Method for preparing glycerin ether from glycerol

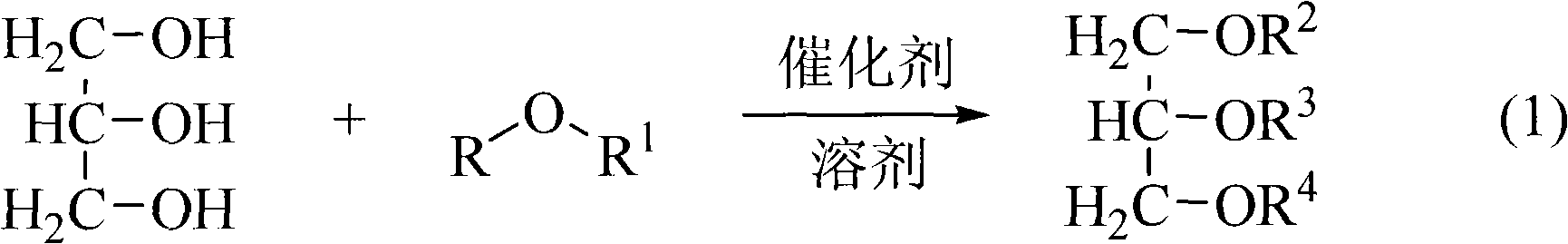

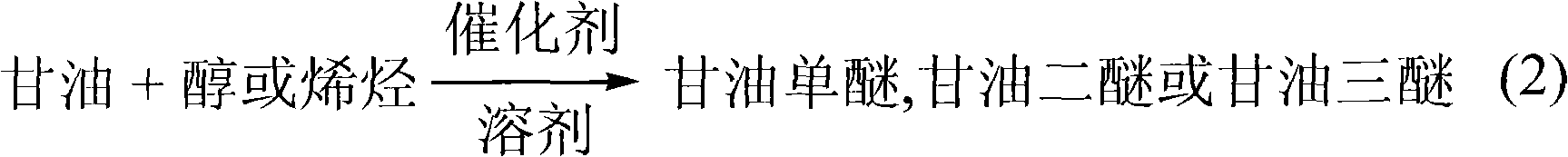

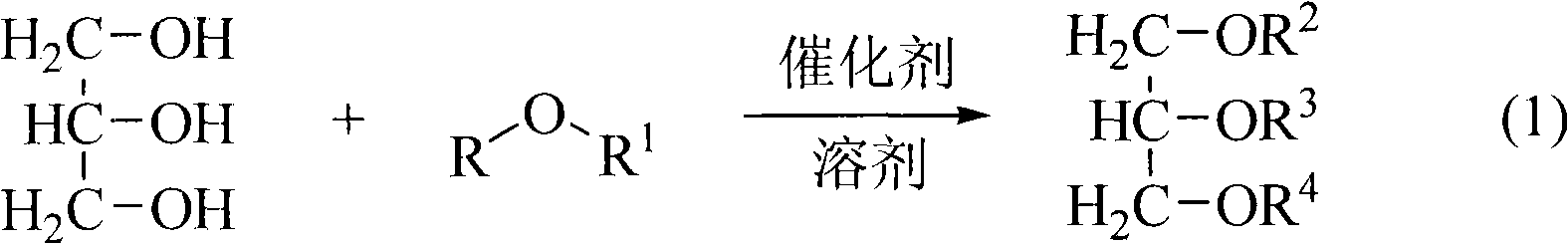

A technology of glycerol ether and glycerol diether is applied in the field of preparation of glycerol ether, and can solve the problems of low yield, inconvenient transportation and storage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] In the 500ml stainless steel autoclave, add NaCl (mass fraction is 8%) and H 2 O (mass fraction is 10%) crude glycerin 22.4g (containing glycerin 0.2mol, 18.4g), 0.6mol (76.9g) ethyl cyclohexyl ether, 18.4mg p-toluenesulfonic acid and 100ml dimethyl sulfoxide, 0.1 MPa N 2 The reaction was carried out at 140°C for 8h under the atmosphere. After the reaction, the lower layer of the mixed solution was dimethyl sulfoxide and unreacted glycerin, which was recovered and reused. The upper layer was evaporated to distill ethyl cyclohexyl ether and washed with water (20ml×3) to obtain 14.0 g of dicyclohexyl glycerin ether, with a yield of 27.3 %. HRMS (EI): C 15 h 28 o 3 (M + ): 256.2022, calculated value: 256.2038.

Embodiment 2

[0025] Add 0.2mol (18.4g) glycerol, 2mol (174.6g) methyl tert-butyl ether and 1.84g Amberlyst 35 into a 500ml stainless steel autoclave, and react at 50°C for 48h. After the reaction, the mixture was filtered, and the lower layer of the filtrate was unreacted glycerin, which was recovered and reused. The upper layer was evaporated to remove methyl tert-butyl ether and washed with water (20ml×3) to obtain 14.5 g of di-tert-butyl glycerol ether, with a yield of 35.5%. . HRMS (EI): C 11 h 24 o 3 (M + ): 204.1730, calculated value: 204.1725.

Embodiment 3

[0027] Add 0.4mol (36.8g) glycerol, 2mol (174.6g) methyl tert-butyl ether and 368mg NR50, 0.1MPaN 2The reaction was carried out at 100°C for 16h under the atmosphere. After the reaction, the mixture was filtered, and the lower layer of the filtrate was unreacted glycerin, which was recovered and reused. The upper layer was evaporated to remove methyl tert-butyl ether and washed with water (20ml×3) to obtain 13.4g of di-tert-butyl glycerol ether, with a yield of 16.4%. . HRMS (EI): C 11 h 24 o 3 (M + ): 204.1730, calculated value: 204.1725.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com