Preparation method of iodine pentafluoride

A technology of iodine pentafluoride and fluorination, which is applied in the field of fluorine-containing compounds, can solve the problems of limited production scale and low output, and achieve the effects of improved utilization rate, low cost and high reaction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Add 20kg sodium iodide and solvent iodine pentafluoride 150kg in the reaction kettle (material: stainless steel 316L, pressure resistance: 1.0MPa) with reflux condenser and stirring, start stirring, and the rotating speed is 150 rev / mins, then add to reaction solution The fluorine-nitrogen mixed gas with a volume concentration of 95% of fluorine gas is passed into the reaction tank for reaction, the speed of feeding the fluorine-nitrogen mixed gas is 50L / h, the reaction temperature in the reactor is controlled at 85°C, and the tail gas generated by the reaction is condensed and refluxed. The non-condensable gas is sent to the tail gas absorption system. After 180 hours of reaction, stop feeding the mixed gas of fluorine and nitrogen, filter and distill the reaction solution in the reactor to obtain 179.3kg of iodine pentafluoride, and remove 150kg of iodine pentafluoride as a solvent. Obtain 29.3kg of iodine pentafluoride product, the yield is 98.9%, and the product puri...

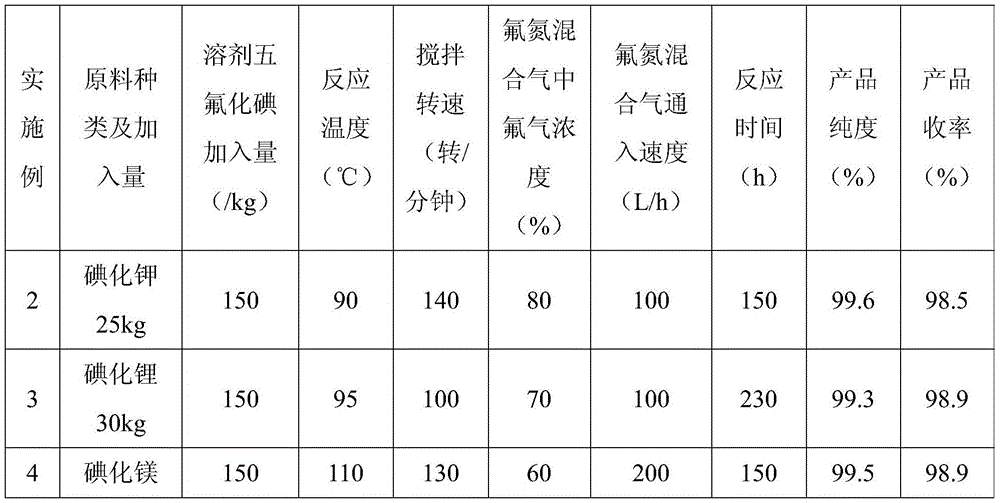

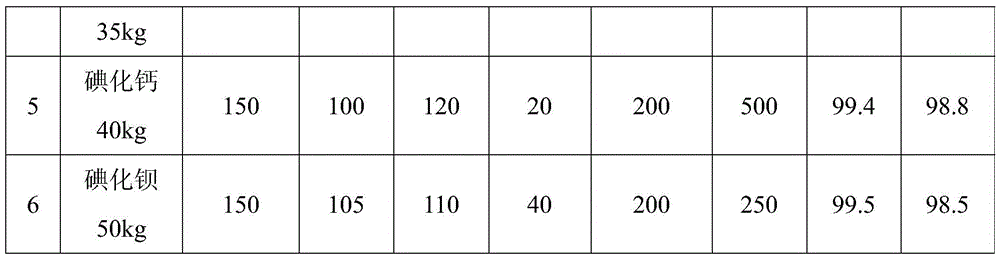

Embodiment 2~6

[0030] The operating method is the same as in Example 1, and the test conditions and results are shown in the following table.

[0031]

[0032]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com