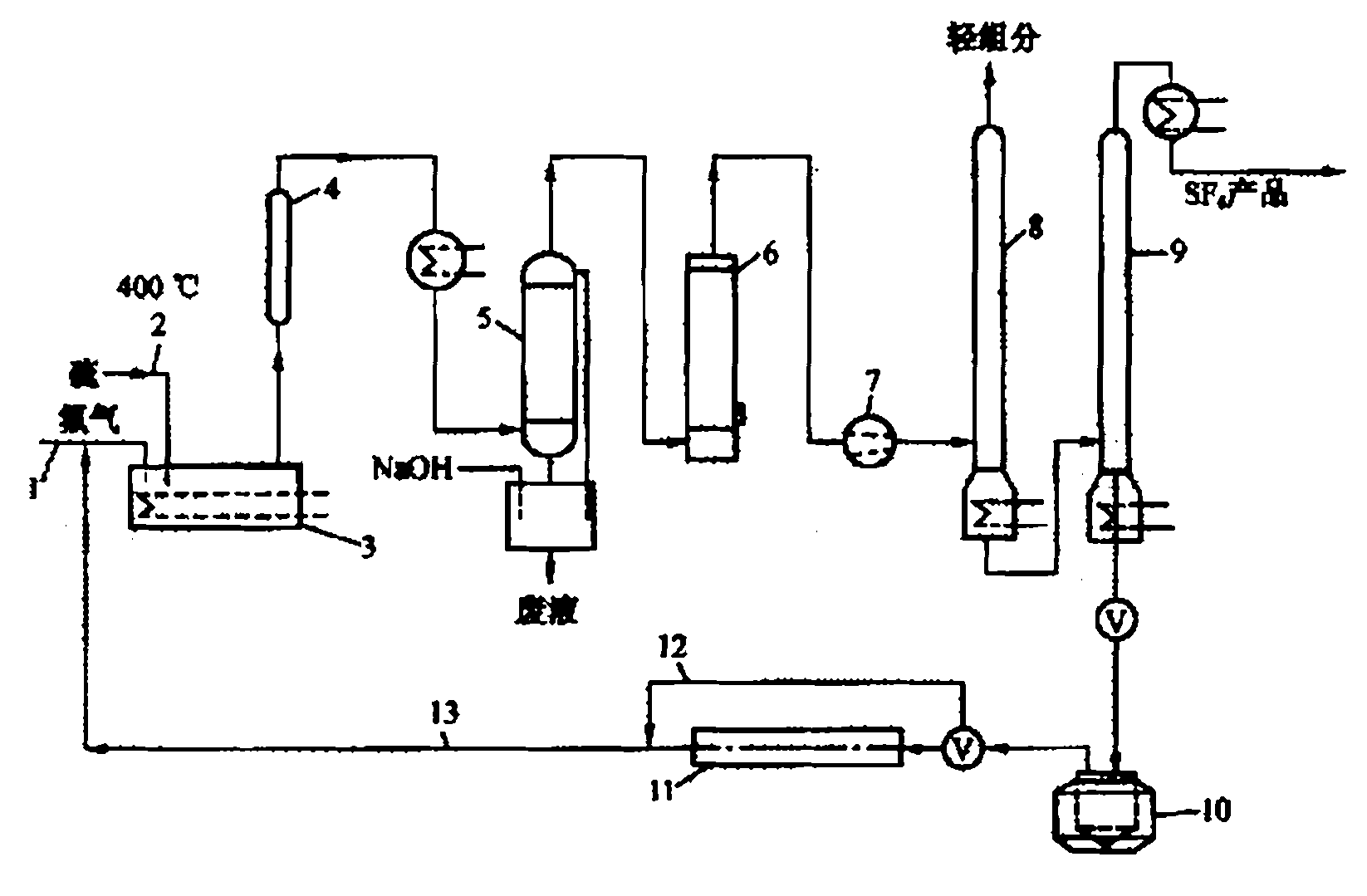

Method for producing and purifying sulfur hexafluoride

The invention discloses a method for producing and purifying sulfur hexafluoride. The flow comprises units such as reactive synthesis, pyrolysis, alkaline wash, adsorption, rectification, gasification, impurity circulating treatment and the like. The method comprises the following steps of: 1, reacting fluorine with melted sulfur in a reactor 3 to synthesize a coarse product of sulfur hexafluoride; 2, allowing the coarse product of the sulfur hexafluoride to pass through a pyrolysis tower 4 at the temperature of 400 DEG C to be decomposed into S2F10 and S2F10O at high temperature; 3, introducing into a washing tower 5 to remove acidic and hydrolyzable impurities such as HF, SF4 and the like; 4, intruding into an adsorption drying tower 6 to remove water and part of low-fluorine sulfur compounds; 5, removing light-component impurities such as CF4, THC, O2 and N2 and heavy impurities by using two levels of pressing rectification towers 8 and 9 to obtain the sulfur hexafluoride product with the content of at least 99.8 percent and meeting the purity requirement from the top of the second-level rectification tower; and 6, allowing the sulfur hexafluoride product to pass through a heat treater at the temperature of between 500 and 600 DEG C or directly returning the sulfur hexafluoride product to a fluorine charging pipe, so that the sulfur hexafluoride product and the fluorine serve as raw materials to enter a synthetic reactor to take part in the reaction. The method is the most simple, convenient and ideal technology for preparing the sulfur hexafluoride.

Owner:TIANJIN TAIHENG GASES

Ultraviolet-cured polyurethane adhesive and preparation method thereof

ActiveCN105542702AFast curing rateHigh bonding strengthNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesPolymer scienceVegetable oil

The invention provides an ultraviolet-cured polyurethane adhesive and a preparation method thereof. The ultraviolet-cured polyurethane adhesive is mainly prepared from a polyurethane acrylate pre-polymer, a mercapto-terminated photo-initiation monomer and a photo-initiator, wherein the polyurethane acrylate pre-polymer is mainly obtained by reactive synthesis of hydroxyl acrylate, vegetable oil polyol and a polyisocyanate-based compound; the mercapto-terminated photo-initiation monomer is mainly obtained by an esterification reaction of mercaptoundecanoic acid and polyol. The preparation method of the ultraviolet-cured polyurethane adhesive is simple in process, and an obtained ultraviolet-cured polyurethane adhesive cured film has low shrinkage factor, low viscosity, high curing speed, high peeling strength and high heat resistance, is free from volatilization of solvents and VOCs (Volatile Organic Compounds), is easy and convenient to use, and is suitable for bonding of an aluminum-plastic compound or a plastic-plastic compound or a paper-plastic compound.

Owner:SOUTH CHINA UNIV OF TECH

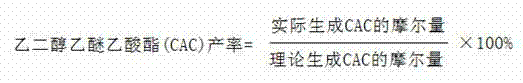

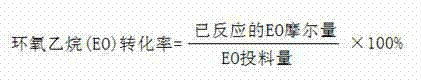

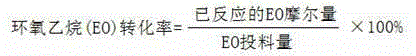

Magnesium-aluminum-zirconium solid catalyst for embedded synthesis of alkoxy alcohol ether ester in one step

ActiveCN103920480AHas acid-base dual active sitesEasy to separatePhysical/chemical process catalystsOrganic compound preparationEpoxyMagnesium salt

The invention relates to a magnesium-aluminum-zirconium solid complex metal oxide catalyst, which can be used for obtaining alkoxy alcohol ether ester by catalyzing one-step embedding reactive synthesis of epoxy ethane (propane) and carboxylic ester to carry out. The catalyst is characterized in that soluble magnesium salt, aluminium salt and zircon salt can be prepared into a solution with certain concentration through deionized water, a certain amount of precipitator is dissolved by deionized water and mixed with the prepared magnesium-aluminum-zirconium solution, under vigorous stirring condition, crystallization is performed for a certain period of time at the temperature of 40-100 DEG C, then precipitate is filtered out, soluble salt attached to the precipitate is washed by deionized water, drying is performed until constant weight is realized, and then the product is roasted in a muffle furnace so that the magnesium-aluminum-zirconium solid complex metal oxide catalyst is prepared. The magnesium-aluminum-zirconium solid complex metal oxide catalyst has the advantages of double acid-base active sites, easiness in separation, environmental protection, high efficiency and the like; the catalyst can catalyze one-step reactive synthesis carboxylic ester and alkyleneoxide, is high in catalyst activity and selectivity, and is easily recyclable and reused.

Owner:JIANGSU YIDA CHEM +1

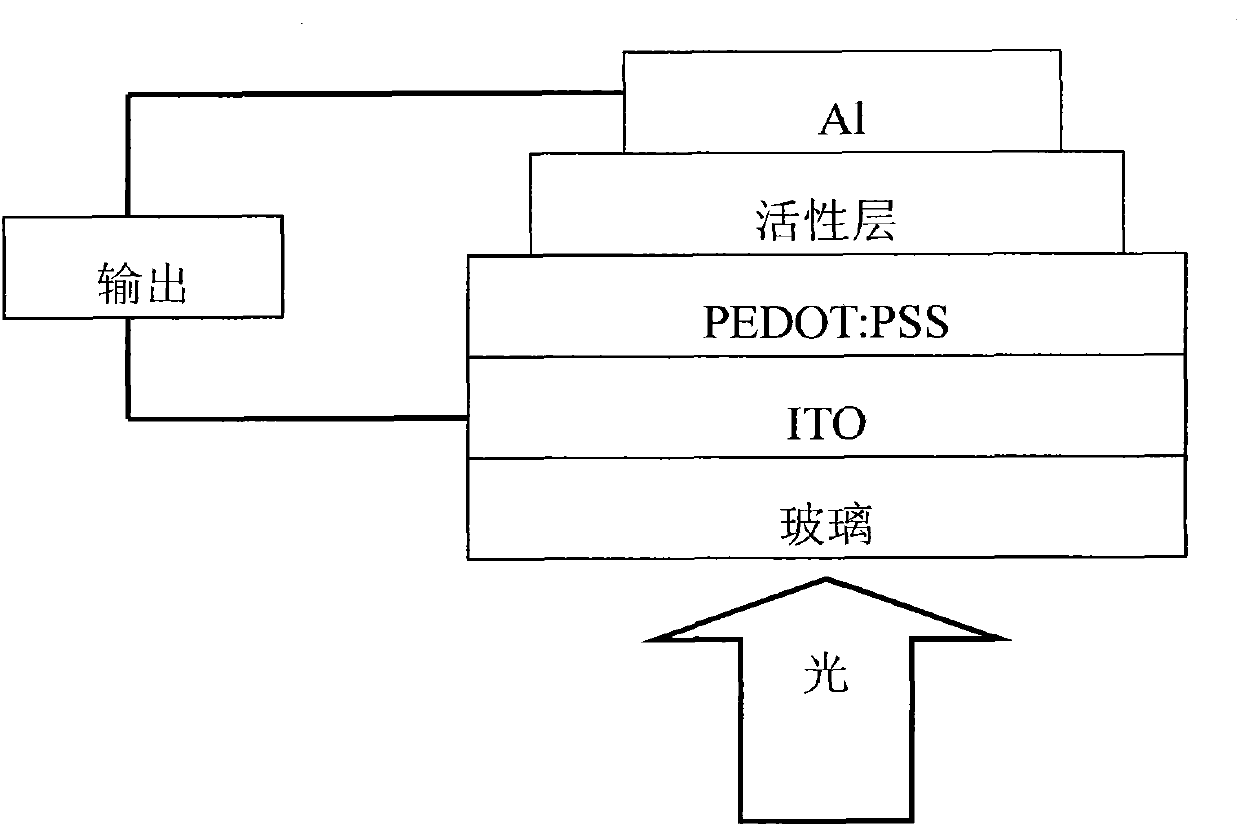

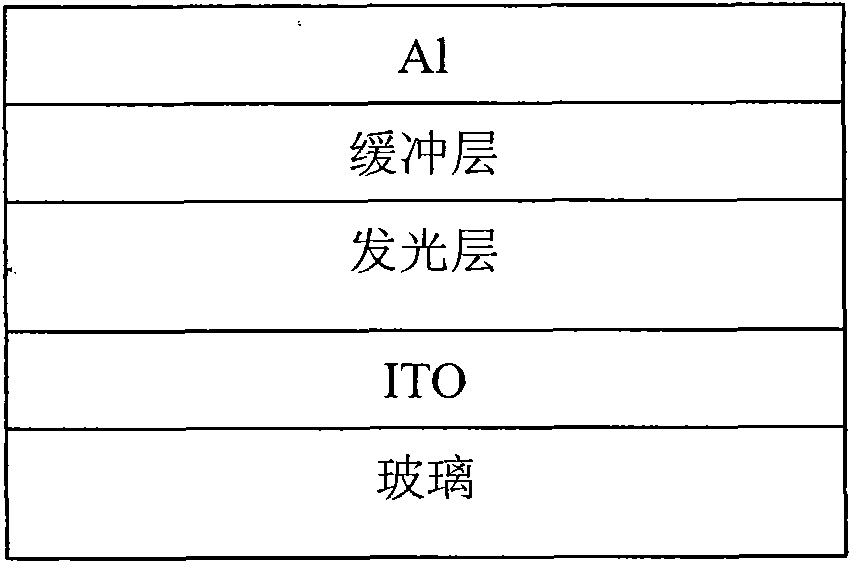

Preparation method of high yield fluorescent CdS/CdSe/CdS quantum well and preparation method of light emitting diode

InactiveCN109585619AEasing Lattice FitPromote crystallizationSemiconductor devicesFluorescenceHole transport layer

The invention relates to a preparation method of a high yield fluorescent CdS / CdSe / CdS quantum well and a preparation method of a light emitting diode, belonging to the technical field of preparationof nanocrystalline materials and light emitting diodes. The preparation method of a high yield fluorescent CdS / CdSe / CdS quantum well comprises the steps of: preparing a CdS nuclear quantum dots with grain sizes about 2.6nm by employing a high temperature thermal injection method; mixing the purified quantum dots with a ligand solvent at a high temperature, adding mixed precursor of positive ions and negative ions dropwise into the mixture to obtain CdS / CdSe quantum dots coated with a CdSe shell layer; continuously adding the mixed anion and cation precursor dropwise to continuously perform reactive synthesis of a CdS / CdSe / CdS quantum well; and obtaining a CdS / CdSe / CdS quantum well light emitting diode by arranging a glass base body, a positive electrode, a hole transport layer, a CdS / CdSe / CdS quantum well luminescence layer, an electron transfer layer and a negative electrode in order from bottom to top. The CdS / CdSe / CdS quantum dot quantum well prepared by the method can allow the luminous efficiency to finally reach 100%, and when the CdS / CdSe / CdS quantum well is taken as a light-emitting layer of the light emitting diode, the external quantum efficiency of the LED can be greatlyimproved.

Owner:LINGNAN NORMAL UNIV

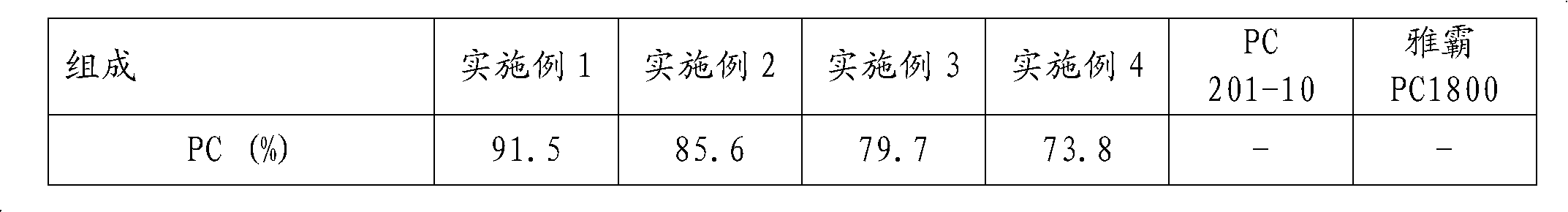

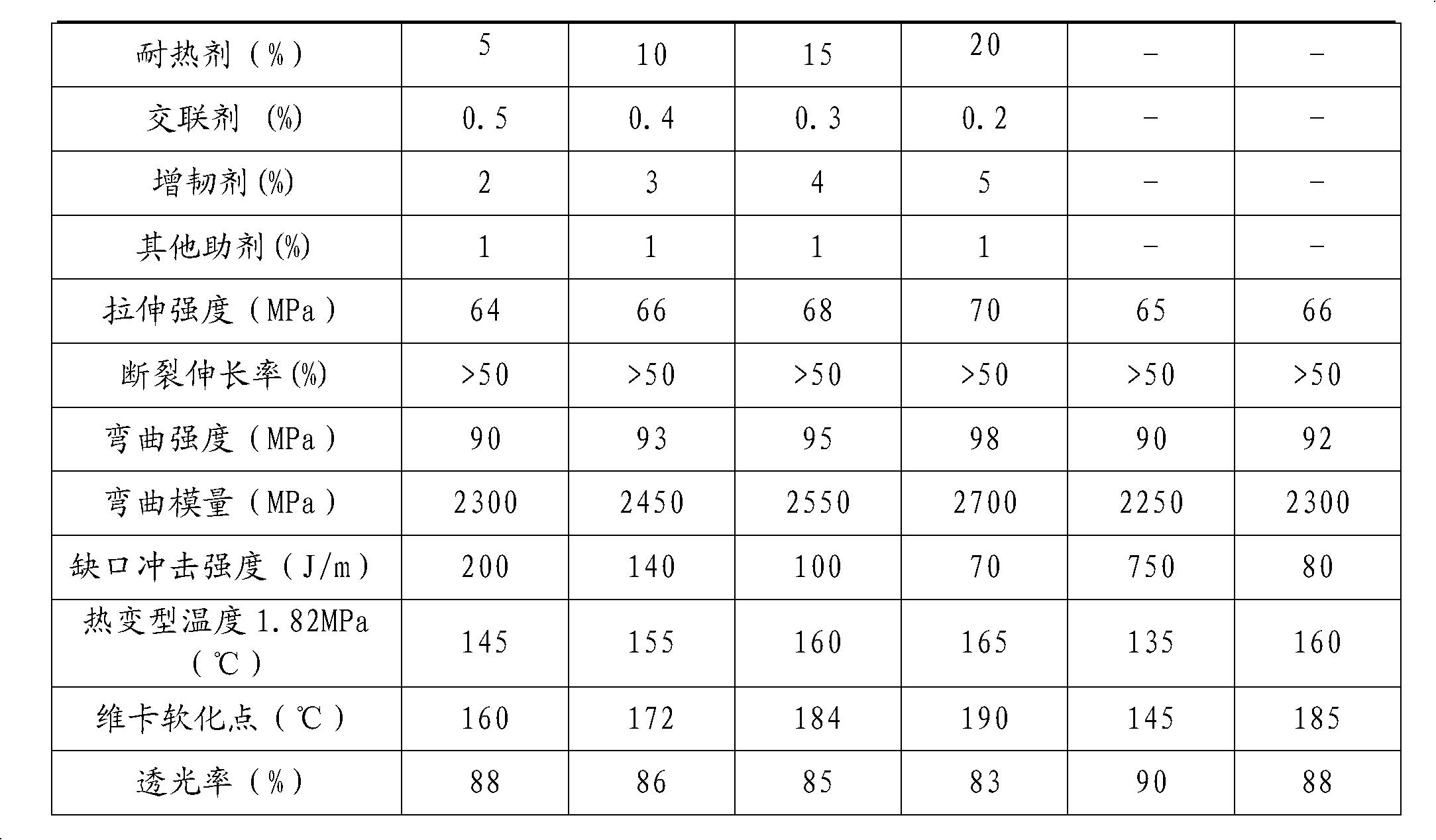

High temperature resistance polycarbonate composite material and preparation method thereof

The invention discloses a high temperature resistance polycarbonate composite material and a preparation method thereof. The high temperature resistance polycarbonate composite material consists of the following components in percentage by weight: 73.5 to 92 percent of polycarbonate, 5 to 20 percent of heat-resisting agent, 0.2 to 0.5 percent of cross-linking agent, 2 to 5 percent of toughening agent and 0.2 to 1 percent of other auxiliaries. The polycarbonate composite material disclosed by the invention has a heat distortion temperature of 145 to 165 DEG C and a vicat softening temperature of 160 to 190 DEG C and keeps excellent transparence of the original material. The design and using requirements of various industries and consumer goods on transparent temperature resistance carbonate ester can be met. The high temperature resistance polycarbonate composite material disclosed by the invention can be prepared by a common blending extrusion pelletizing preparation method. Compared with the material prepared by a reactive synthesis method, the high temperature resistance polycarbonate composite material has simple preparation process and low cost.

Owner:ANHUI KEJU NEW MATERIALS

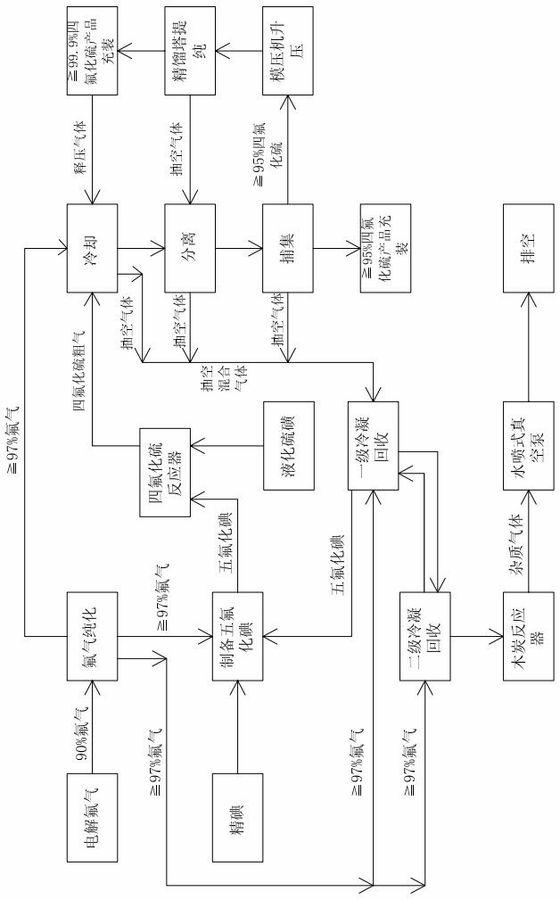

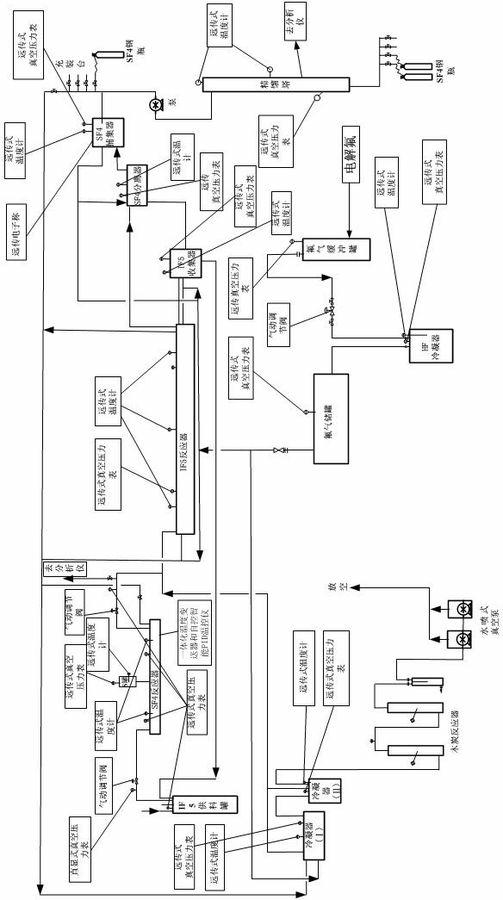

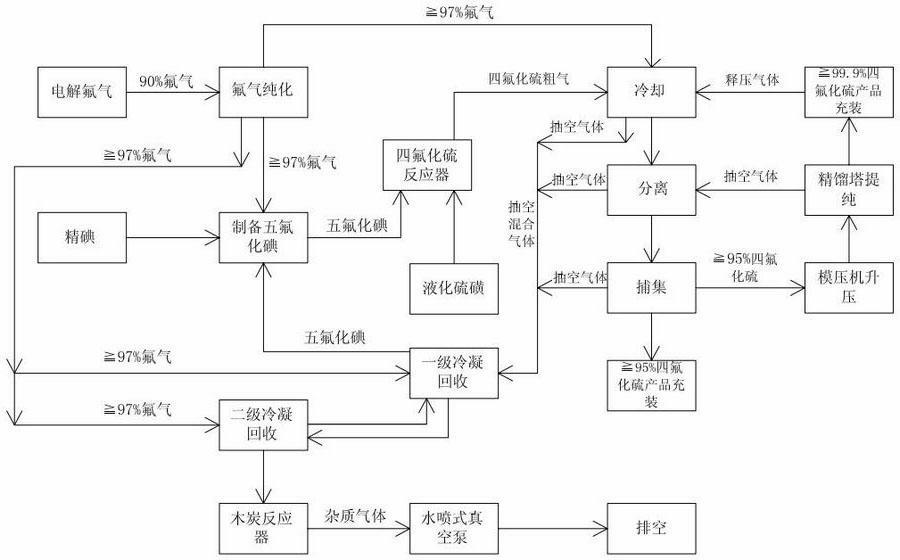

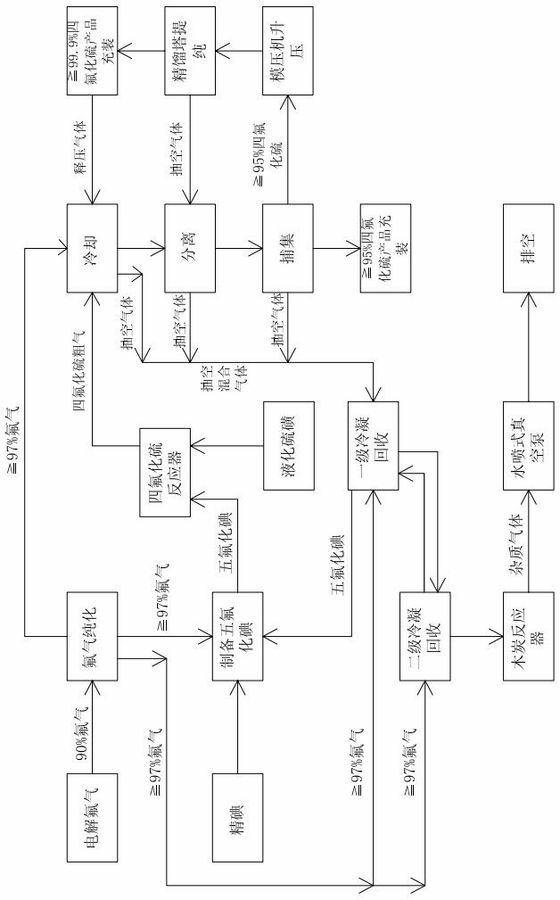

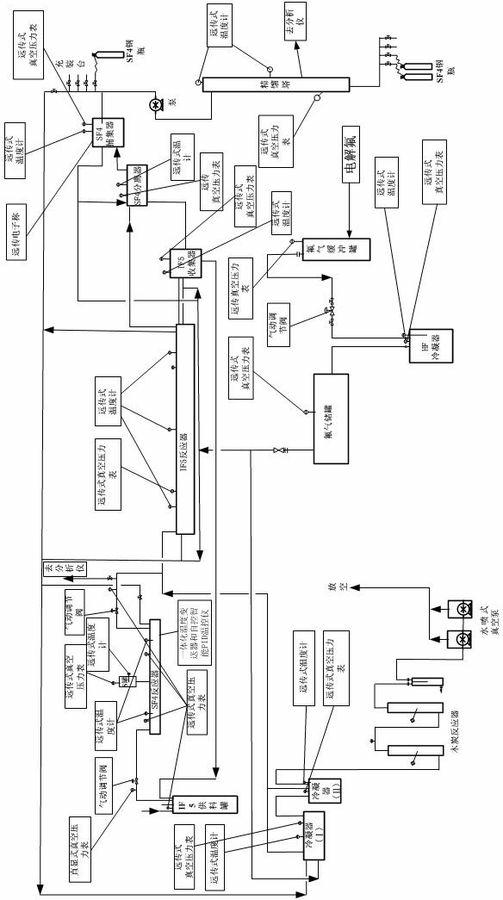

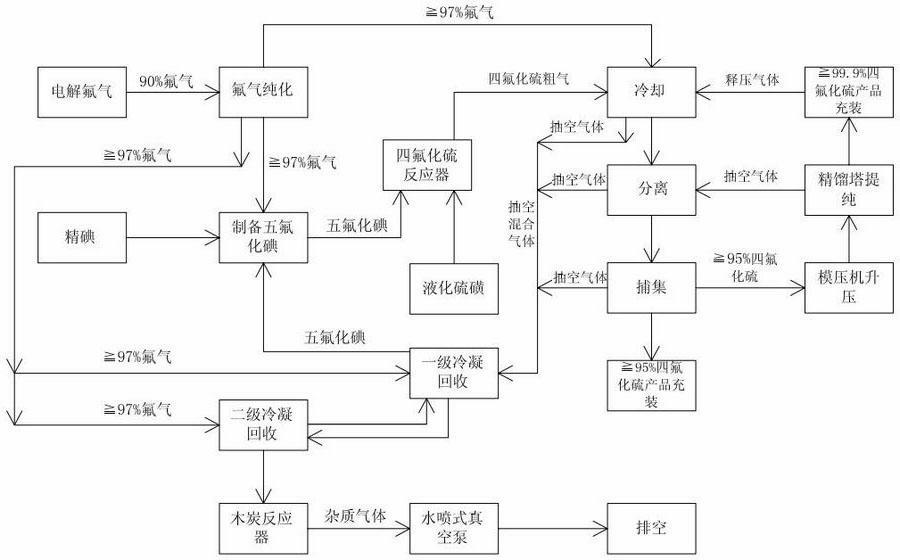

Sulfur tetrafluoride production technique

ActiveCN102173393AIncrease concentrationImprove conversion rateSulfur and halogen compoundsHydrogen fluorideTrapping

The invention relates to a sulfur tetrafluoride production technique, belonging to the field of fluorochemicals. The sulfur tetrafluoride production technique comprises fluorine gas purification, iodine pentafluoride preparation, sulfur tetrafluoride reactive synthesis, sulfur tetrafluoride separation and trapping, sulfur tetrafluoride distillation and canning, secondary recycling of iodine pentafluoride as well as discharge of exhaust gas. By using a low-temeprature condensing device, the electrolytic fluorine is purified to remove a great amount of hydrogen fluoride, so the fluorine gas concentration is largely improved. A condensing and recycling device is employed to recycle iodine and iodine pentafluoride for re-use, thus the utilization ratio of iodine can reach above 70% and material losses can be reduced. Due to a constant distillation method, the purity of sulfur tetrafluoride products can reach above 99.9%, and the products can be charged into a steel cylinder more safely. In addition, the entire sulfur tetrafluoride production technique is controlled by a automatic DCS (distributed control system) device, which reduces artificial randomness and experience and improves the stability of product quality.

Owner:山东锐华氟业有限公司

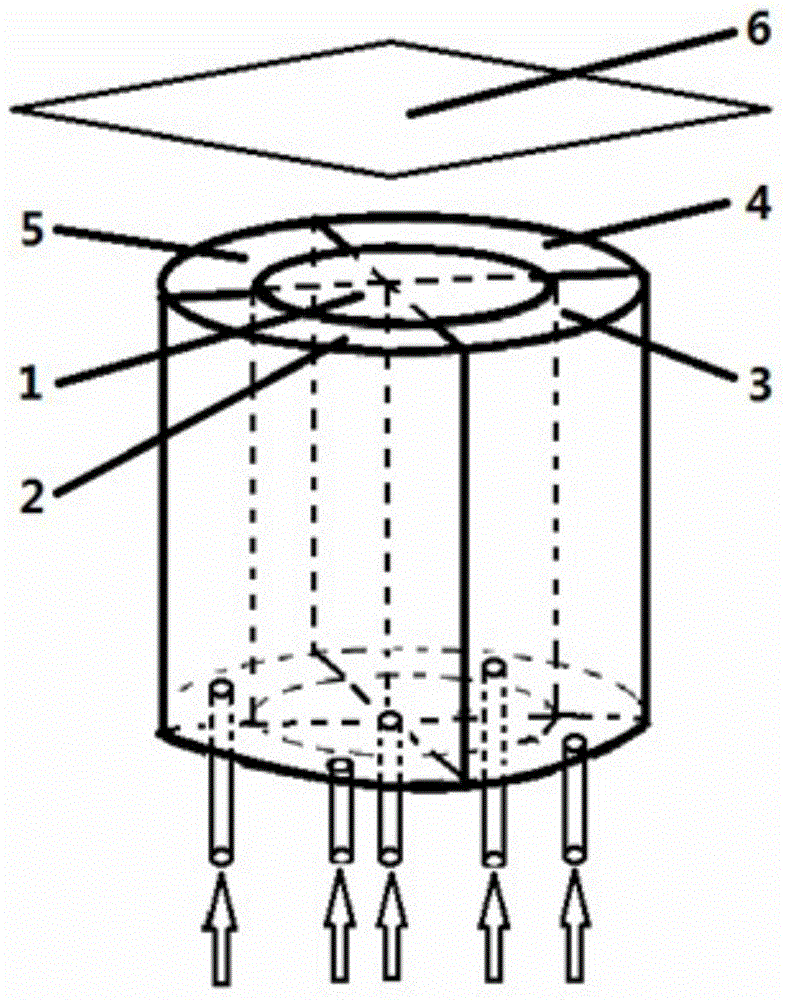

Controllable flame burner and method for synthesizing carbon nano tubes

ActiveCN104627980ASynthetic guaranteeIncrease synthesis temperatureMaterial nanotechnologyNano catalystCarbon nanotube

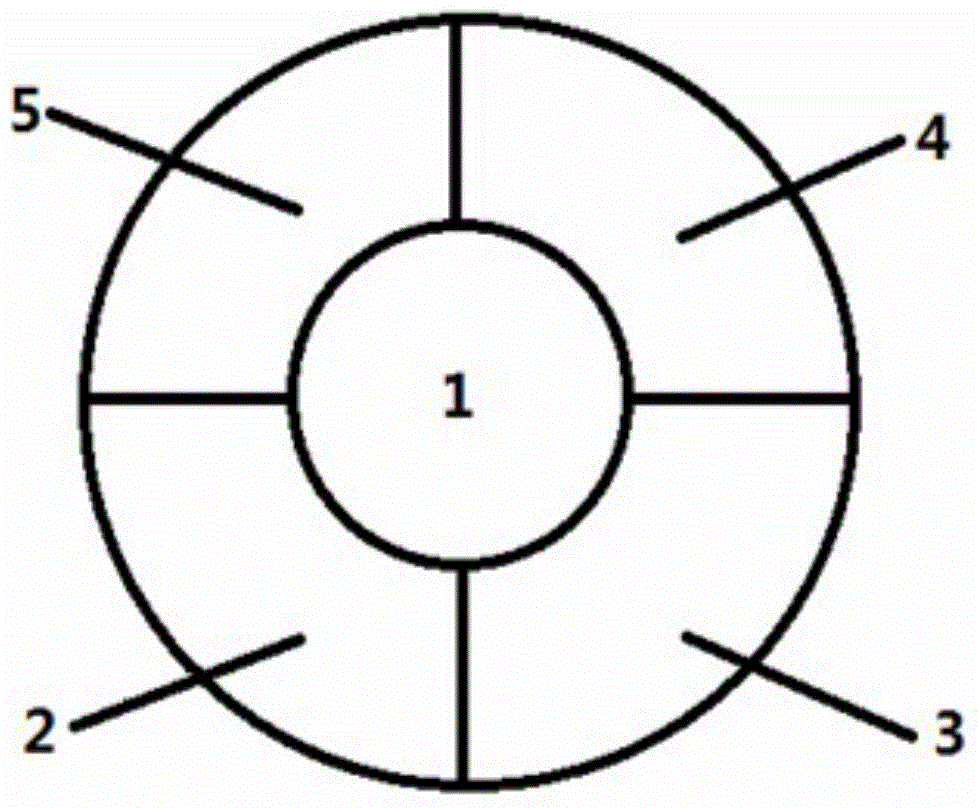

The invention discloses a controllable flame burner and a method for synthesizing carbon nano tubes. The controllable flame burner comprises vertically penetrated double layers of straight round tubes embedded with one another, wherein an area encircled by the inner layer straight round tube refers to a central reactive synthesis area; an area encircled between the inner layer straight round tube and the outer layer straight round tube is segmented into a high-temperature heat source area and a low-temperature cooling area; a carbon nano tube sampling area is formed at the upper outlet of the double-layer straight round tube; the lower opening of the central reactive synthesis area refers to an inlet of reactant mixed gas, inert gases and nano catalyst particles; the lower opening of the high-temperature heat source area refers to an inlet of combustible premixed gas; and the lower opening of the low-temperature cooling area refers to an inlet of cooling gas. The large-scale controllable and continuous synthesis of the carbon nano tubes can be realized at low cost, and the yield of the carbon nano tubes can be improved.

Owner:BEIJING INSTITUTE OF PETROCHEMICAL TECHNOLOGY

Carbon quantum dot nano-materials and preparation method and application thereof

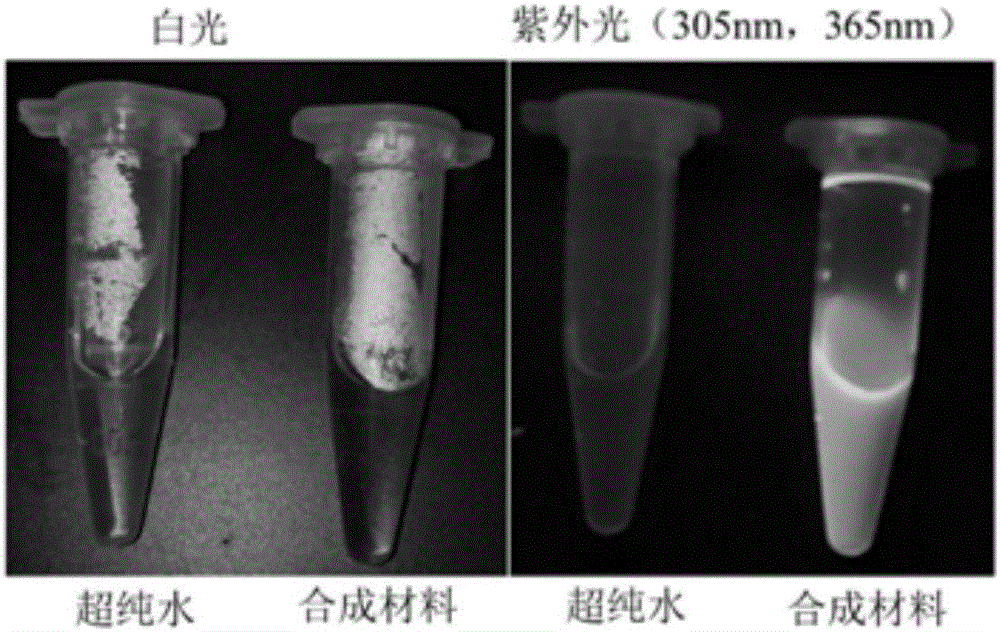

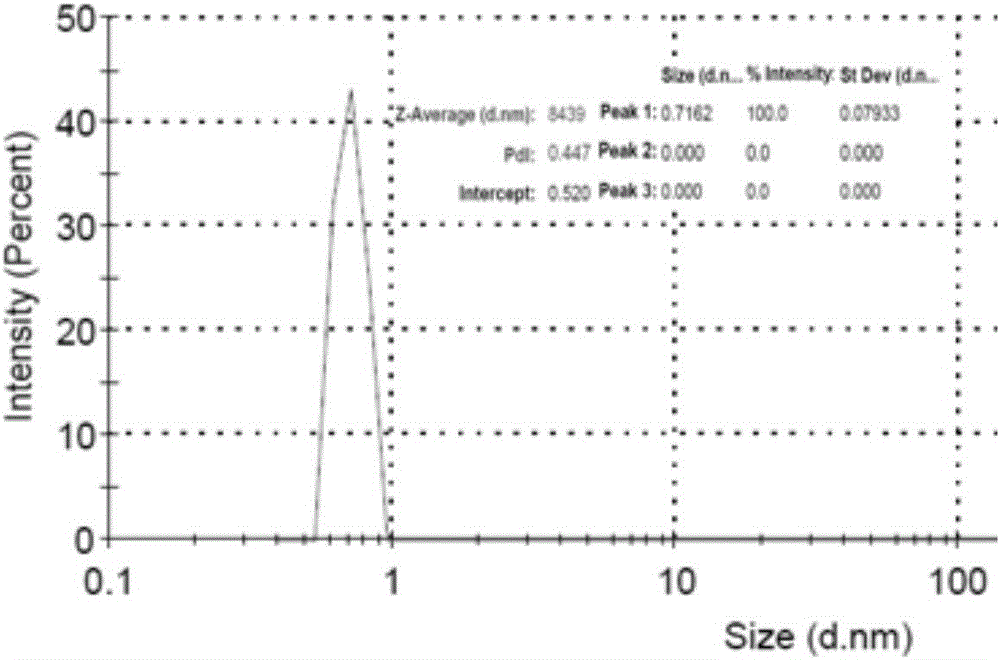

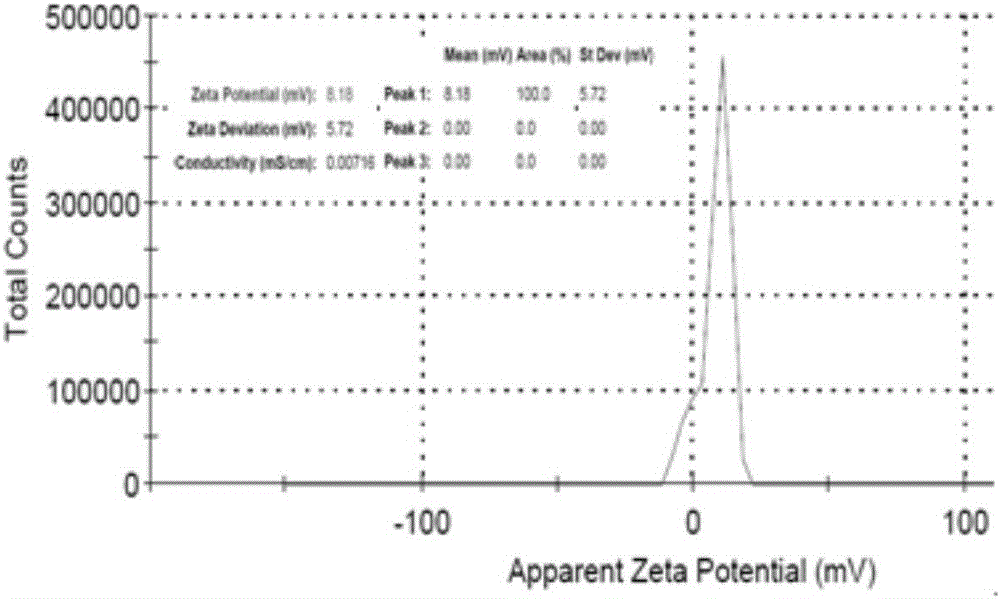

ActiveCN106497563ARealize tuning synthesis functionThe synthesis method is simpleMaterial nanotechnologyNanoopticsPlant cellCell wall

The invention discloses carbon quantum dot nano-materials and a preparation method and application of the carbon quantum dot nano-materials. The method comprises the following steps: taking citric acid, mercaptoethylamine and polyethyleneimine, dissolving in ultrapure water, stirring uniformly, carrying out ultrasonic treatment, at the temperature of 120 to 170 DEG C, performing microwave heating, dialyzing a mixed subjected to reactive synthesis in ultrapure water through a dialysis bag, then drying by a vacuum rotary dryer, and collecting materials to obtain the nano-materials. According to the invention, mercaptoethylamine and citric acid are hydrothermally synthesized with polyethyleneimine to obtain carbon quantum dots with multiple biological functions under microwave controlled auxiliary heating conditions, thus the carbon quantum dots with characterization performances of different materials of high brightness fluorescence or high charges and the like can be obtained, and cell wall fluorescent markers of live plant cells with high aqueous-phase dispersion and low cytotoxicity, or materials which promote endocytosis of animal and plant cells and realize high-efficient absorption of external solutions, or materials of plant intact cells realizing the delivery of nucleic acid transfection and with cell walls are optimally selected based on changing synthesis conditions according to needs of different biological applications.

Owner:NANJING FORESTRY UNIV

High-efficiency high-stereoselectivity semisynthesis method of harringtonine and allied alkaloids

ActiveCN102304132AHigh yieldHigh selectivityAntibacterial agentsGroup 4/14 element organic compoundsLewis acid catalysisAlkaloid

The invention relates to a high-efficiency high-stereoselectivity semisynthesis method of harringtonine and allied alkaloids, which uses optical pure cephalotaxin serving as a raw material to perform reactive synthesis with substituted silicon ketene in Lewis acid catalysis. The structural general formula of the compound is shown as (A), wherein the meaning of each group is shown as the specification. The method has the advantages of high chemical yield and diastereoselectivity of key reactions, convenient operation, short synthesis steps and the like. The method is a universal method for synthesizing the optical pure compound with the structural general formula shown as (A), and is suitable for massive preparation. The compound is widely applied to anti-tumor (malignant and non-malignant tumors), anti-parasitic, antifungal and antimicrobial chemotherapy medicaments.

Owner:NANKAI UNIV

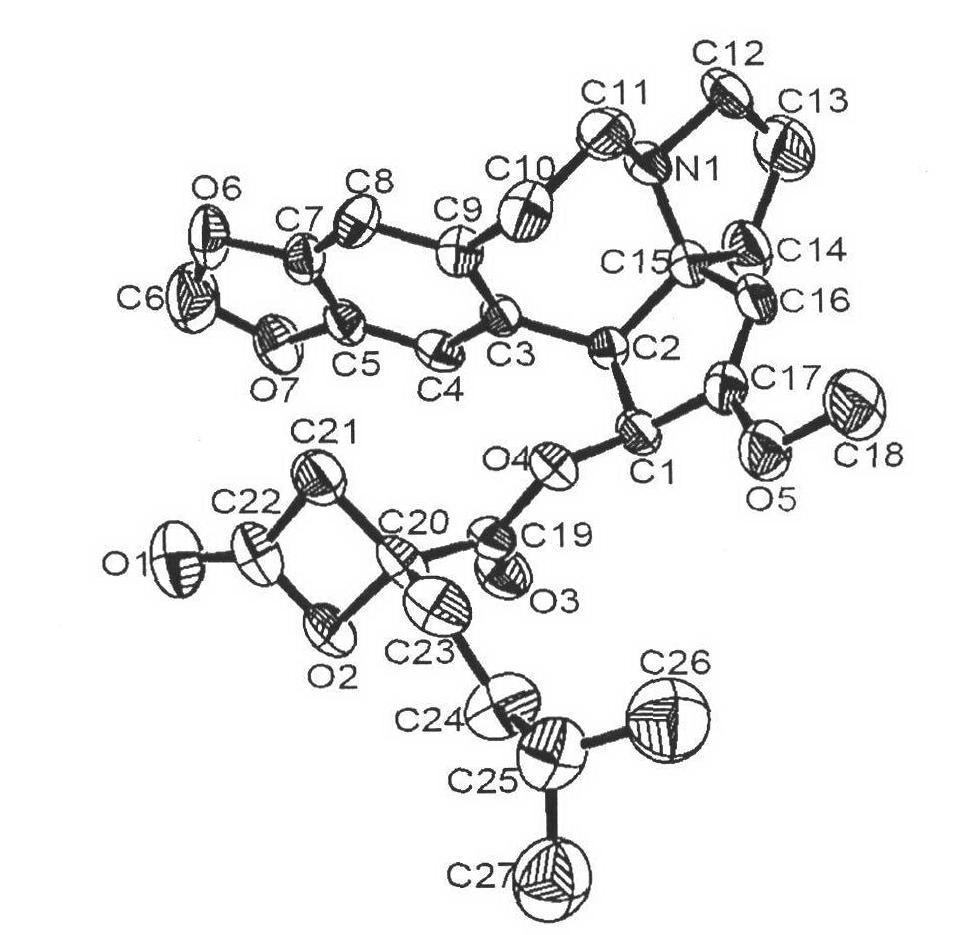

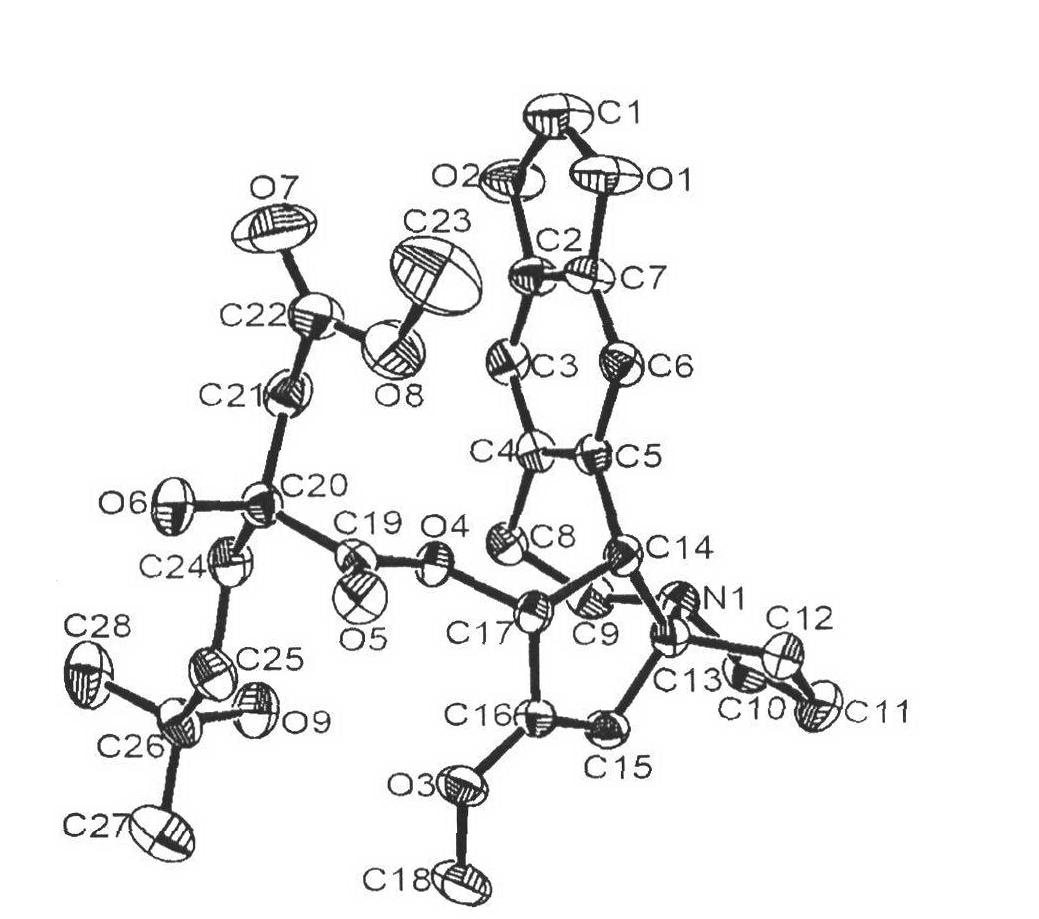

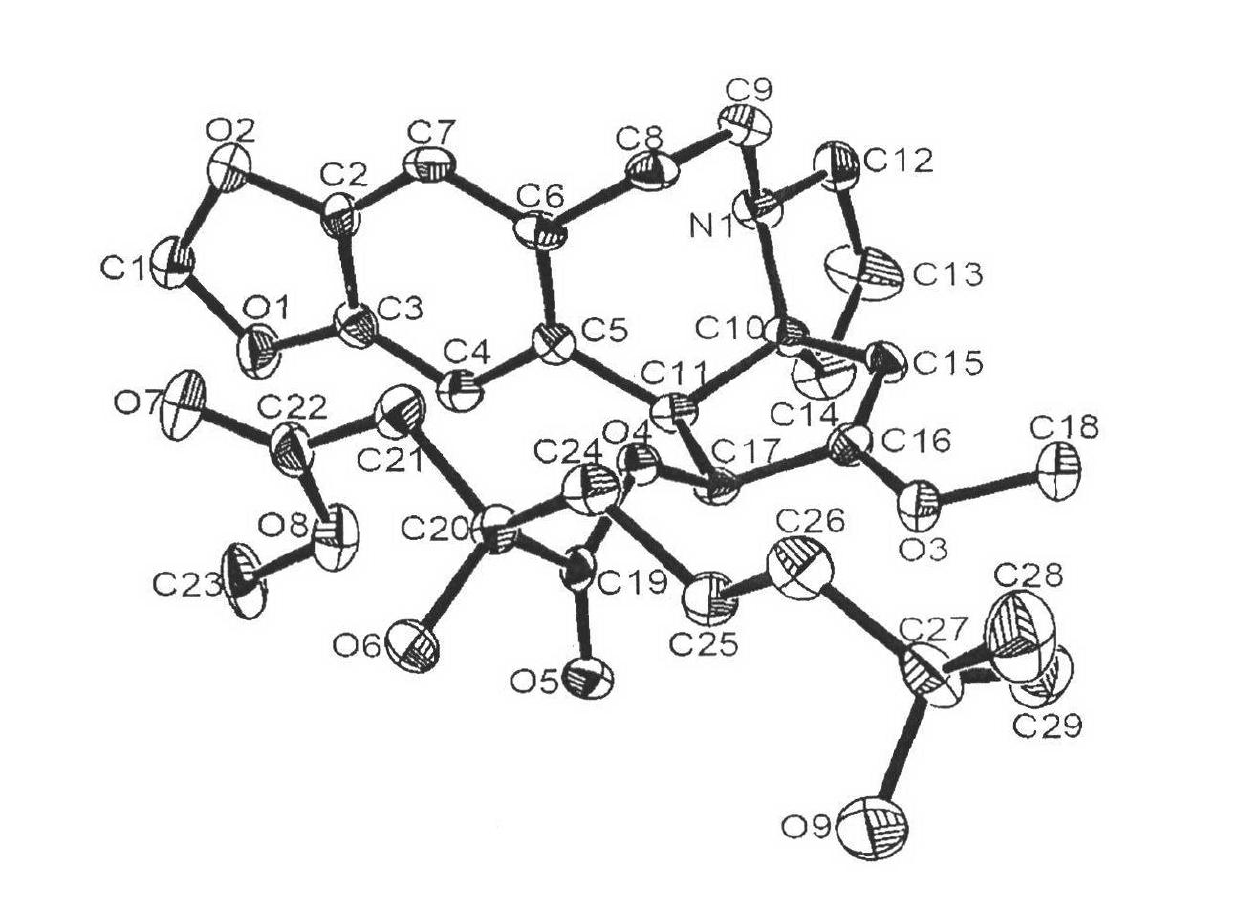

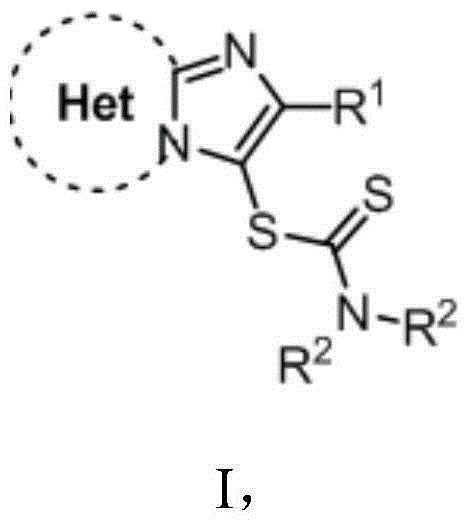

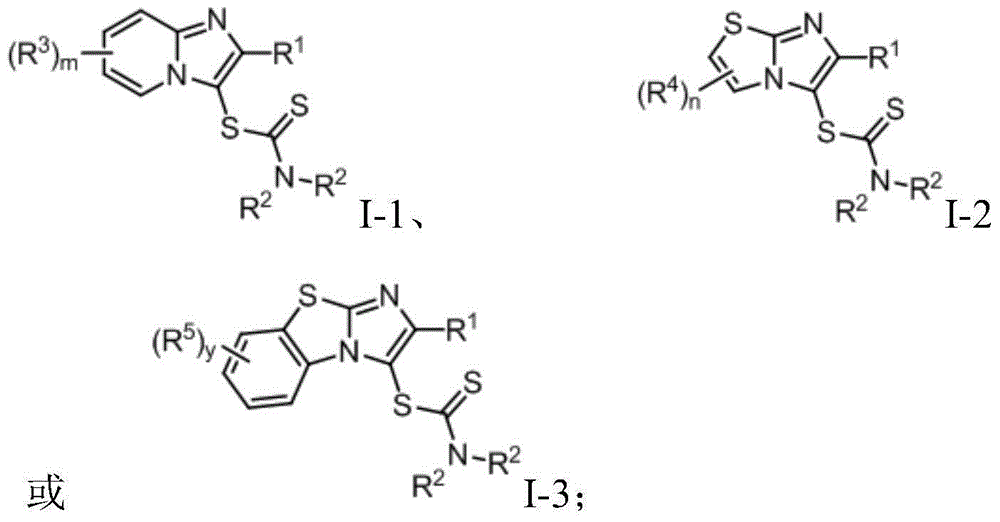

Imidazo heterocyclic amino dithiocarbamate and preparation method therefor

The invention discloses imidazo heterocyclic amino dithiocarbamate and a preparation method therefor. The structural formula is shown in the description. In the presence of a lewis acid catalyst and an iodine reagent, a reaction on an imidazo heterocyclic compound and dialkyl amino dithio compound in a reaction solvent so as to prepare target amino dithiocarbamate imidazo heterocyclic compound. The method disclosed by the invention in one-step reactive synthesis is simple to operate and is mild in reaction condition, raw materials are cheap and easily available, and the method has a good market application prospect.

Owner:SOUTH CHINA AGRI UNIV

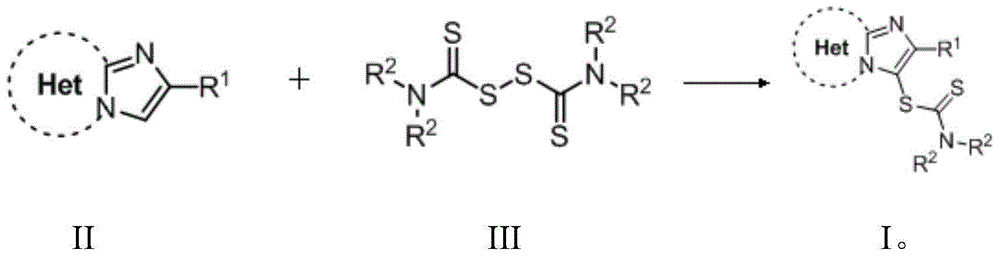

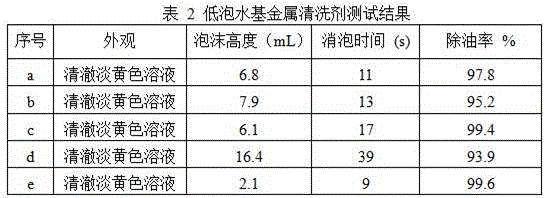

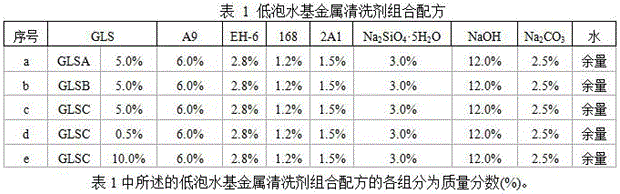

Amphoteric lignin-based surfactant and preparation method and application thereof

ActiveCN105664787AGood emulsifying effectExcellent physical and chemical propertiesTransportation and packagingMixingWater basedCleansing Agents

The invention discloses an amphoteric lignin-based surfactant. Lignin and laurinol glycidyl ether are subjected to reactive synthesis and bleached to obtain the amphoteric lignin-based surfactant. The invention further discloses a preparation method and application of the amphoteric lignin-based surfactant. The amphoteric lignin-based surfactant can effectively lower the surface tension of a water solution, and shows the excellent emulsifying ability and oil removal rate. The surfactant is applied in a low foam water-based metal cleaning agent, has the effects of being low in foam and high in defoaming speed, meanwhile achieves the effect of improving the oil removal rate for metal devices, and has the potential application prospect in the daily chemical washing field.

Owner:广州市日用化学工业研究所有限公司

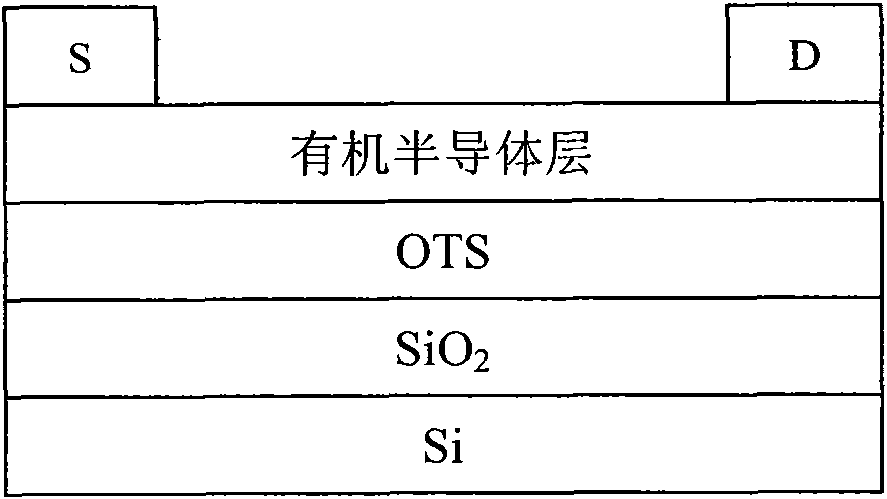

Conjugated polymer containing cyclopentadienyl diene dithiophene-naphthalene tetracarboxylic diimide and preparation method and application thereof

InactiveCN102329414AQuality improvementThe synthetic route is simpleSolid-state devicesSemiconductor/solid-state device manufacturingPolymer scienceHydrogen

The invention discloses a conjugated polymer containing cyclopentadienyl diene dithiophene-naphthalene tetracarboxylic diimide, which is characterized by being a compound with the formula shown as below, wherein R1 is C1-C20 alkyl, R2 is C1-C20 alkyl or substituted phenyl, R3, R4 and R5 are identically or differently expressed as hydrogen, C1-C20 alkyl or alkoxy, x is greater than or equal to 1 and less than 2, y is greater than 0 and less than or equal to 1, the sum of x and y is 2 and n is an integer from 1 to 120. The conjugated polymer containing cyclopentadienyl diene dithiophene-naphthalene tetracarboxylic diimide is prepared via Stille with a simple reactive synthesis route and low processing requirements and has better film-forming properties, better thermal stability, high carrier mobility, higher molar absorption coefficient and wide optical absorption range, the degree of matching with solar transmission spectrum is improved, the photoelectric conversion efficiency is increased, and the conjugated polymer has a wide scope of application.

Owner:OCEANS KING LIGHTING SCI&TECH CO LTD +1

Catalyst for reactive synthesis of carbamate by urea and organic carbonic ester as well as preparation method and application thereof

InactiveCN102397786AEasy to makeEasy to recycleCarbamic acid derivatives preparationMolecular sieve catalystsMolecular sieveCarbamate

The invention discloses a catalyst for reactive synthesis of carbamate by urea and organic carbonic ester, which comprises the following components in percentage by weight: 1-20wt% of alkali metal oxide and the balance of carrier, wherein the alkali metal is selected from more than two of Li, Na, K, Rb and Cs; and the carrier is an oxide carrier or a molecular sieve carrier. The catalyst has the advantages of simple preparation process, low raw material cost, high target product yield and no pollution on the environment.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

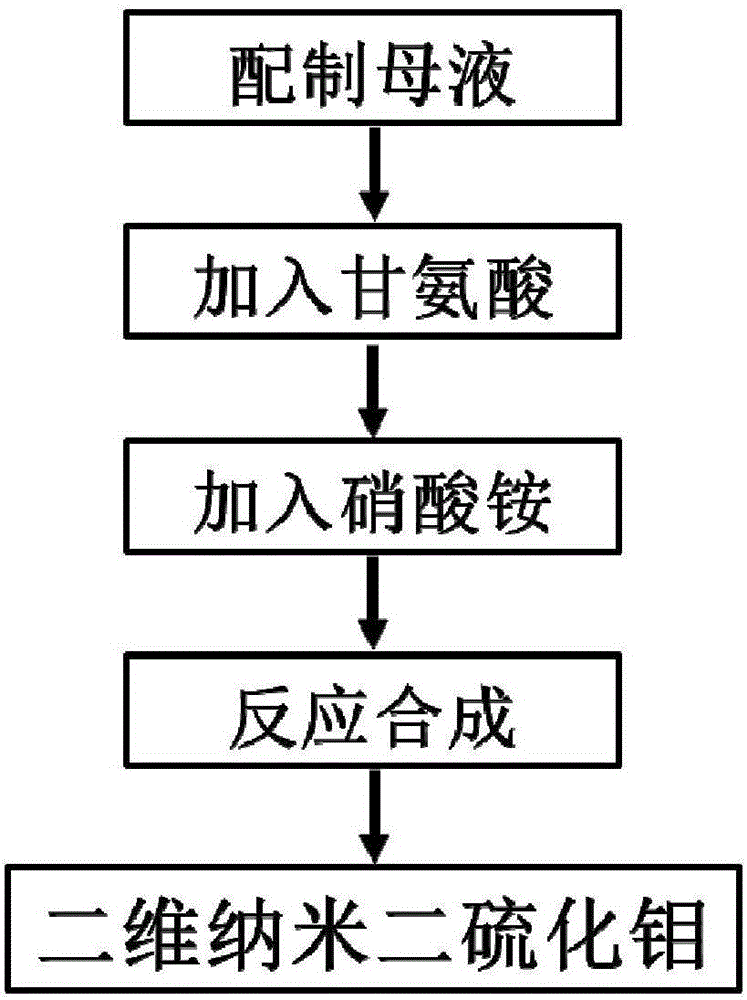

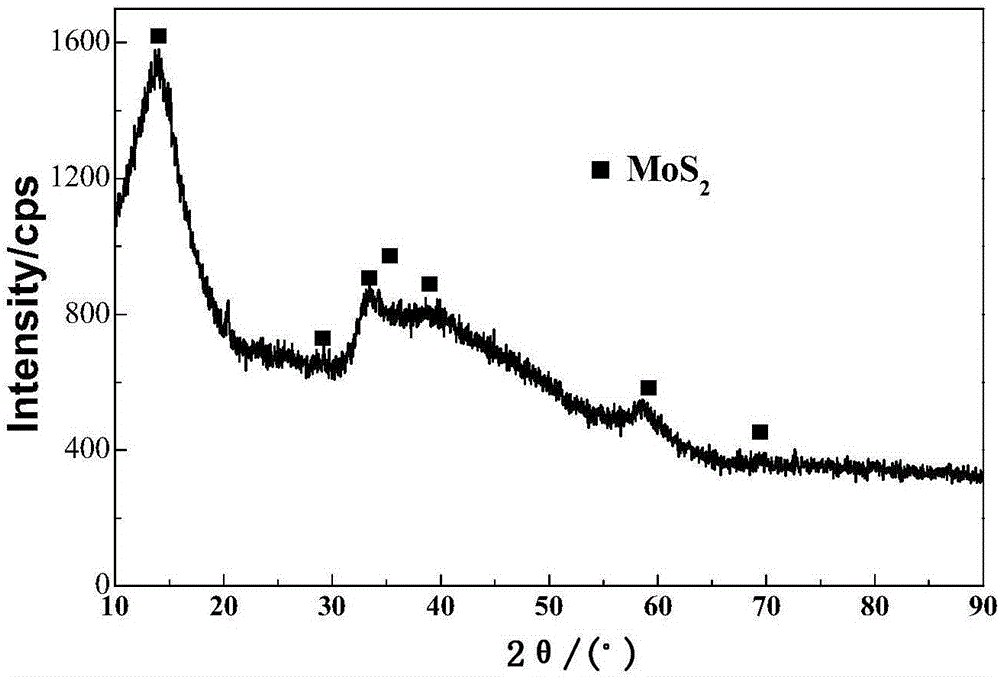

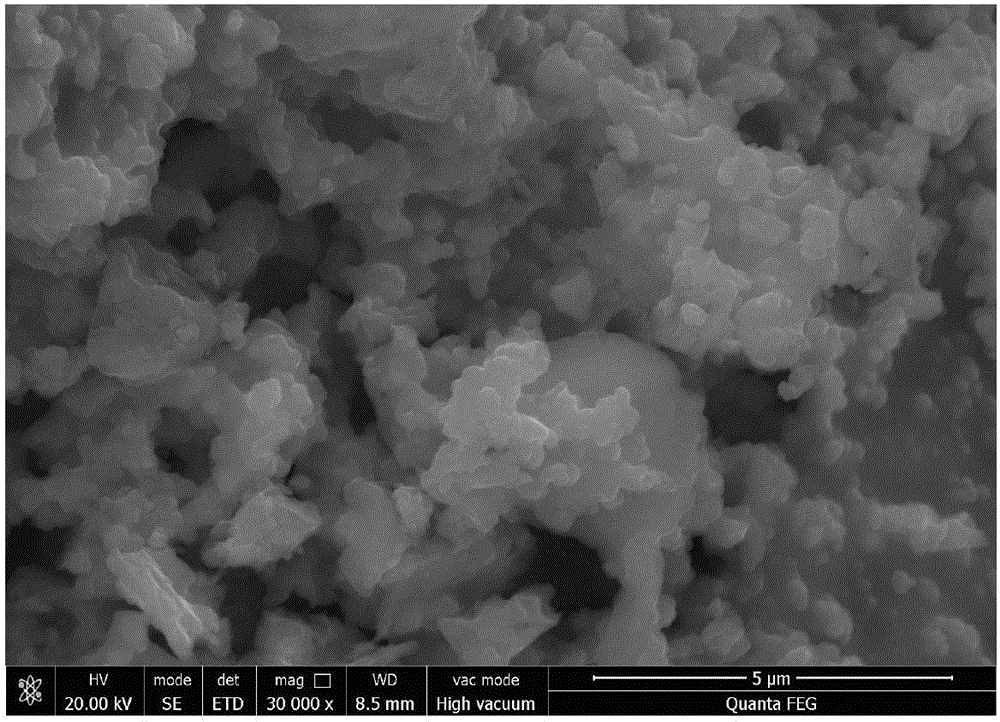

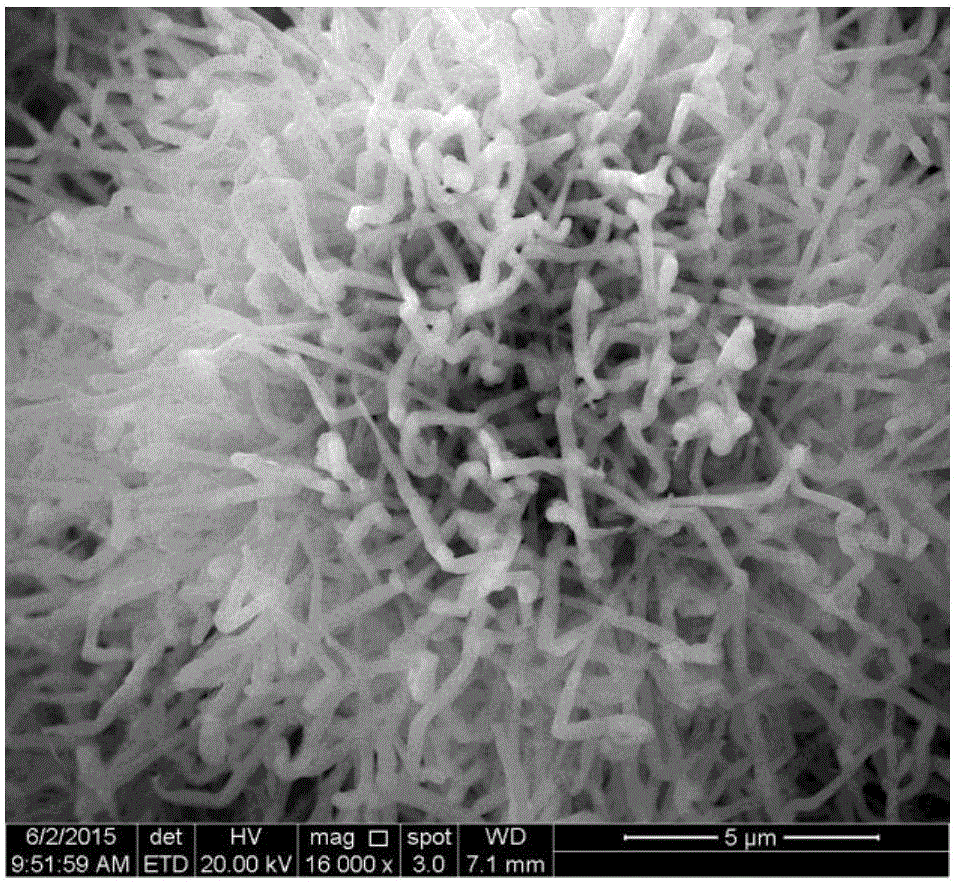

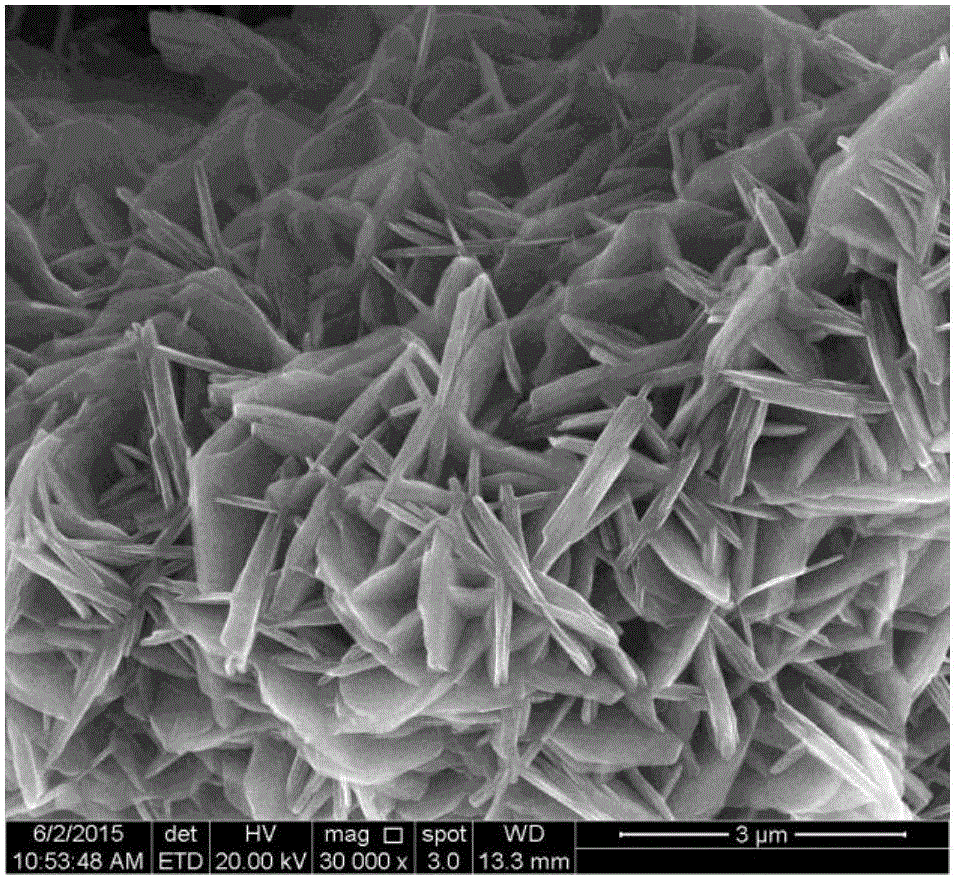

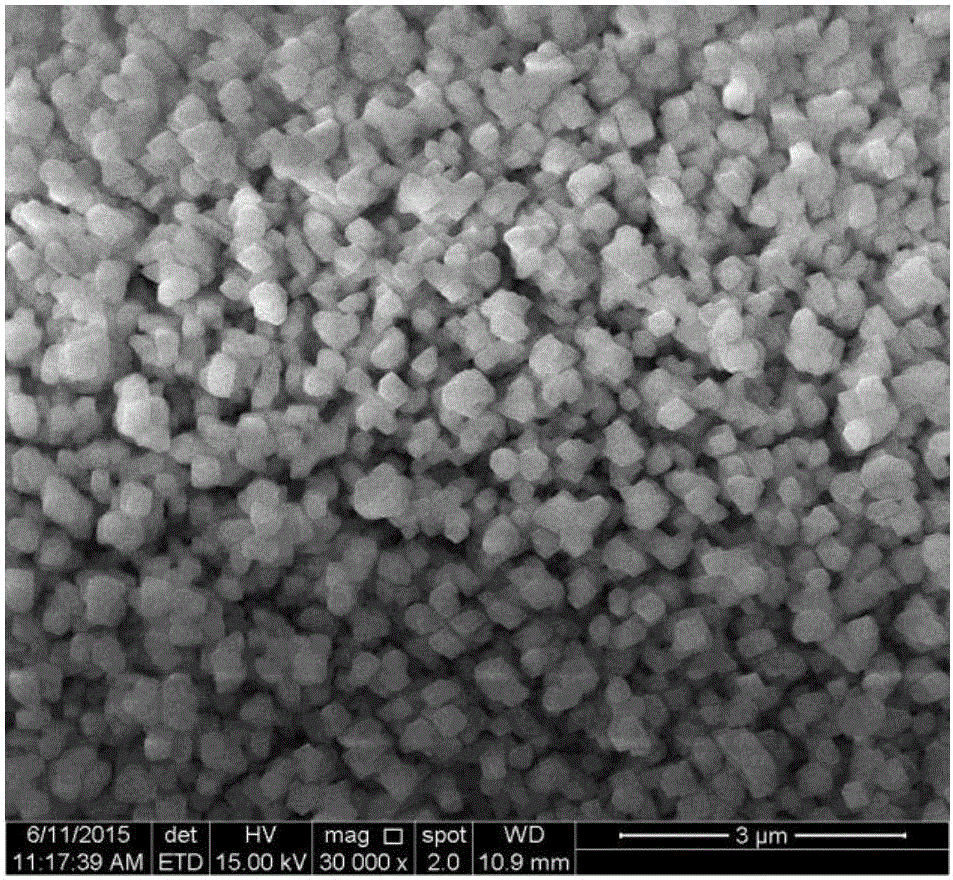

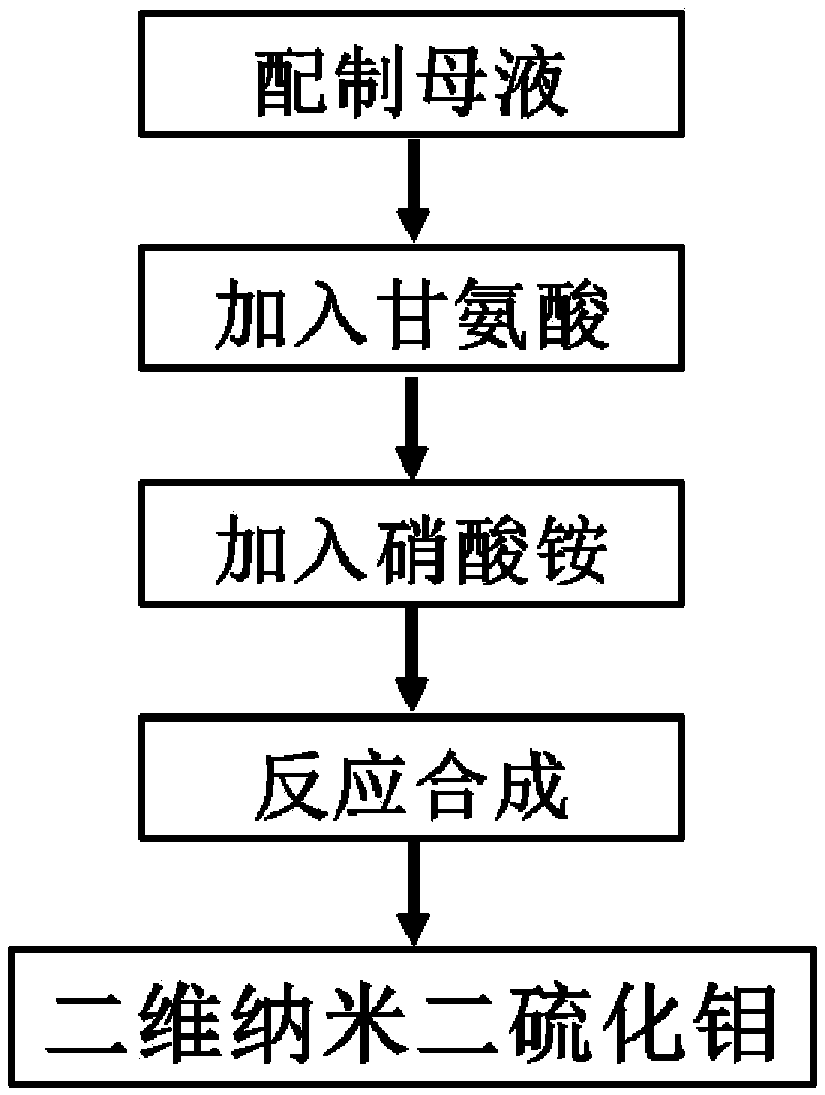

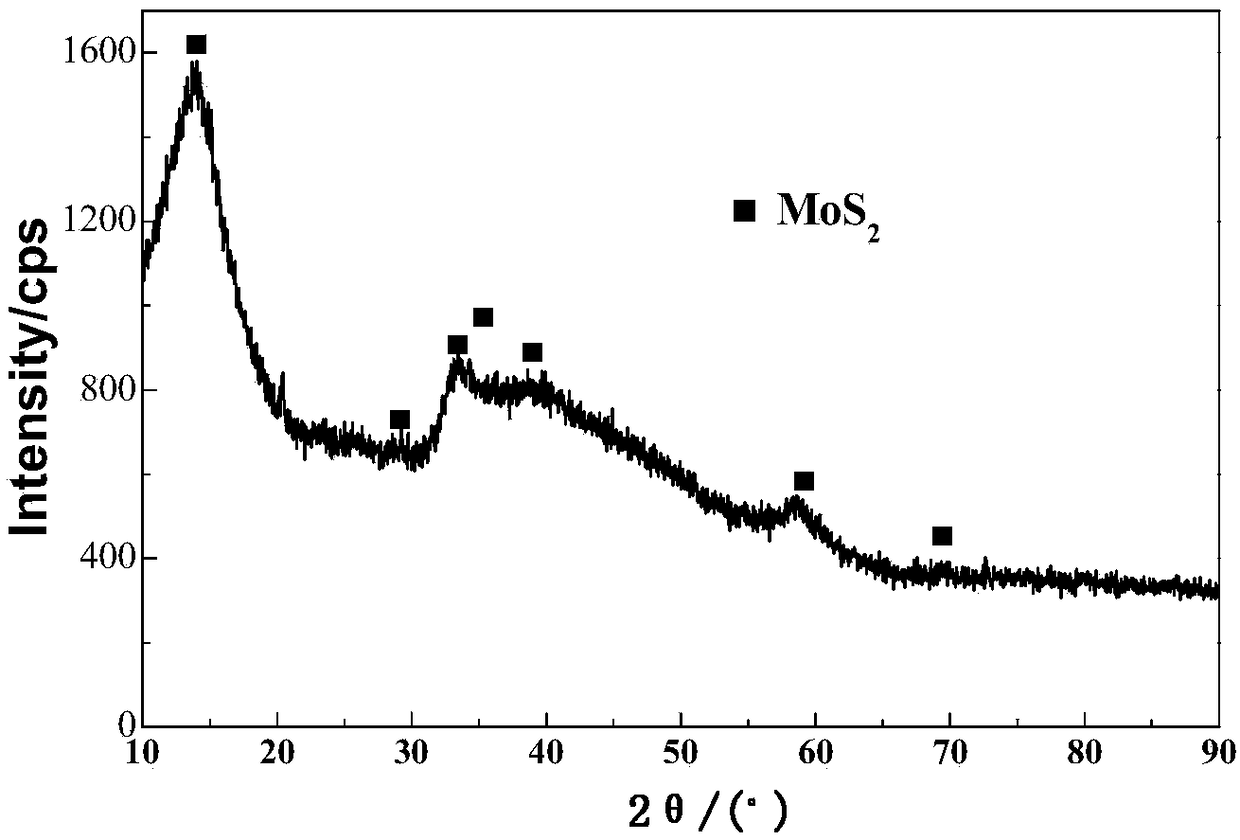

Two-dimensional nano-molybdenum disulfide and preparation method thereof

ActiveCN106379940AQuality improvementThe number of layers is controllableNanotechnologyMolybdenum sulfidesVulcanizationDecomposition

The invention discloses two-dimensional nano-molybdenum disulfide and a preparation method thereof. Ammonium paramolybdate tetrahydrate serving as a molybdenum source is added into stronger ammonia water, an ammonium sulfide solution is used as a sulfur source, and ammonium nitrate and glycine are used as reaction fuel; molybdenum disulfide with a two-dimensional nano laminar structure is prepared by using chalcophile oxygen hydrophobic properties of molybdenum through vulcanization reaction and high-temperature decomposition. The preparation method adopts the following preparation process flow: preparing a mother solution, adding the glycine, adding the ammonium nitrate, performing reactive synthesis, and obtaining the two-dimensional nano-molybdenum disulfide. The particle size of two-dimensional nano-molybdenum disulfide powder prepared by the process is 30 to 100nm; the layer number of most molybdenum disulfide is 2 to 6, and the layer space is 0.60 to 0.69nm. The invention provides a simple and efficient method for preparing two-dimensional nano laminar molybdenum disulfide.

Owner:厦门宇树康信息技术有限公司

Environment-friendly co-condensed resin wood adhesive with high solid content, and preparation method and application thereof

ActiveCN107603541AHigh solid contentReduce pollutionAldehyde/ketone condensation polymer adhesivesAdhesiveParaformaldehyde

The invention discloses an environment-friendly co-condensed resin wood adhesive with high solid content, and a preparation method and an application thereof. The environment-friendly co-condensed resin wood adhesive with high solid content contains raw materials such as glyoxal, urea and paraformaldehyde, and is prepared by addition and condensing reactive synthesis; and the molar ratio of glyoxal to urea to paraformaldehyde is (0.5-1.0):1.0:(0.3-0.9). The preparation method comprises the steps of material preparation, addition reaction, condensation polymerization and after-treatment. The application is the application of the environment-friendly co-condensed resin wood adhesive with high solid content in production and / or manufacture of artificial boards, solid wood plywood, clothing and impregnated paper. The environment-friendly co-condensed resin wood adhesive with high solid content prepared according to the invention has the characteristics of being great in viscosity, high insolid content, steady in structure and excellent in performance and having the free formaldehyde content of less than 0.1%, and can be directly used in production without dehydration treatment, thus having a good industrial application prospect and practical application value.

Owner:SOUTHWEST FORESTRY UNIVERSITY

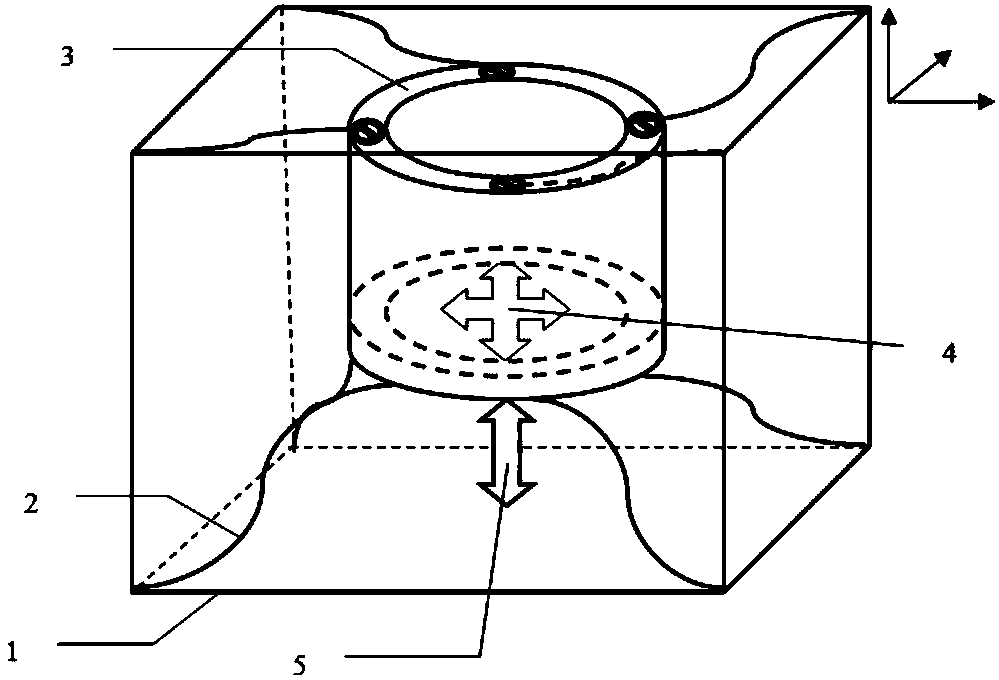

Method for synthesizing and preparing nano-particle reinforced composite through multi-dimension vibration assistance

The invention provides a method for synthesizing and preparing a nano-particle reinforced composite through multi-dimension vibration assistance, and belongs to the technical field of material preparation. In the melt reactive synthesis process of the in-situ particle reinforced composite, multi-dimension high-frequency low-amplitude vibration is applied to melt, melt reactive synthesis is promoted, and meanwhile the obvious function effect is achieved on particle dispersion promoting, clustering overcoming and residue-gold separation promoting. The method further has other advantages of beingsimple, free of contact, low in cost, obvious in effect and the like.

Owner:JIANGSU UNIV

Method for controllably preparing aluminum oxide powder with multiple morphologies

InactiveCN105731510ASolve pollutionAddressing Purity IssuesAluminium oxide/hydroxide preparationMicrowave methodMicrowave technology

The invention provides a method for controllably preparing aluminum oxide powder with multiple morphologies.The method includes the steps that aluminum powder and a carbon source are used as raw materials, and an aluminum oxide powder material is prepared through a microwave method.The aluminum powder and the carbon source are fully mixed uniformly through a ball milling technology, then the mixed powder is put into a crucible, the crucible is put into a microwave tube furnace to conduct reactive synthesis, the two ends of the tube furnace are opened, and the obtained product is the aluminum oxide powder after being cooled.A simple path is provided for preparation and morphology adjustment and control of the aluminum oxide powder by adopting the microwave technology, the problems of serious pollution, low purity, long technological time, complex operation and the like in the prior art are solved, the application range of the technology is expanded into preparation of other oxide materials, and development of a novel material is further promoted.

Owner:ZHONGYUAN ENGINEERING COLLEGE

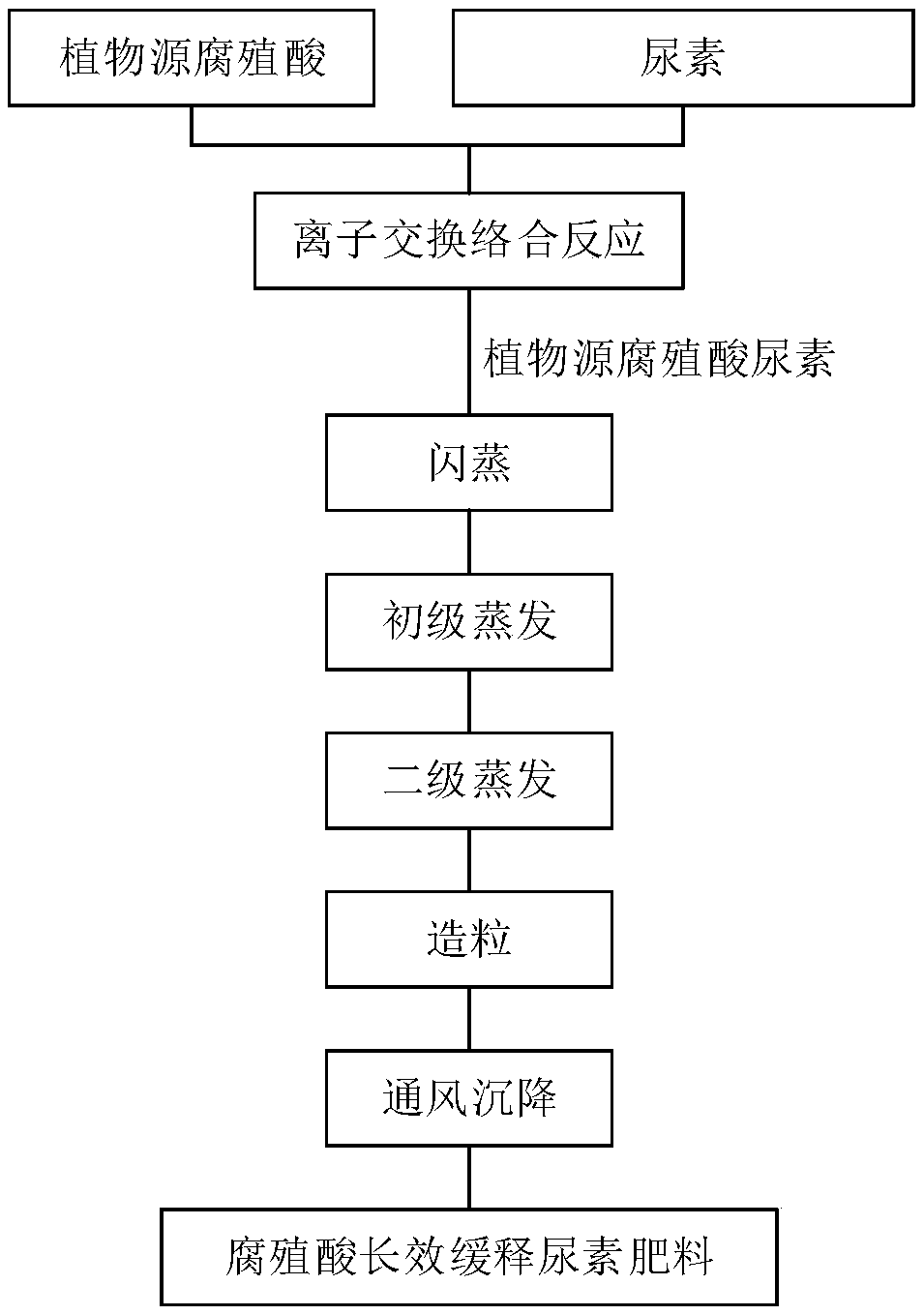

Plant source humic acid long-acting slow-release urea fertilizer and production process thereof

InactiveCN109516837AIncrease the content of fulvic acidImprove long-term sustained-release effectUrea compound fertilisersPlant SourcesImpurity

The invention belongs to the field of agricultural means of production, and particularly relates to a plant source humic acid long-acting slow-release urea fertilizer and a production process thereof.The plant source humic acid long-acting slow-release urea fertilizer is prepared from plant source humic acid urea; the plant source humic acid urea is suitable for the reactive synthesis of plant source humic acid and urea, the content of humic acid and fulvic acid in the plant source humic acid urea is improved, and the long-acting slow-release effect of the urea fertilizer is improved, meanwhile, the content of heavy metals and impurities in urea fertilizer can be further reduced, and the use effect is improved.

Owner:石家庄农信生物科技集团有限公司

Material recycling technique used during sulfur tetrafluoride production

ActiveCN102173394AReduce lossesReduce the amount of purification treatmentSulfur and halogen compoundsTrappingGas phase

The invention relates to a material recycling technique used during sulfur tetrafluoride production. Firstly, the coarse sulfur tetrafluoride gas is produced through reactive synthesis of iodine pentafluoride and sulfur in a sulfur tetrafluoride reactor and then raw materials are initially recycled through condensation, separation and trapping. The impure gases obtained by gas pahse purification during condensation, separation and trapping of sulfur tetrafluoride are evacuated and recovered again through a secondary condensation recovery device. The condensation recovery devices in the initial and secondary stages are utilized to recycle iodine and iodine pentafluoride, which can increase the utilization rate of iodine by more than 70%. The technique can not only reduce material losses and lower production cost but also cut down the volumes to be purified.

Owner:山东锐华氟业有限公司

A magnesium-aluminum-zirconium solid catalyst for one-step intercalation synthesis of alkoxy alcohol ether esters

ActiveCN103920480BHas acid-base dual active sitesEasy to separatePhysical/chemical process catalystsOrganic compound preparationEpoxyMagnesium salt

Owner:JIANGSU YIDA CHEM +1

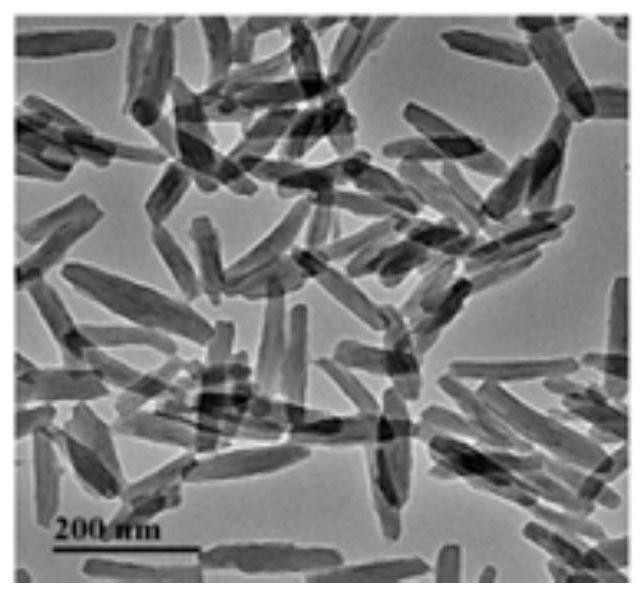

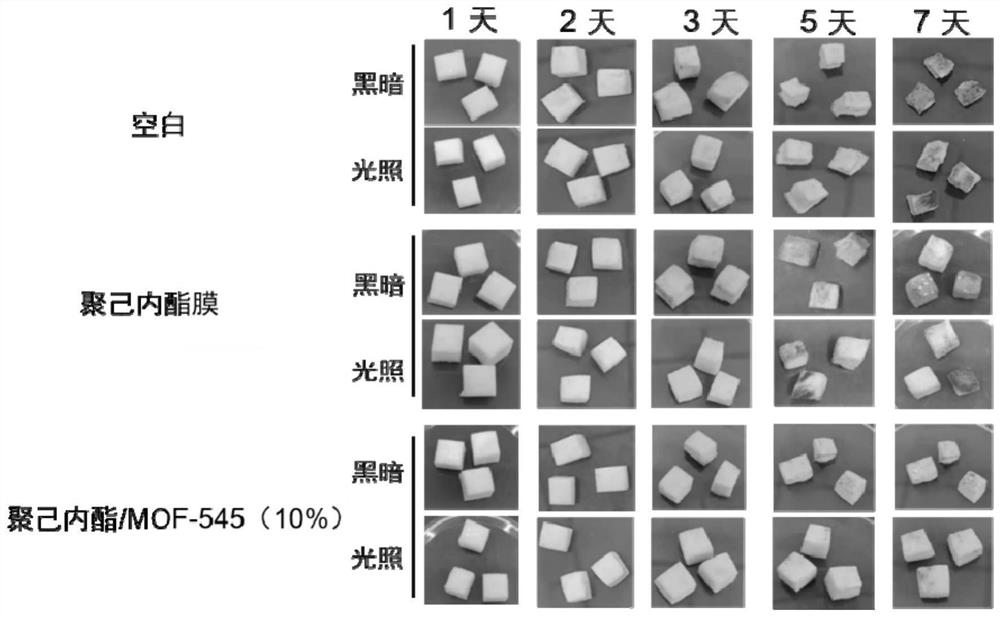

Degradable antibacterial film and preparation method thereof

ActiveCN113667156AGood antibacterial effectPrevent browningBio-packagingN dimethylformamidePorphyrin

The invention relates to a degradable antibacterial film and a preparation method thereof, and belongs to the technical field of film materials. The method comprises: synthesizing a porphyrin metal organic framework material from an acidity regulator, a zircon salt and tetra-carboxyl phenyl porphyrin through a solvothermal reaction; and dissolving the porphyrin metal organic framework material in N, N-dimethylformamide, and mixing with polycaprolactone dissolved in N, N-dimethylformamide to prepare the degradable food antibacterial packaging film which is used for resisting bacteria of fresh-cut apples. The degradable antibacterial film prepared by the invention can realize efficient sterilization of the surfaces of fresh-cut apples, can avoid water loss of the apples and prevent browning of apple pulp to a certain extent, can be repeatedly used, has the advantage of biodegradability, and cannot cause adverse effects on the environment, so that the antibacterial film has a huge application prospect in the field of food antibacterial packaging.

Owner:JIANGNAN UNIV

A kind of amino terminal hyperbranched polymer solid amine adsorption material and its preparation method and application

ActiveCN104923186BReduce utilizationImprove adsorption capacityOther chemical processesDispersed particle separationCross-linkTrapping

The invention discloses an amine-terminated hyperbranched polymer solid amine adsorption material as well as a preparation method and application thereof. The preparation method comprises the following steps: carrying out a Michael addition reaction between an amination reagent and an unsaturated monomer, so as to generate a hyperbranched polymer precursor; realizing polycondensation reactive synthesis in programmed temperature, so as to obtain an amine-terminated hyperbranched polymer; carrying out cross-linking and solidifying; reducing amide groups and imine groups so as to obtain the solid amine adsorption material. The solid amine adsorption material prepared according to the method has high alkyl amine density, has not only very high adsorption capacities for acid gases such as CO2, SO2 and H2S, but also excellent adsorptive regeneration performance, is high in heat stability and chemical stability, and high in adsorption capacity even after multiple regeneration, and can be used in the fields of acid gas adsorption trapping and environmental management, and the field of CO2 removing in a closed system.

Owner:SUN YAT SEN UNIV

A kind of two-dimensional nanomolybdenum disulfide and preparation method thereof

ActiveCN106379940BQuality improvementThe number of layers is controllableNanotechnologyMolybdenum sulfidesVulcanizationAmmonium sulfide

The invention discloses two-dimensional nano-molybdenum disulfide and a preparation method thereof. Ammonium paramolybdate tetrahydrate serving as a molybdenum source is added into stronger ammonia water, an ammonium sulfide solution is used as a sulfur source, and ammonium nitrate and glycine are used as reaction fuel; molybdenum disulfide with a two-dimensional nano laminar structure is prepared by using chalcophile oxygen hydrophobic properties of molybdenum through vulcanization reaction and high-temperature decomposition. The preparation method adopts the following preparation process flow: preparing a mother solution, adding the glycine, adding the ammonium nitrate, performing reactive synthesis, and obtaining the two-dimensional nano-molybdenum disulfide. The particle size of two-dimensional nano-molybdenum disulfide powder prepared by the process is 30 to 100nm; the layer number of most molybdenum disulfide is 2 to 6, and the layer space is 0.60 to 0.69nm. The invention provides a simple and efficient method for preparing two-dimensional nano laminar molybdenum disulfide.

Owner:厦门宇树康信息技术有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com