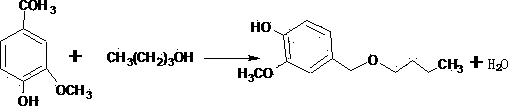

Process for producing vanillyl alcohol butyl ether

A technology of vanillyl butyl ether and process is applied in the technological field of producing vanillyl butyl ether, can solve problems such as high price, and achieve the effects of low cost, simplified production process and good product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] 1. Pump 380Kg of n-butanol into the 1000L reaction kettle, stir for 30 minutes, add 40kg of vanillic alcohol, and start heating when the temperature of the kettle rises to 50-60 degrees, start adding 100kg of anhydrous sodium sulfate. Anhydrous sodium sulfate is added in four times at different temperatures, followed by: the temperature is controlled between 50-52 degrees, and 30% of the total weight of anhydrous sodium sulfate is added; the temperature is controlled between 52-54 degrees, and the total weight is added 30%; the temperature is controlled between 54-56 degrees, and 20% of the total weight is added; the temperature is controlled between 56-60 degrees, and the remaining anhydrous sodium sulfate is added, and anhydrous sodium sulfate is added each time according to the temperature rise. The time for sodium sulfate water is 10-15 hours. After the addition, the temperature is controlled between 50-55 degrees, and then the temperature is kept for 10-15 hours, an...

Embodiment 2

[0032] 1. Pump 760Kg of n-butanol into the 1000L reaction kettle, start stirring, add 80kg of vanillin alcohol, and start heating when the temperature of the kettle rises to 50-60 degrees, start adding 200kg of anhydrous sodium sulfate. Anhydrous sodium sulfate is added in four times at different temperatures, followed by: the temperature is controlled between 50-52 degrees, and 30% of the total weight of anhydrous sodium sulfate is added; the temperature is controlled between 52-54 degrees, and the total weight is added 30%; the temperature is controlled between 54-56 degrees, and 20% of the total weight is added; the temperature is controlled between 56-60 degrees, and the remaining anhydrous sodium sulfate is added, and anhydrous sodium sulfate is added each time according to the temperature rise. The time for sodium sulfate water is 10-15 hours. After the addition, the temperature is controlled between 50-55 degrees, and then the temperature is kept for 10-15 hours, and the...

Embodiment 3

[0041]1. Pump 1140Kg of n-butanol into the 3000L reaction kettle, start stirring, add 120kg of vanillin alcohol, start heating when the temperature of the kettle rises to 50-60 degrees, start adding 300kg of anhydrous sodium sulfate. Anhydrous sodium sulfate is added in four times at different temperatures, followed by: the temperature is controlled between 50-52 degrees, and 30% of the total weight of anhydrous sodium sulfate is added; the temperature is controlled between 52-54 degrees, and the total weight is added 30%; the temperature is controlled between 54-56 degrees, and 20% of the total weight is added; the temperature is controlled between 56-60 degrees, and the remaining anhydrous sodium sulfate is added, and anhydrous sodium sulfate is added each time according to the temperature rise. The time for sodium sulfate water is 10-15 hours. After the addition, the temperature is controlled between 50-55 degrees, and then the temperature is kept for 10-15 hours, and the sa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com