Patents

Literature

90results about "Ether preparation by organic exchange" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Droplet Microreactor

InactiveUS20080124252A1Improve purification effectInexpensive to fabricateChemical/physical/physico-chemical microreactorsMaterial analysis by electric/magnetic meansMicroreactorLab-on-a-chip

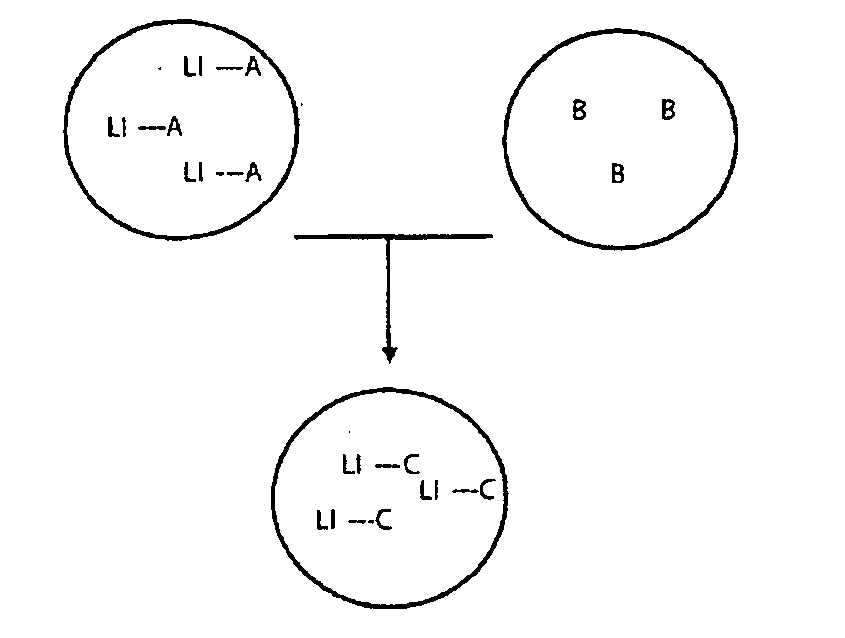

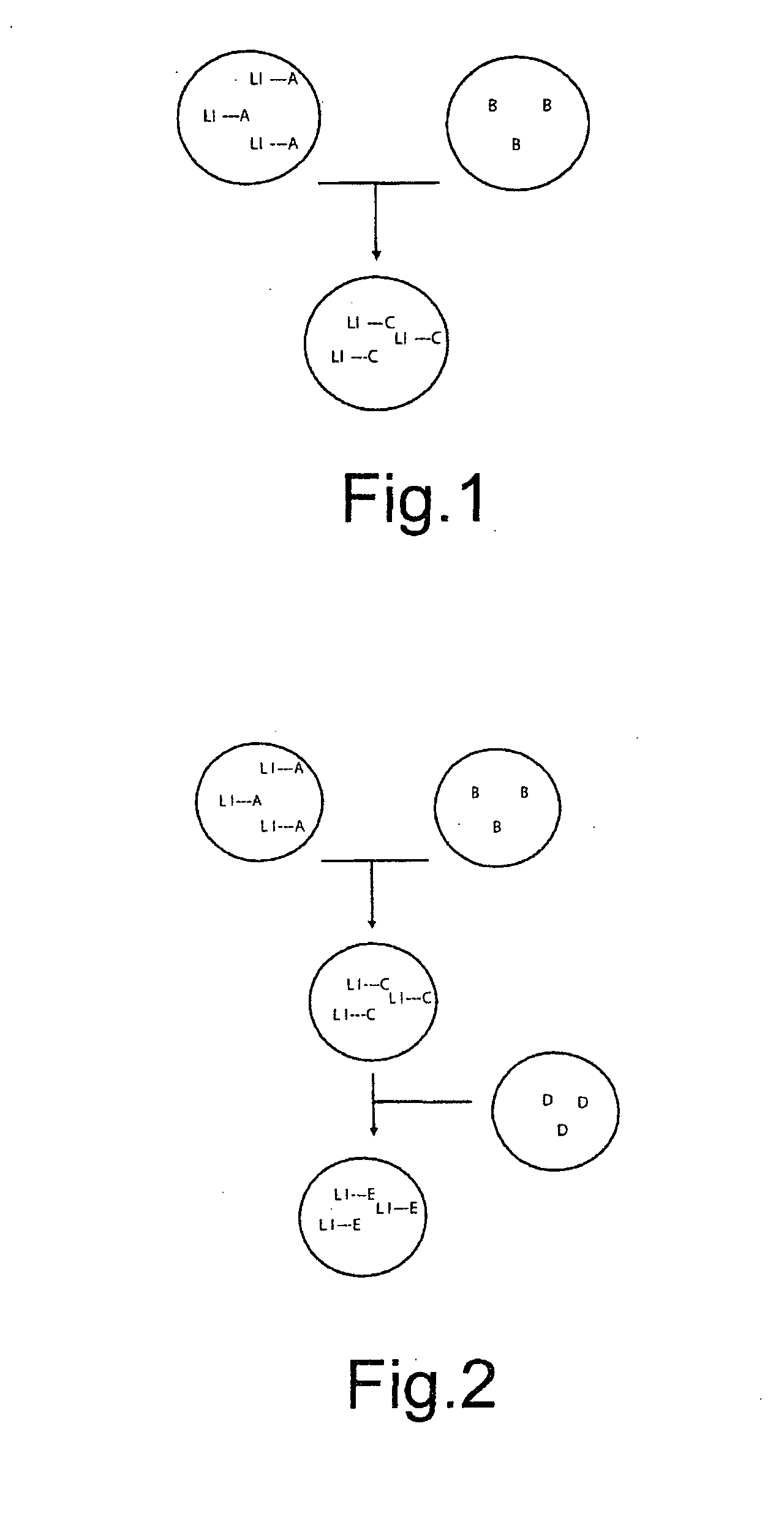

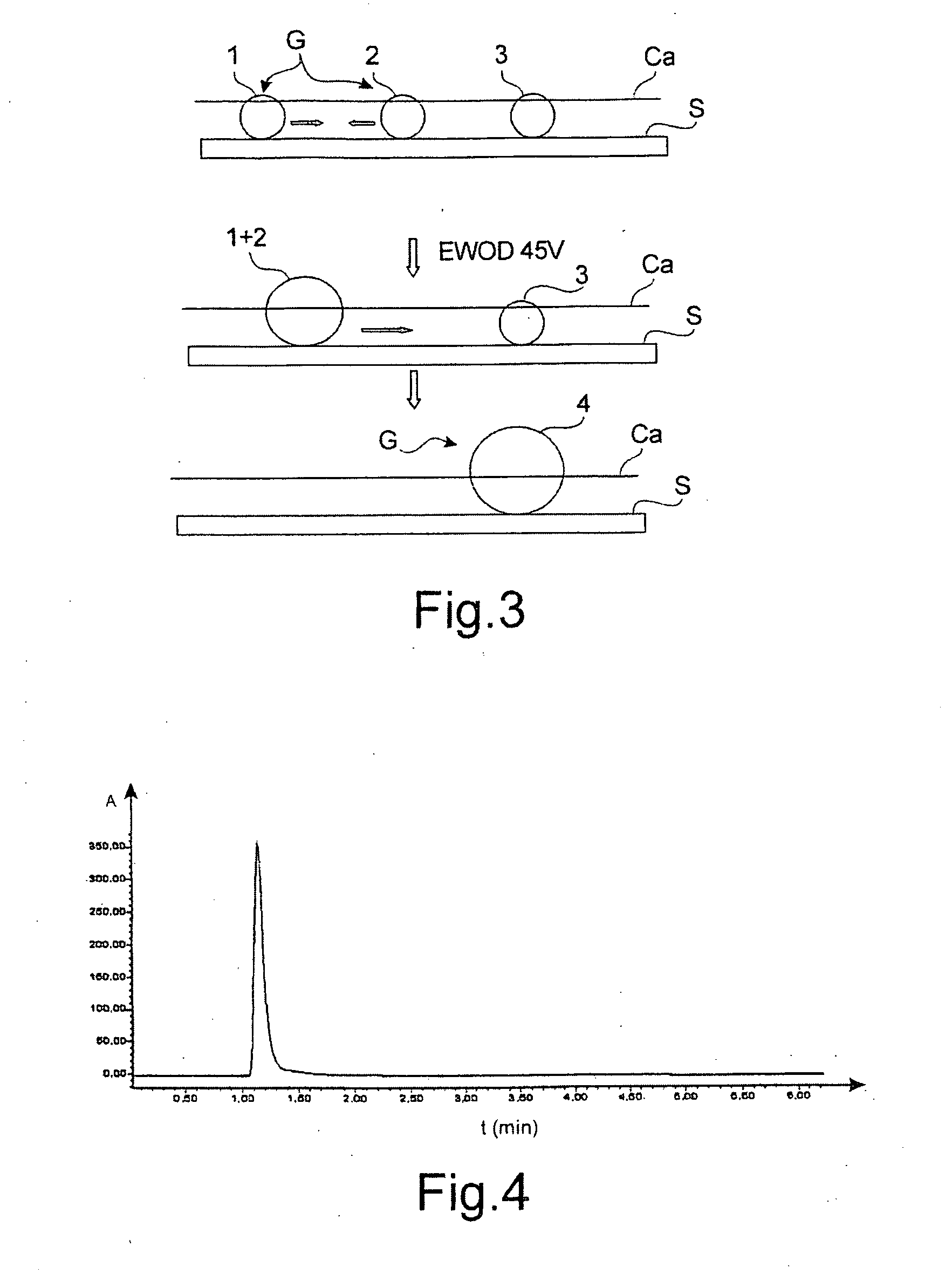

The present invention relates to a droplet microreactor, i.e. a microreactor consisting of a droplet of a specific liquid, the microreactor being wall-less, wherein the interface of the specific liquid with the ambient environment and with the support on which the droplet is deposited defines the limits of the microreactor. The microreactor is characterized in that it consists of a droplet comprising at least one ionic liquid. The present invention also relates to methods for carrying out chemical or biochemical reactions and / or mixes using said droplet microreactor, and also to a lab-on-chip comprising a microreactor according to the invention.

Owner:COMMISSARIAT A LENERGIE ATOMIQUE ET AUX ENERGIES ALTERNATIVES +1

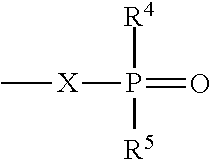

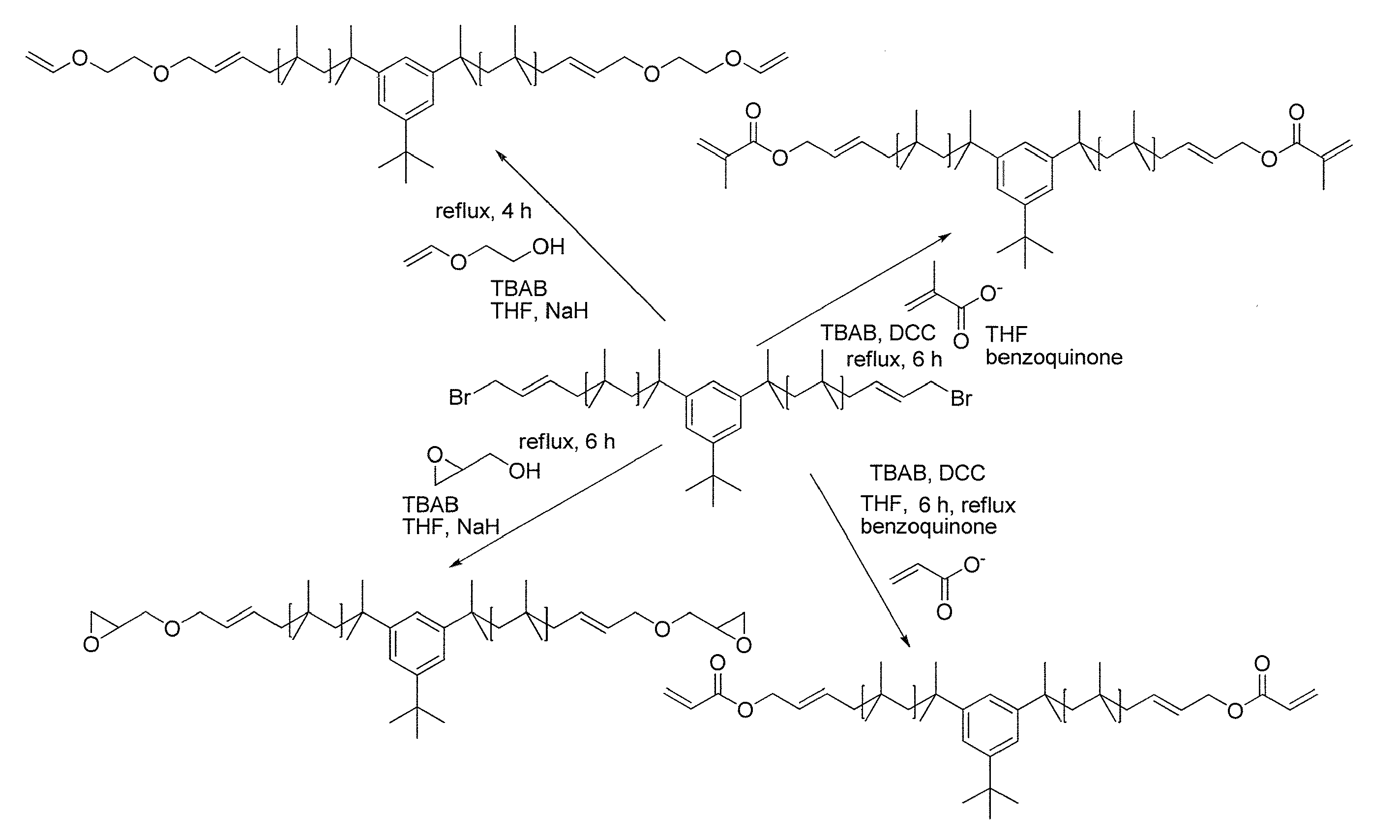

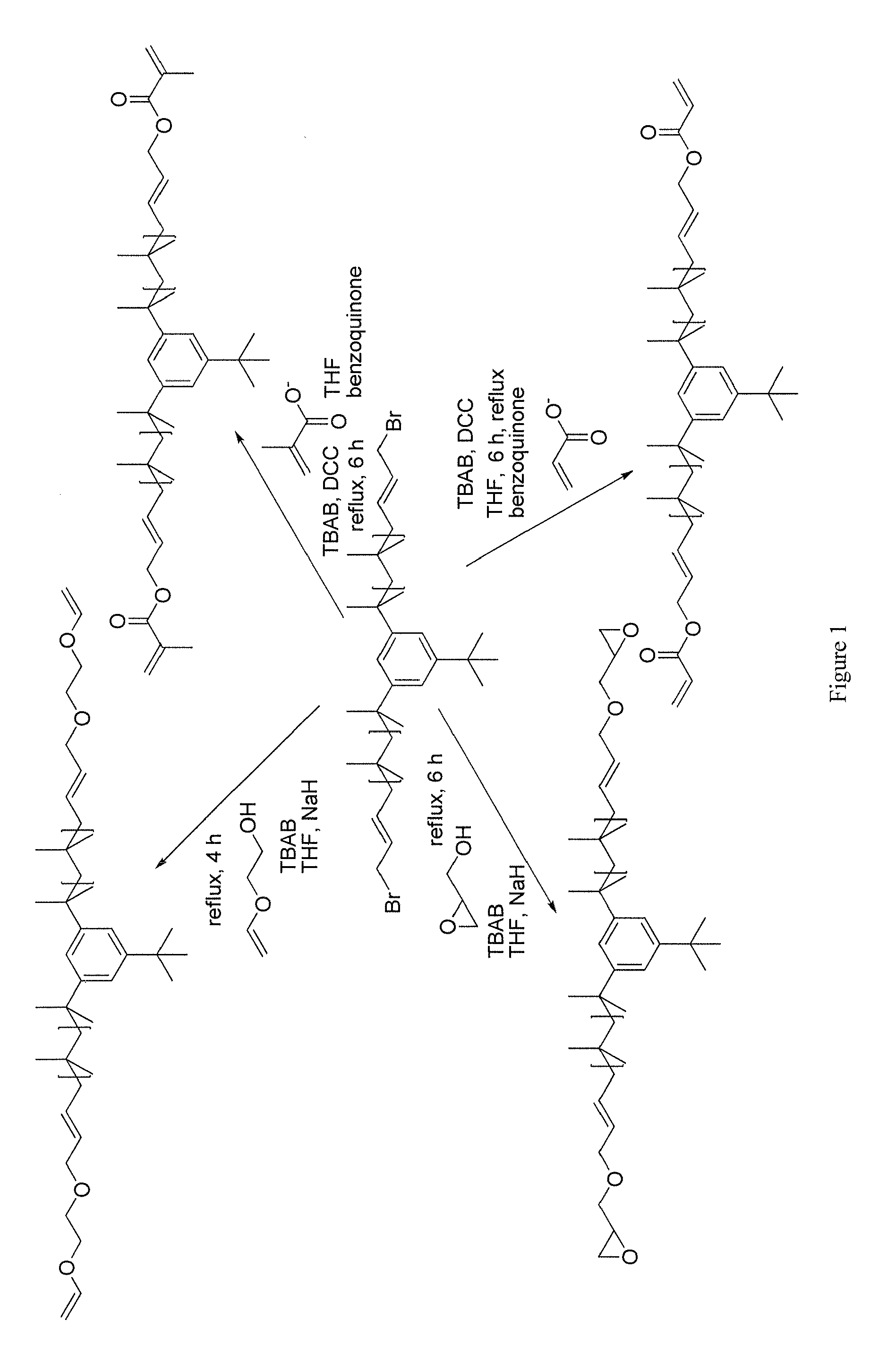

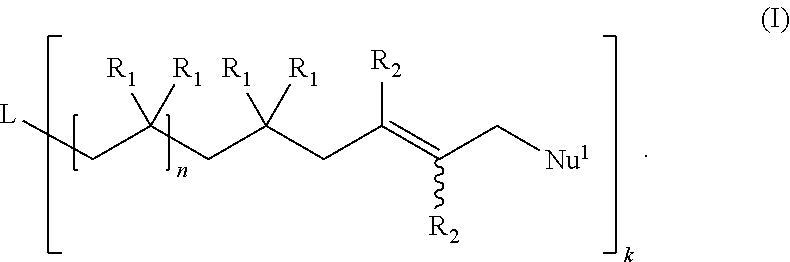

Functional Polyisobutylene Based Macromonomers And Methods For Making And Using The Same

InactiveUS20120077934A1Easily and economically preparedOrganic compound preparationCarboxylic acid esters preparationStructural formulaMacromonomer

A method of synthesizing a functionalized polymer represented by the structural formula (I) comprising a step of reacting a polymer represented by structural formula (II) with a compound Nu1-M to nucleophilically substitute moiety X1 with moiety Nu1. Values and preferred values of the variables in formulas (I) and (II) are defined herein.

Owner:UNIV OF MASSACHUSETTS

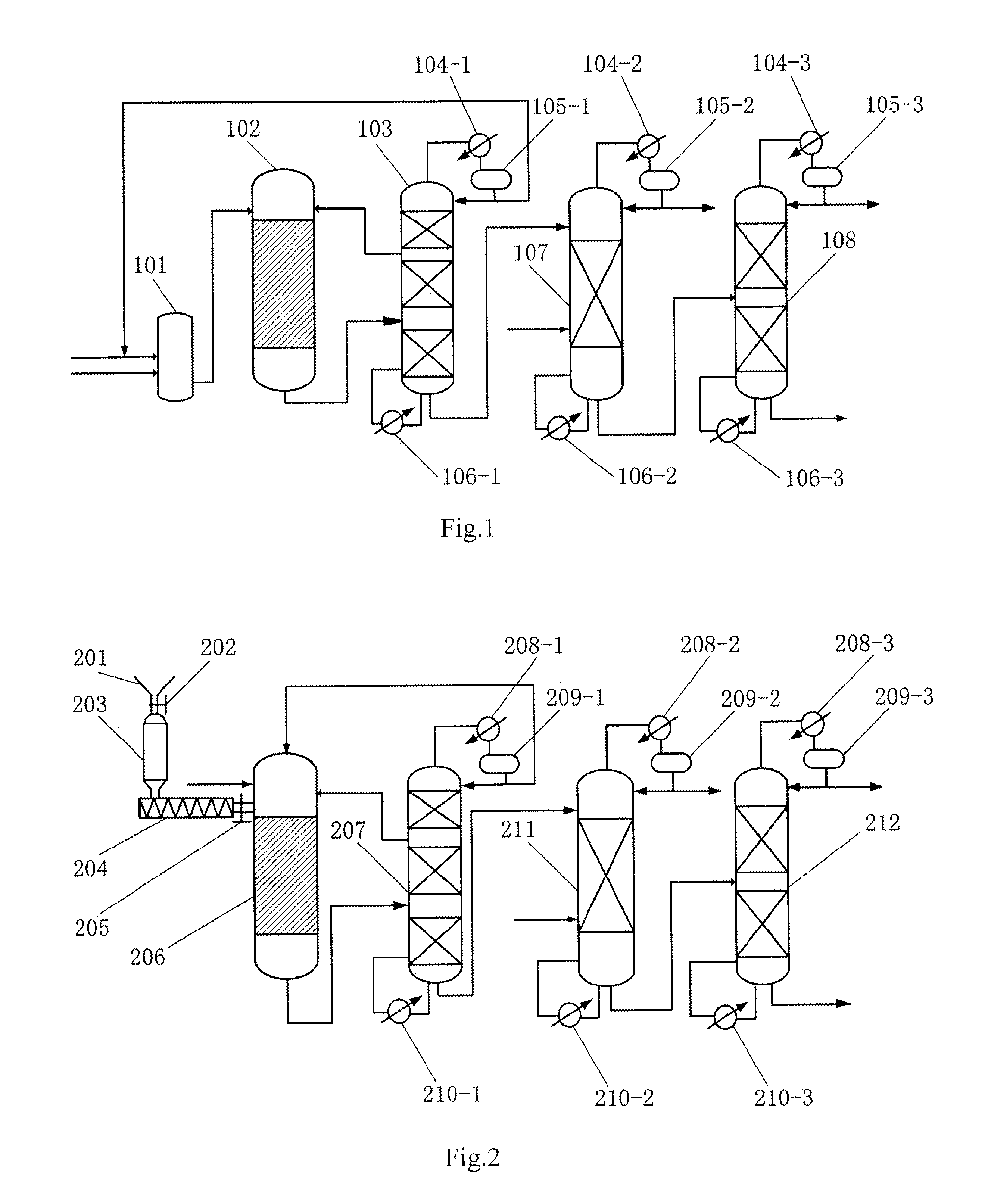

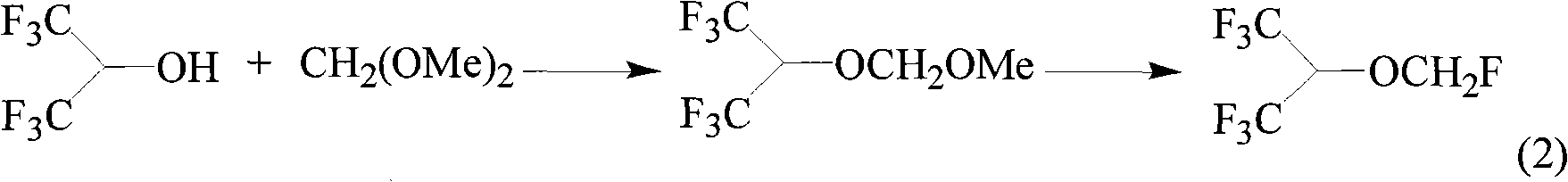

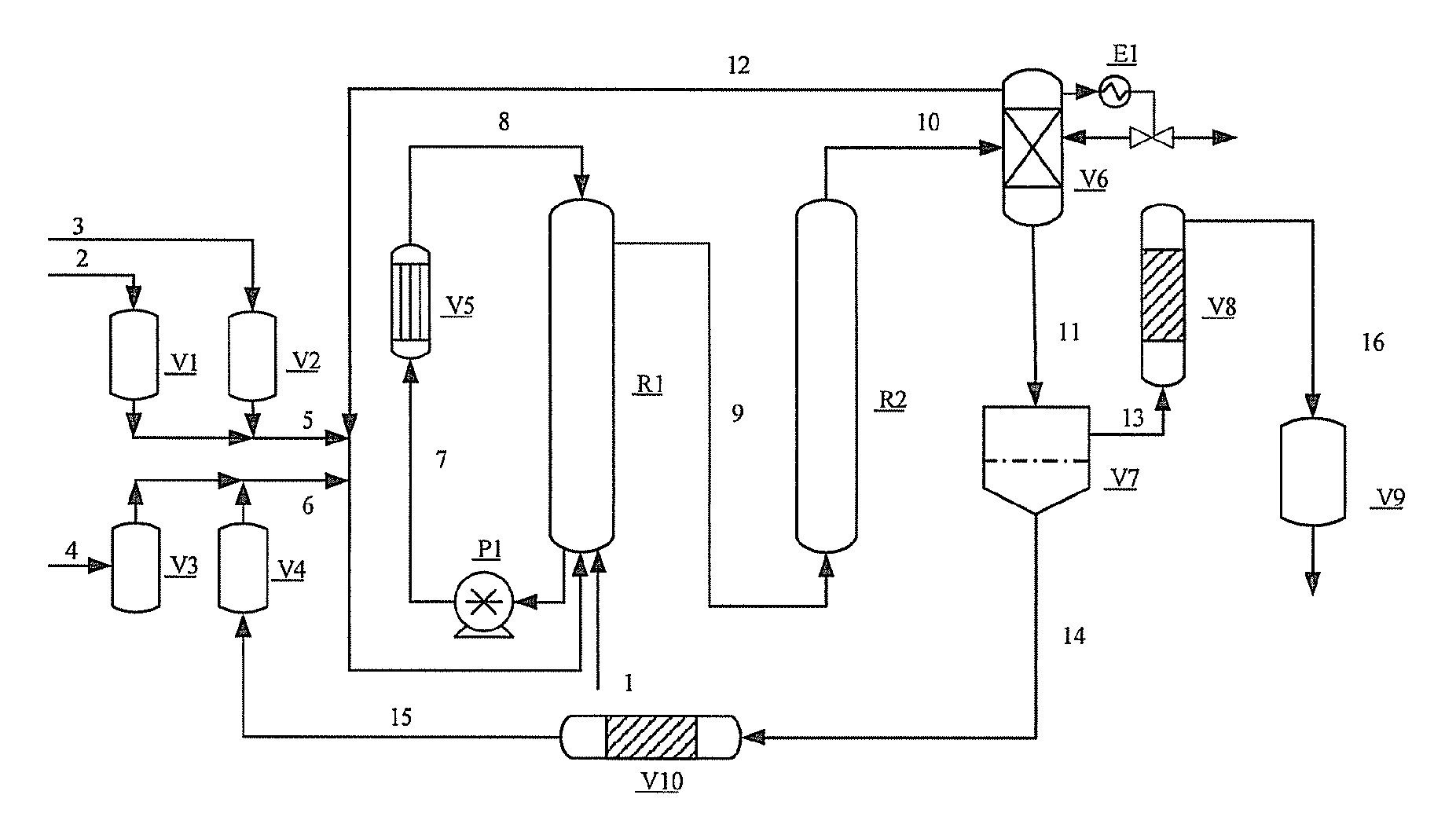

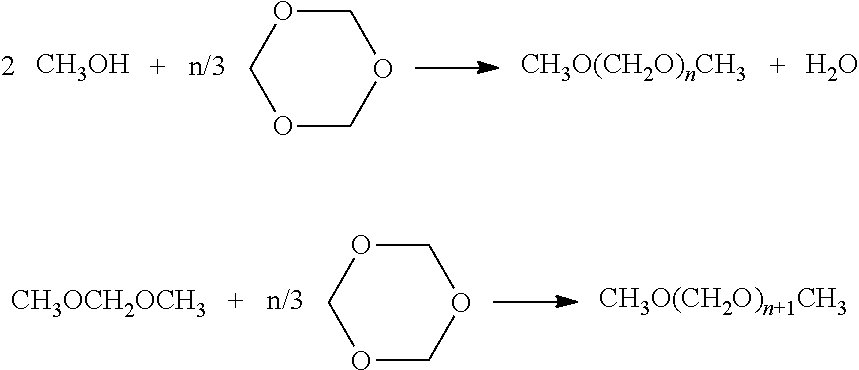

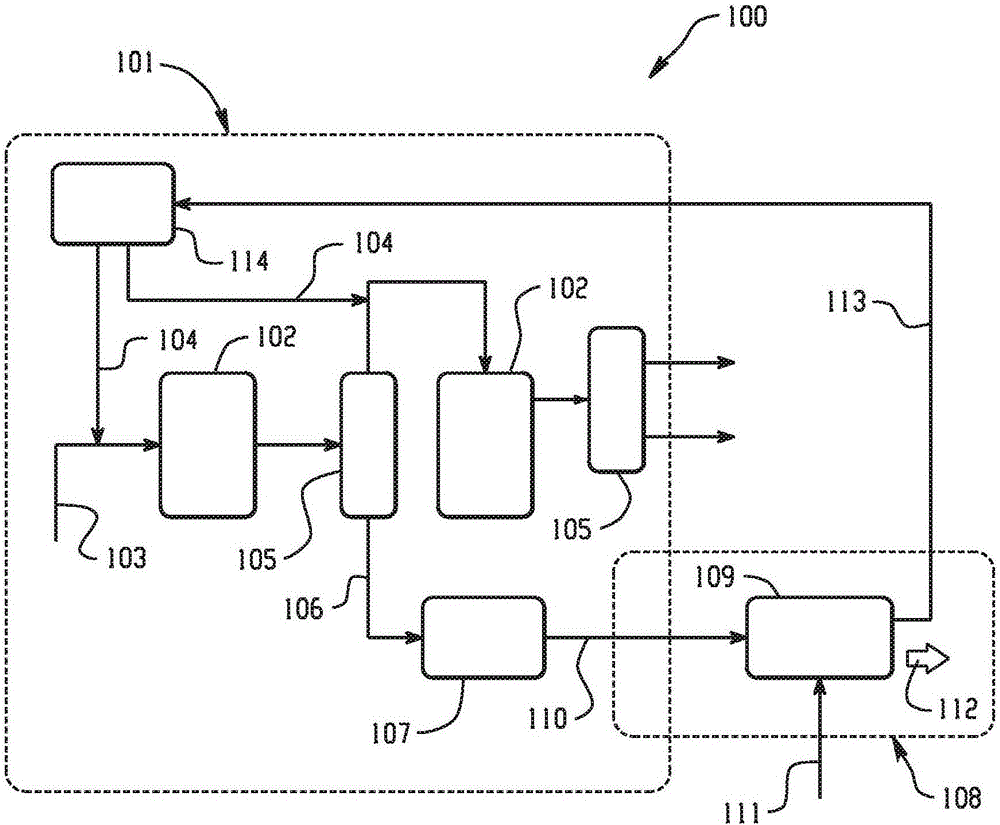

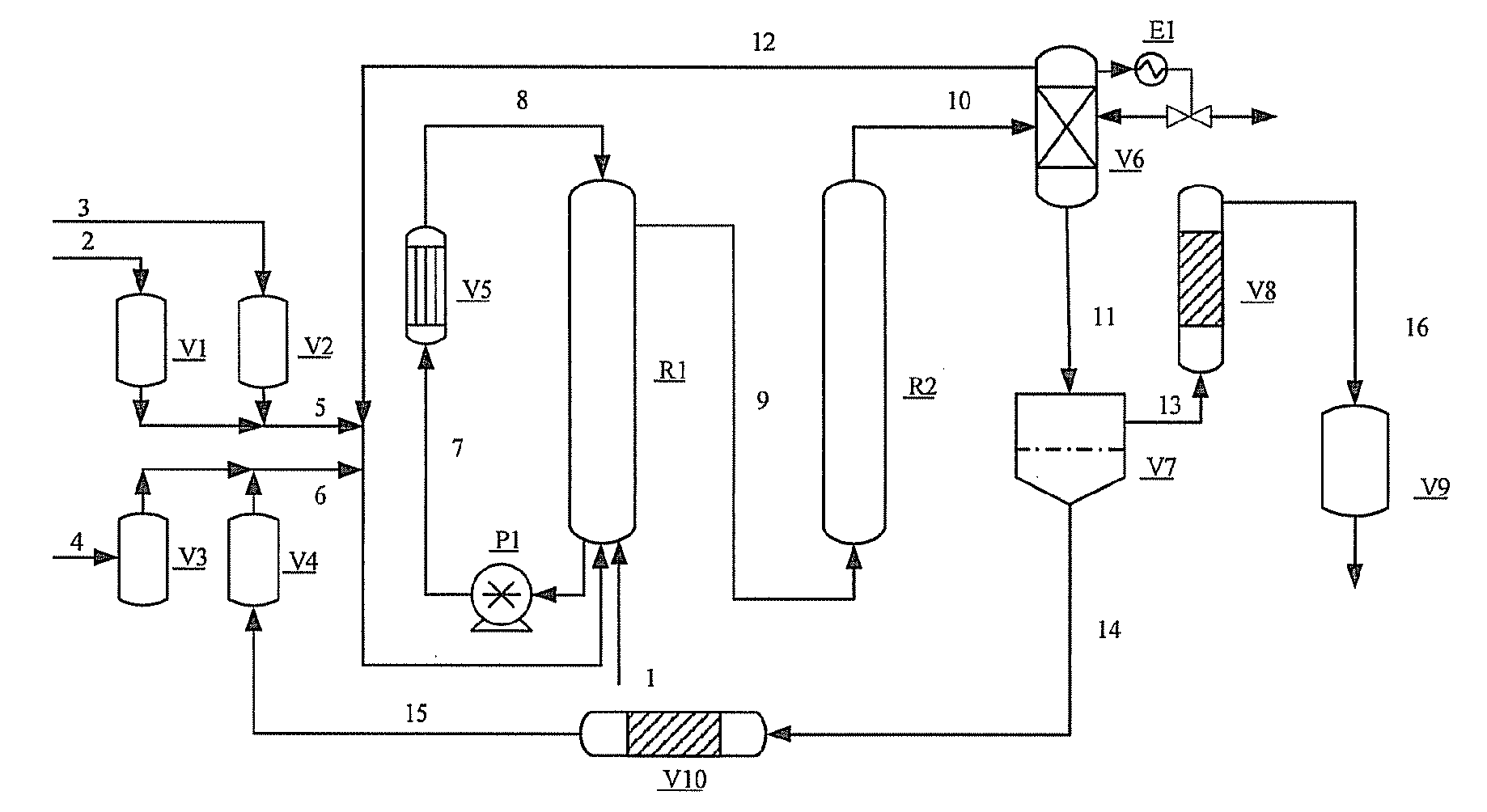

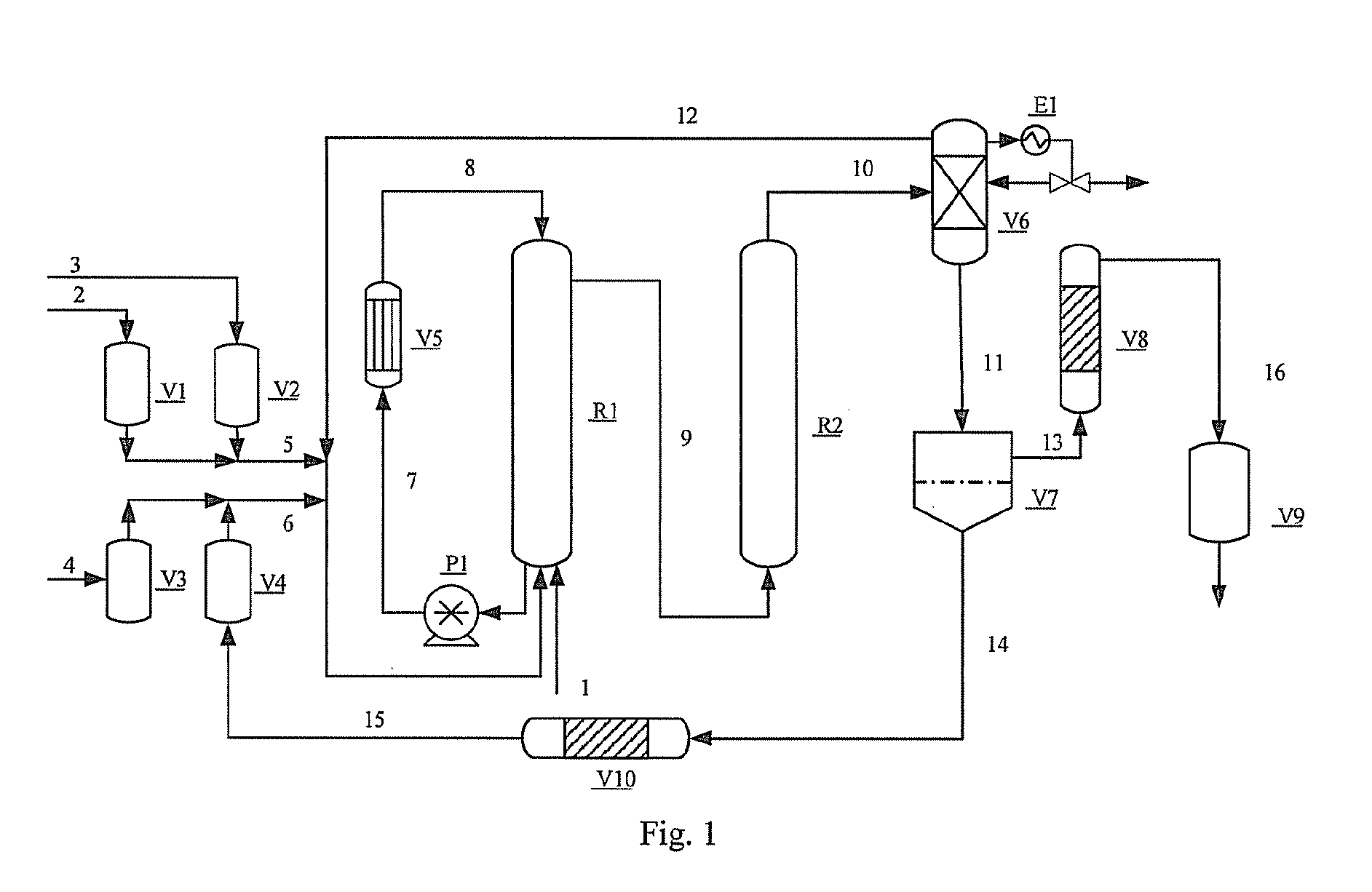

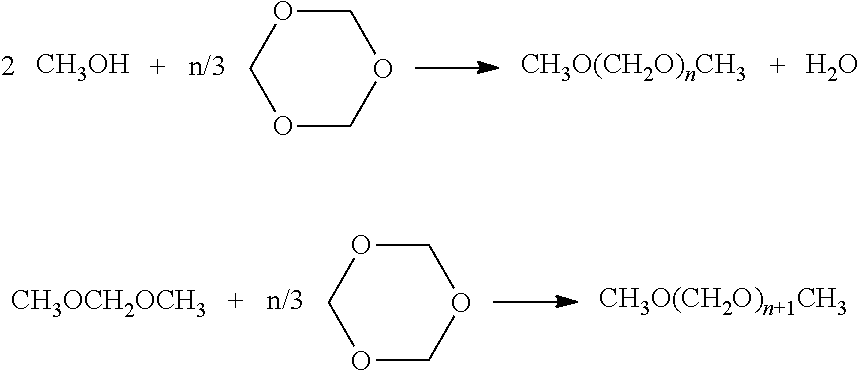

Method for synthesizing polyoxymethylene dimethyl ethers catalyzed by an ionic liquid

InactiveUS20110288343A1Increase conversionsHigh selectivityOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsReaction zoneDimethoxymethane

It is related to a method for preparing polyoxymethylene dimethyl ethers by a continuous acetalation reaction of trioxymethylene and methanol or methylal catalyzed by an ionic liquid. The processing apparatus used in the method includes a reaction zone, a separation zone, a catalyst regeneration zone and a product dehydration zone. A manner of circulating tubular reaction is used, resulting in a high external heat exchange efficiency, a simple structure of design and a low investment. A film evaporator is used, realizing a rapid separation and recycling of the light component, with a high separation efficiency. The separation of the catalyst solution from the crude product is simple, thereby realizing the regeneration and recycling of the catalyst.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

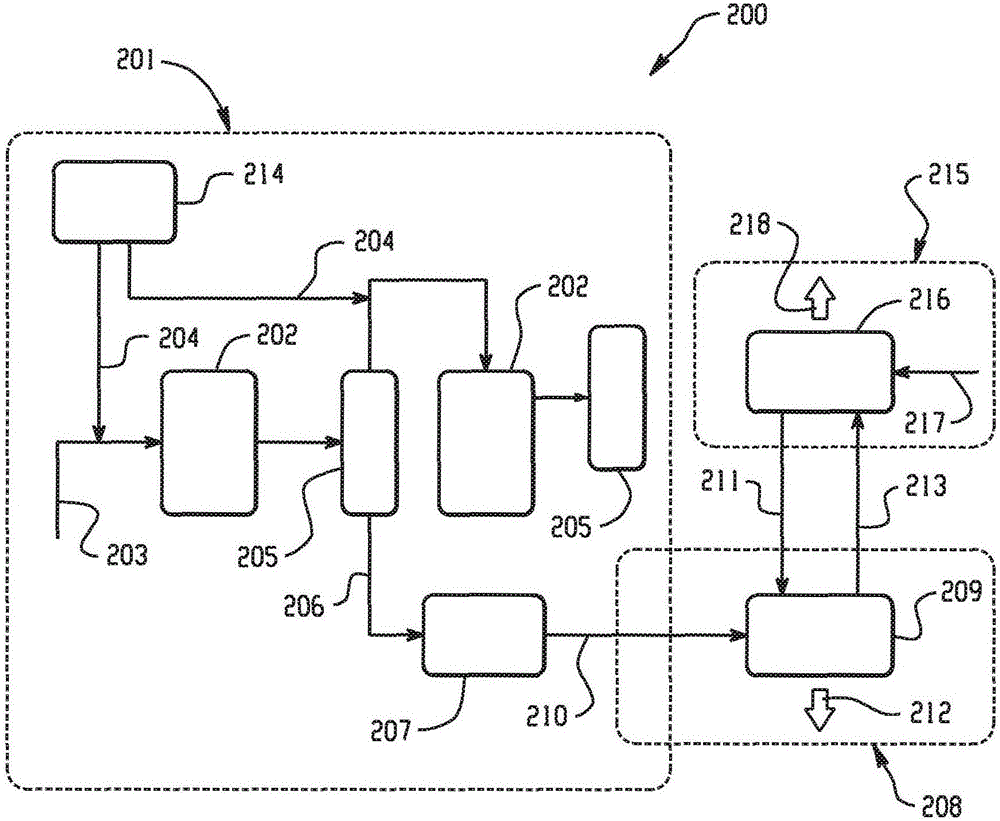

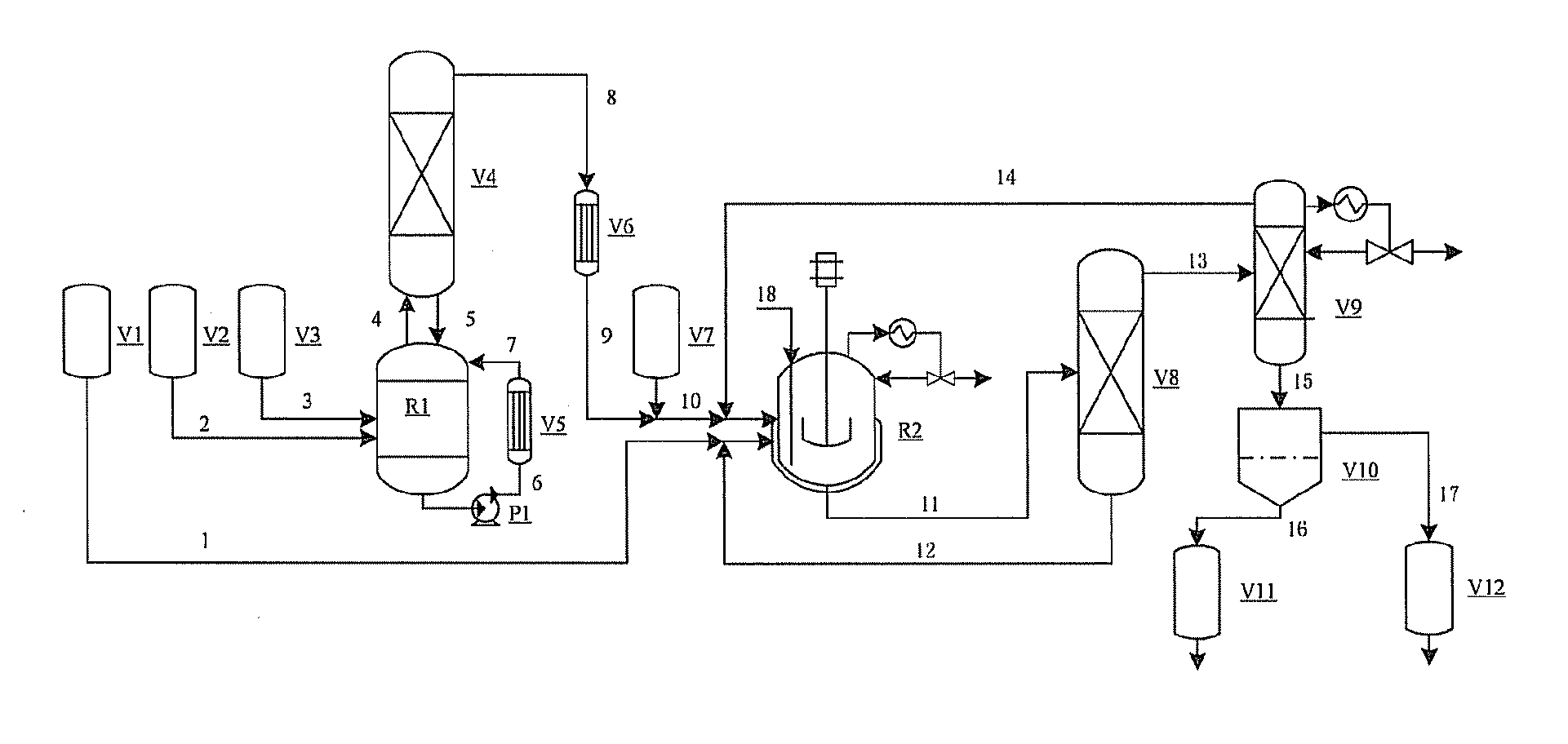

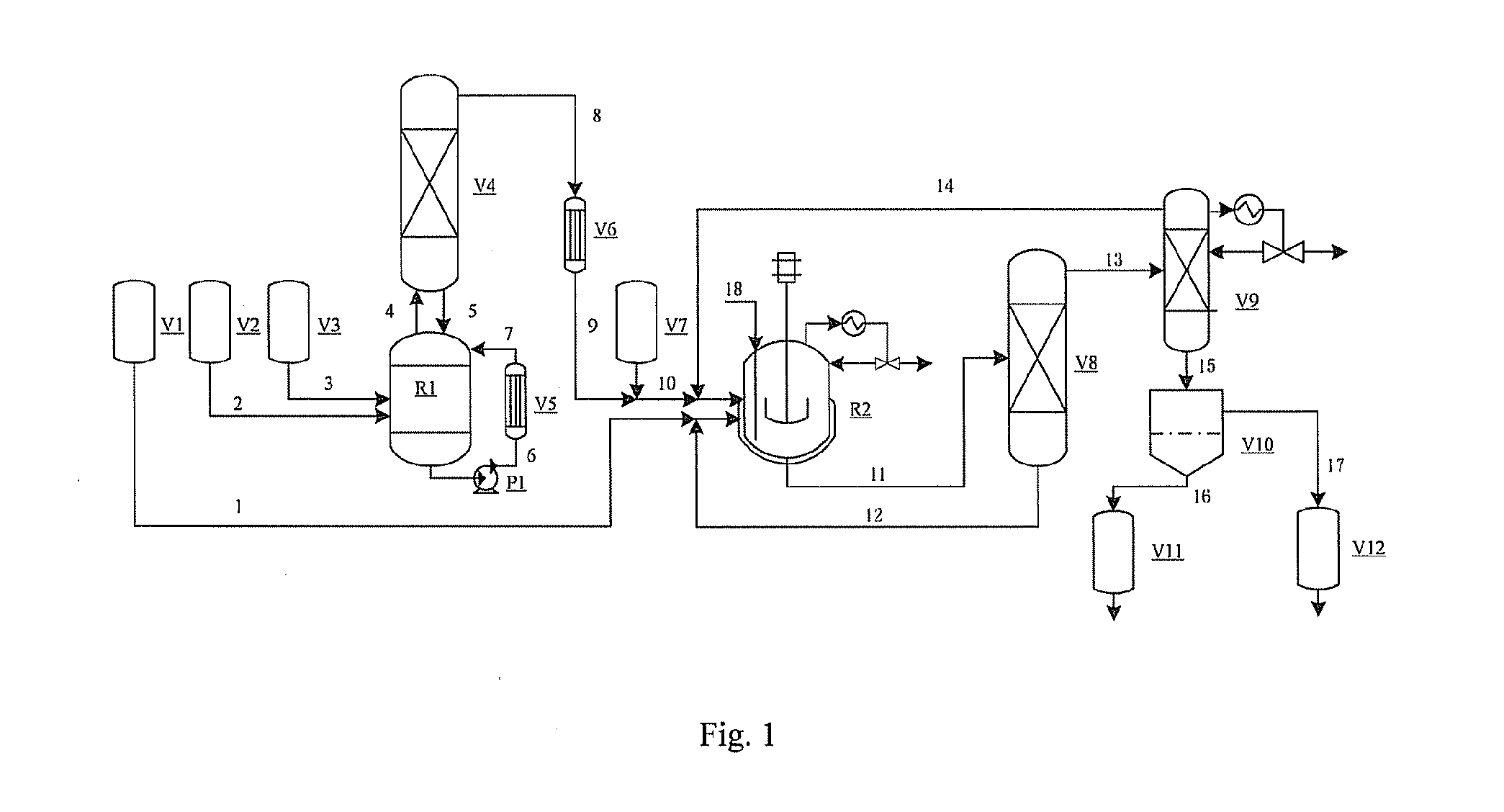

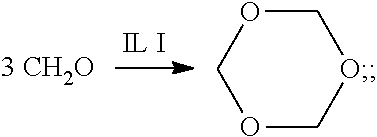

Method for preparing polyoxymethylene dimethyl ethers by acetalation reaction of formaldehyde with methanol

ActiveUS20110313202A1Rapid separation and recyclingEasy to separateOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsTwo stepAqueous solution

It is disclosed a method for preparing polyoxymethylene dimethyl ethers by continuous polymerization and acetalation reactions. The method may include two steps: performing a polymerization reaction of an aqueous formaldehyde solution under catalysis of an ionic liquid IL I to obtain a mixed aqueous solution of trioxymethylene and formaldehyde; and an acetalation reaction of the mixed aqueous solution of trioxymethylene and formaldehyde with methanol is performed under catalysis of an ionic liquid IL II to prepare polyoxymethylene dimethyl ethers. The method may use an aqueous formaldehyde solution as a starting material to prepare polyoxymethylene dimethyl ethers by continuous polymerization and acetalation reactions, achieving a high use ratio of formaldehyde. A film evaporator is used in the invention, realizing a rapid separation and recycling of the light components, with a high separation efficiency. The separation of the catalyst is simple, thereby realizing recycling of the catalyst.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Process for preparing hydrofluoroethers

InactiveUS6023002AFurther reactionAchieve efficiencyOrganic compound preparationEther preparation by compound additionEtherHydrofluoroether

Owner:3M INNOVATIVE PROPERTIES CO

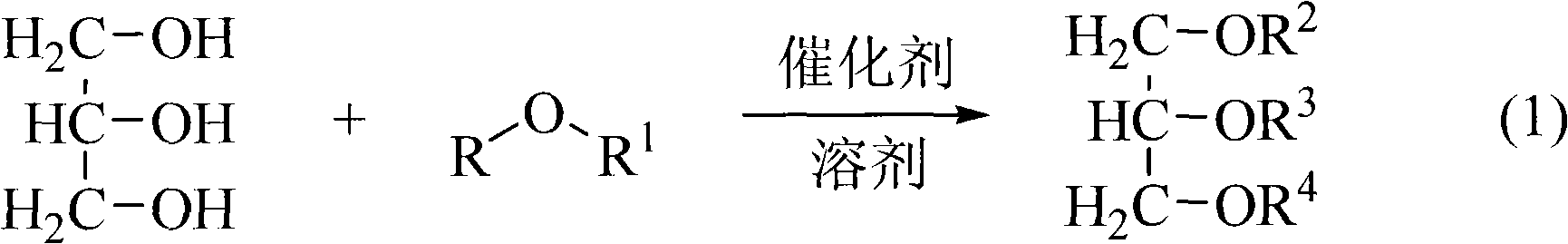

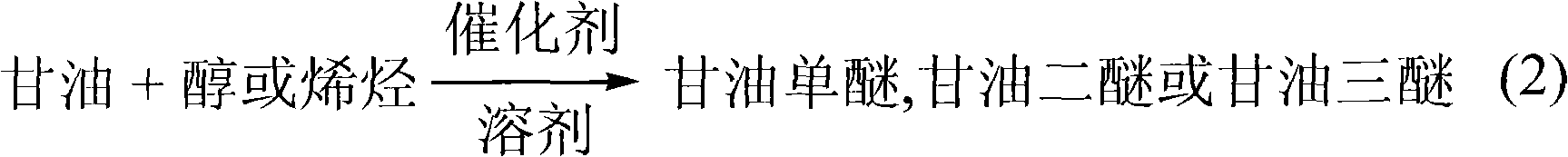

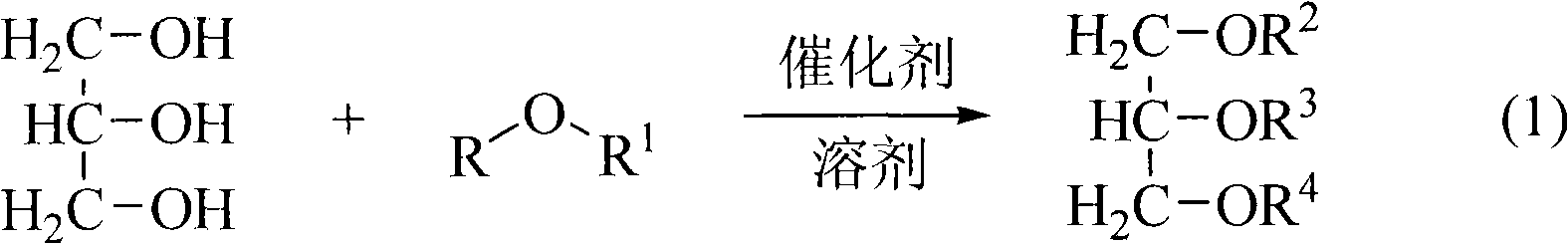

Method for preparing glycerin ether from glycerol

InactiveCN101624334AHigh yieldEther preparation by compound additionBulk chemical productionAlcoholTert butyl

The invention relates to a method for preparing glycerin ether from glycerol. The glycerol reacts with ether, alcohol or olefinic hydrocarbon in the existence of a catalyst to obtain di-tert-butyl glycerin ether, tri-tert-butyl glycerin ether and other glycerin ethers which can be used as diesel fuel additives, antibacterial agents, flavoring agents, humectants, emulsifying agents and surfactants at a high yield.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

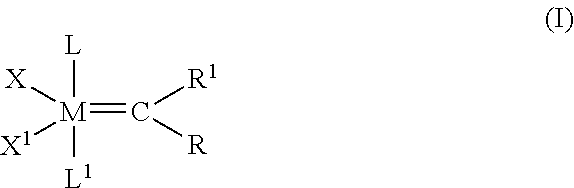

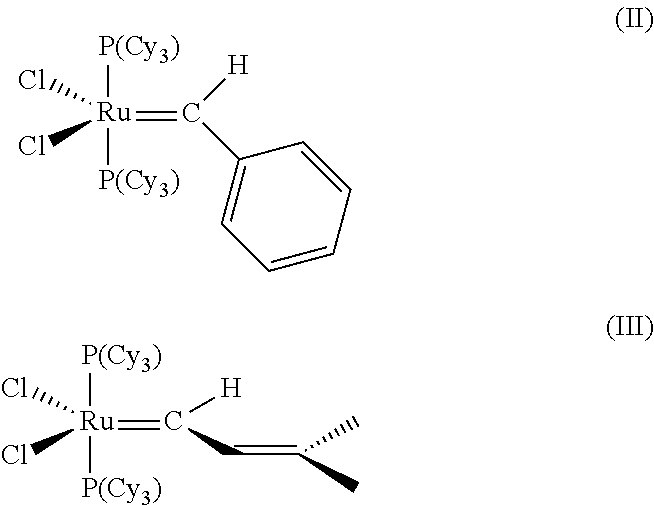

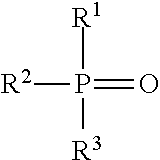

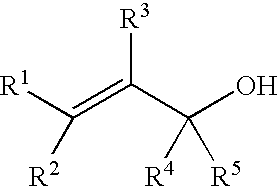

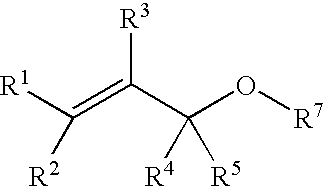

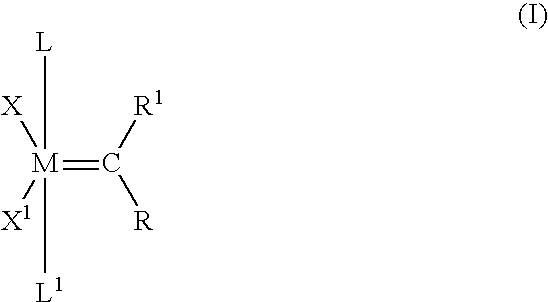

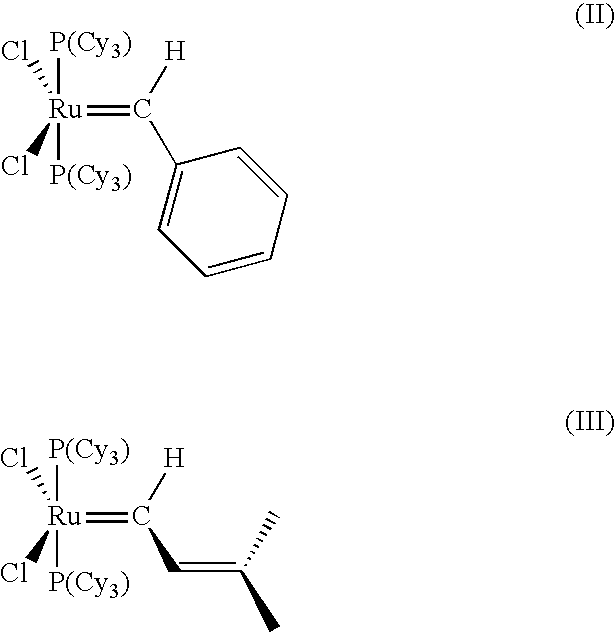

Cross-metathesis reaction of functionalized and substituted olefins using group 8 transition metal carbene complexes as metathesis catalysts

InactiveUS20070155975A1Carboxylic acid esters preparationHydroxy compound preparationFunctional diversityAlkene

The invention pertains to the use of Group 8 transition metal carbene complexes as catalysts for olefin cross-metathesis reactions. In particular, ruthenium and osmium alkylidene complexes substituted with an N-heterocyclic carbene ligand are used to catalyze cross-metathesis reactions to provide a variety of substituted and functionalized olefins, including phosphonate-substituted olefins, directly halogenated olefins, 1,1,2-trisubstituted olefins, and quaternary allylic olefins. The invention further provides a method for creating functional diversity using the aforementioned complexes to catalyze cross-metathesis reactions of a first olefinic reactant, which may or may not be substituted with a functional group, with each of a plurality of different olefinic reactants, which may or may not be substituted with functional groups, to give a plurality of structurally distinct olefinic products. The methodology of the invention is also useful in facilitating the stereoselective synthesis of 1,2-disubstituted olefins in the cis configuration.

Owner:CALIFORNIA INST OF TECH

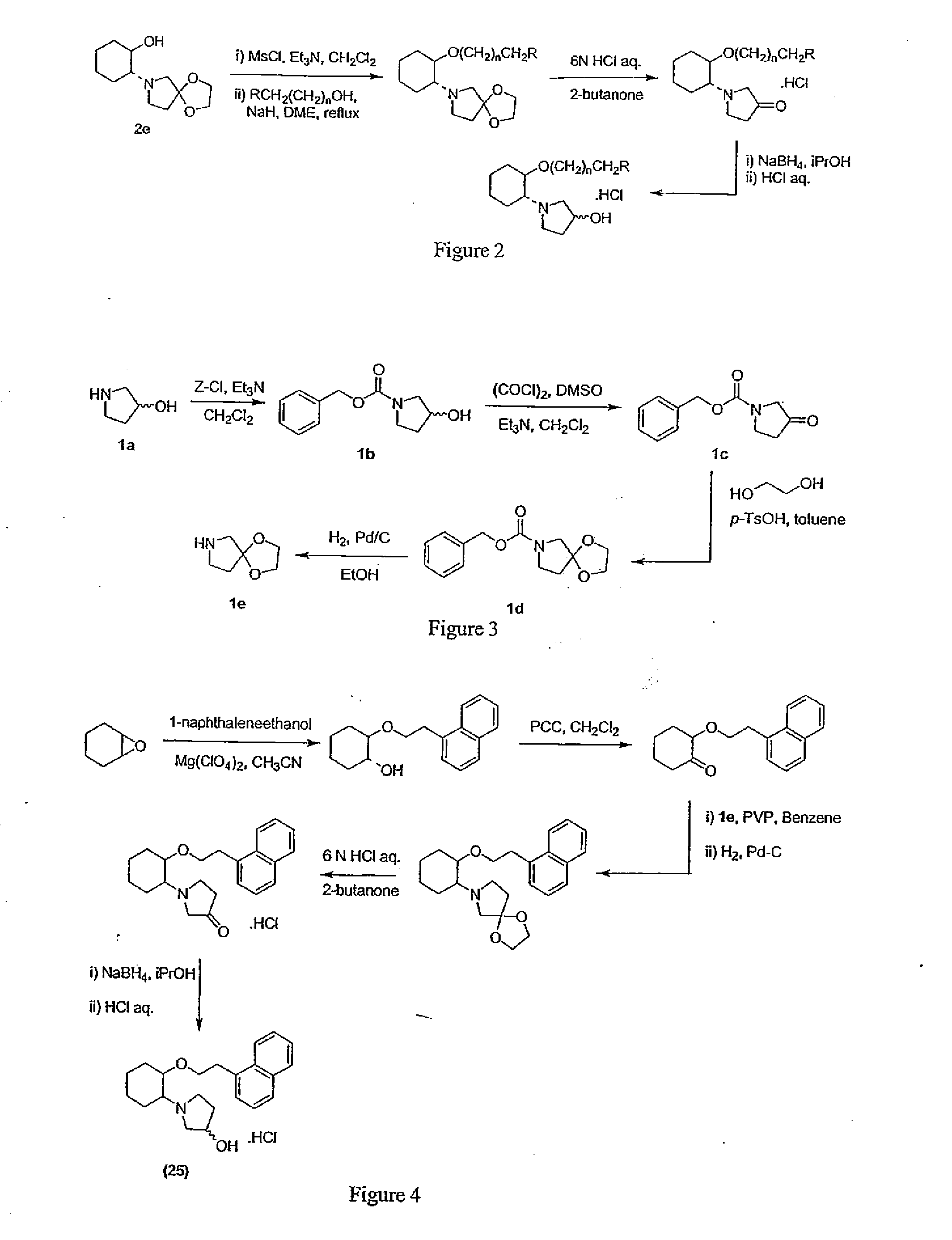

Aminocyclohexyl ether compounds and uses thereof

InactiveUS20070254945A1Reduce actionIncrease heart rateBiocideOrganic compound preparationEtherMedicinal chemistry

Owner:CORREVIO INT SARL

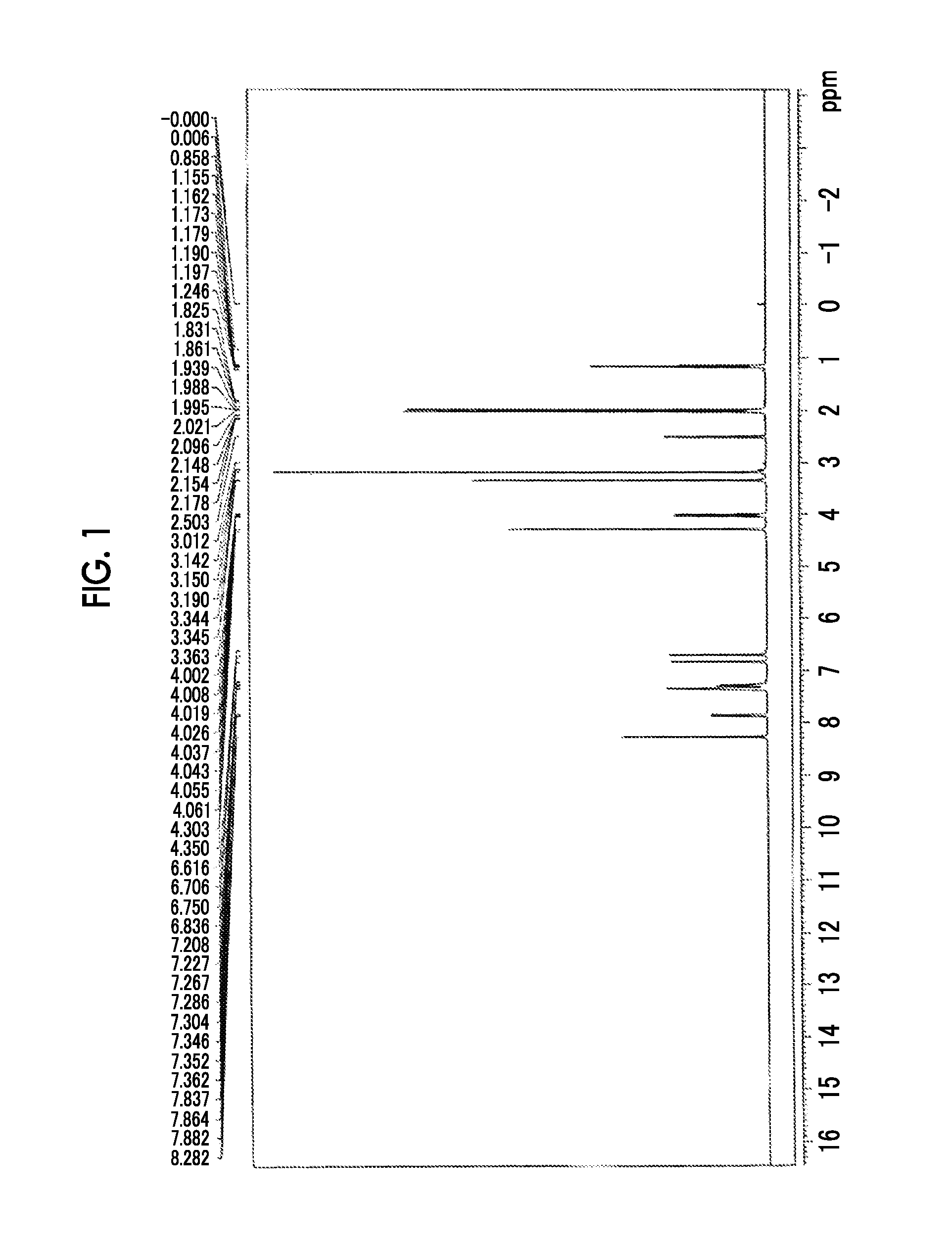

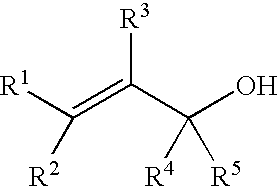

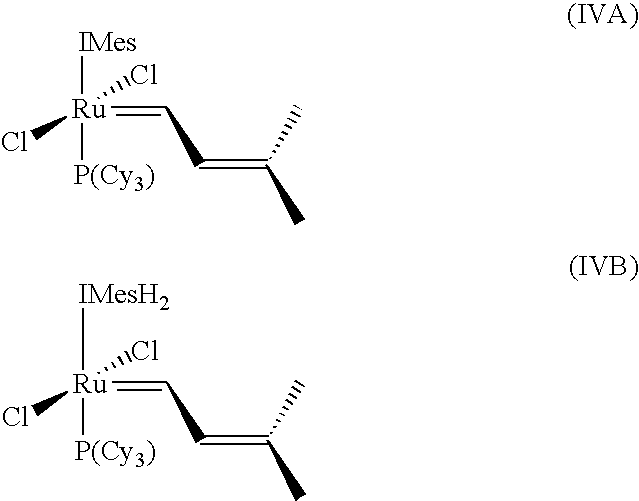

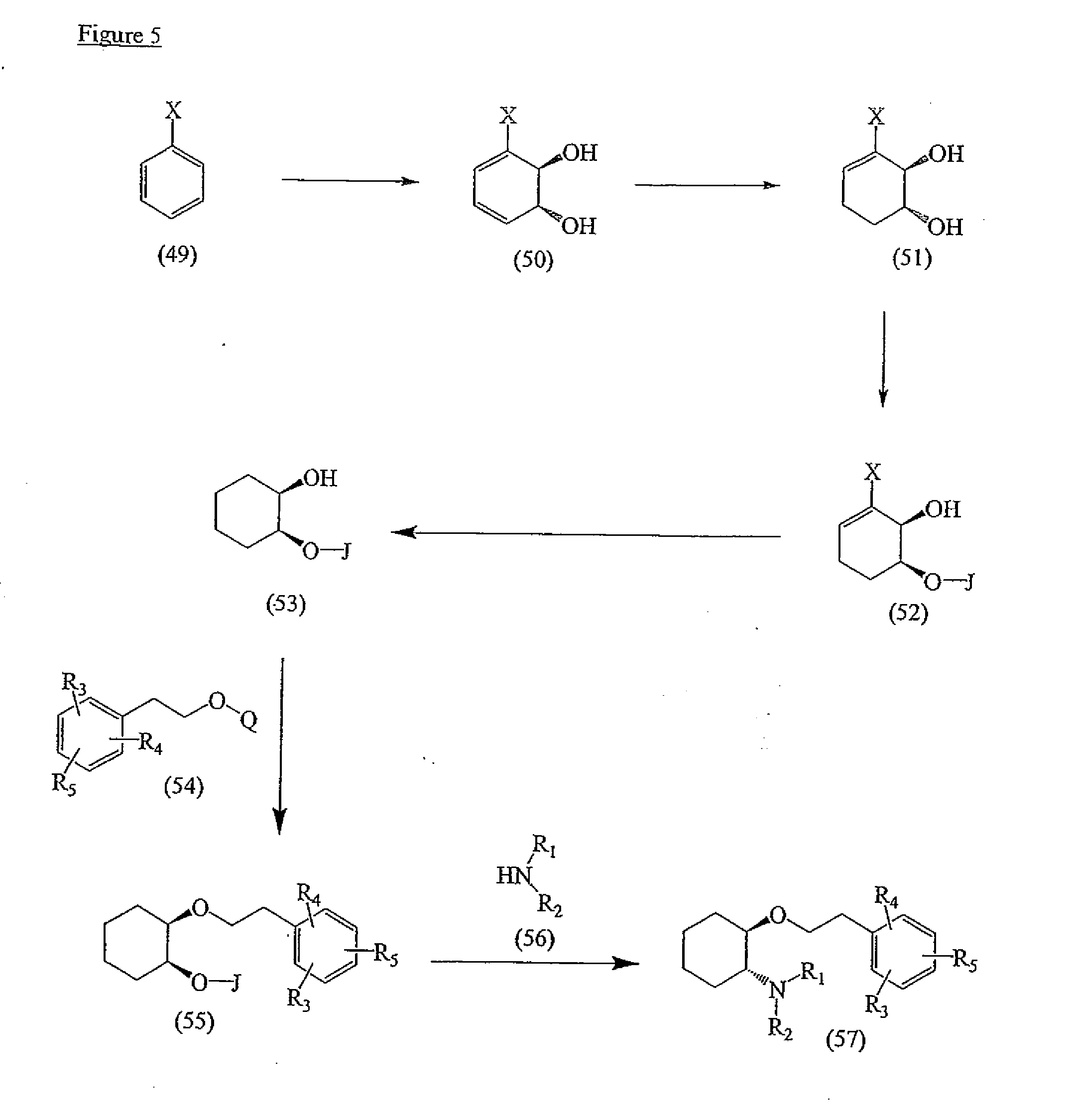

Method for the preparation of 2-{2-[4-(4-chloro-1,2-diphenylbut-1-enyl)phenoxy]ethoxy}ethanol and its isomers

InactiveUS6891070B2BiocideOrganic compound preparationEstrogen receptor modulatorCombinatorial chemistry

A new method for the preparation of a selective estrogen receptor modulator and its isomers. Also disclosed is the preparation of new intermediates and their use in the preparation of the selective estrogen receptor modulator.

Owner:FORENDO PHARMA LTD

Cross-metathesis reaction of functionalized and substituted olefins using group 8 transition metal carbene complexes as metathesis catalysts

InactiveUS20140288319A1Hydroxy compound preparationHydrocarbon by metathesis reactionHaloalkenePtru catalyst

The invention pertains to the use of Group 8 transition metal carbene complexes as catalysts for olefin cross-metathesis reactions. In particular, ruthenium and osmium alkylidene complexes substituted with an N-heterocyclic carbene ligand are used to catalyze cross-metathesis reactions to provide a variety of substituted and functionalized olefins, including phosphonate-substituted olefins, directly halogenated olefins, 1,1,2-trisubstituted olefins, and quaternary allylic olefins. The invention further provides a method for creating functional diversity using the aforementioned complexes to catalyze cross-metathesis reactions of a first olefinic reactant, which may or may not be substituted with a functional group, with each of a plurality of different olefinic reactants, which may or may not be substituted with functional groups, to give a plurality of structurally distinct olefinic products. The methodology of the invention is also useful in facilitating the stereoselective synthesis of 1,2-disubstituted olefins in the cis configuration.

Owner:CALIFORNIA INST OF TECH

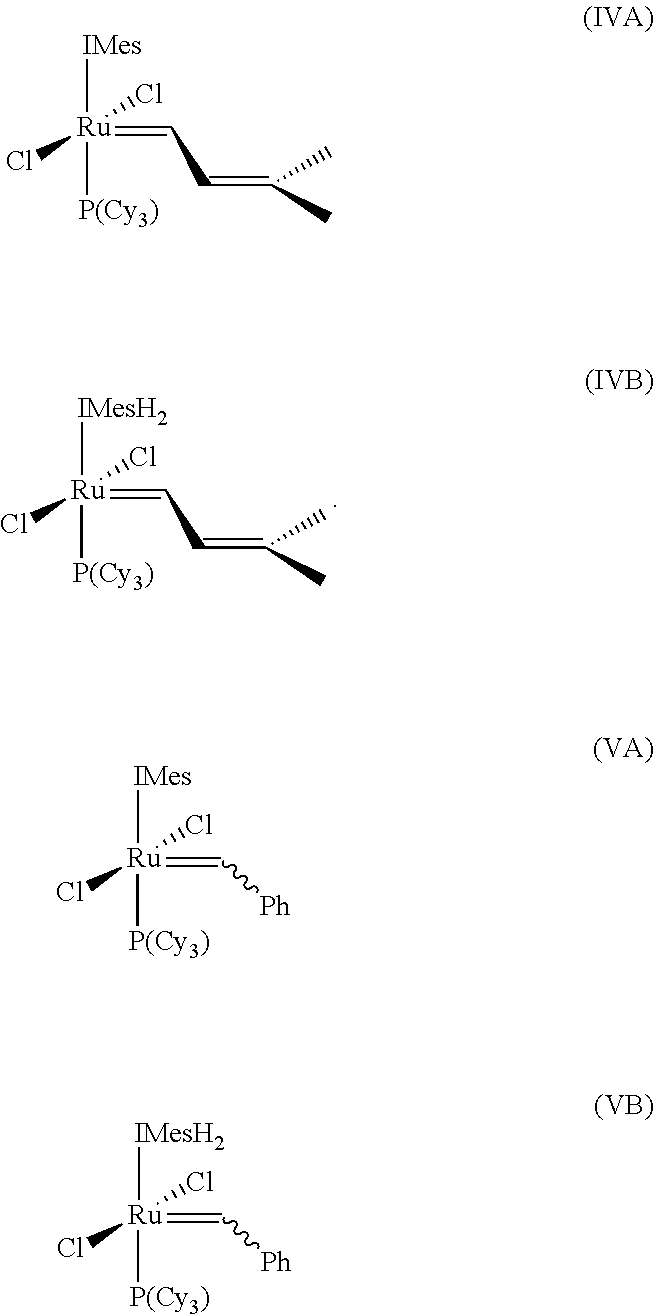

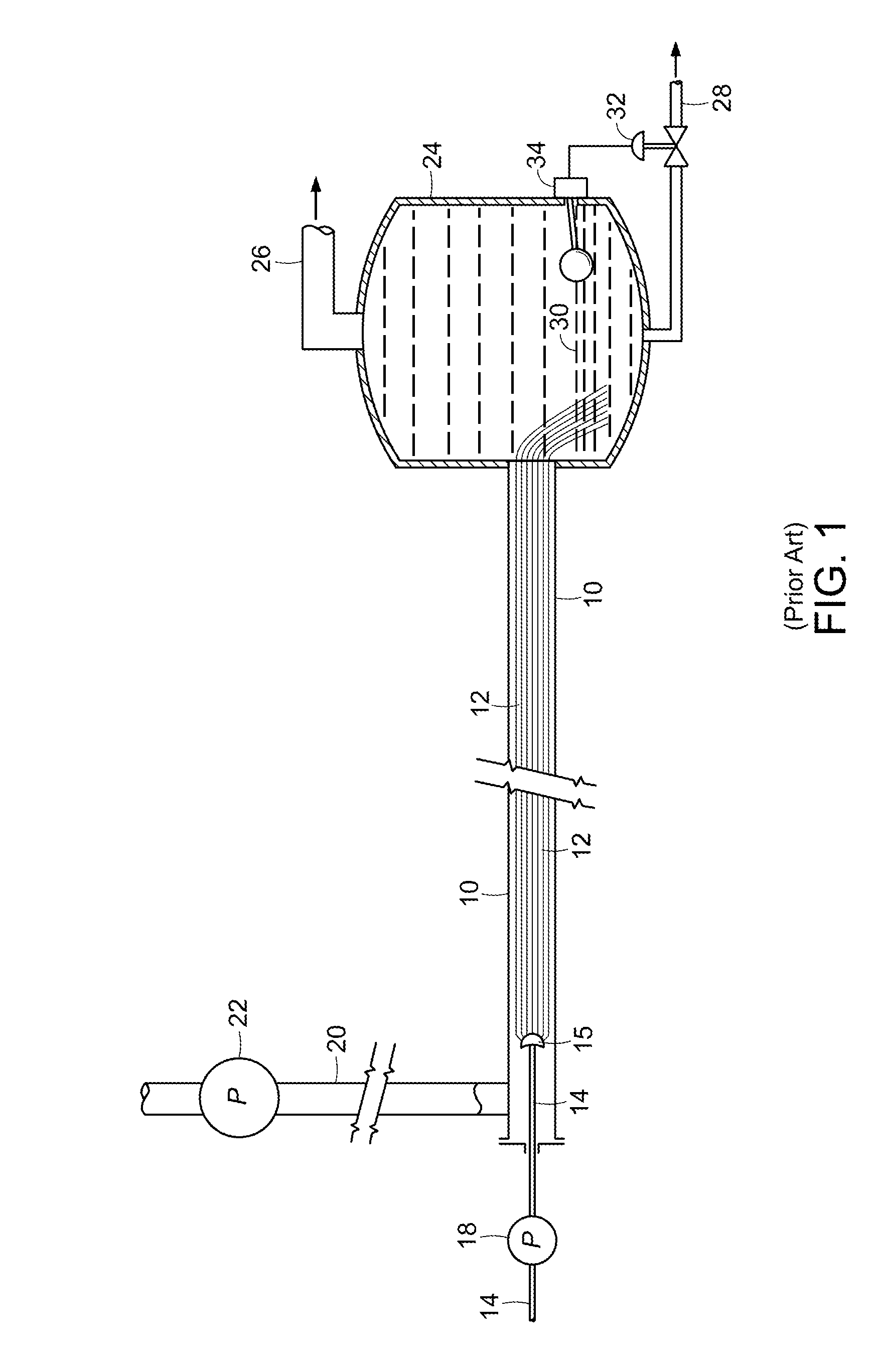

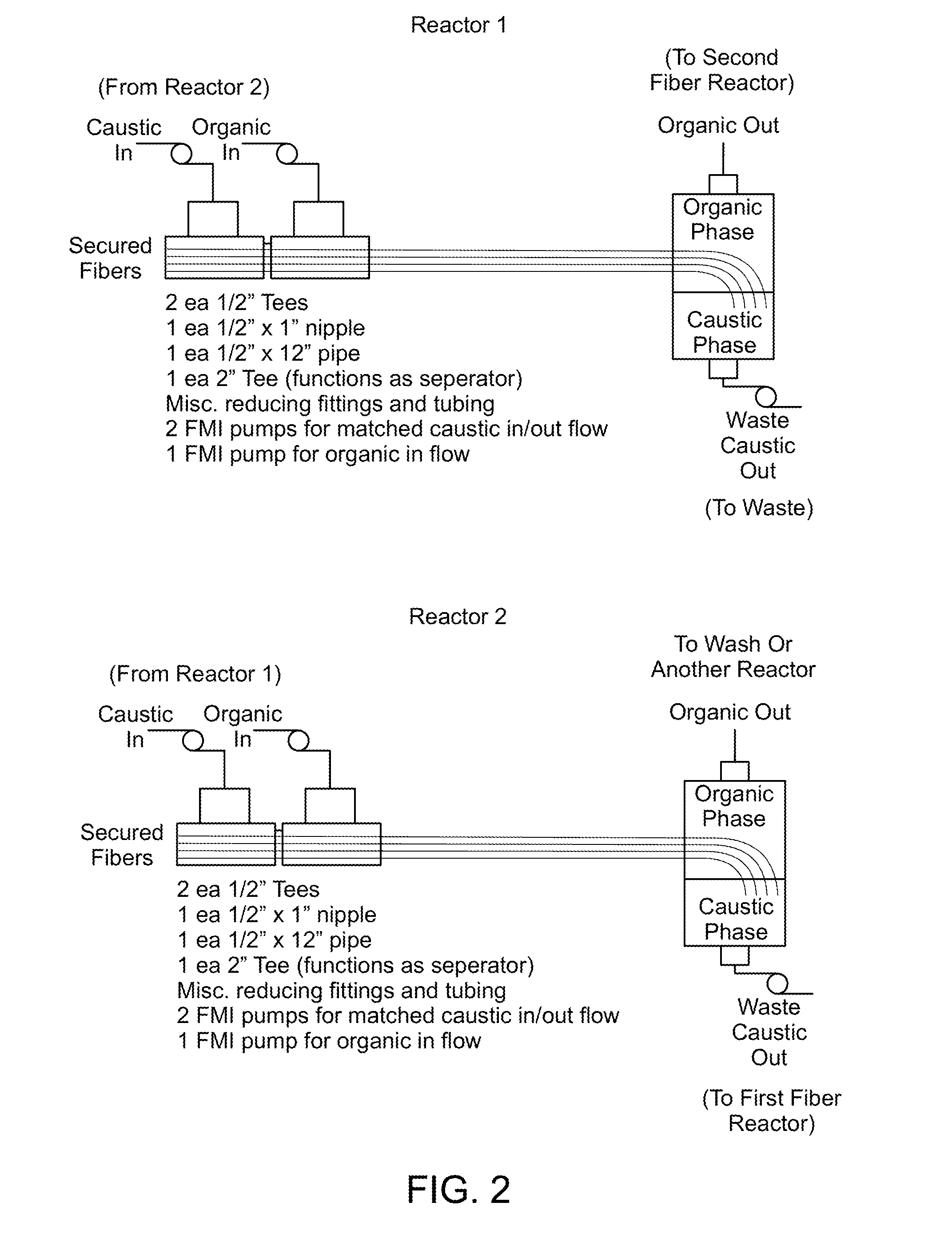

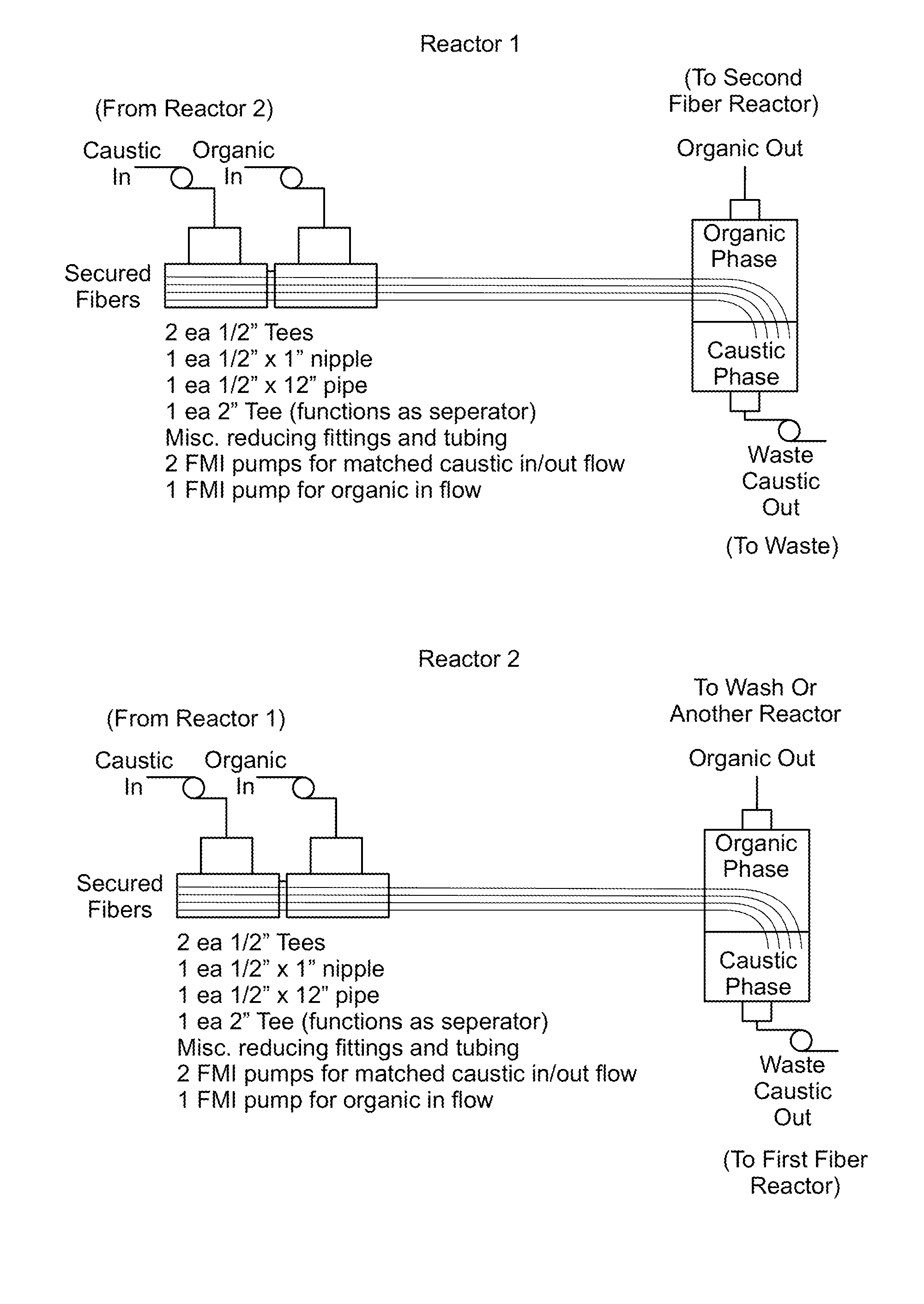

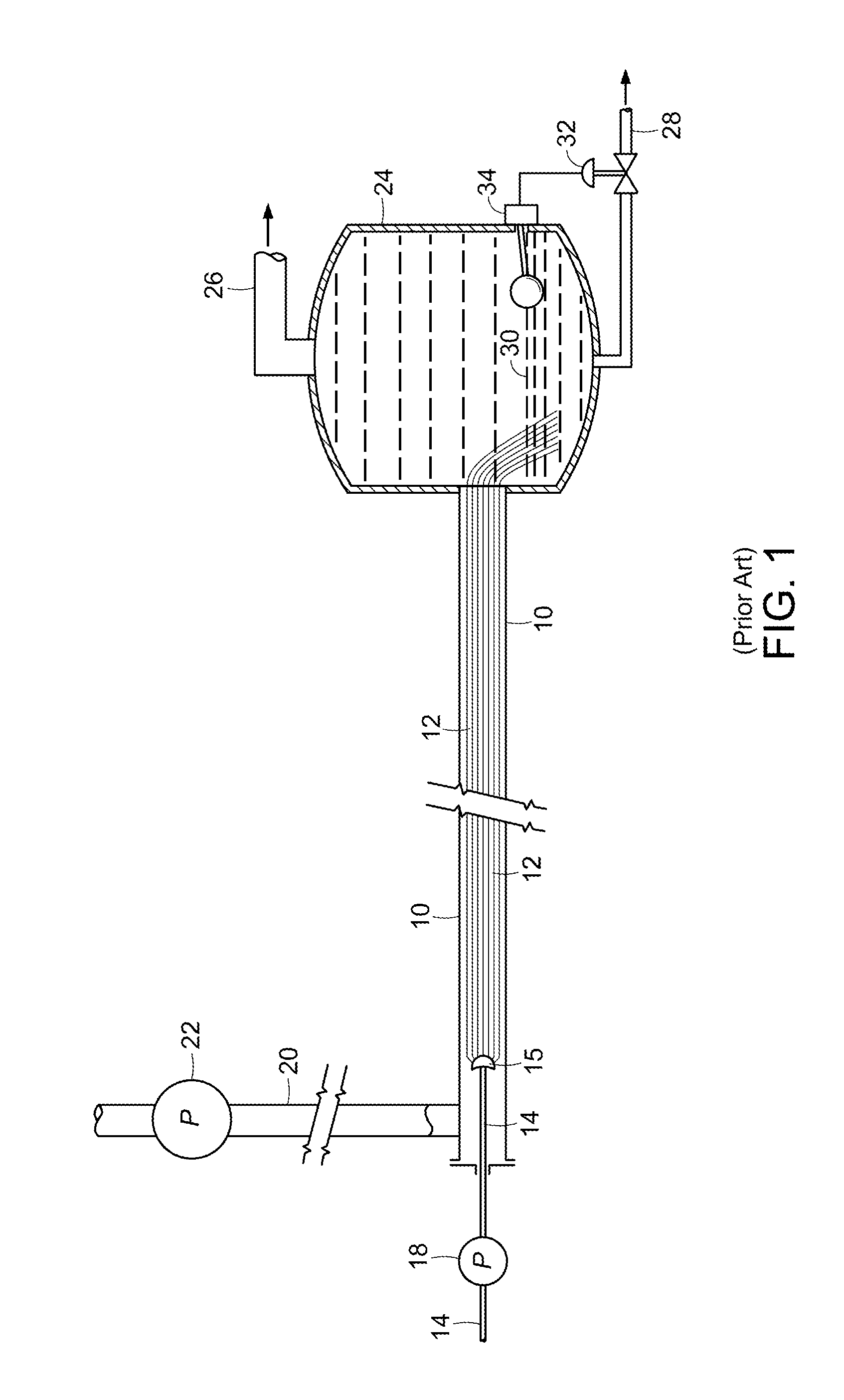

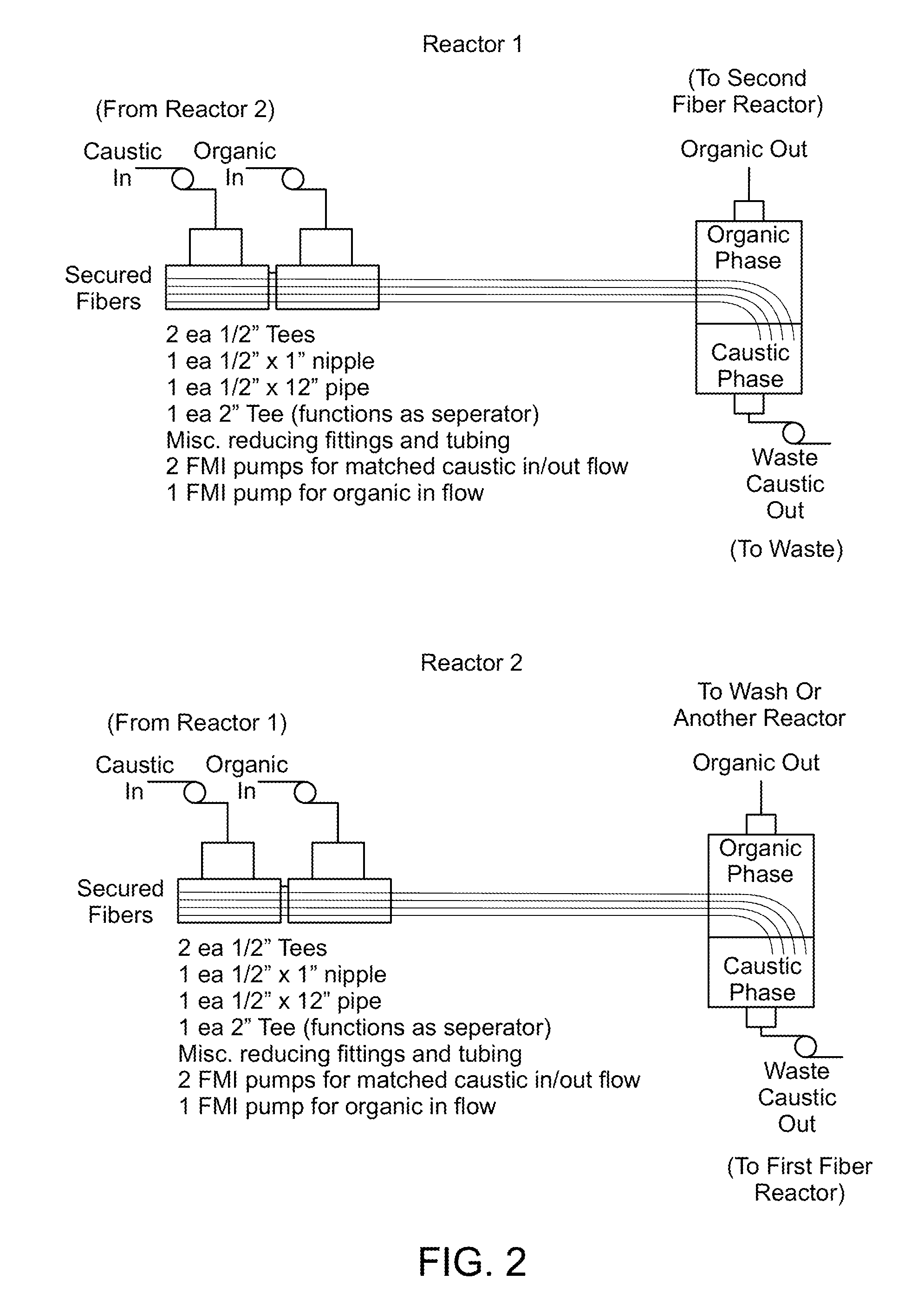

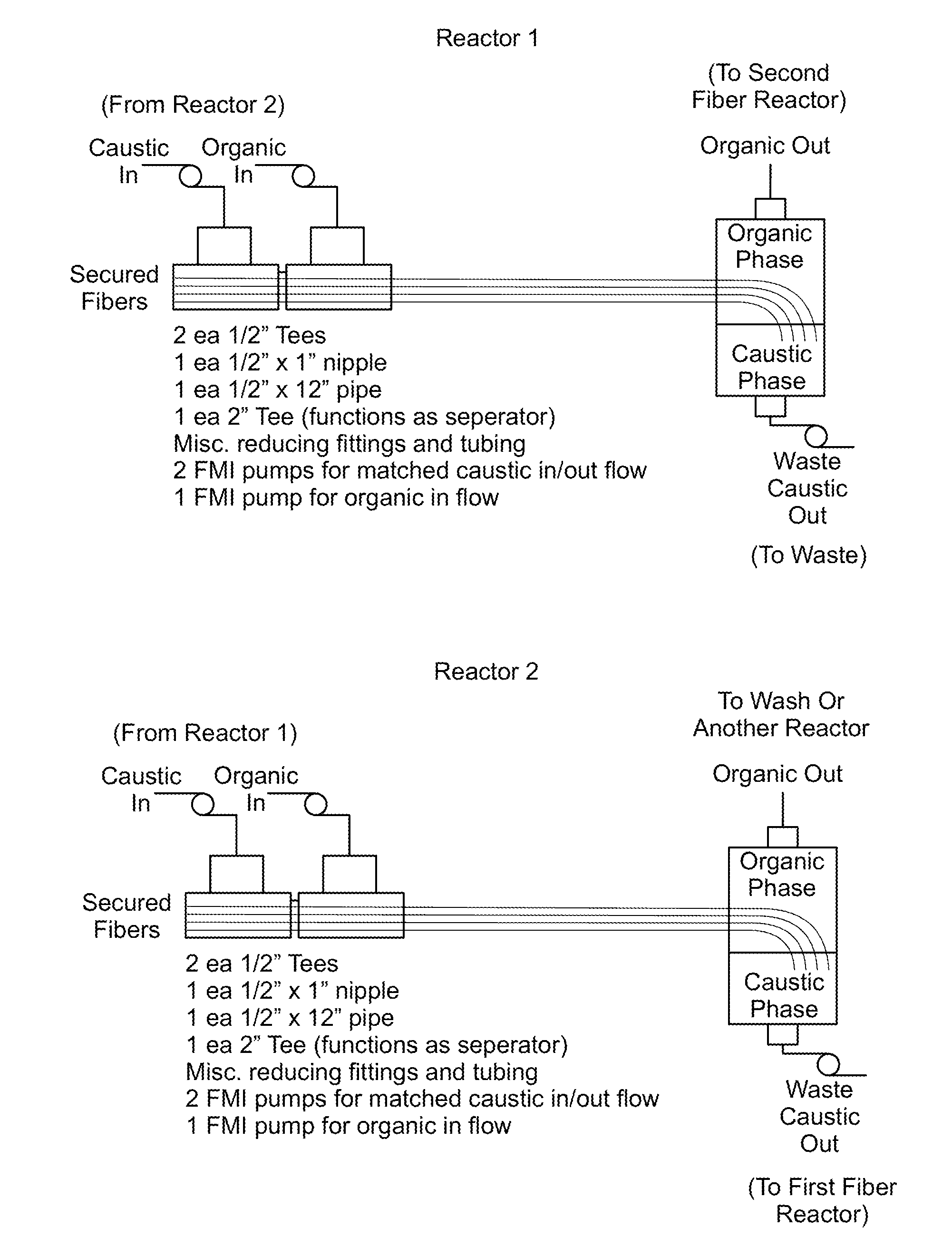

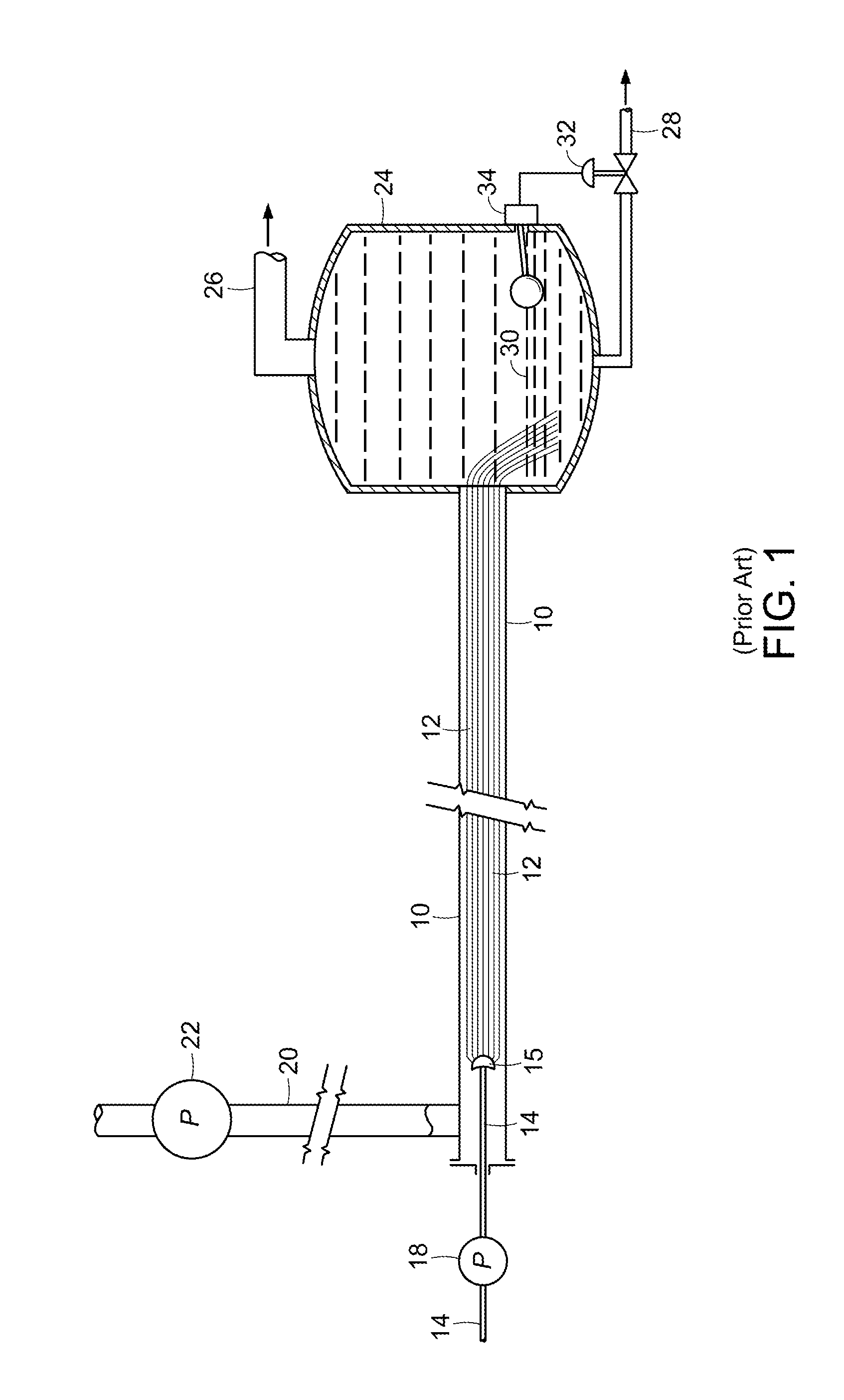

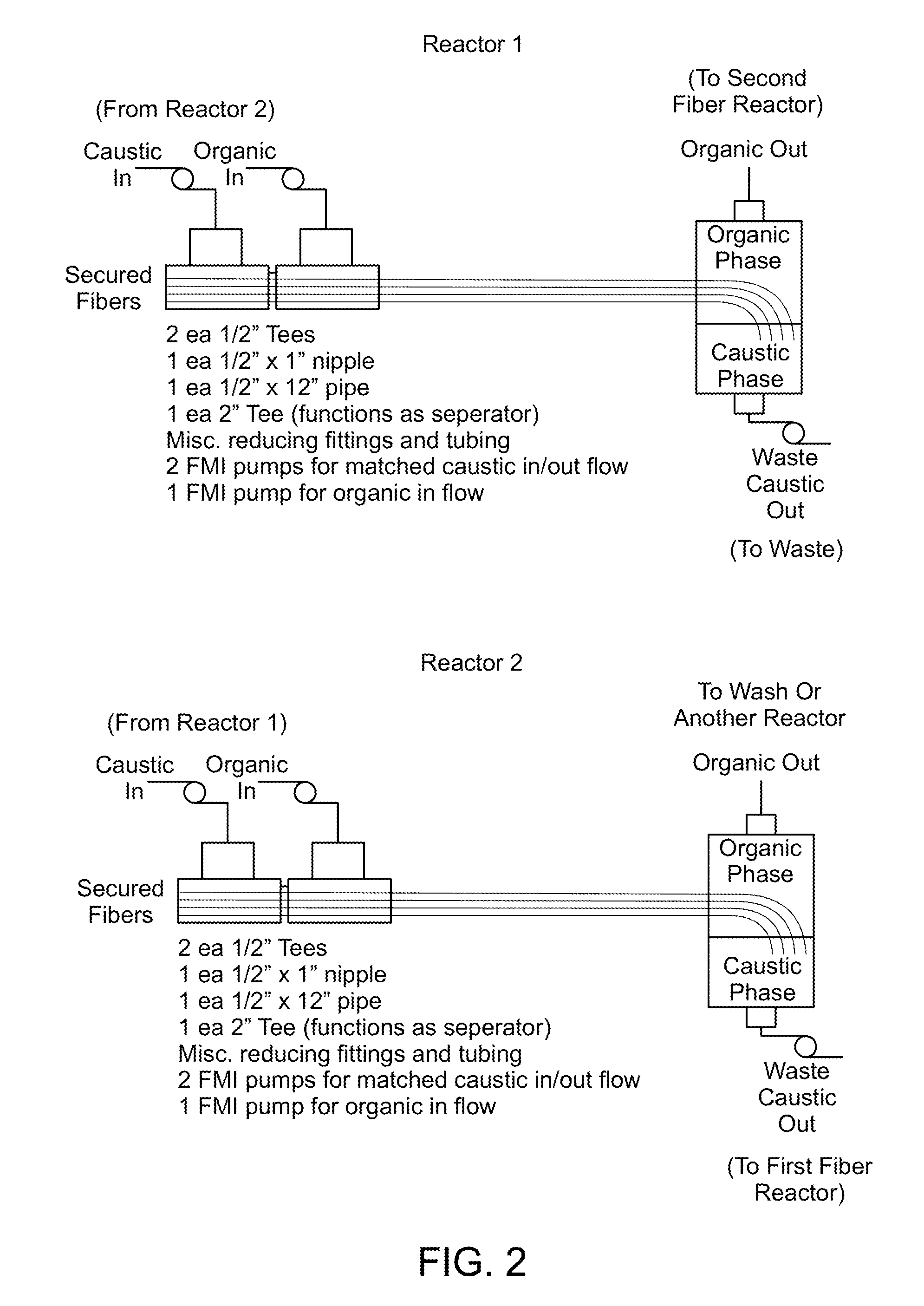

Method and System for Production of a Chemical Commodity Using a Fiber Conduit Reactor

ActiveUS20160024036A1Improve solubilityEnhanced mass transferFatty acid esterificationFatty acids production/refiningFiberChemical reaction

A fiber reaction process whereby reactive components contained in immiscible streams are brought into contact to effect chemical reactions and separations. The conduit reactor utilized contains wettable fibers onto which one stream is substantially constrained and a second stream is flowed over to continuously create a new interface there between to efficiently bring about contact of the reactive species and thus promote reactions thereof or extractions thereby. Co-solvents and phase transfer catalysts may be employed to facilitate the process.

Owner:CHEMTOR LP

Method and system for production of a chemical commodity using a fiber conduit reactor

ActiveUS9168469B2Improve solubilityEnhanced mass transferFatty acid esterificationFatty acids production/refiningFiberChemical reaction

A fiber reaction process whereby reactive components contained in immiscible streams are brought into contact to effect chemical reactions and separations. The conduit reactor utilized contains wettable fibers onto which one stream is substantially constrained and a second stream is flowed over to continuously create a new interface there between to efficiently bring about contact of the reactive species and thus promote reactions thereof or extractions thereby. Co-solvents and phase transfer catalysts may be employed to facilitate the process.

Owner:CHEMTOR LP

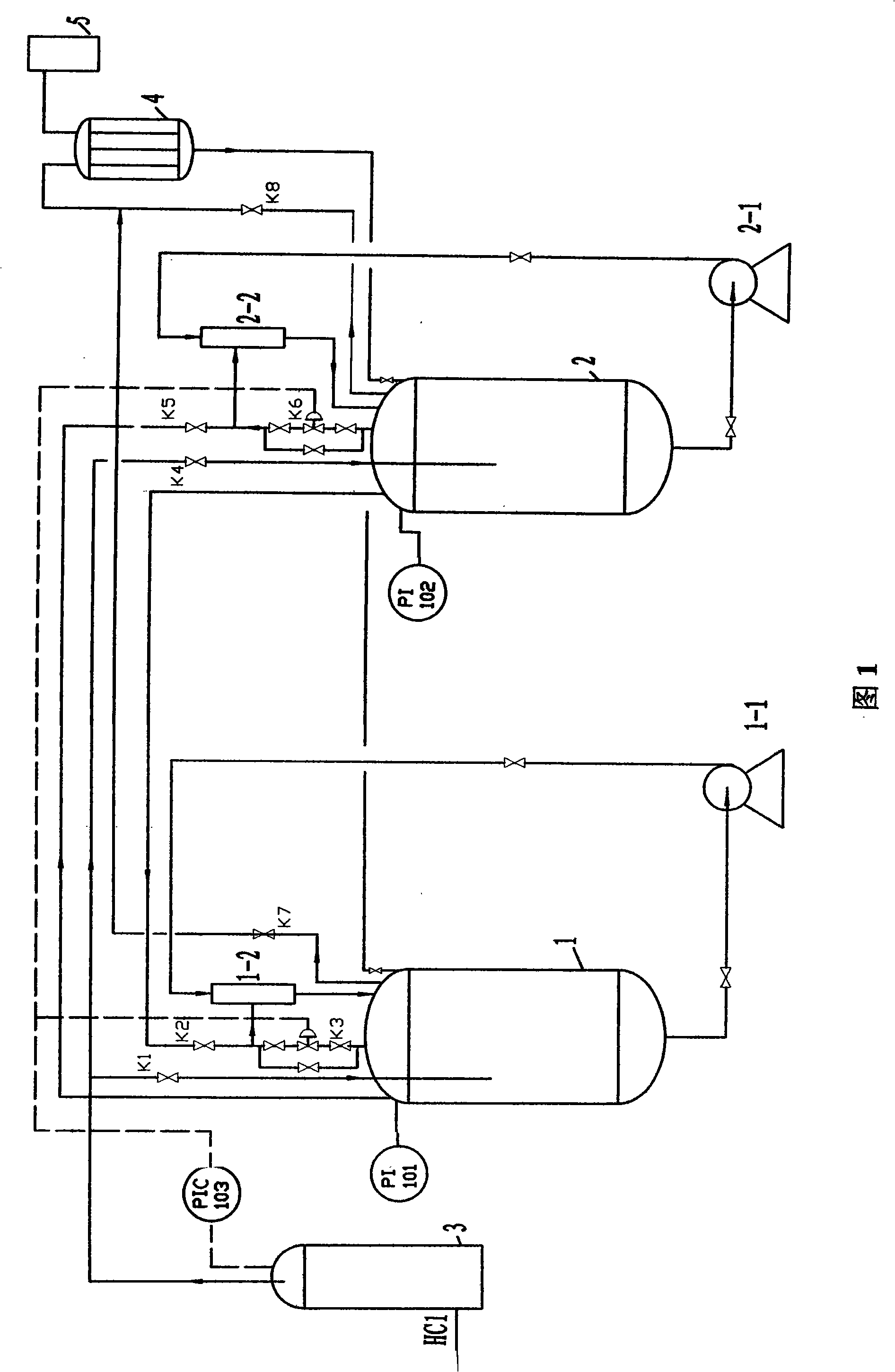

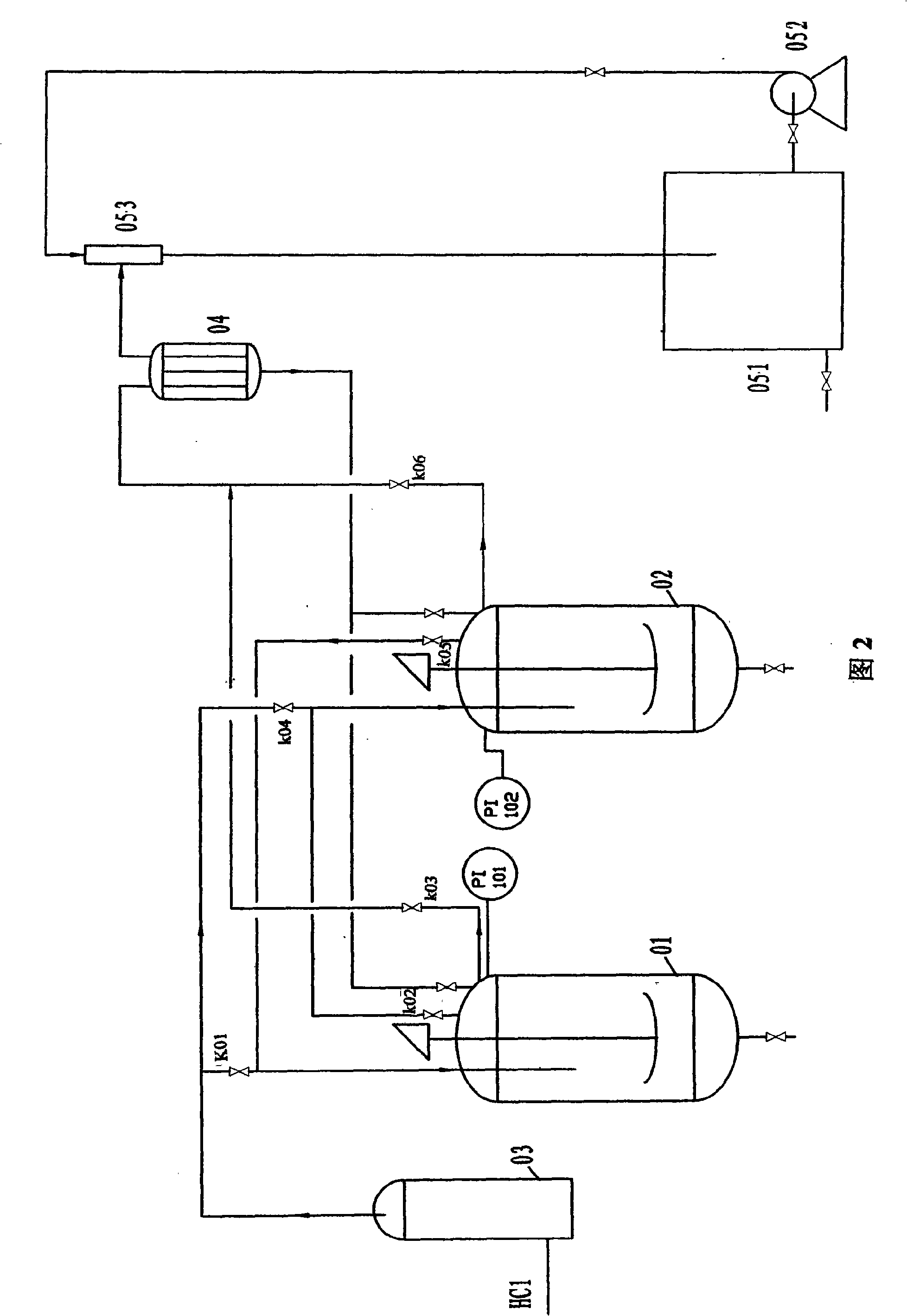

Method and apparatus for synthesizing of chloromethylether of ethylamine intermediate product

InactiveCN101302144AHighlight substantiveSignificant progressEther preparation by organic exchangeAlcoholChloromethyl ethyl ether

The invention discloses a method and a device for synthesizing chloromethyl ethyl ether, an immediate of acetochlor. Polyformaldehyde and alcohol with the needed amount are added into an A kettle and a B kettle; through circulating ejection systems of the A kettle and the B kettle, hydrochloric acid gas enters the A kettle to react, escaped hydrochloric acid gas continues to be etherified in an ejector of the A kettle and the A kettle, and the unreacted hydrochloric acid gas enters an ejector of the B kettle and the B kettle and continues to react; and uncondensed gas enters a condenser and an absorbing tank. When a product in the A kettle is qualified, the product is discharged; the operation is switched to feed fillings into the A kettle; the hydrochloric acid gas enters the B kettle for etherification, the escaped hydrochloric acid gas continues to be etherified in the B kettle and the ejector of the B kettle, the unreacted hydrochloric acid gas enters the A kettle and the ejector of the A kettle and continues to react, and unreacted light component gas enters the condenser and the absorbing tank; when a product in the B kettle is qualified, the product is discharged, and one-time switching operation of the A kettle and the B kettle is finished. The utilization rate of the hydrochloric acid gas is improved by 30 percent or so, no waste water exists during the etherification, and the cost of the product is apparently reduced.

Owner:CNPC JILIN CHEM GROUP CORP

Method and System for Production of a Chemical Commodity Using a Fiber Conduit Reactor

ActiveUS20120209014A1Improve solubilityEnhanced mass transferFatty acid esterificationPreparation by ester-hydroxy reactionFiberChemical reaction

A fiber reaction process whereby reactive components contained in immiscible streams are brought into contact to effect chemical reactions and separations. The conduit reactor utilized contains wettable fibers onto which one stream is substantially constrained and a second stream is flowed over to continuously create a new interface there between to efficiently bring about contact of the reactive species and thus promote reactions thereof or extractions thereby. Co-solvents and phase transfer catalysts may be employed to facilitate the process.

Owner:CHEMTOR LP

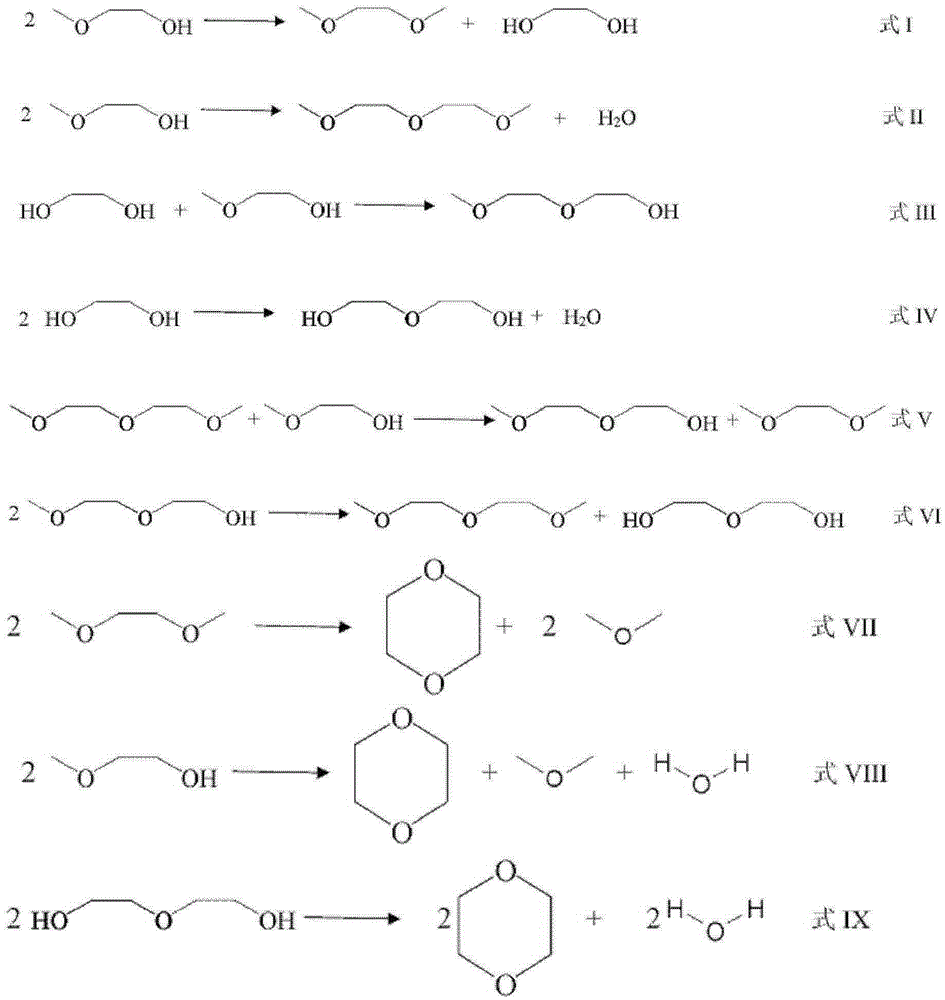

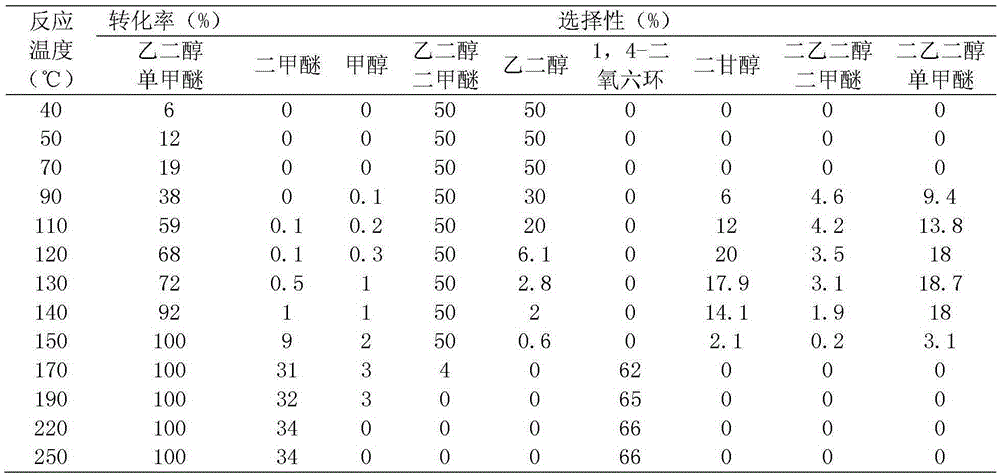

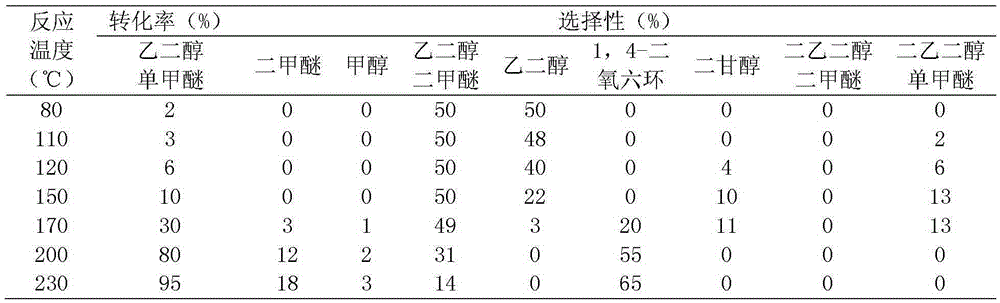

Method for directly co-preparing glycol dimethyl ether and ethylene glycol from ethylene glycol monomethyl ether

ActiveCN106554258ALess side effectsMolecular sieve catalystsBulk chemical productionPolyethylene glycolReaction temperature

The invention provides a method for directly co-preparing glycol dimethyl ether and ethylene glycol from ethylene glycol monomethyl ether. The method specifically comprises the following steps: enabling a raw material ethylene glycol monomethyl ether and optional inert gas which is taken as carrier gas to pass through a reactor loaded with a solid acid catalyst; reacting under conditions with a reaction temperature ranging from 40 DEG C to 150 DEG C and reaction pressure ranging from 0.1 Mpa to 15.0 Mpa to generate glycol dimethyl ether and ethylene glycol, wherein mass space velocity of the raw material ethylene glycol monomethyl ether ranges from 0.05 h<-1> to 5.0 h<-1>; and volume concentration of the raw material ethylene glycol monomethyl ether is 1-100%, and volume concentration of the carrier gas is 0-99%. Under a low-temperature condition, the method takes solid acid as a catalyst and takes ethylene glycol monomethyl ether as the raw material to prepare glycol dimethyl ether and ethylene glycol with high selectivity; and meanwhile, formation of a byproduct 1,4-dioxane which pollutes the environment or damages a human body or an animal body is basically or completely avoided.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

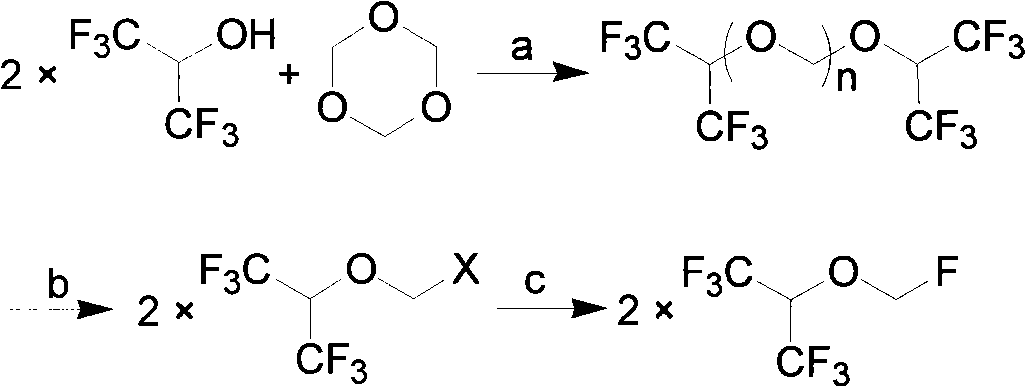

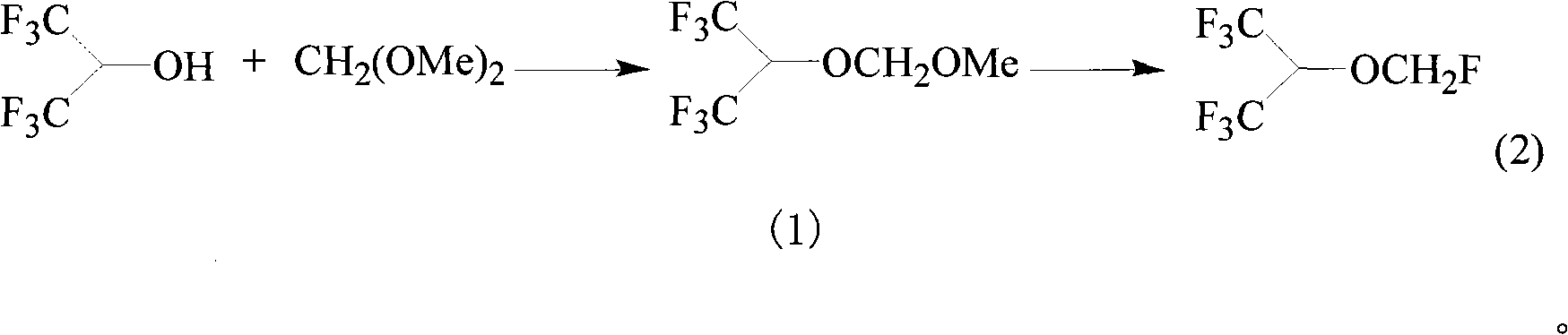

Process for synthesizing Sevoflurane

ActiveCN101314560AReduce consumptionEasy to storeOrganic compound preparationEther preparation by organic exchangeFluorideParaformaldehyde

Owner:LUNAN PHARMA GROUP CORPORATION

Compounds and methods of arylmethylation (benzylation) as protection for alcohol groups during chemical synthesis

InactiveUS7754909B1Promote oxidationGroup 4/14 element organic compoundsOrganic compound preparationChemical synthesisScavenger

A process for benzylating an alcohol includes mixing 2-benzyloxy-1-methylpyridinium triflate in an aromatic hydrocarbon solvent having a predetermined boiling point; adding an acid scavenger to the mixture; combining the alcohol to be benzylated with the mixture; reacting the alcohol with the 2-benzyloxy-1-methylpyridinium triflate by heating above ambient temperature to generate the benzylated alcohol; and separating the benzylated alcohol from the mixture.

Owner:FLORIDA STATE UNIV RES FOUND INC

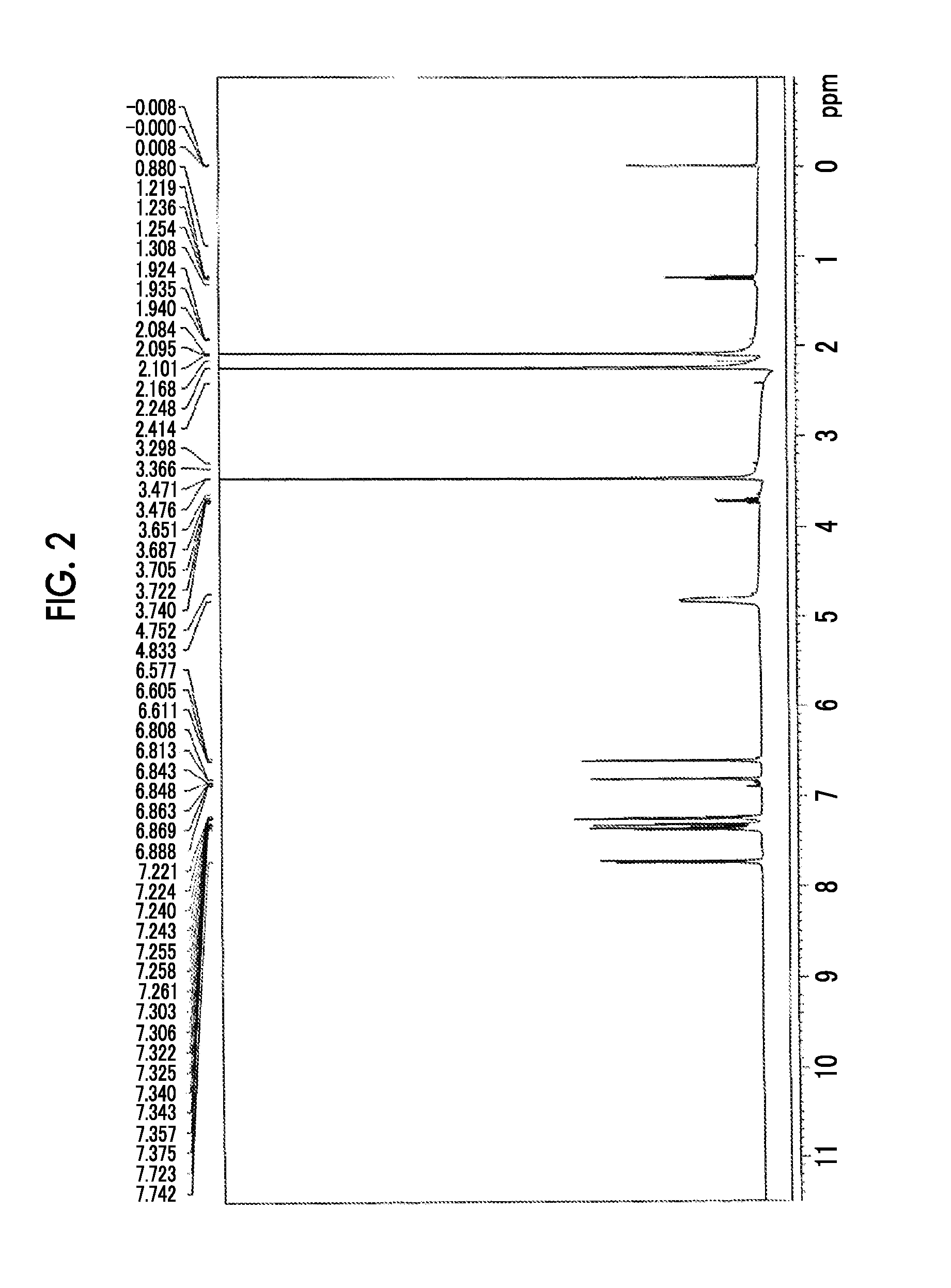

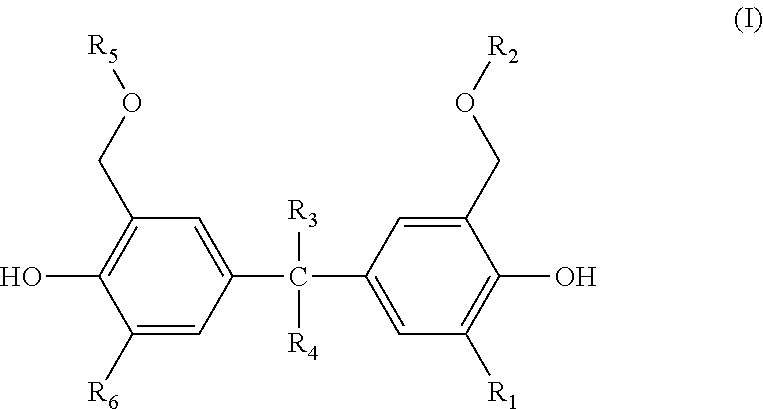

Actinic ray-sensitive or radiation-sensitive resin composition, actinic ray-sensitive or radiation-sensitive film, mask blank provided with actinic ray-sensitive or radiation-sensitive film, photomask, pattern forming method, method for manufacturing electronic device, electronic device, compound, and method for producing compound

ActiveUS20160280621A1Good storage stabilityReduce Line Width VariationOrganic compound preparationPhotomechanical exposure apparatusActinic RaysHydrogen atom

The composition contains an alkali-soluble resin and a crosslinking agent that is represented by the following General Formula (I). In the formula, each of R1 and R6 independently represents a hydrogen atom or a hydrocarbon group having 5 or less carbon atoms; each of R2 and R5 independently represents an alkyl group, a cycloalkyl group, an aryl group, or an acyl group; and each of R3 and R4 independently represents a hydrogen atom or an organic group having 2 or more carbon atoms, and R3 and R4 may be bonded to each other to form a ring.

Owner:FUJIFILM CORP

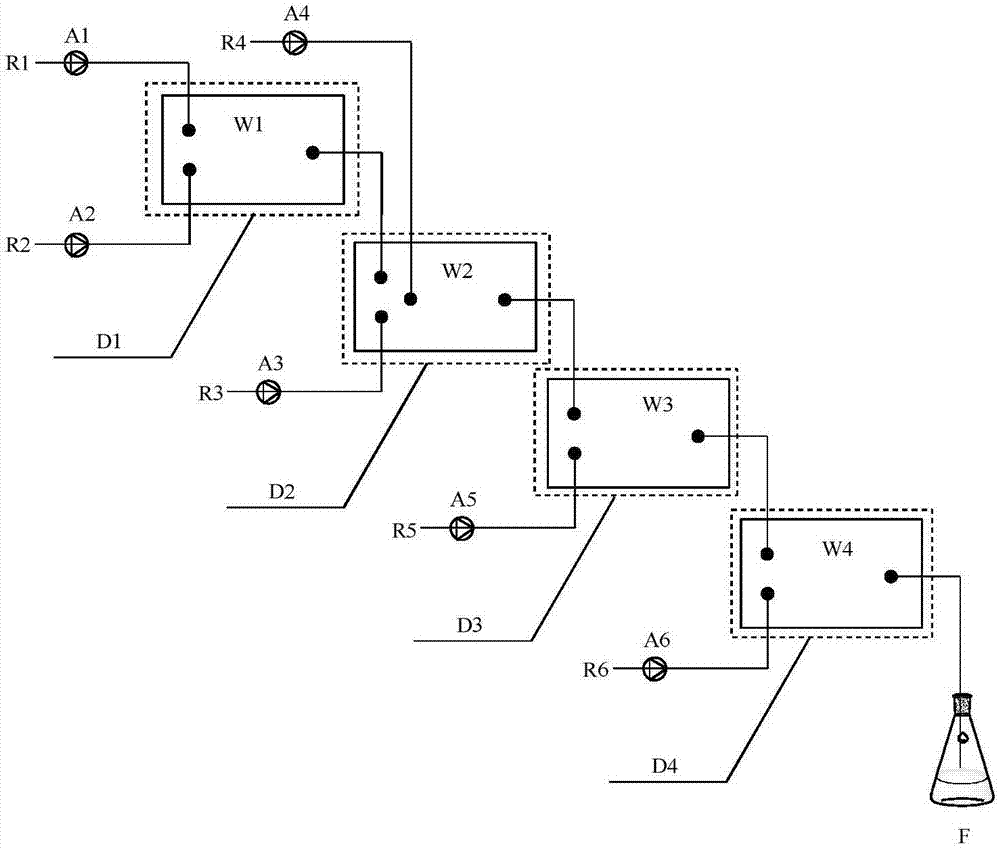

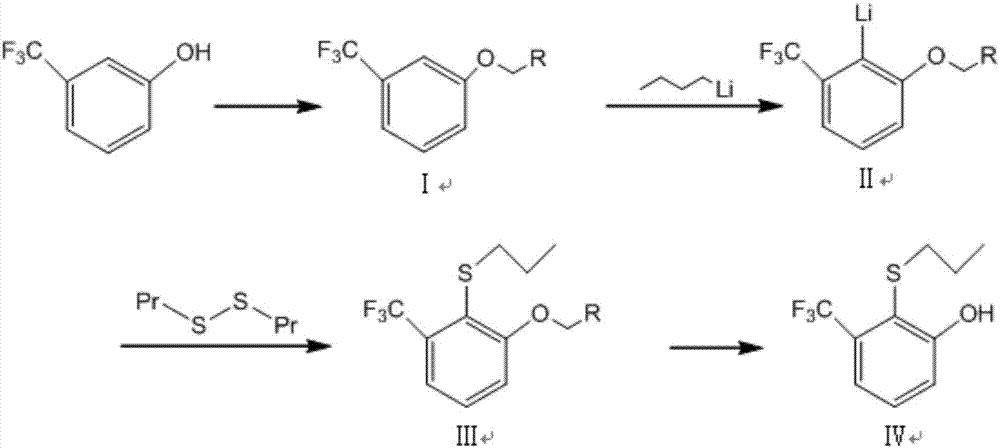

Method for preparing 2-(propylthio)-3-(trifluoromethyl)phenol in microstructural reactor

ActiveCN108003076ASolve the problems of long reaction time and high energy consumptionAvoid multiple feedsLithium organic compoundsSulfide preparationReaction temperatureRoom temperature

The invention relates to the field of fine chemical engineering, in particular to a method for preparing a penoxsulam key intermediate 2-(propylthio)-3-(trifluoromethyl)phenol in a microstructural reactor. By means of the method for preparing 2-(propylthio)-3-(trifluoromethyl)phenol in the microstructural reactor, the problem in a traditional technology that feeding and purifying need to be conducted multiple times is solved, the reaction yield is increased, the problems in the traditional technology that the reaction time is long and the energy consumption is high when butyl lithium is dropwise added at an ultralow temperature are solved, the yield is greatly increased, and meanwhile, the reaction temperature is close to the room temperature and the reaction is milder.

Owner:HUAIAN GUORUI CHEM CO LTD

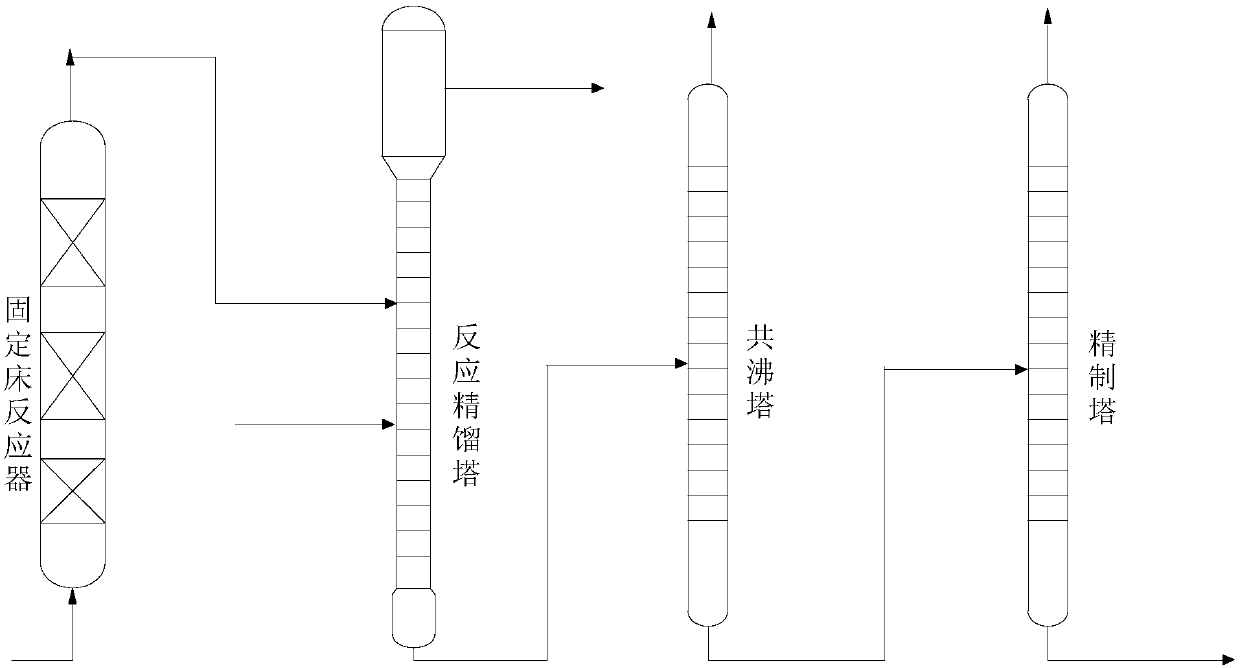

Preparation method of ethylene glycol mono-tert-butyl ether

ActiveCN110759817ALow reaction pressureSimple processEther separation/purificationChemical industryPolymer sciencePtru catalyst

The invention relates to a preparation method of ethylene glycol mono-tert-butyl ether, and belongs to the technical field of organic chemical engineering. The preparation method of the ethylene glycol mono-tert-butyl ether provided by the invention uses ethylene glycol and methyl tert-butyl ether as raw materials, uses a solid acid catalyst, and uses a fixed bed reaction and a reactive distillation process to prepare the ethylene glycol mono-tert-butyl ether. The method has low reaction pressure, a simple process flow and low production costs, and belongs to environment-friendly processes.

Owner:CHINA PETROLEUM & CHEM CORP

Method for Producing Polyoxymethylene Dimethyl Ethers

InactiveUS20150291722A1Simple processIncrease conversionsEther separation/purificationOrganic compound preparationProduct selectionFluidized bed

A method for producing polyoxymethylene dimethyl ethers using fluidized bed reactor is provided. The fluidized bed reactor gives high conversion of feedstock during synthesis of polyoxymethylene dimethyl ethers. The product separation process includes pre-rectification, extractive rectification and vacuum rectification in series. In the pre-rectification process, the side-draw fraction PODE2 is recycled into the fluidized bed reactor, thus product distribution and selectivity to target components in the reactor can be improved. The extractive rectification process realizes coupling of neutralization, extraction, recovery of unconverted feedstock and products separation, thus significantly simplifies the process. The method for preparation of polyoxymethylene dimethyl ethers in this invention is simple, and has high conversion of feedstock, low energy cost and high selectivity to products.

Owner:SHANDONG YUHUANG CHEM CO LTD +1

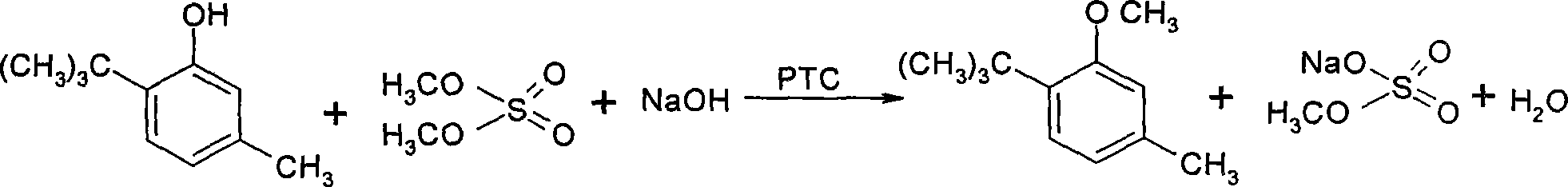

Method for preparing 3-methoxyl-4-t-butyltoluene

InactiveCN101234955AReduce pollutionSimple processEther preparation by organic exchangeMetacresolToluene

The invention discloses a method for preparing 3-methoxyl-4-tert-butyl toluene. Under the existence of quaternary ammonium salt type phase transfer catalysts, 6-tert-butyl metacresol reacts with dimethyl sulphate and water solution of hydroxides or carbonates of alkali metals at 20-50 DEG C, and 3-methoxyl-4-tert-butyl toluene can be produced with high yield. Post treatment of the reaction mixture is very simple and 3-methoxyl-4-tert-butyl toluene with a content of higher than 99.2 percent can be obtained after only two water washing operations. The method has the advantages of simple process, easy product quality control, low cost, low environment pollution and safe production and is suitable for industrialized application.

Owner:孔繁昇

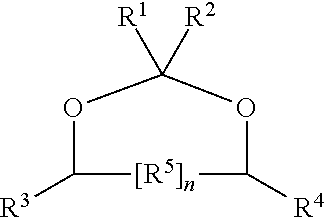

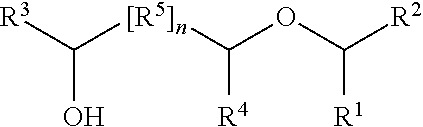

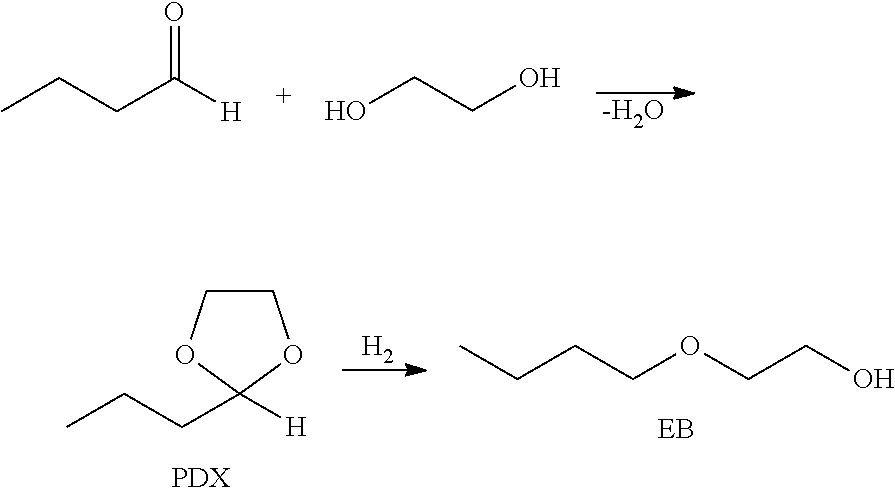

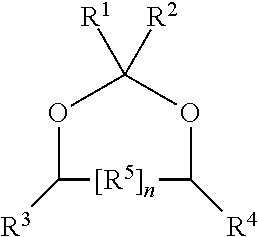

Production of hydroxy ether hydrocarbons by liquid phase hydrogenolysis of cyclic acetals or cyclic ketals

ActiveUS20120330069A1High selectivityOrganic compound preparationEther preparation by organic exchangePhosphoric acidHydroquinone Compound

A liquid phase hydrogenolysis of acetal compounds such as cyclic acetals and cyclic ketals are fed to a reaction zone and reacted in the presence of a noble metal catalyst supported on a carbon or silica support to make hydroxy ether mono-hydrocarbons in high selectivity, without the necessity to use acidic co-catalysts such as phosphorus containing acids or stabilizers such as hydroquinone.

Owner:EASTMAN CHEM CO

Method for preparing double-sealed-end glycol ether

ActiveUS20170334818A1Long single-pass lifespanHigh selectivityMolecular sieve catalystsChemical recyclingMolecular sieveAlcohol

Disclosed is a method for preparing a double end capped glycol ether, the method comprising: introducing into a reactor a raw material comprising a glycol monoether and a monohydric alcohol ether, and enabling the raw material to contact and react with an acidic molecular sieve catalyst to generate a double end capped glycol ether, a reaction temperature being 50-300° C., a reaction pressure being 0.1-15 MPa, a WHSV of the glycol monoether in the raw material being 0.01-15.0 h−1, and a mole ratio of the monohydric alcohol ether to the glycol monoether in the raw material being 1-100:1. The method of the present invention enables a long single-pass lifespan of the catalyst and repeated regeneration, has a high yield and selectivity of a target product, low energy consumption during separation of the product, a high economic value of a by-product, and is flexible in production scale and application.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Production of hydroxy ether hydrocarbons by vapor phase hydrogenolysis of cyclic acetals and ketals

ActiveUS9000229B2High selectivityEfficient responseOrganic compound preparationEther preparation by organic exchangeHydrogenGas phase

A vapor phase hydrogenolysis reaction to convert cyclic acetal compounds and / or cyclic ketal compounds in the presence of hydrogen to their corresponding hydroxy ether hydrocarbon reaction products using a supported noble metal catalyst. The hydrogenolysis reaction can be carried out in the vapor phase and in the absence of a polyhydroxyl hydrocarbon co-solvent.

Owner:EASTMAN CHEM CO

Process for producing ether compounds in presence of a copper (II) salt

InactiveUS20060052646A1High selectivityOrganic compound preparationOrganic chemistry methodsAlcoholPropyl ether

A process for producing allylic ether compounds in presence of a catalyst comprising at least one Cu(II) salt by reaction of an allylic alcohol with either itself or another alcohol.

Owner:SHOWA DENKO KK

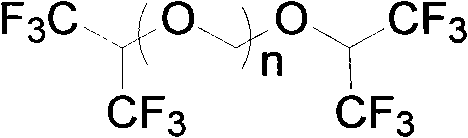

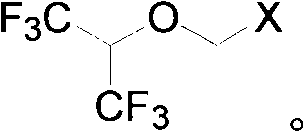

Method for preparing sevoflurane

ActiveCN101337863AIncrease profitHigh yieldEther preparation by organic exchangeStrong acidsDimethoxymethane

The invention relates to a method for preparing sevoflurane [fluoromethyl 2,2,2-trifluoro-1-(trifluoromethyl) ethyl ether], which comprises the following steps: reacting hexafluoroisopropanol with dimethoxymethane in the presence of a catalyst to obtain methoxymethylene hexafluoroisopropyl ether, and reacting methoxymethylene hexafluoroisopropyl ether with a fluoride in the presence of a strong acid to obtain the sevoflurane.

Owner:JIANGSU HENGRUI MEDICINE CO LTD +2

Method for synthesizing polyoxymethylene dimethyl ethers catalyzed by an ionic liquid

InactiveUS8816131B2Increase conversionsHigh selectivityOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsReaction zoneDimethoxymethane

It is related to a method for preparing polyoxymethylene dimethyl ethers by a continuous acetalation reaction of trioxymethylene and methanol or methylal catalyzed by an ionic liquid. The processing apparatus used in the method includes a reaction zone, a separation zone, a catalyst regeneration zone and a product dehydration zone. A manner of circulating tubular reaction is used, resulting in a high external heat exchange efficiency, a simple structure of design and a low investment. A film evaporator is used, realizing a rapid separation and recycling of the light component, with a high separation efficiency. The separation of the catalyst solution from the crude product is simple, thereby realizing the regeneration and recycling of the catalyst.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

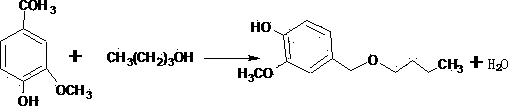

Process for producing vanillyl alcohol butyl ether

InactiveCN108658734AReduce energy consumptionImprove product qualityEther separation/purificationEther preparation by organic exchangeSaline waterEther

The invention relates to a process for producing vanillyl alcohol butyl ether. The process comprises the following steps: 1, generation of vanillyl alcohol butyl ether: extracting n-butanol, adding the n-butanol into a reaction kettle, adding vanillyl alcohol, starting carry out heating, adding 100-500 kg of anhydrous sodium sulfate in four times when the kettle temperature is increased to 50-60 DEG C, controlling the time for adding the anhydrous sodium sulfate to be 10-15 hours at each time according to the rising situation of the kettle temperature, controlling the kettle temperature to bebetween 50 DEG C and 55 DEG C after the all the anhydrous sodium sulfate is added, and then keeping the temperature for 10-15 hours, and carrying out sampling and analyzing until the reaction is completed and the vanillyl alcohol butyl ether is obtained; 2, water washing and desolvation of the vanillyl alcohol butyl ether: pumping the vanillyl alcohol butyl ether generated by the reaction in the step 1 into a desolvation kettle, carrying out washing with water, then carrying out washing with saturated saline water for twice, and carrying out standing for layering; and 3, rectification of the vanillyl alcohol butyl ether product: carrying out rectification on the vanillyl alcohol butyl ether product by using a rectification kettle, starting a vacuum pump, heating the system, controlling thetemperature to be 80-120 DEG C, and collecting the qualified product rectified out when the product containing vanillyl alcohol butyl ether is larger than or equal to 97% into a qualified product tank.

Owner:TENGZHOU TIANSHUI BIO TECH CO LTD

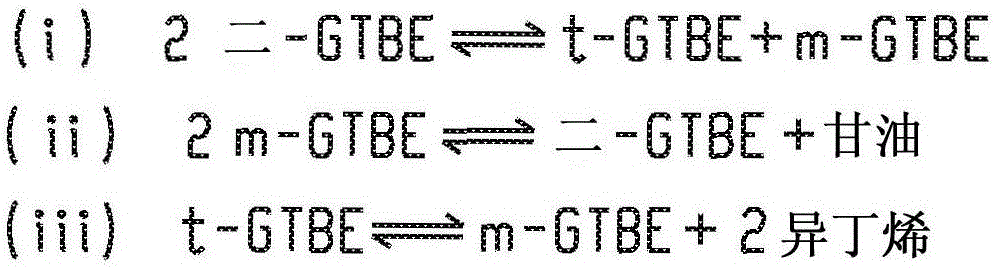

Processes and systems for generating glycerol ethers through transetherification

A process of generating a glycerol ether is provided. The process includes reacting isobutylene with an alcohol to obtain a tertiary alkyl ether through an etherification reaction and generating a glycerol ether from the tertiary alkyl ether and glycerol through a transetherification reaction, A system for generating a glycerol ether is also provided.

Owner:SAUDI BASIC IND CORP SA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com

![Method for the preparation of 2-{2-[4-(4-chloro-1,2-diphenylbut-1-enyl)phenoxy]ethoxy}ethanol and its isomers Method for the preparation of 2-{2-[4-(4-chloro-1,2-diphenylbut-1-enyl)phenoxy]ethoxy}ethanol and its isomers](https://images-eureka.patsnap.com/patent_img/79fd2cae-e8f3-4a25-9386-d56340c40fbc/US06891070-20050510-C00001.png)

![Method for the preparation of 2-{2-[4-(4-chloro-1,2-diphenylbut-1-enyl)phenoxy]ethoxy}ethanol and its isomers Method for the preparation of 2-{2-[4-(4-chloro-1,2-diphenylbut-1-enyl)phenoxy]ethoxy}ethanol and its isomers](https://images-eureka.patsnap.com/patent_img/79fd2cae-e8f3-4a25-9386-d56340c40fbc/US06891070-20050510-C00002.png)

![Method for the preparation of 2-{2-[4-(4-chloro-1,2-diphenylbut-1-enyl)phenoxy]ethoxy}ethanol and its isomers Method for the preparation of 2-{2-[4-(4-chloro-1,2-diphenylbut-1-enyl)phenoxy]ethoxy}ethanol and its isomers](https://images-eureka.patsnap.com/patent_img/79fd2cae-e8f3-4a25-9386-d56340c40fbc/US06891070-20050510-C00003.png)