Patents

Literature

37 results about "Iodine pentafluoride" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Iodine pentafluoride is an interhalogen compound with chemical formula IF₅. It is one of the fluorides of iodine. It is a colorless liquid, although impure samples appear yellow. It is used as a fluorination reagent and even a solvent in specialized syntheses.

Method for preparing iodine pentafluoride

ActiveCN101214927ASimple processLow reaction temperatureInter-halogen compoundsChemical reactionReaction temperature

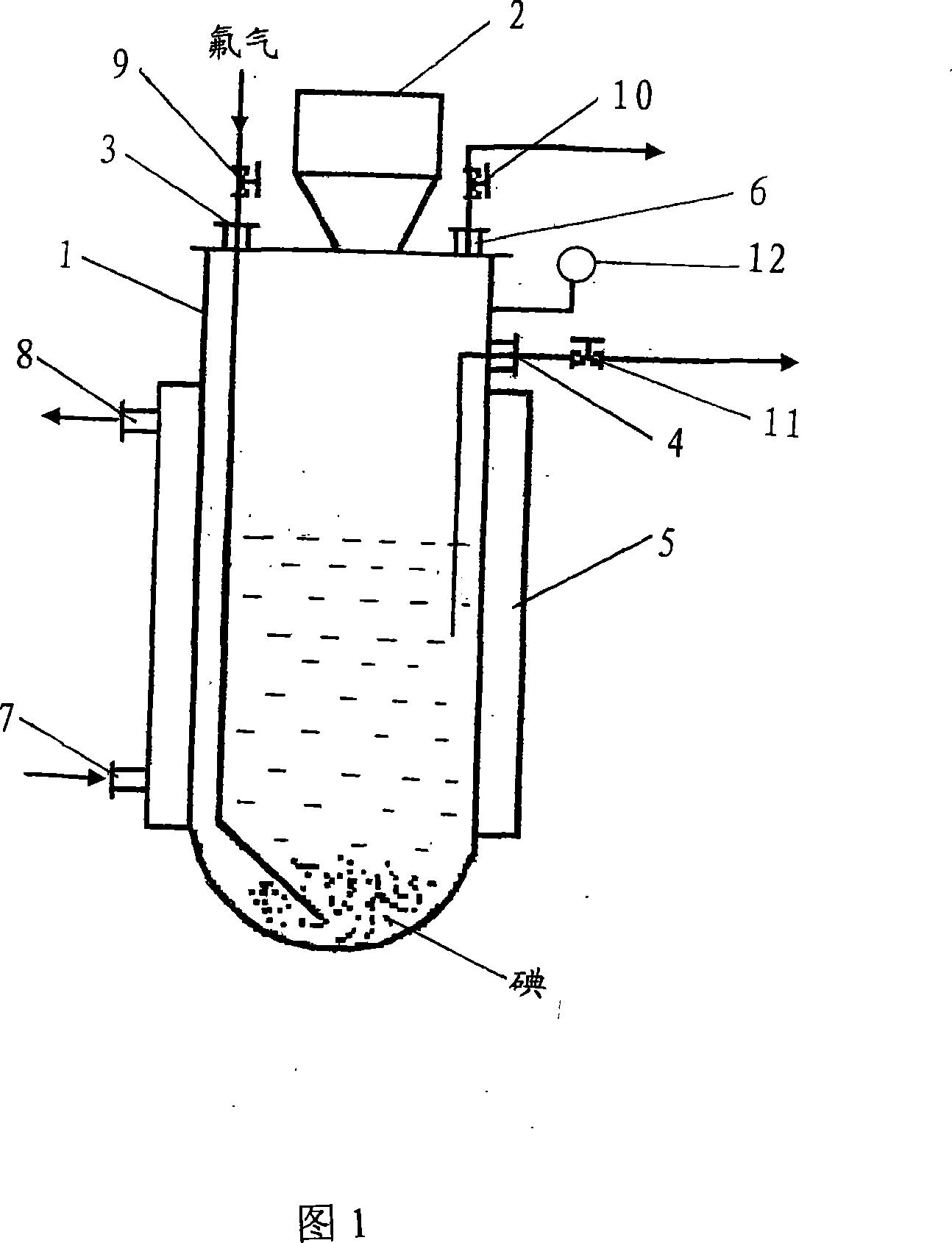

The invention discloses a method of preparing iodine pentafluoride by chemical reaction in a negative pressure container with iodine and fluorine gas as raw materials, and iodine pentafluoride as the carrier. The method includes the following steps: firstly, the iodine is put in a reactor with iodine pentafluoride liquid; the reactor is sealed and evacuated, with pressure of -0.08 to -0.06MPa; cooling water is fed to cool the product. Then fluorine gas is fed into the reactor to have chemical reaction with the iodine, so as to form the three-phase reaction of gas, liquid and solid; the pressure in the reactor is controlled to be less than -0.02MPa and the temperature is controlled to be lower than 85 DEG C. The invention has the advantages of simple process, low reaction temperature, easiness in being controlled, stable and reliable production quality, and high yield.

Owner:RES INST OF PHYSICAL & CHEM ENG OF NUCLEAR IND

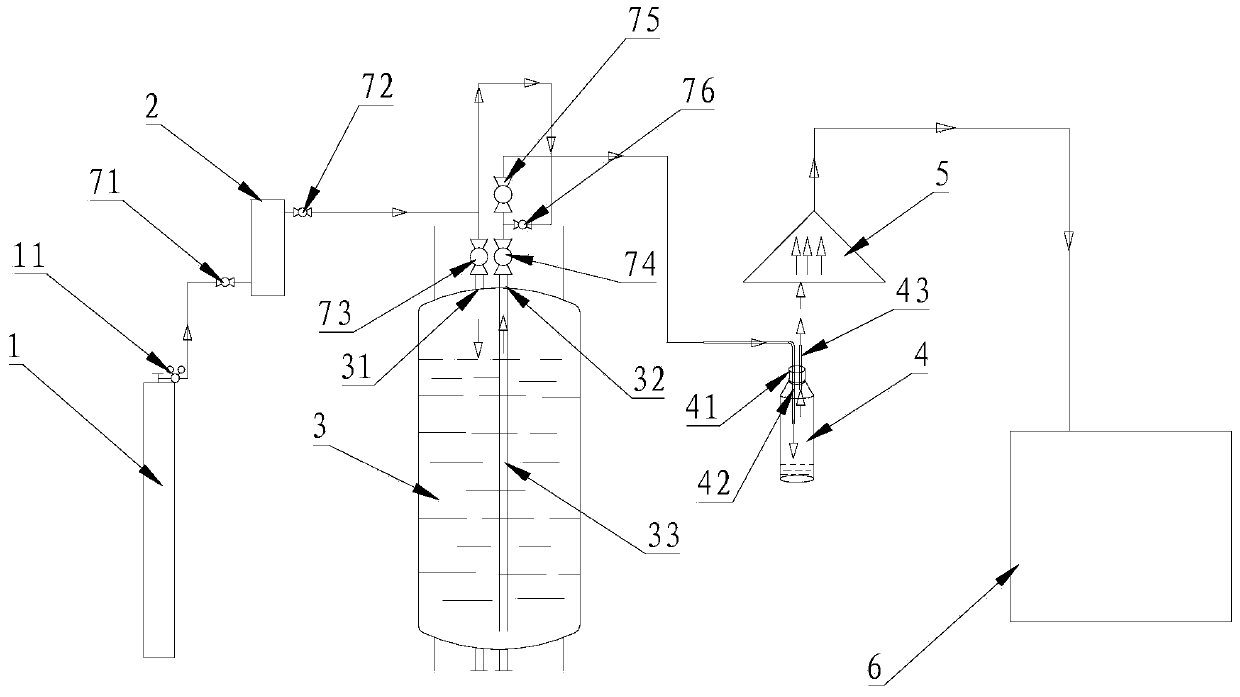

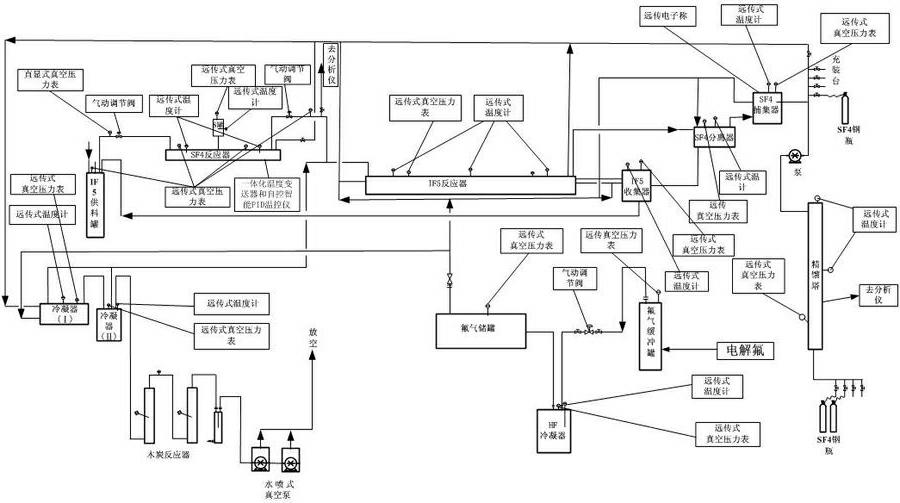

Preparation method and reaction equipment of iodine pentafluoride

ActiveCN101920937AHigh yieldMild responseInter-halogen compoundsIodine pentafluorideContinuous reaction

The invention discloses a preparation method of iodine pentafluoride, which has the advantages of continuous reaction, high yield, mild and complete reaction and very light pollution level and comprises the following steps: placing solid iodine above liquid iodine pentafluoride or an iodine pentafluoride solution of iodine, introducing fluorine gas in the liquid iodine pentafluoride or the iodine pentafluoride solution of iodine, and reacting solid iodine and fluorine gas to generate iodine pentafluoride which flows in the liquid iodine pentafluoride or the iodine pentafluoride solution of iodine after dissolving the iodine partially. The invention also discloses reaction equipment dedicated for the method.

Owner:FUJIAN YONGJING TECH CO LTD

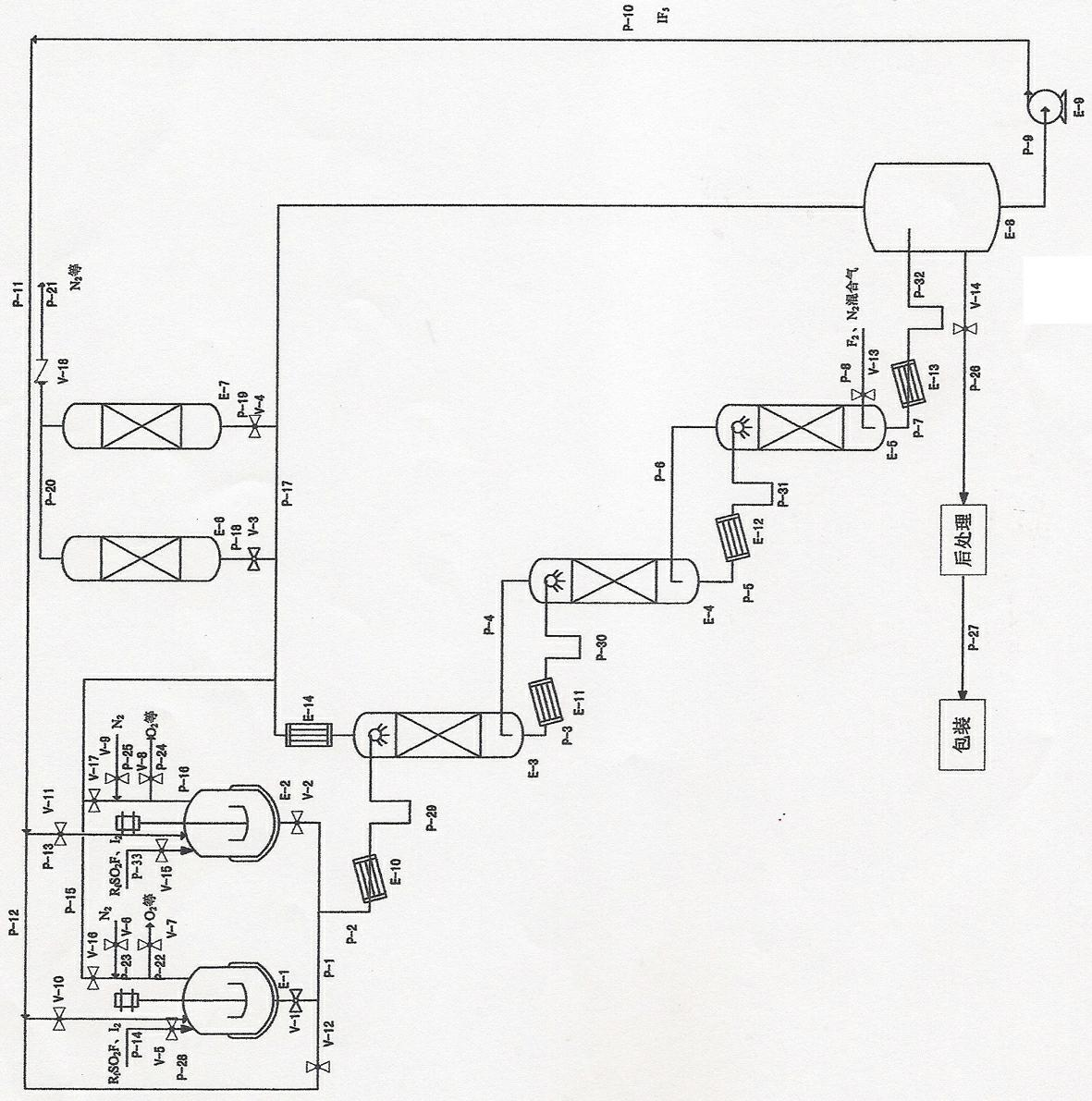

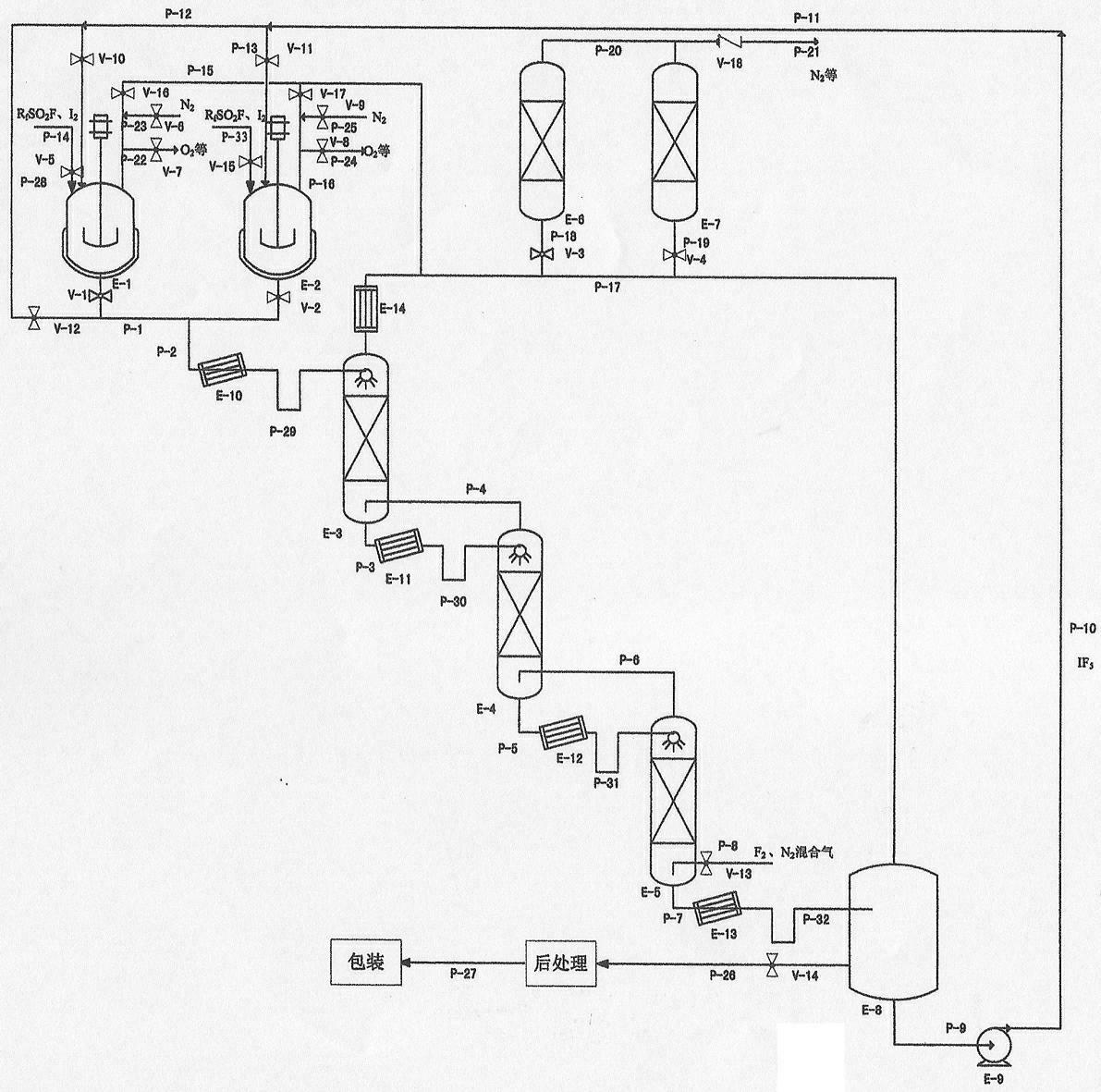

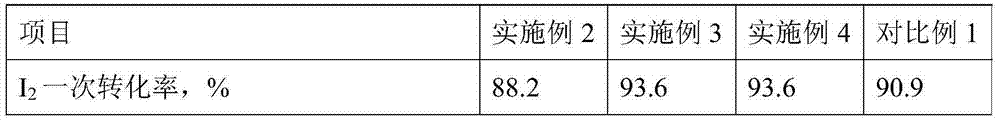

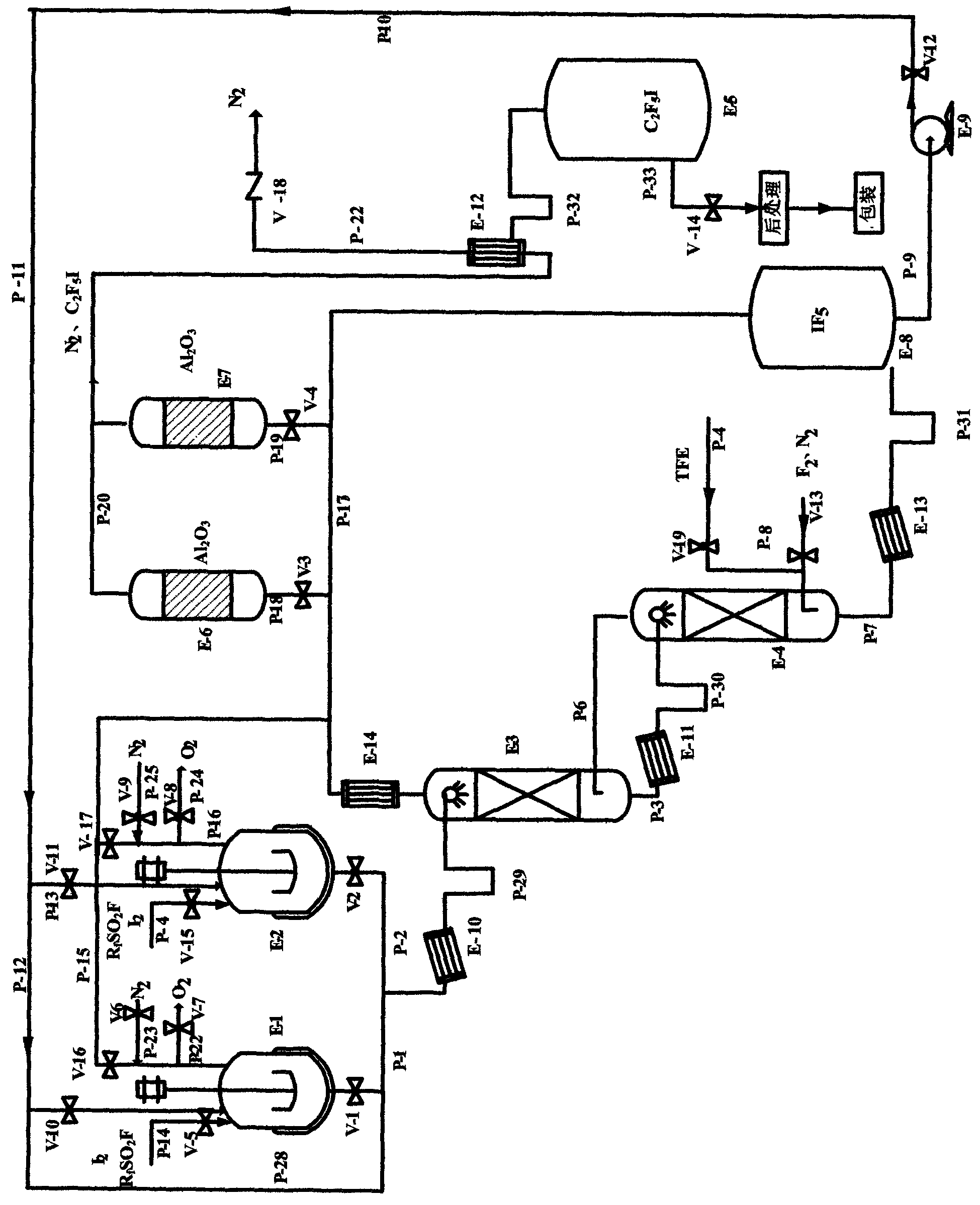

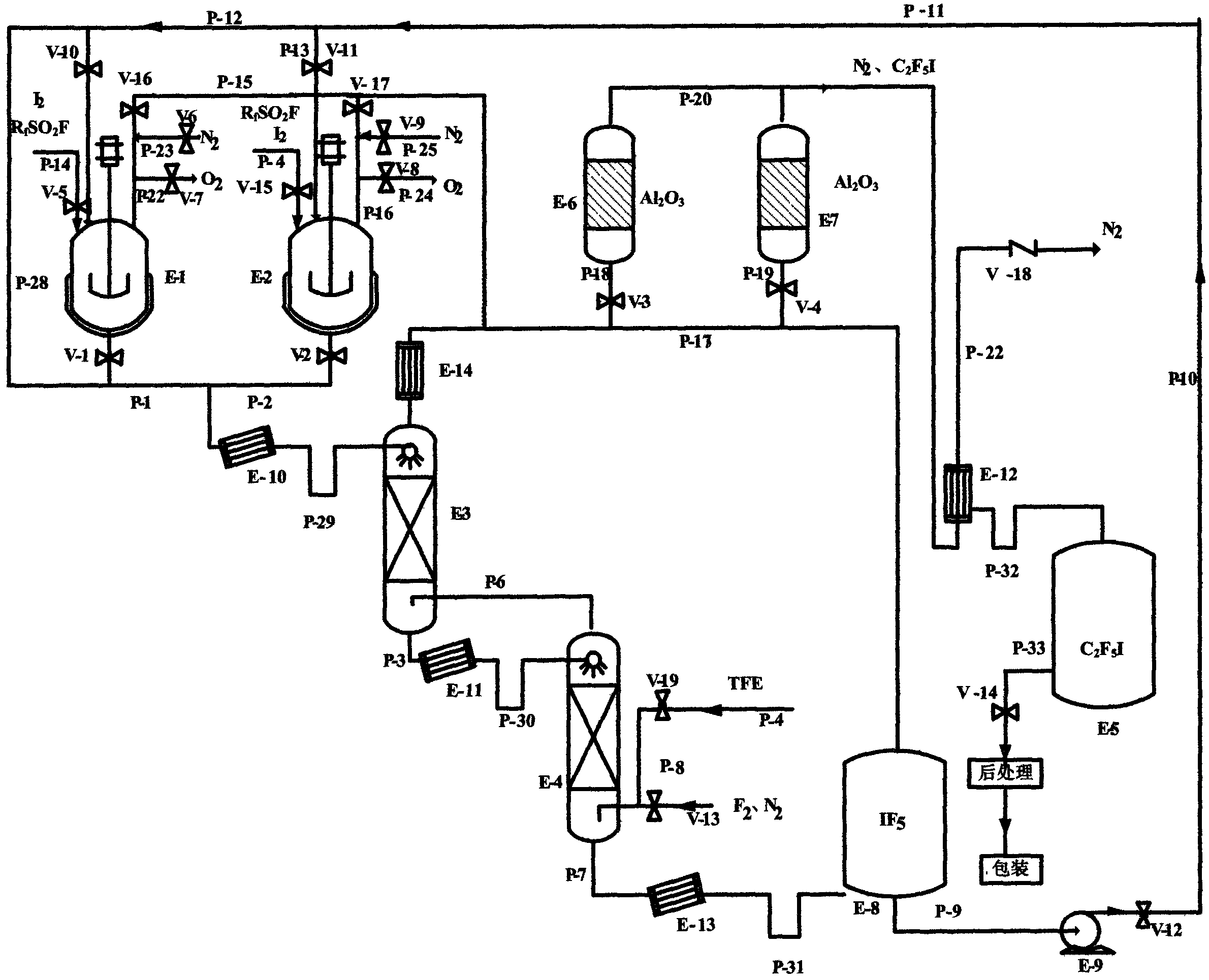

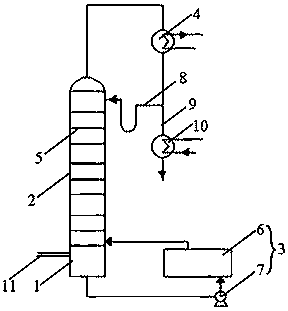

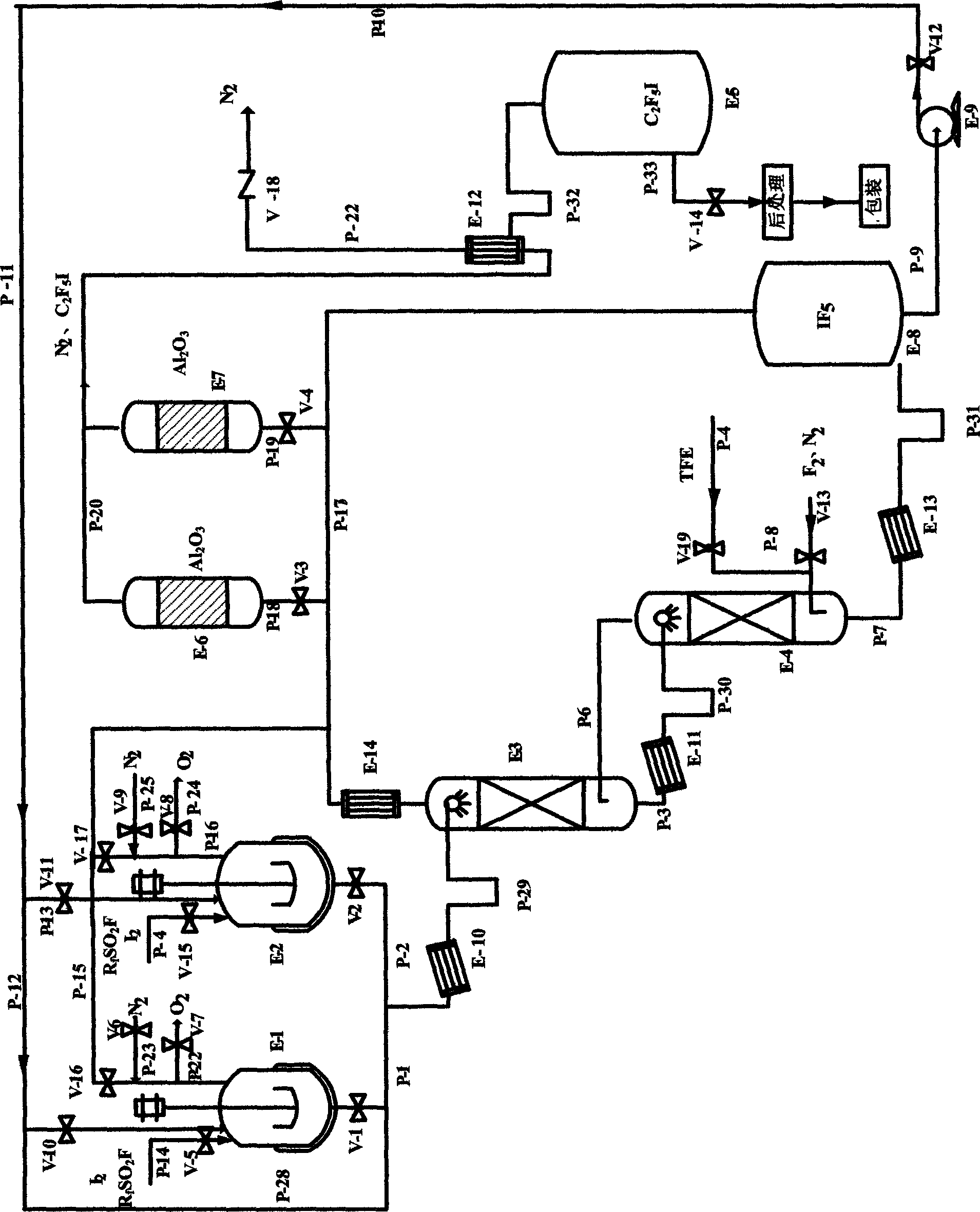

Method for continuously preparing iodine pentafluoride

ActiveCN102556974AThe reaction temperature is easy to controlReaction temperature safetyInter-halogen compoundsProcess equipmentReaction temperature

The invention discloses a method for continuously preparing iodine pentafluoride. According to the method, a serial process flow of a multistage tower type reactor is adopted; according to process requirement, the tower number can be 1-N grades, wherein N is more than or equal to 3; in the atmosphere containing sulfuryl fluoride (RfSO2F), an iodine pentafluoride solution of iodine and fluoride gas or mixed gas of fluoride and nitrogen respectively enter a multistage reaction tower from two ends, reversely flow and generate a reaction. The method has the advantages that the reaction temperature is controllable, higher safety is ensured and the phenomenon that the iodine is excessively fluoridized at high temperature to generate IF7 is avoided; two iodine dissolving tanks are alternatively used so as to facilitate the continuous atomization; the sulfuryl fluoride atmosphere facilitates the operation of a gas-liquid reaction and is remarkably superior to the hydrogen fluoride existing atmosphere introduced in other patents, so that the purification of products is facilitated; and unreacted fluoride gas in tail gas can be adsorbed by solid salts or alkali and then be recycled. The process equipment and parts are made of general steel; and pitting-free chemical nickel-plating treatment and fluorine gas passivation treatment are used in sequence so as to effectively reduce the investment cost and facilitate the industrialization.

Owner:HUBEI ZHUOXI FLUOROCHEM

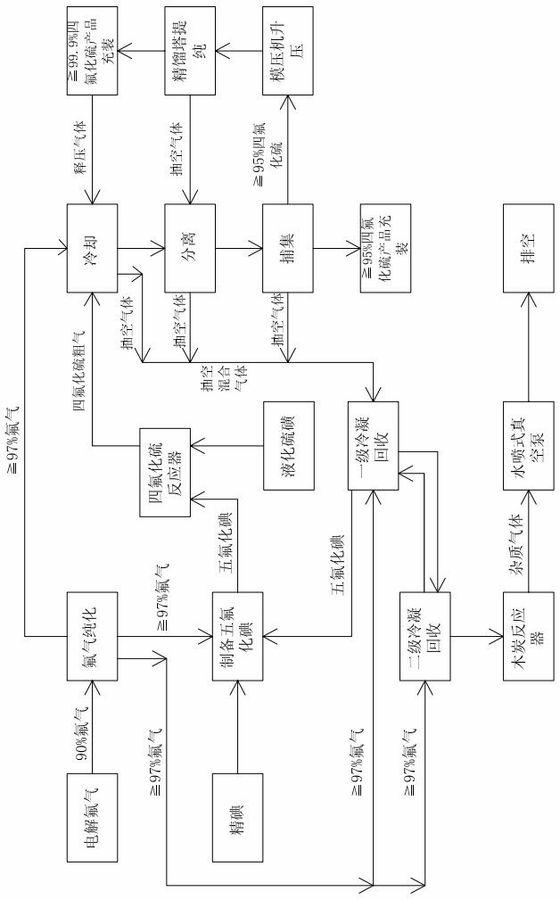

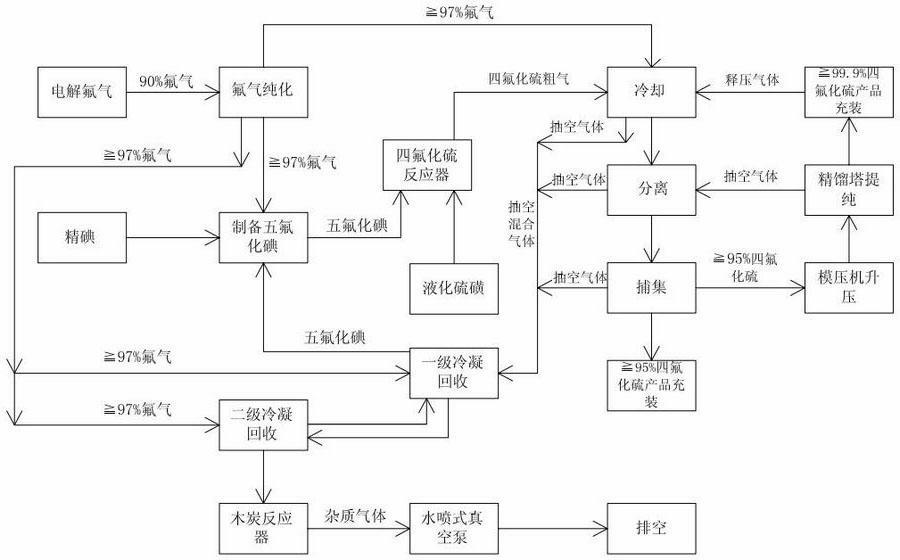

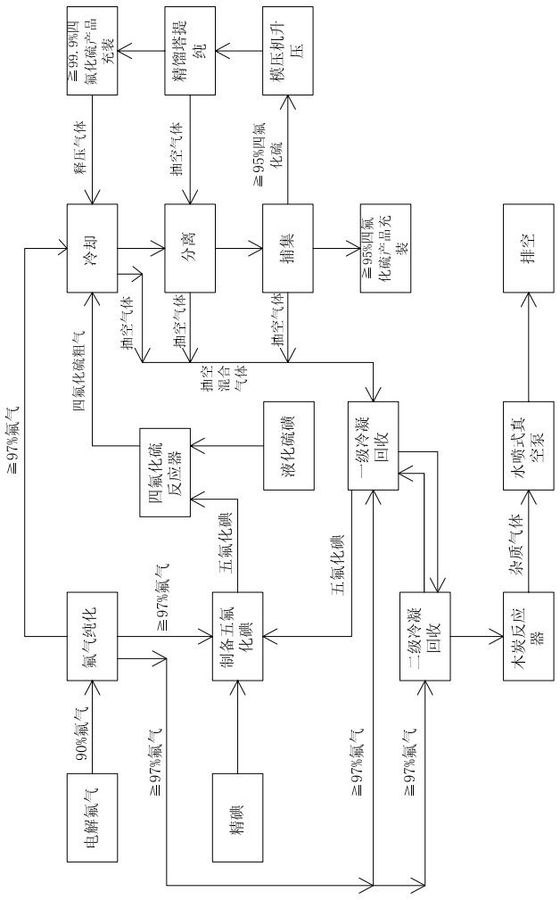

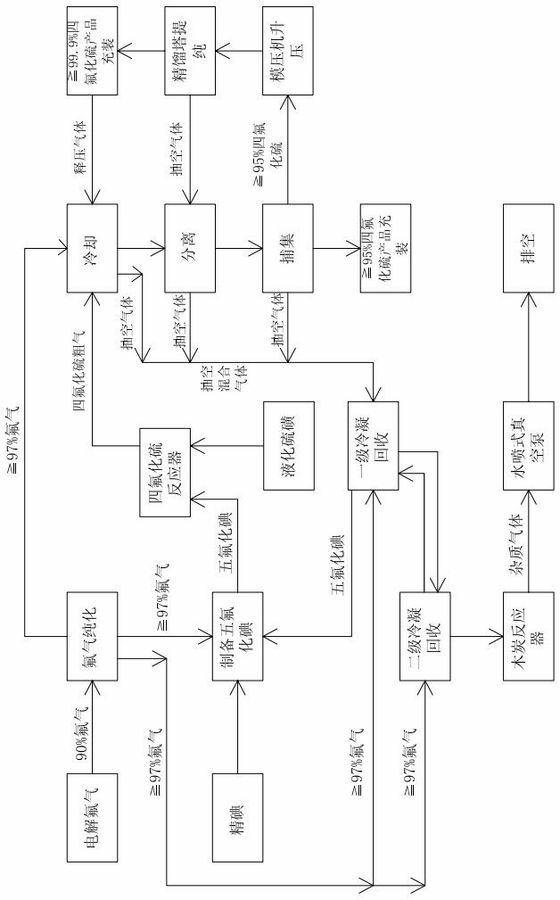

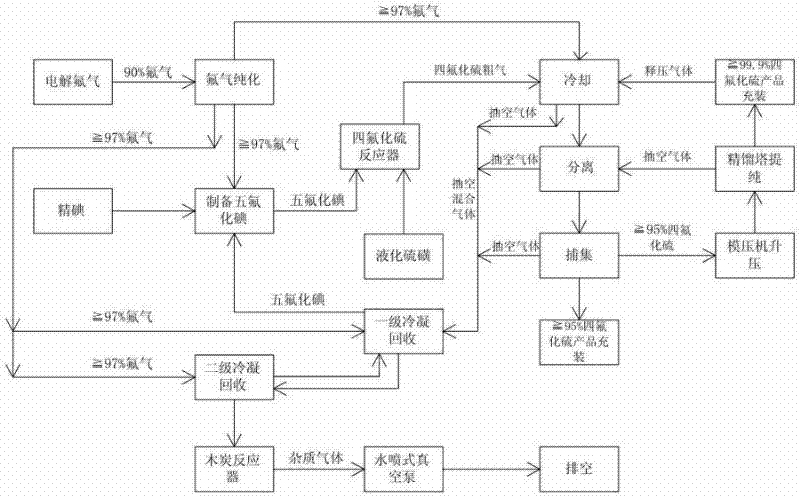

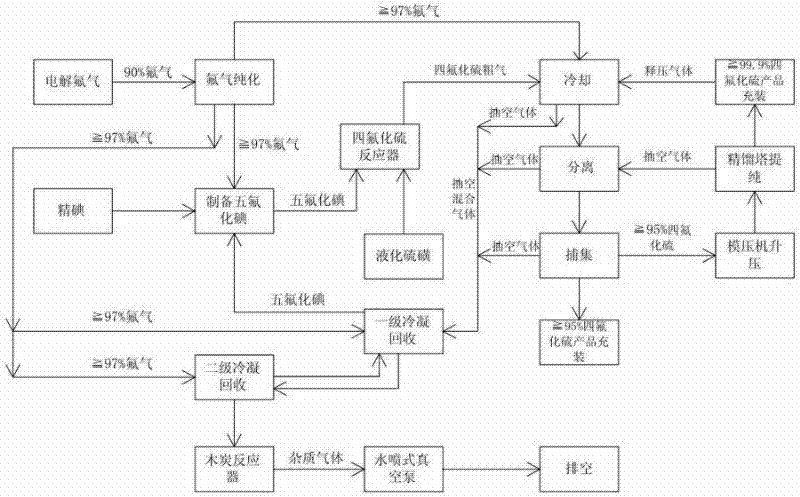

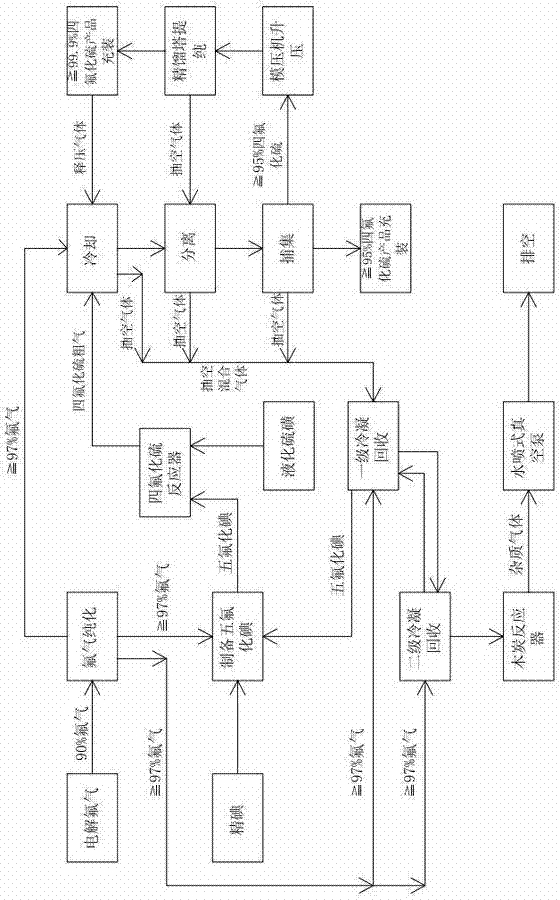

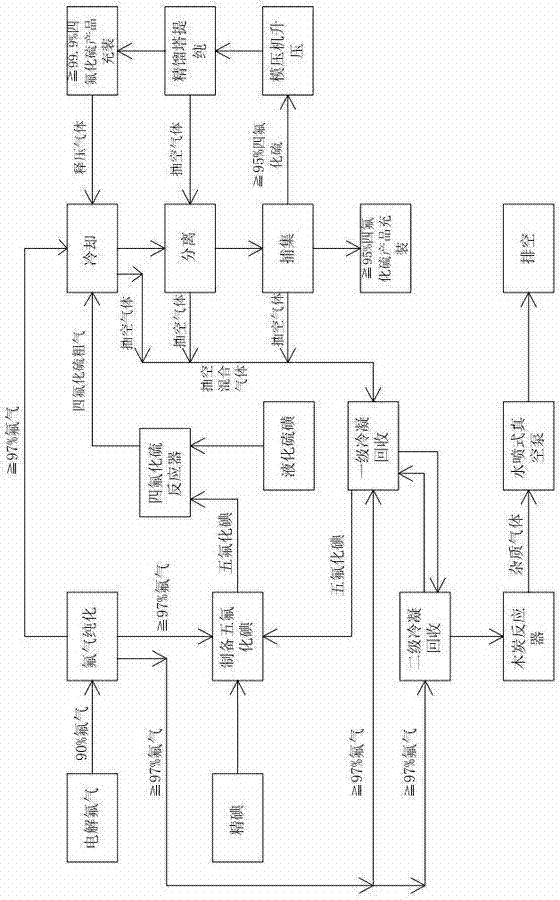

Sulfur tetrafluoride production technique

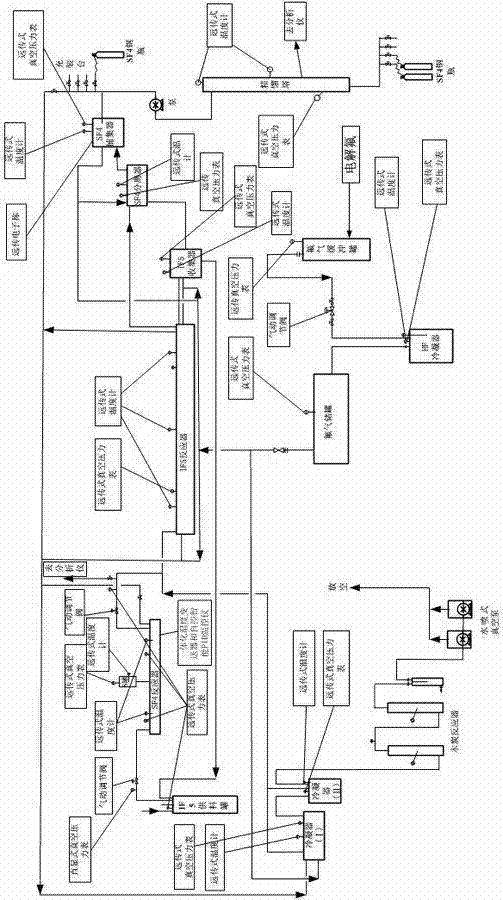

ActiveCN102173393AIncrease concentrationImprove conversion rateSulfur and halogen compoundsHydrogen fluorideTrapping

The invention relates to a sulfur tetrafluoride production technique, belonging to the field of fluorochemicals. The sulfur tetrafluoride production technique comprises fluorine gas purification, iodine pentafluoride preparation, sulfur tetrafluoride reactive synthesis, sulfur tetrafluoride separation and trapping, sulfur tetrafluoride distillation and canning, secondary recycling of iodine pentafluoride as well as discharge of exhaust gas. By using a low-temeprature condensing device, the electrolytic fluorine is purified to remove a great amount of hydrogen fluoride, so the fluorine gas concentration is largely improved. A condensing and recycling device is employed to recycle iodine and iodine pentafluoride for re-use, thus the utilization ratio of iodine can reach above 70% and material losses can be reduced. Due to a constant distillation method, the purity of sulfur tetrafluoride products can reach above 99.9%, and the products can be charged into a steel cylinder more safely. In addition, the entire sulfur tetrafluoride production technique is controlled by a automatic DCS (distributed control system) device, which reduces artificial randomness and experience and improves the stability of product quality.

Owner:山东锐华氟业有限公司

Process method for purifying iodine pentafluoride

ActiveCN103449371AReduce contentEasy to operateInter-halogen compoundsIodine pentafluorideProduct gas

The technical scheme of the invention is to provide a process method for purifying iodine pentafluoride. The process method comprises the following steps of: (i) evacuating an evaporator until the pressure is between -0.08MPa and -0.10MPa; (ii) adding an iodine pentafluoride raw material into the evaporator; (iii) heating the evaporator, and controlling the temperature of the evaporator to be 30-60 DEG C to ensure that light component impurities such as N2, O2, HF and the like in the iodine pentafluoride are gasified and separated out; (iv) controlling the temperature of the evaporator to be 90-130 DEG C to ensure that the iodine pentafluoride in the evaporator is gasified and the gasified iodine pentafluoride enters a condenser, and controlling the temperature of the condenser to be 60-80 DEG C to ensure that the iodine pentafluoride gas is condensed and liquefied; (v) removing deposited substances such as KF, FeF2 and other heavy components in an iodine pentafluoride crude product. The process method provided by the invention is simple in equipment, convenient in operation and safe in equipment running, the content of the impurities in the iodine pentafluoride is effectively reduced, and the product purity reaches more than 99.5%.

Owner:RES INST OF PHYSICAL & CHEM ENG OF NUCLEAR IND

One-step preparation method of perfluoroalkyl iodide

InactiveCN102241561AImprove responseReduce production stepsPhysical/chemical process catalystsPreparation by halogen additionTetrafluoroethylenePtru catalyst

The invention relates to a one-step preparation method of perfluoroalkyl iodide, belonging to the field of fluoride product intermediates. The preparation method comprises the following steps: adding iodine, iodine pentafluoride and a composite catalyst into a reaction vessel, vacuumizing to -0.095 MPa, replacing air in the reaction vessel with high-purity nitrogen gas for times until the water content is not more than 100 ppm and the oxygen content is not more than 30 ppm, heating the reaction vessel until the internal temperature is 60-80 DEG C, adding tetrafluoroethylene, and maintaining the pressure at 0.5-0.7 MPa for reaction; and raising the reaction temperature to 130-150 DEG C when the pressure does not decrease after adding tetrafluoroethylene, continuing introducing tetrafluoroethylene, and controlling the pressure at 2.8 MPa for reaction to obtain the perfluoroalkyl iodide. In the preparation method, the perfluoroalkyl iodide is synthesized by one-step reaction from iodine pentafluoride, two-step reaction is continuously carried out in the reaction vessel, and the reaction effect is greatly enhanced by using the composite catalyst; and the original two-step reaction is changed into a one-step reaction, thus reducing the production steps, simplifying the production process and equipment and lowering the production investment.

Owner:山东中氟化工科技有限公司

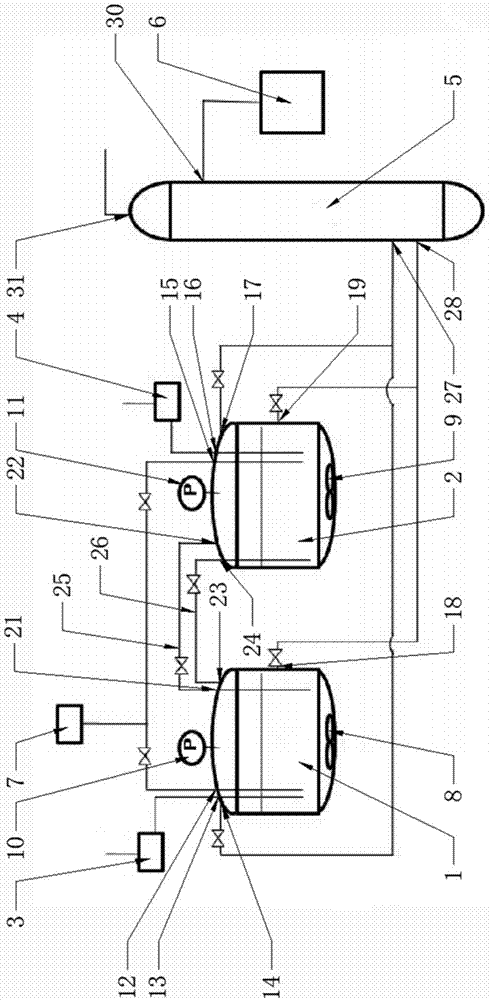

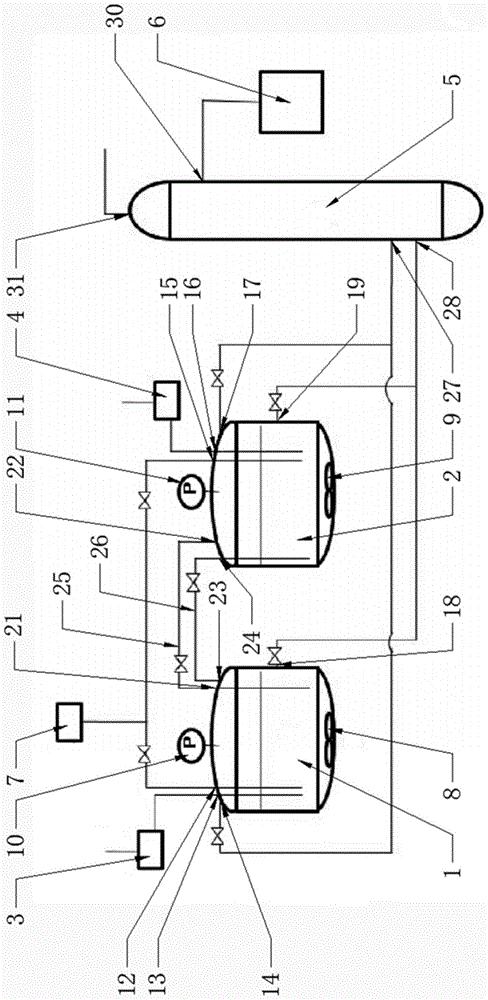

Preparation method and production device of iodine pentafluoride

ActiveCN104326443ARealize continuous productionIncrease profitInter-halogen compoundsNitrogenIodine pentafluoride

The invention discloses a preparation method and production device of iodine pentafluoride. The preparation method comprises following steps: (1) adding iodine pentafluoride and molten iodine respectively into a first reaction kettle and a second reaction kettle to form a mixed system; (2) feeding a mixed gas containing fluorine and nitrogen into the first reaction kettle, feeding the rest mixed gas into the second reaction kettle for reaction, and discharging the rest gas; (3) when the reaction in the first reaction kettle is finished, discharging generated iodine pentafluoride and then preparing the mixed system; (4) feeding the mixed gas containing fluorine and nitrogen into the second reaction kettle, feeding the rest mixed gas into the first reaction kettle for reaction, and discharging the rest gas; (5) when the reaction in the second reaction kettle is finished, discharging generated iodine pentafluoride and then preparing the mixed system; and (6) repeatedly performing the operations from the step (2) to the step (5). The preparation method achieves continuous production of the iodine pentafluoride and increase a utilization ratio of the raw materials. A product is stable in quality and high in yield. Meanwhile, waste of a fluorine resource and environmental pollution are avoided.

Owner:DO FLUORIDE CHEM CO LTD

Soilless cultivation nutrient formula of peonies and application thereof

InactiveCN104945162ASynchronous absorptionIncrease resistanceAgriculture gas emission reductionCultivating equipmentsAdditive ingredientNutrient solution

The invention discloses a soilless cultivation nutrient formula of peonies. The soilless cultivation nutrient formula is composed of, by weight, 13-16.5 parts of diphenylamine, 11.5-12.5 parts of ammonium ferric sulfate, 2-20 parts of auxin, 4-5 parts of methionine, 0.4-0.8 part of barium sulfide, 0.1-0.3 part of barium vanadate, 0.1-0.3 part of iodine pentafluoride, 0.05-0.2 part of glycerol phosphate calcium and the balance water. The soilless cultivation nutrient formula is made by weighing and evenly mixing the ingredients according to the ratio. By the adoption of the nutrient liquid, the seepage force and diffusivity of the nutrient liquid are greatly enhanced in the breeding process, so that the seeding stage is greatly shortened, the emergence rate is increased, the quality of emergence is improved, and meanwhile the cost is lowered; the nutrient liquid is more suitable for high-altitude low-temperature seedling cultivation.

Owner:汤在英

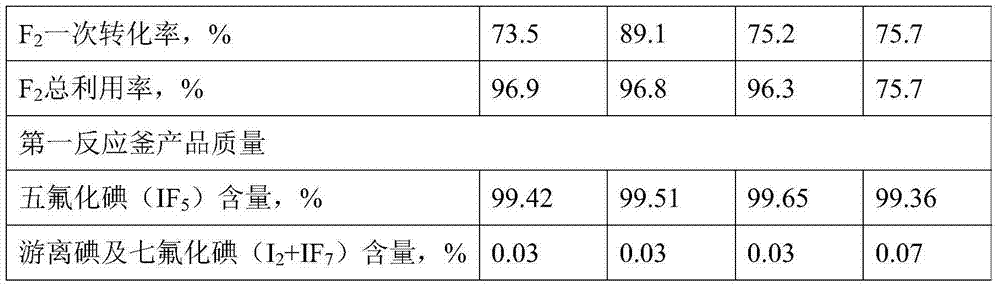

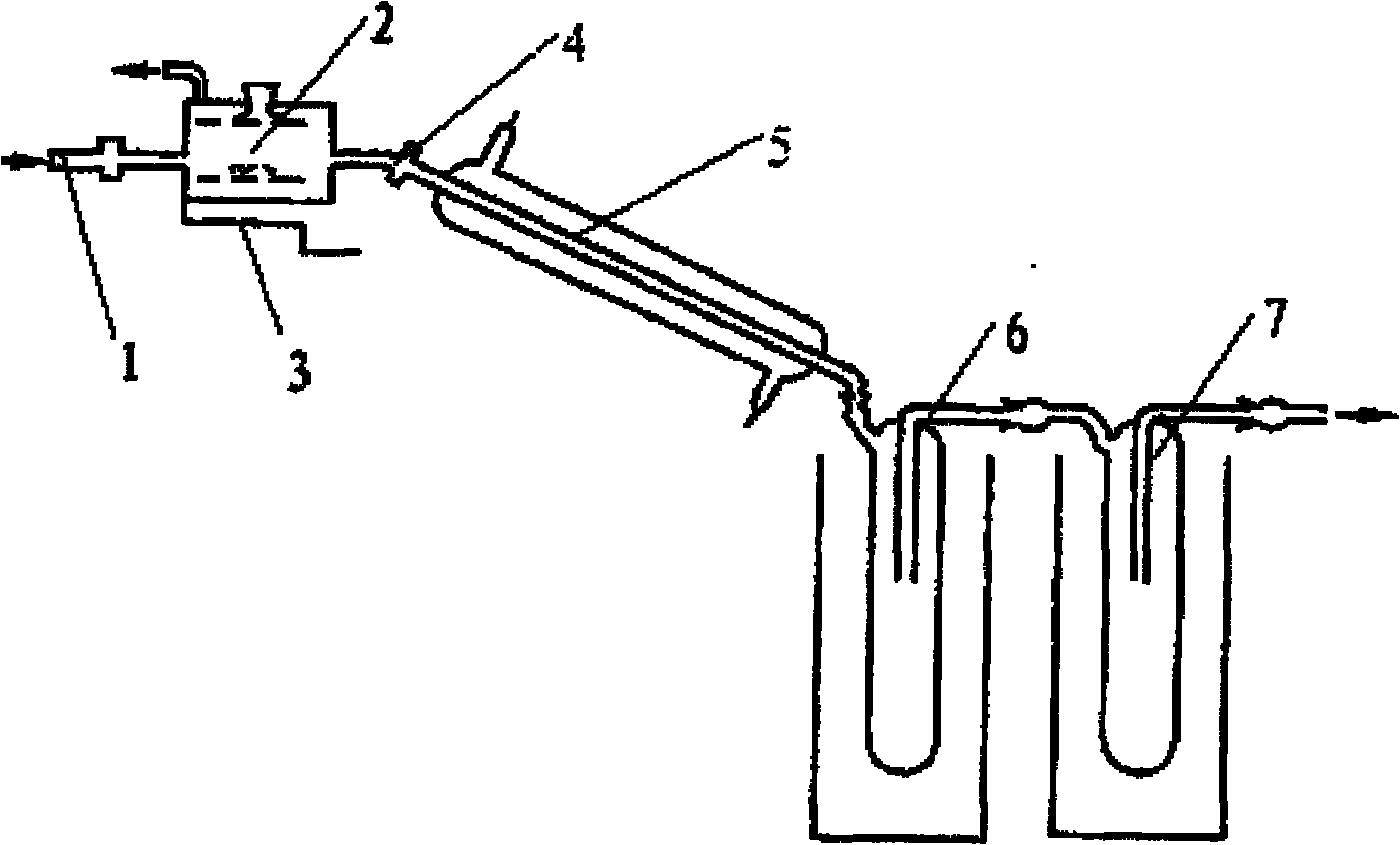

Technology for preparing iodine pentafluoride from reaction between gaseous fluorine and solid iodine at room temperature

InactiveCN101973526ASolve pollutionReasonable workmanshipInter-halogen compoundsRoom temperaturePhysical chemistry

The invention discloses a technology for preparing iodine pentafluoride by directly fluorating iodine by elemental iodine. The method is mainly characterized in that: an integrated electrolytic reactor is externally connected with a cooling sleeve; an inlet end of the electrolytic reactor is connected with a fluorine inlet pipe; and an iron condenser, a left quartz cold trap and a right quartz cold trap are connected together through a connection pipe. The technology has reasonable process, ensures simple preparation and solves the problem of environmental pollution during the production of iodine pentafluoride, thereby being an ideal technology for preparing iodine pentafluoride.

Owner:天津东方宜信物流有限公司

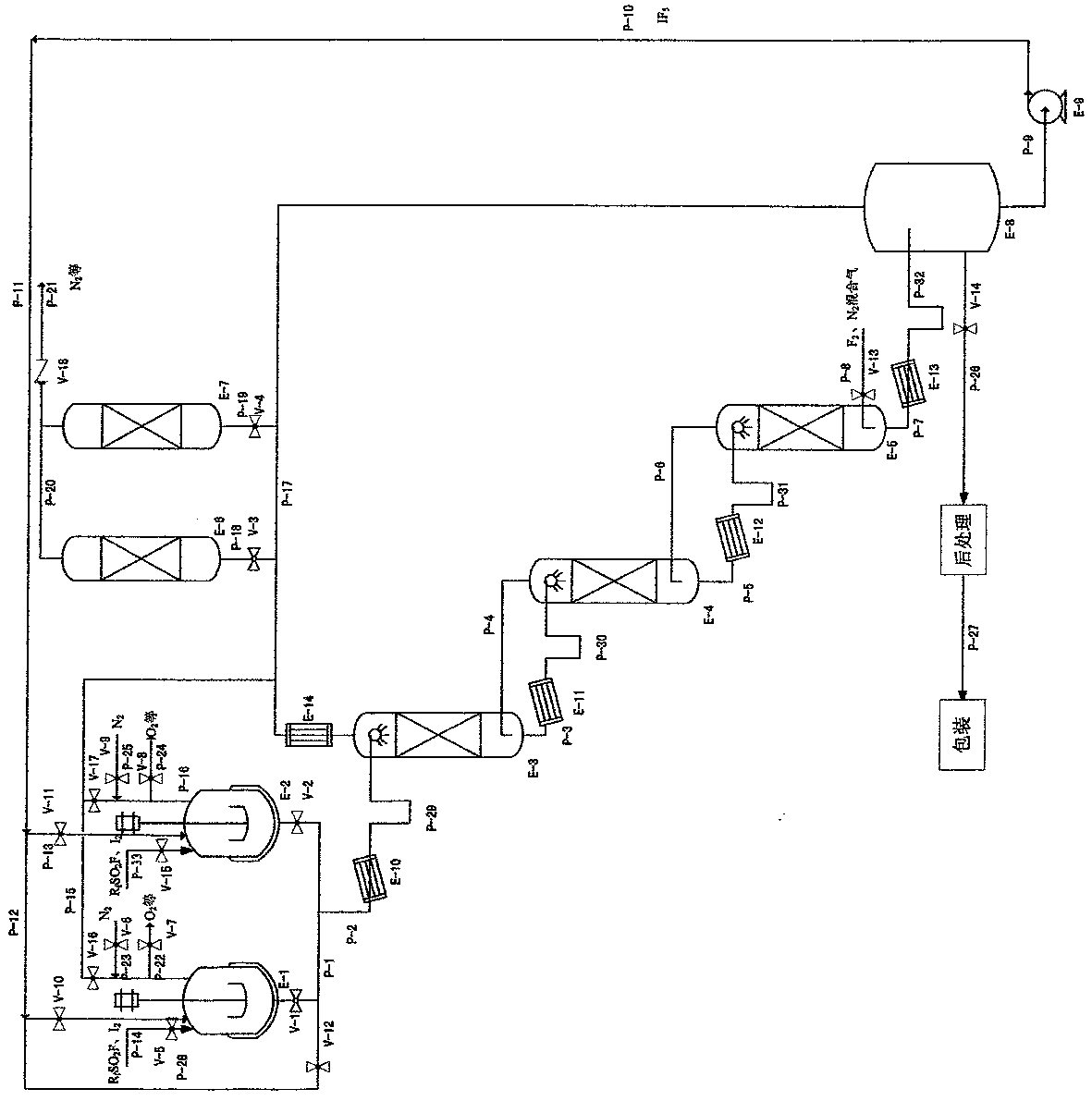

Novel technology for preparing pentafluoroethyl iodide by one-step method

ActiveCN102351636ASave energyLess investmentPreparation by halogen additionCorrosive chemicalProcess equipment

A technology for preparing pentafluoroethyl iodide by a one-step method. By the adoption of a multiple-stage tower reactor series connection process flow (N is greater than or equal to 2 upon the process requirements), an iodine pentafluoride solution, a gas mixture of perfluoroalkyl sulfonyl fluoride and fluorine nitrogen and tetrafluoroethene respectively enter into the multiple-stage tower reactor from two ends and countercurrently flow for reaction. The invention has the following advantages: fluorine gas, iodine and tetrafluoroethene are used as raw materials to react so as to synthesize pentafluoroethyl iodide in one step; the newborn iodine pentafluoride in the invention has high activity and can perform a mild reaction at the temperature of 60-65 DEG C; the catalyst perfluoroalkyl sulfonyl fluoride can be used as a catalyst and a surfactant to raise the reaction rate and the yield; two iodine-eroded grooves and a tail gas absorbing tower cooperate and are alternatively used to make the reaction continuously automated; unreacted fluorine gas can be adsorbed by active alumina and then recovered and reused; the technological equipment and parts, which are made from regular steel, undergo a pock-free electroless nickel plating treatment and a fluorine passivation treatment, so as to prevent the damage of corrosive chemicals to the equipment, reduce the investment cost and benefit for industrialization.

Owner:HUBEI ZHUOXI FLUOROCHEM

Sampling system of iodine pentafluoride or antimony fluoride

InactiveCN103728157ANo pollutionEasy to operateWithdrawing sample devicesPulp and paper industryIodine pentafluoride

The invention discloses a sampling system of iodine pentafluoride or antimony fluoride. The sampling system comprises a liquid storage pot, a nitrogen decompressor, a sampling bottle and a pumping negative pressure device, wherein the upper end of the liquid storage pot is provided with an air inlet / outlet, a material inlet / outlet, an inlet / outlet pipe; one end of the inlet / outlet pipe stretches into the liquid of the liquid storage pot, and the other end of the inlet / outlet pipe is connected with the material inlet / outlet; the nitrogen decompressor comprises a high pressure nitrogen cylinder and a gas dryer, one end of the gas dryer is communicated with an air outlet of the high pressure nitrogen cylinder through a pipeline, the other end of the gas dryer is communicated with the air inlet / outlet arranged on the liquid storage pot through the pipeline, and a bottle port of the sampling bottle is provided with a choke plug, a feeding pipe and an exhaust pipe are inserted on the choke plug, one end of the feeding pipe stretches into the bottom end of the sampling bottle, and the other end of the feeding pipe is communicated with the liquid storage pot through the pipeline; and the pumping negative pressure device comprises a vacuum machine and an air exhaust cover, the air exhaust cover is mutually communicated with a pumping port of the vacuum machine, and the air exhaust cover is positioned on the upper end of the sampling bottle. The sampling system provided by the invention has the advantages that the sampling is safe and reliable, the operation is easy, and the environment is not polluted.

Owner:FUJIAN YONGJING TECH CO LTD

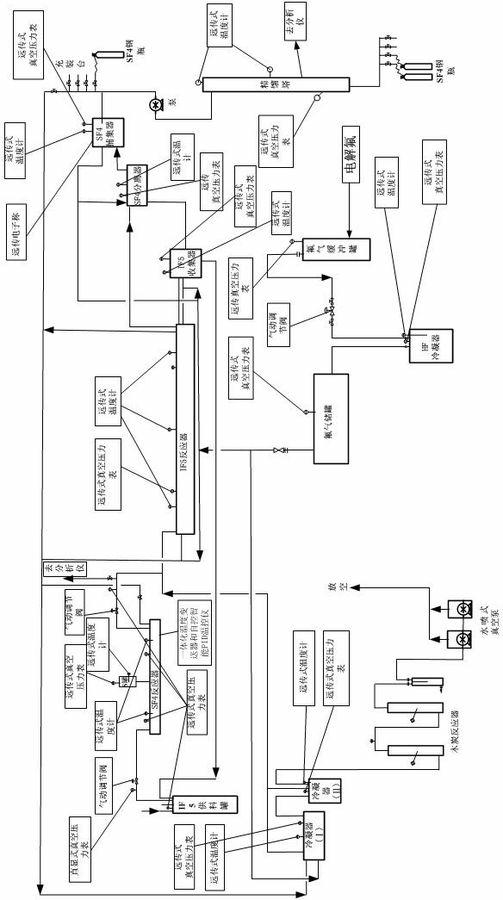

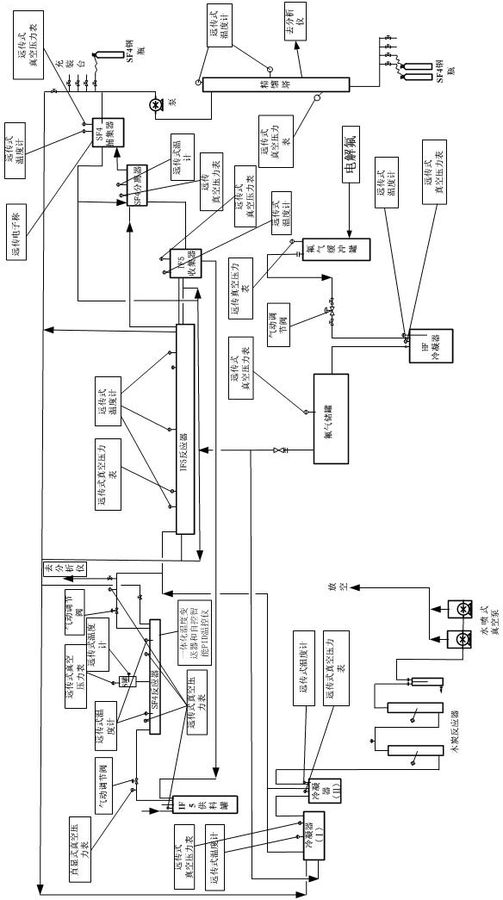

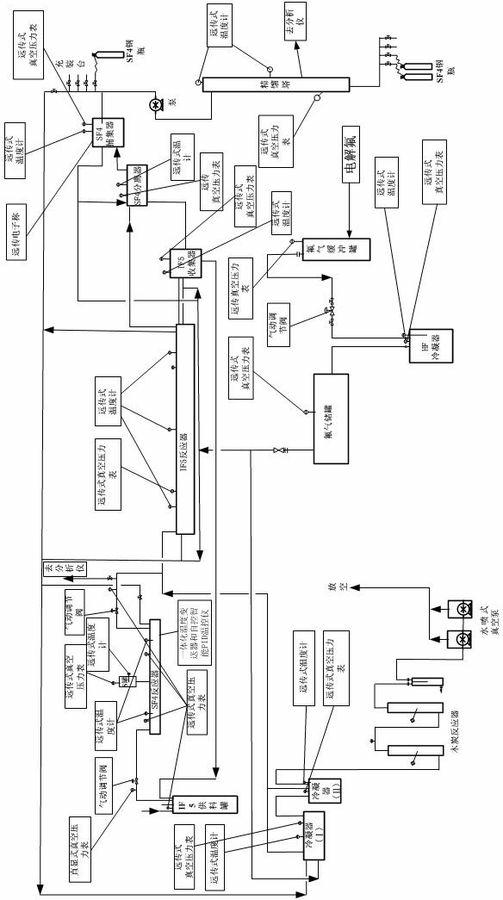

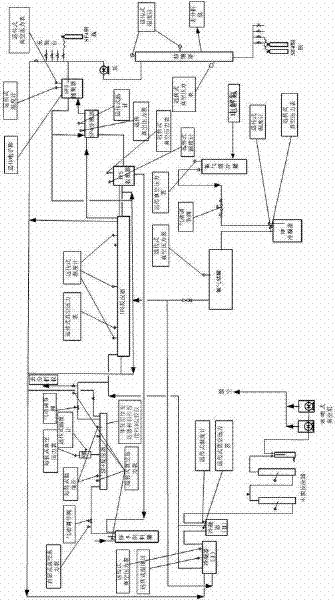

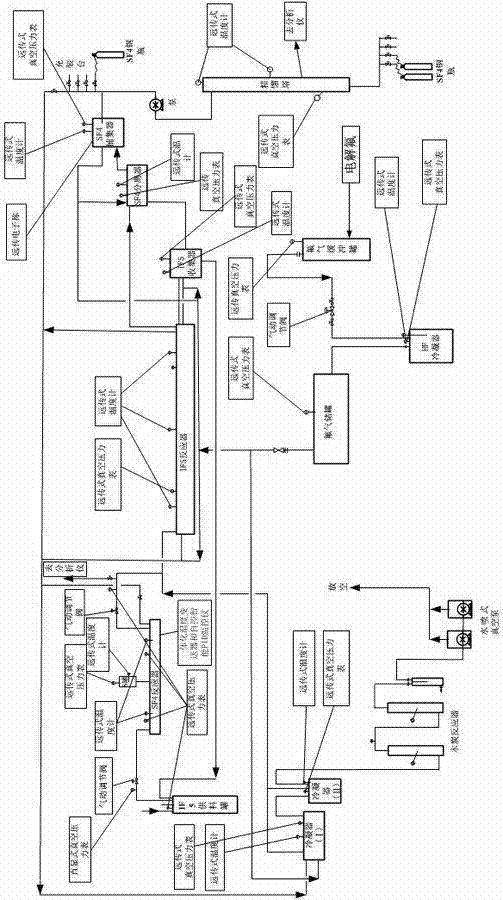

Automatic control of sulfur tetrafluoride production process

ActiveCN102079509AGuaranteed stabilityImprove stabilitySulfur and halogen compoundsAutomatic controlSulfur tetrafluoride

The invention relates to automatic control of a sulfur tetrafluoride production process, comprising the automatic control of sulfur tetrafluoride synthesis reaction, the automatic control of sulfur tetrafluoride cooling, separating and capturing, the automatic control of iodine pentafluoride preparation, the automatic control of fluoride preparation and purification, the automatic control of rectification and purification and the automatic control of recycling. The invention ensures the stability of the quality of the sulfur tetrafluoride product by adopting measures of system process control analysis, product mass spectrum analysis and chemical analysis and also ensures the continuous and stable running of production; the production process for synthesizing sulfur tetrafluoride adopts DCS (Distributed Control System) automation device control in the whole course, reduces artificial randomness and experience, improves the stability of the product quality as well as the purity, the yield and the production efficiency of the product and reduces the raw material waste and the production cost.

Owner:山东锐华氟业有限公司

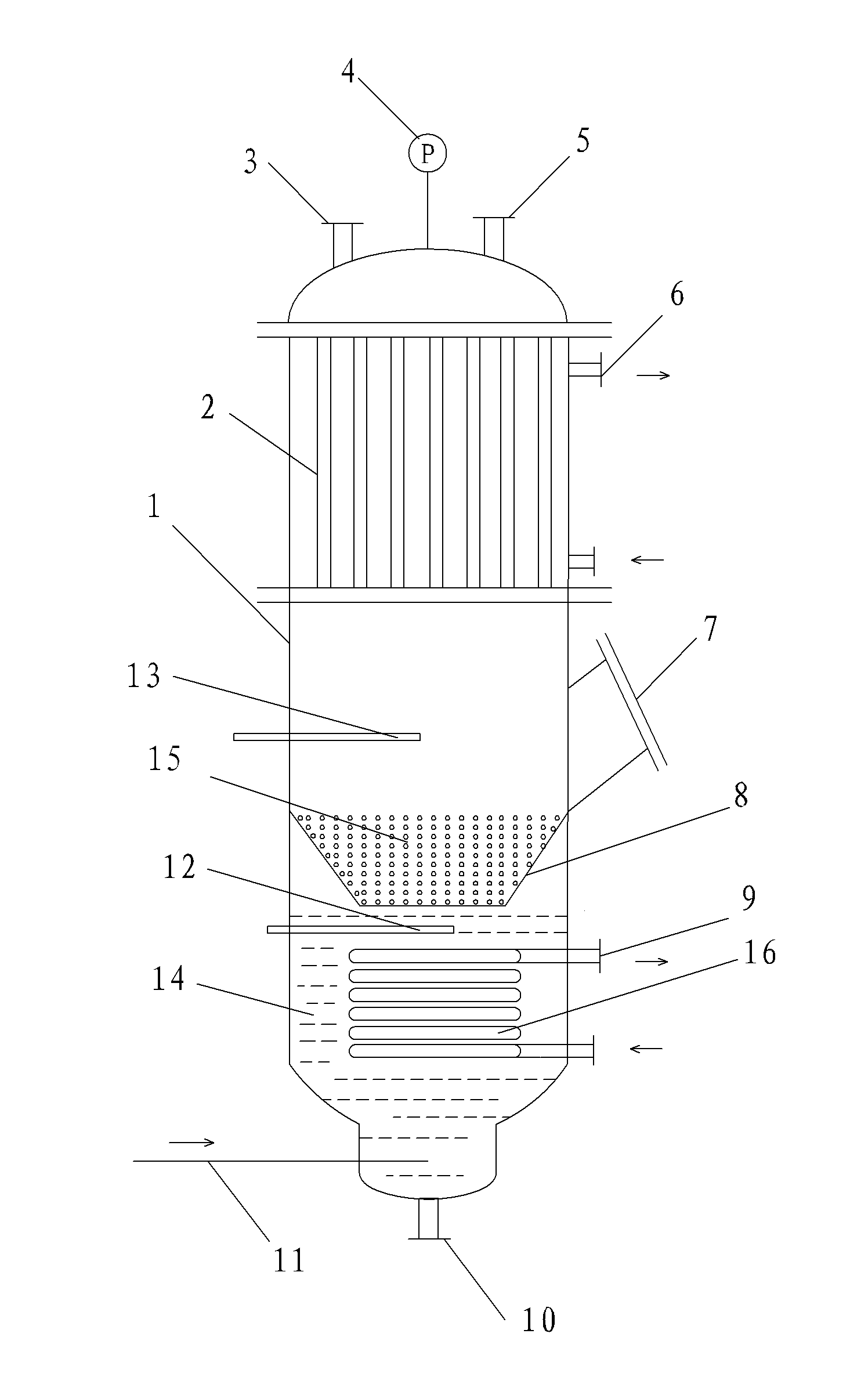

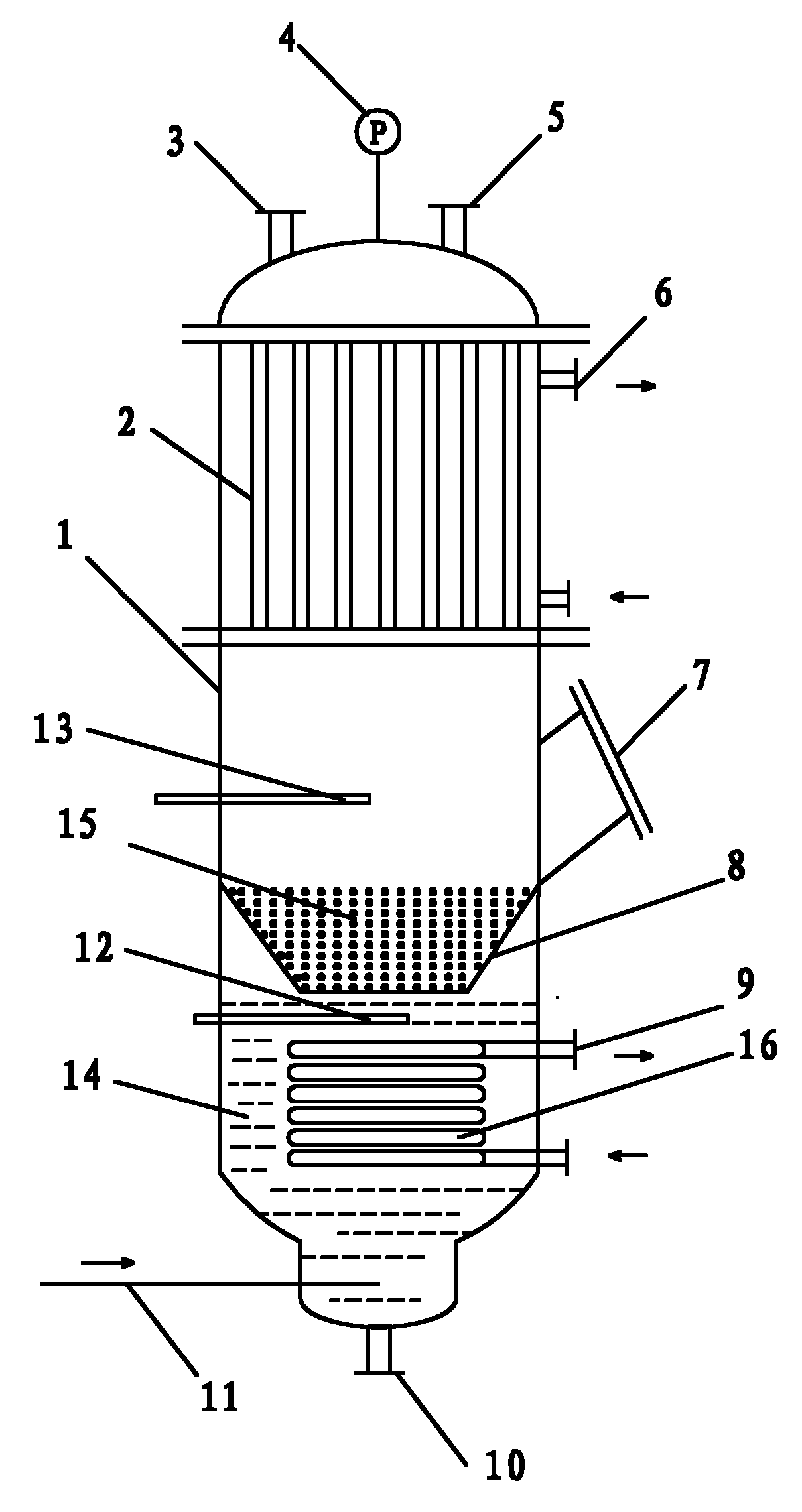

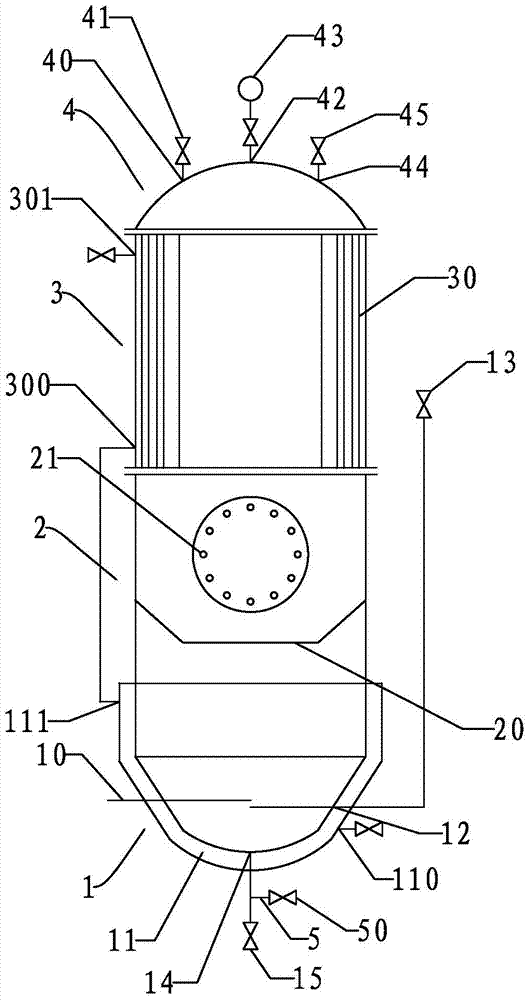

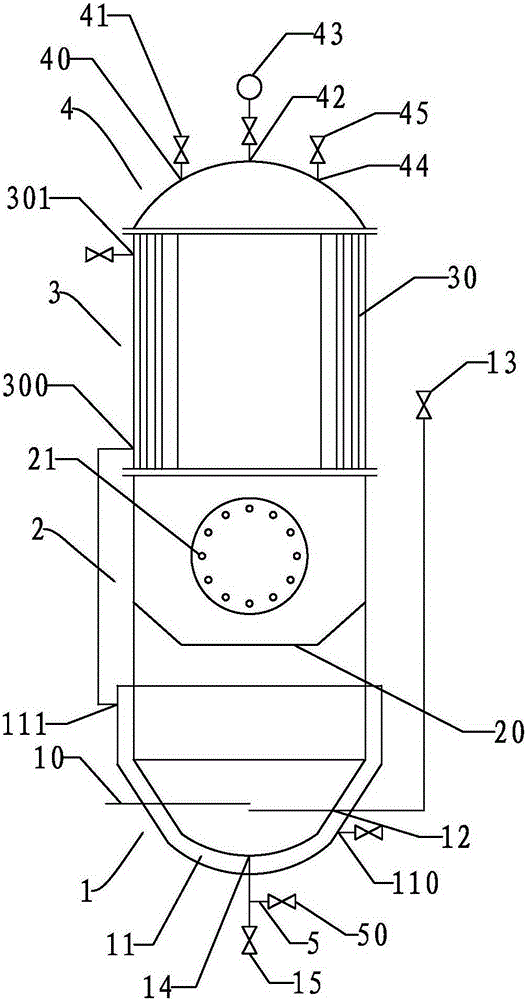

Iodine pentafluoride production equipment and production method

ActiveCN103754826AControl reaction speedTransfer in timeInter-halogen compoundsGas phaseIodine pentafluoride

The invention discloses an iodine pentafluoride production method characterized by continuous reaction, high yield, mild and complete reaction, and extremely light pollution degree. The method includes: in an airtight reactor, placing solid iodine above liquid iodine pentafluoride or an iodine pentafluoride solution of iodine; then introducing fluorine gas into the liquid iodine pentafluoride or the iodine pentafluoride solution of iodine, and simultaneously employing a flowable cooling medium to cool the liquid iodine pentafluoride or the iodine pentafluoride solution of iodine and the gas phase generated above solid iodine in a flow direction from the bottom up, controlling the temperature of the liquid iodine pentafluoride or the iodine pentafluoride solution of iodine at 15-100DEG C, and making the iodine pentafluoride steam and iodine steam in the gas phase generated above the solid iodine condense and flow back to the liquid iodine pentafluoride or the iodine pentafluoride solution of iodine. The invention also discloses production equipment special for the method.

Owner:FUJIAN YONGJING TECH CO LTD

Material recycling technique used during sulfur tetrafluoride production

ActiveCN102173394AReduce lossesReduce the amount of purification treatmentSulfur and halogen compoundsTrappingGas phase

The invention relates to a material recycling technique used during sulfur tetrafluoride production. Firstly, the coarse sulfur tetrafluoride gas is produced through reactive synthesis of iodine pentafluoride and sulfur in a sulfur tetrafluoride reactor and then raw materials are initially recycled through condensation, separation and trapping. The impure gases obtained by gas pahse purification during condensation, separation and trapping of sulfur tetrafluoride are evacuated and recovered again through a secondary condensation recovery device. The condensation recovery devices in the initial and secondary stages are utilized to recycle iodine and iodine pentafluoride, which can increase the utilization rate of iodine by more than 70%. The technique can not only reduce material losses and lower production cost but also cut down the volumes to be purified.

Owner:山东锐华氟业有限公司

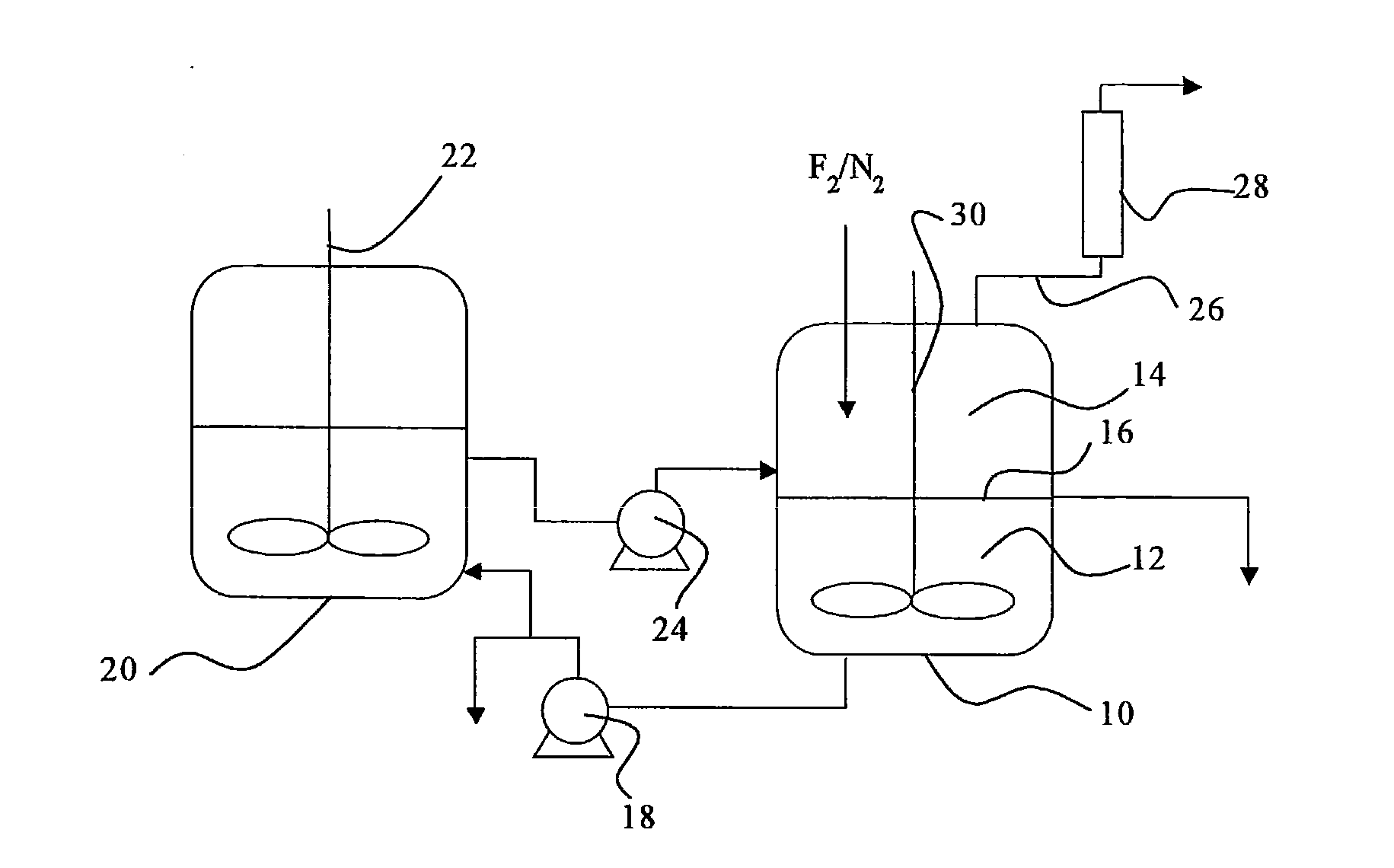

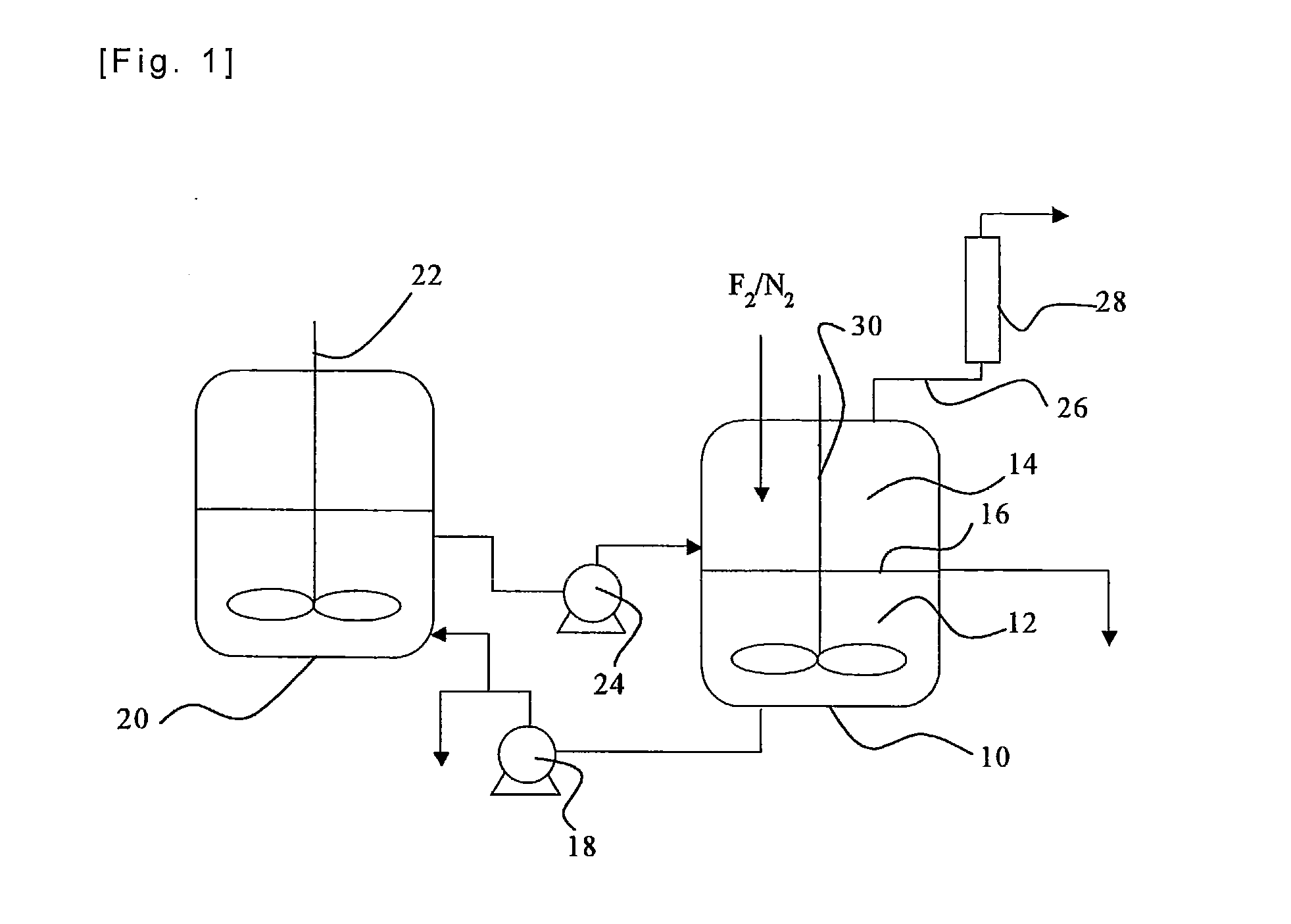

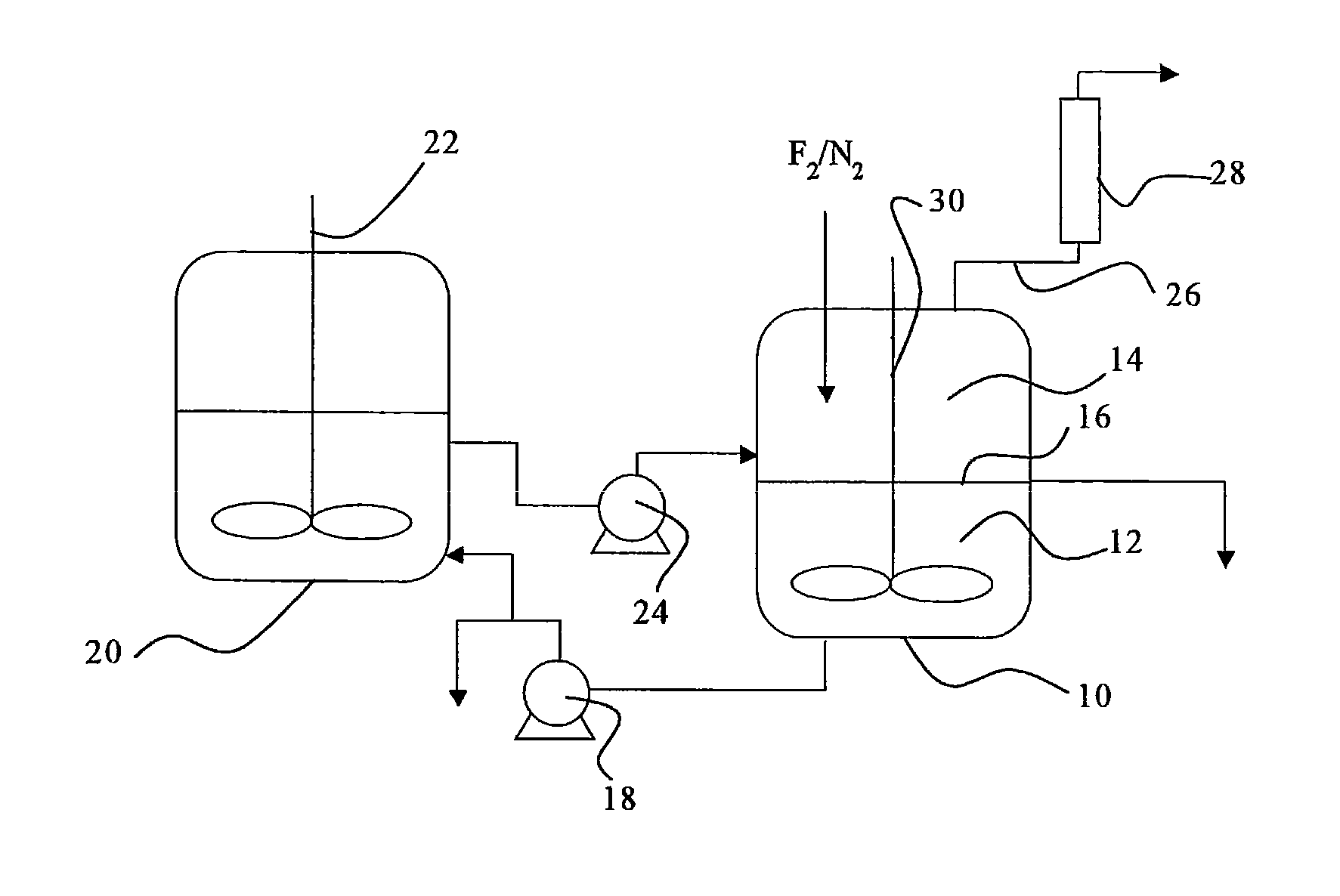

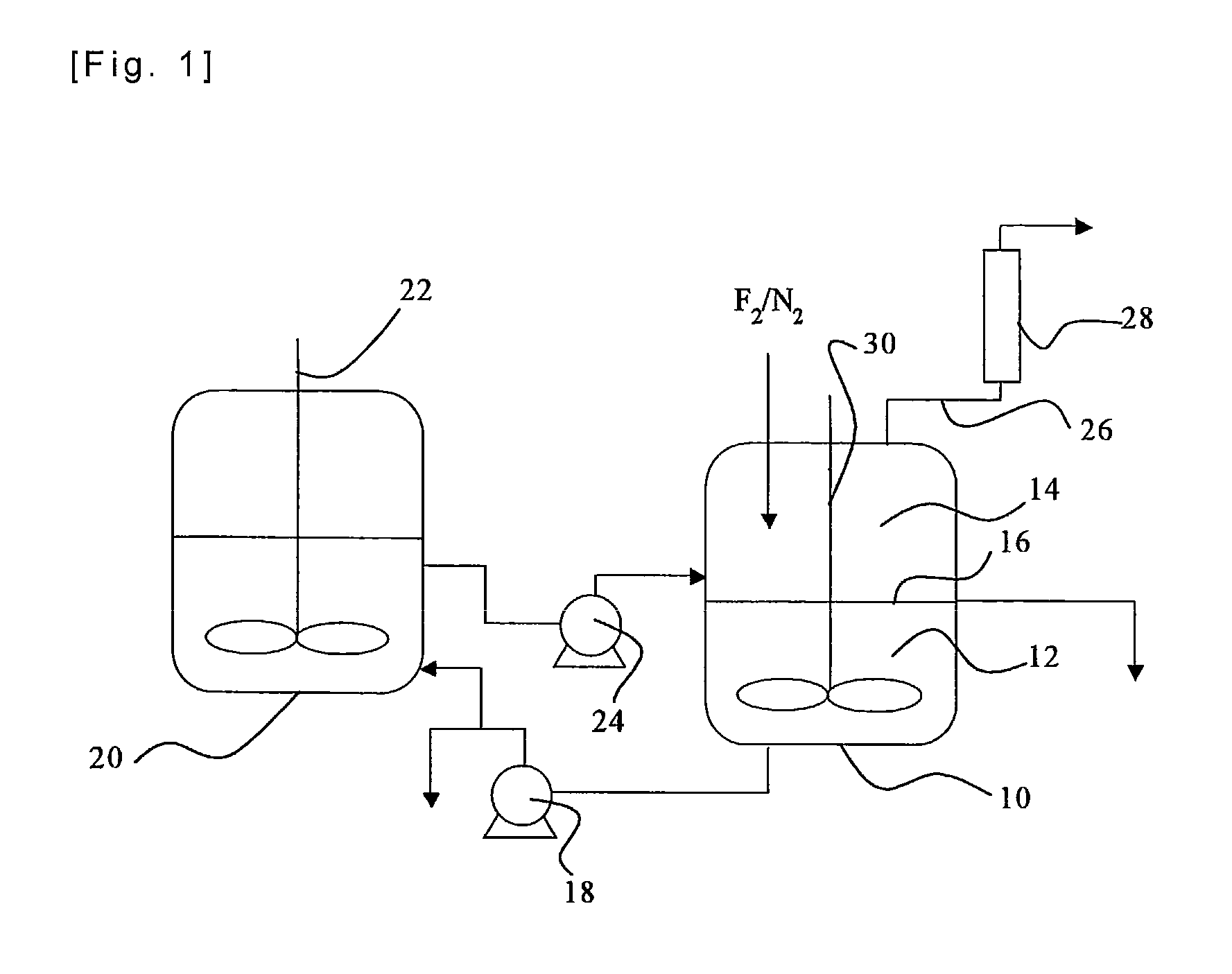

Process for production of iodine pentafluoride

InactiveUS20100166638A1Reduce depositionReduce solidificationFluoride preparationInter-halogen compoundsGas phaseIodine pentafluoride

There is provided a process for the production of iodine pentafluoride which avoids the problems of the production process of iodine pentafluoride of the prior art as much as possible, and which carries out the reaction of fluorine and iodine moderately, so that iodine pentafluoride is produced more safely and more productively.In the process for the production of iodine pentafluoride by reacting fluorine and iodine, fluorine is supplied to the gas phase 14 which is adjacent to the liquid phase 12 of iodine pentafluoride which contains iodine.

Owner:DAIKIN IND LTD

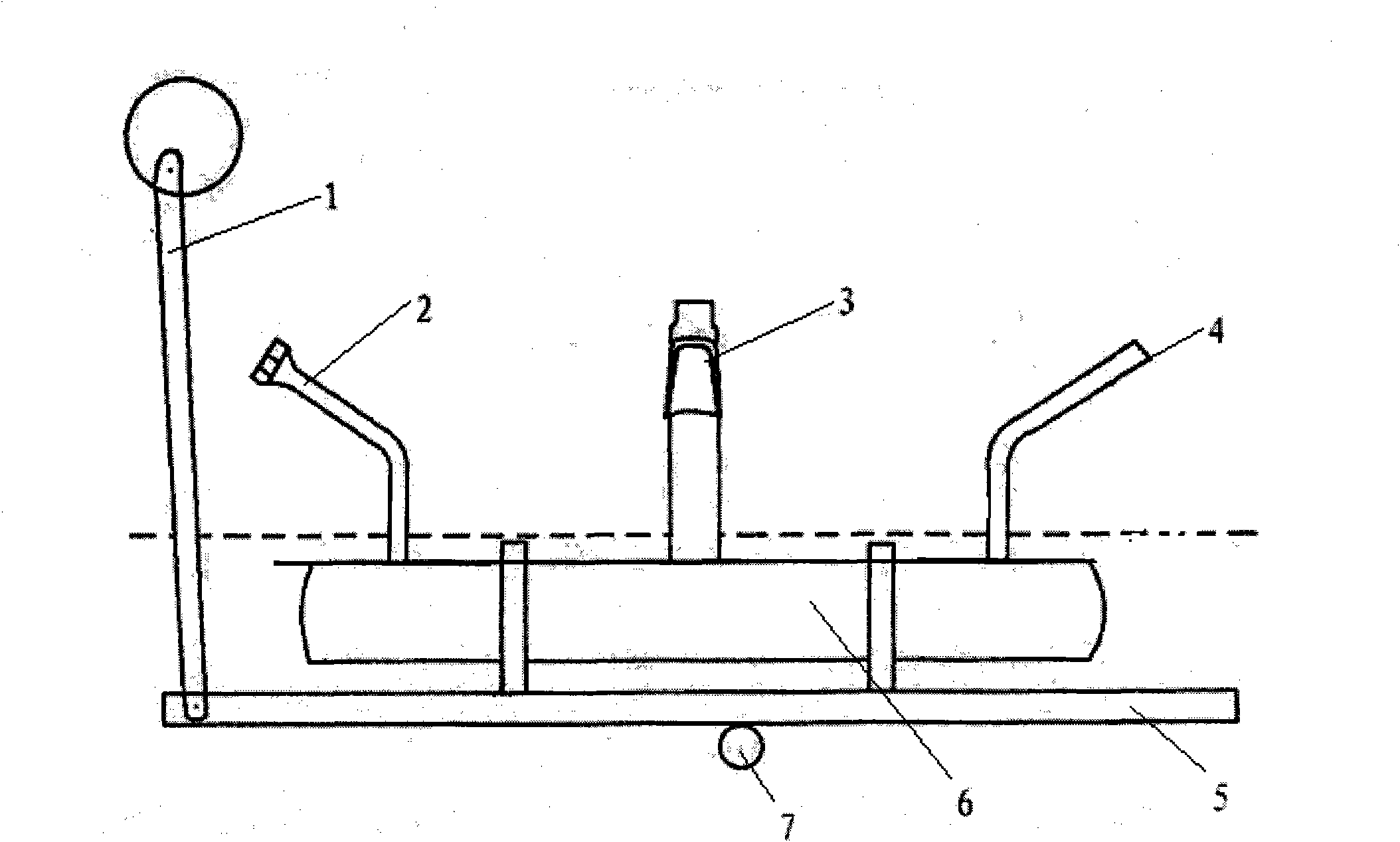

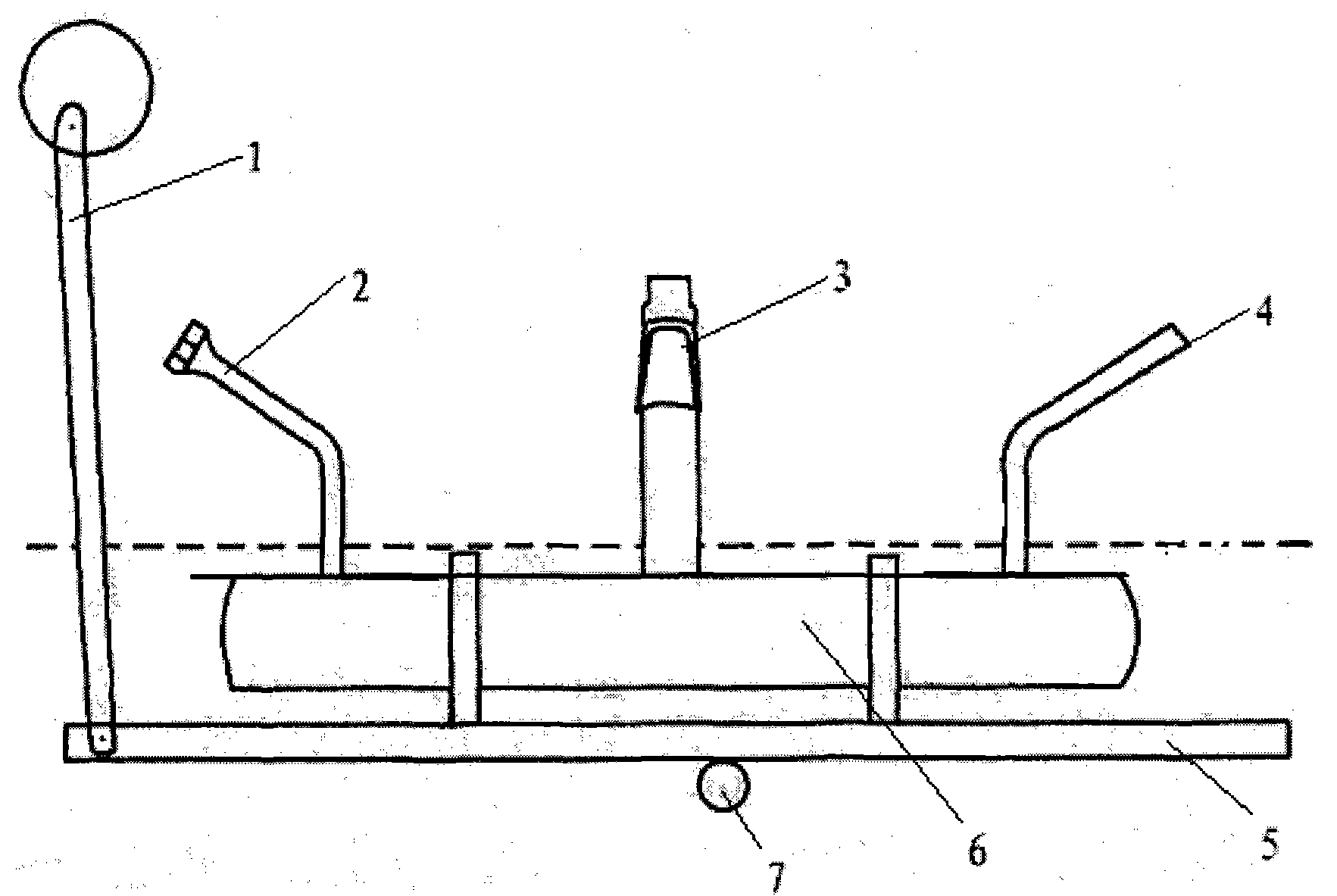

Technology for leading gaseous fluorine and solid iodine to carry out reaction for preparing iodine pentafluoride under room temperature

InactiveCN101966980ASolve pollutionReasonable workmanshipInter-halogen compoundsRoom temperatureIodine pentafluoride

The invention discloses a technology for leading gaseous fluorine and solid iodine to carry out reaction for preparing iodine pentafluoride under room temperature, which is mainly constituted as follows: a fluorine gas inlet pipe, an iodine powder adding pipe and a tail gas test pipe are communicated and mounted on a reactor which is integrally produced, an assembly is mounted on a platform, a fulcrum shaft is connected below the platform, an eccentric wheel is mounted beside the platform, and all the components are assembled into a whole. The technology has reasonable process, simple preparation and capability of solving the environmental pollution problem during the process of producing the iodine pentafluoride.

Owner:天津东方宜信物流有限公司

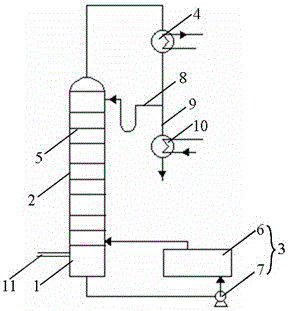

Method and equipment for distilling and purifying iodine pentafluoride

ActiveCN106276802AContinuous and stable acquisitionInter-halogen compoundsReboilerPhysical chemistry

The invention discloses a method and equipment for distilling and purifying iodine pentafluoride. The method comprises steps as follows: (I), performing a leakage test on a tower reactor; (II), performing feeding on the tower reactor; (III), performing vacuum pumping treatment; (IV), heating the tower reactor and receiving front cut fractions; (V), receiving main distillate fractions; (VI), performing after-cut fraction treatment. The equipment comprises a distillation column, the tower reactor, a tower bottom oil bath reboiler and a tower top fractional condenser. According to the method and the equipment for distilling, separating and purifying iodine pentafluoride prepared with an iodine and fluorine fluorination method, an iodine pentafluoride product with the purity of 99.5% or higher can be obtained continuously and stably, and the content of metal ions is 50 ppm or lower.

Owner:RES INST OF PHYSICAL & CHEM ENG OF NUCLEAR IND

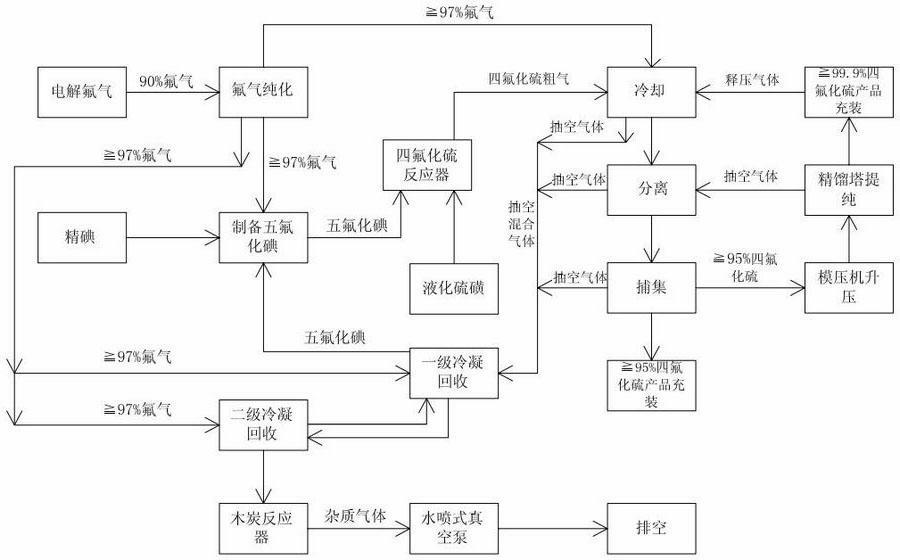

Process for purifying and rectifying sulfur tetrafluoride

ActiveCN102107857BHigh risk of operationProne to production accidentsSulfur and halogen compoundsSulfur tetrafluoridePhysical chemistry

The invention relates to a process for purifying and rectifying sulfur tetrafluoride, which comprises the following steps of: reacting iodine pentafluoride and sulfur in a sulfur tetrafluoride reactor to synthesize crude sulfur tetrafluoride gas, obtaining a liquid primary sulfur tetrafluoride product with purity of more than or equal to 95 percent through a cooler, a condensation separator and acondensation trap, obtaining a liquid sulfur tetrafluoride product with purity of more than or equal to 99.9 percent by a rectifying process, and continuously charging the product into a steel bottle. The liquid sulfur tetrafluoride product is directly trapped and produced and continuously liquefied and bottled, so damage of low-temperature bottling to the steel bottle is avoided, and the safety is higher. The purity of the sulfur tetrafluoride product is greatly improved by the cooling, separation, trapping and continuous rectification technology adopted in the process.

Owner:山东锐华氟业有限公司

Process for production of iodine pentafluoride

InactiveUS8057779B2Reduce depositionReduce solidificationFluoride preparationInter-halogen compoundsGas phaseIodine pentafluoride

There is provided a process for the production of iodine pentafluoride which avoids the problems of the production process of iodine pentafluoride of the prior art as much as possible, and which carries out the reaction of fluorine and iodine moderately, so that iodine pentafluoride is produced more safely and more productively. In the process for the production of iodine pentafluoride by reacting fluorine and iodine, fluorine is supplied to the gas phase 14 which is adjacent to the liquid phase 12 of iodine pentafluoride which contains iodine.

Owner:DAIKIN IND LTD

A kind of iodine pentafluoride production equipment and production method

ActiveCN103754826BControl reaction speedTransfer in timeInter-halogen compoundsGas phaseIodine pentafluoride

Owner:FUJIAN YONGJING TECH CO LTD

Method and equipment for rectifying and purifying iodine pentafluoride

ActiveCN106276802BContinuous and stable acquisitionInter-halogen compoundsReboilerPhysical chemistry

The invention discloses a method and equipment for distilling and purifying iodine pentafluoride. The method comprises steps as follows: (I), performing a leakage test on a tower reactor; (II), performing feeding on the tower reactor; (III), performing vacuum pumping treatment; (IV), heating the tower reactor and receiving front cut fractions; (V), receiving main distillate fractions; (VI), performing after-cut fraction treatment. The equipment comprises a distillation column, the tower reactor, a tower bottom oil bath reboiler and a tower top fractional condenser. According to the method and the equipment for distilling, separating and purifying iodine pentafluoride prepared with an iodine and fluorine fluorination method, an iodine pentafluoride product with the purity of 99.5% or higher can be obtained continuously and stably, and the content of metal ions is 50 ppm or lower.

Owner:RES INST OF PHYSICAL & CHEM ENG OF NUCLEAR IND

Sulfur tetrafluoride production technique

ActiveCN102173393BIncrease concentrationImprove conversion rateSulfur and halogen compoundsHydrogen fluorideElectrolysis

The invention relates to a sulfur tetrafluoride production technique, belonging to the field of fluorochemicals. The sulfur tetrafluoride production technique comprises fluorine gas purification, iodine pentafluoride preparation, sulfur tetrafluoride reactive synthesis, sulfur tetrafluoride separation and trapping, sulfur tetrafluoride distillation and canning, secondary recycling of iodine pentafluoride as well as discharge of exhaust gas. By using a low-temeprature condensing device, the electrolytic fluorine is purified to remove a great amount of hydrogen fluoride, so the fluorine gas concentration is largely improved. A condensing and recycling device is employed to recycle iodine and iodine pentafluoride for re-use, thus the utilization ratio of iodine can reach above 70% and material losses can be reduced. Due to a constant distillation method, the purity of sulfur tetrafluoride products can reach above 99.9%, and the products can be charged into a steel cylinder more safely. In addition, the entire sulfur tetrafluoride production technique is controlled by a automatic DCS (distributed control system) device, which reduces artificial randomness and experience and improves the stability of product quality.

Owner:山东锐华氟业有限公司

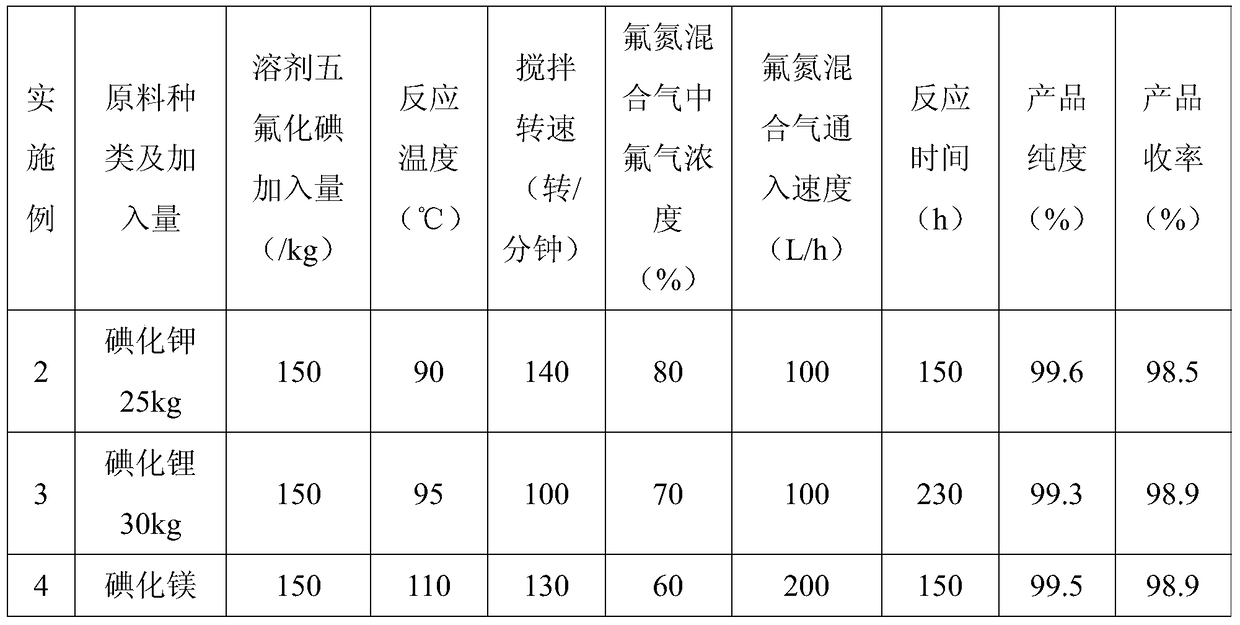

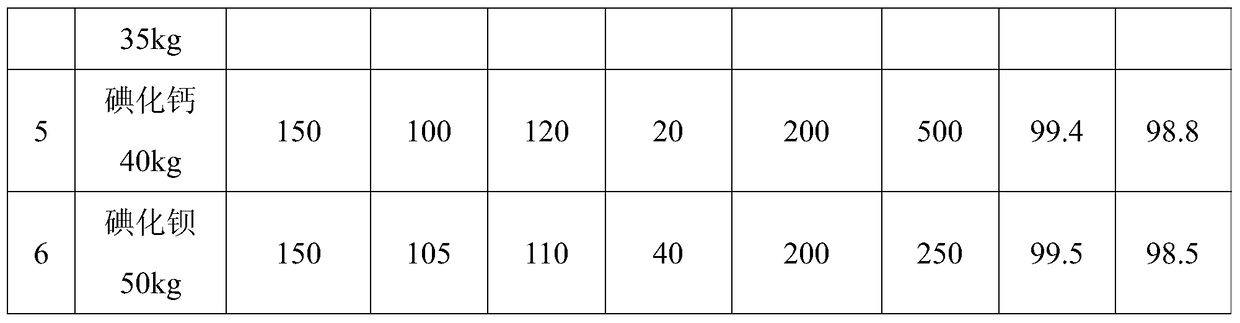

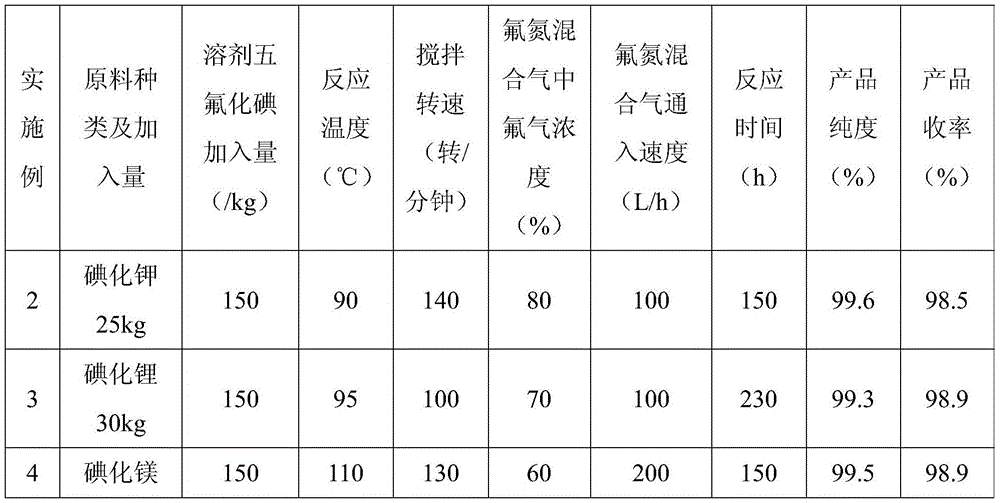

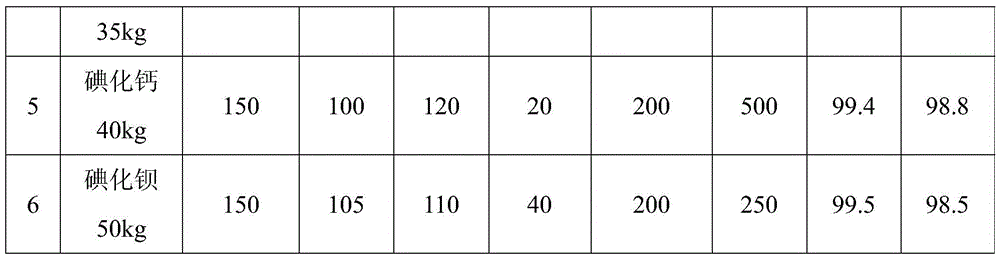

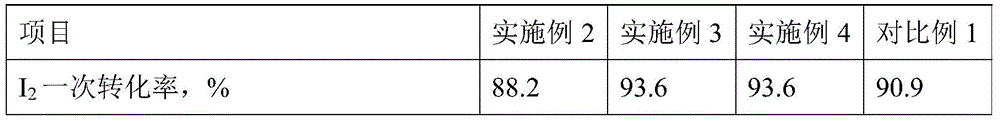

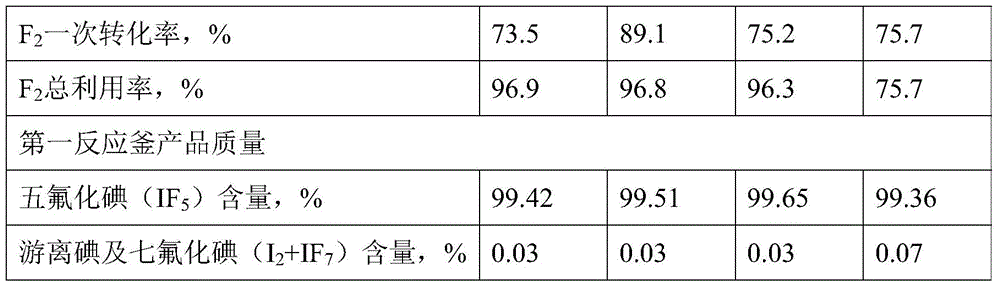

A kind of preparation method of iodine pentafluoride

ActiveCN105523522BAvoid using directlyAvoid sublimationInter-halogen compoundsAlkaline earth metalReaction temperature

The invention discloses a preparation method of iodine pentafluoride. According to the preparation method, iodized alkali metal salt or iodized alkaline-earth metal salt is used as a raw material, iodine pentafluoride is used as a solvent, and a fluorine-nitrogen gas mixture is continuously introduced. At the reaction temperature of 50-150 DEG C, the iodized alkali metal salt or alkaline-earth metal salt is fluorinated for 150-500 h so as to obtain iodine pentafluoride. The invention has advantages as follows: the technology is simple; the raw material is easily available; reaction efficiency is high; and the method is green and environmentally friendly and is suitable for industrial production.

Owner:JUHUA GROUP TECH CENT

Preparation method of iodine pentafluoride

ActiveCN105523522AAvoid using directlyAvoid sublimationInter-halogen compoundsAlkaline earth metalReaction temperature

The invention discloses a preparation method of iodine pentafluoride. According to the preparation method, iodized alkali metal salt or iodized alkaline-earth metal salt is used as a raw material, iodine pentafluoride is used as a solvent, and a fluorine-nitrogen gas mixture is continuously introduced. At the reaction temperature of 50-150 DEG C, the iodized alkali metal salt or alkaline-earth metal salt is fluorinated for 150-500 h so as to obtain iodine pentafluoride. The invention has advantages as follows: the technology is simple; the raw material is easily available; reaction efficiency is high; and the method is green and environmentally friendly and is suitable for industrial production.

Owner:JUHUA GROUP TECH CENT

Method for preparing nano graphite fluoride at low temperature

ActiveCN108439367AMany active sitesHigh activityMaterial nanotechnologyCarbon fluoridesSynthesis methodsFiltration

The invention discloses a method for preparing nano graphite fluoride at a low temperature. The method comprises the following steps that (1) nano graphite, citric acid and absolute ethyl alcohol aremixed to be uniform and activated for 3-5 hours at the temperature of 120-130 DEG C, after the temperature of the mixed liquid is decreased to be room temperature, silver fluoride and iodine pentafluoride are added in the mixed liquid, the mixed liquid is reacted for 1.5 to 2 hours at the temperature of 37-52 DEG C, and a reaction product is obtained; (2) the reaction product is subjected to vacuum filtration to obtain a solid product, the solid product is added into a potassium iodide solution to be stirred and then filtered, after the obtained filter residue is treated, nano graphite subjected to pretreatment is obtained; and (3) mixed gas of fluorine and nitrogen is injected into the nano graphite subjected to pretreatment to react for 1.5-2.5 hours at the temperature of 200-240 DEG C,and a finished product is obtained. Compared with a high temperature gas phase synthesis method, the graphite intercalation compound has higher activity than graphite, is more liable to react with fluorine, the content of fluorine is higher, the reaction temperature is lower, and the safety is higher.

Owner:HUBEI ZHUOXI FLUOROCHEM

A kind of preparation method and production equipment of iodine pentafluoride

ActiveCN104326443BRealize continuous productionIncrease profitInter-halogen compoundsNitrogenIodine pentafluoride

The invention discloses a preparation method and production device of iodine pentafluoride. The preparation method comprises following steps: (1) adding iodine pentafluoride and molten iodine respectively into a first reaction kettle and a second reaction kettle to form a mixed system; (2) feeding a mixed gas containing fluorine and nitrogen into the first reaction kettle, feeding the rest mixed gas into the second reaction kettle for reaction, and discharging the rest gas; (3) when the reaction in the first reaction kettle is finished, discharging generated iodine pentafluoride and then preparing the mixed system; (4) feeding the mixed gas containing fluorine and nitrogen into the second reaction kettle, feeding the rest mixed gas into the first reaction kettle for reaction, and discharging the rest gas; (5) when the reaction in the second reaction kettle is finished, discharging generated iodine pentafluoride and then preparing the mixed system; and (6) repeatedly performing the operations from the step (2) to the step (5). The preparation method achieves continuous production of the iodine pentafluoride and increase a utilization ratio of the raw materials. A product is stable in quality and high in yield. Meanwhile, waste of a fluorine resource and environmental pollution are avoided.

Owner:DO FLUORIDE CHEM CO LTD

A kind of synthetic method of 1,3,3,3-tetrafluoropropene

ActiveCN105481638BEasy to operateLess investmentPreparation by hydrogen halide split-offPreparation by halogen addition1,3,3,3-TetrafluoropropeneGas phase

The invention discloses a synthetic method for 1,3,3,3-tetrafluoropropene. The synthetic method comprises the following steps: (1) adding a mixture of iodine, iodine pentafluoride and a catalyst into a reactor, controlling reaction temperature, introducing trifluoropropene, and stopping the reaction when system pressure is stable so as to obtain 1,3,3,3-tetrafluoro-2-iodopropane, wherein a mass ratio of iodine to iodine pentafluoride is 1: 0.4-0.5, a mass ratio of iodine to the catalyst is 1: 0.01-0.05, reaction temperature is -15 to 35 DEG C and reaction pressure is 0.1 to 0.6 MPa; and (2) evaporating the material 1,3,3,3-tetrafluoro-2-iodopropane in the reactor, introducing the evaporated 1,3,3,3-tetrafluoro-2-iodopropane into a reactor filled with alkali lye, carrying out a reaction at normal pressure, and subjecting a gas phase product to drying and compression so as to obtain the product 1,3,3,3-tetrafluoropropene, wherein reaction temperature is 35 to 80 DEG C. The method provided by the invention has the advantages of simple equipment, high operation security, high product purity, etc.

Owner:JUHUA GROUP TECH CENT

Material recycling technique used during sulfur tetrafluoride production

ActiveCN102173394BReduce lossesReduce the amount of purification treatmentSulfur and halogen compoundsSulfur tetrafluoridePhysical chemistry

The invention relates to a material recycling technique used during sulfur tetrafluoride production. Firstly, the coarse sulfur tetrafluoride gas is produced through reactive synthesis of iodine pentafluoride and sulfur in a sulfur tetrafluoride reactor and then raw materials are initially recycled through condensation, separation and trapping. The impure gases obtained by gas pahse purification during condensation, separation and trapping of sulfur tetrafluoride are evacuated and recovered again through a secondary condensation recovery device. The condensation recovery devices in the initial and secondary stages are utilized to recycle iodine and iodine pentafluoride, which can increase the utilization rate of iodine by more than 70%. The technique can not only reduce material losses and lower production cost but also cut down the volumes to be purified.

Owner:山东锐华氟业有限公司

Method for continuously preparing iodine pentafluoride

ActiveCN102556974BThe reaction temperature is easy to controlReaction temperature safetyInter-halogen compoundsProcess equipmentReaction temperature

The invention discloses a method for continuously preparing iodine pentafluoride. According to the method, a serial process flow of a multistage tower type reactor is adopted; according to process requirement, the tower number can be 1-N grades, wherein N is more than or equal to 3; in the atmosphere containing sulfuryl fluoride (RfSO2F), an iodine pentafluoride solution of iodine and fluoride gas or mixed gas of fluoride and nitrogen respectively enter a multistage reaction tower from two ends, reversely flow and generate a reaction. The method has the advantages that the reaction temperature is controllable, higher safety is ensured and the phenomenon that the iodine is excessively fluoridized at high temperature to generate IF7 is avoided; two iodine dissolving tanks are alternatively used so as to facilitate the continuous atomization; the sulfuryl fluoride atmosphere facilitates the operation of a gas-liquid reaction and is remarkably superior to the hydrogen fluoride existing atmosphere introduced in other patents, so that the purification of products is facilitated; and unreacted fluoride gas in tail gas can be adsorbed by solid salts or alkali and then be recycled. The process equipment and parts are made of general steel; and pitting-free chemical nickel-plating treatment and fluorine gas passivation treatment are used in sequence so as to effectively reduce the investment cost and facilitate the industrialization.

Owner:HUBEI ZHUOXI FLUOROCHEM

Novel technology for preparing pentafluoroethyl iodide by one-step method

ActiveCN102351636BLess investmentSave energyPreparation by halogen additionCorrosive chemicalProcess equipment

A technology for preparing pentafluoroethyl iodide by a one-step method. By the adoption of a multiple-stage tower reactor series connection process flow (N is greater than or equal to 2 upon the process requirements), an iodine pentafluoride solution, a gas mixture of perfluoroalkyl sulfonyl fluoride and fluorine nitrogen and tetrafluoroethene respectively enter into the multiple-stage tower reactor from two ends and countercurrently flow for reaction. The invention has the following advantages: fluorine gas, iodine and tetrafluoroethene are used as raw materials to react so as to synthesize pentafluoroethyl iodide in one step; the newborn iodine pentafluoride in the invention has high activity and can perform a mild reaction at the temperature of 60-65 DEG C; the catalyst perfluoroalkyl sulfonyl fluoride can be used as a catalyst and a surfactant to raise the reaction rate and the yield; two iodine-eroded grooves and a tail gas absorbing tower cooperate and are alternatively used to make the reaction continuously automated; unreacted fluorine gas can be adsorbed by active alumina and then recovered and reused; the technological equipment and parts, which are made from regular steel, undergo a pock-free electroless nickel plating treatment and a fluorine passivation treatment, so as to prevent the damage of corrosive chemicals to the equipment, reduce the investment cost and benefit for industrialization.

Owner:HUBEI ZHUOXI FLUOROCHEM

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com