Modified bio-based high-performance water reducing agent and preparation method thereof

A high-performance, bio-based technology, applied in the field of concrete admixtures, can solve the problems of high equipment requirements and energy consumption, low conversion utilization rate of grafting and copolymerization reactions, and difficulty in meeting low-carbon energy saving, etc. The effect of high-value utilization and efficient utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

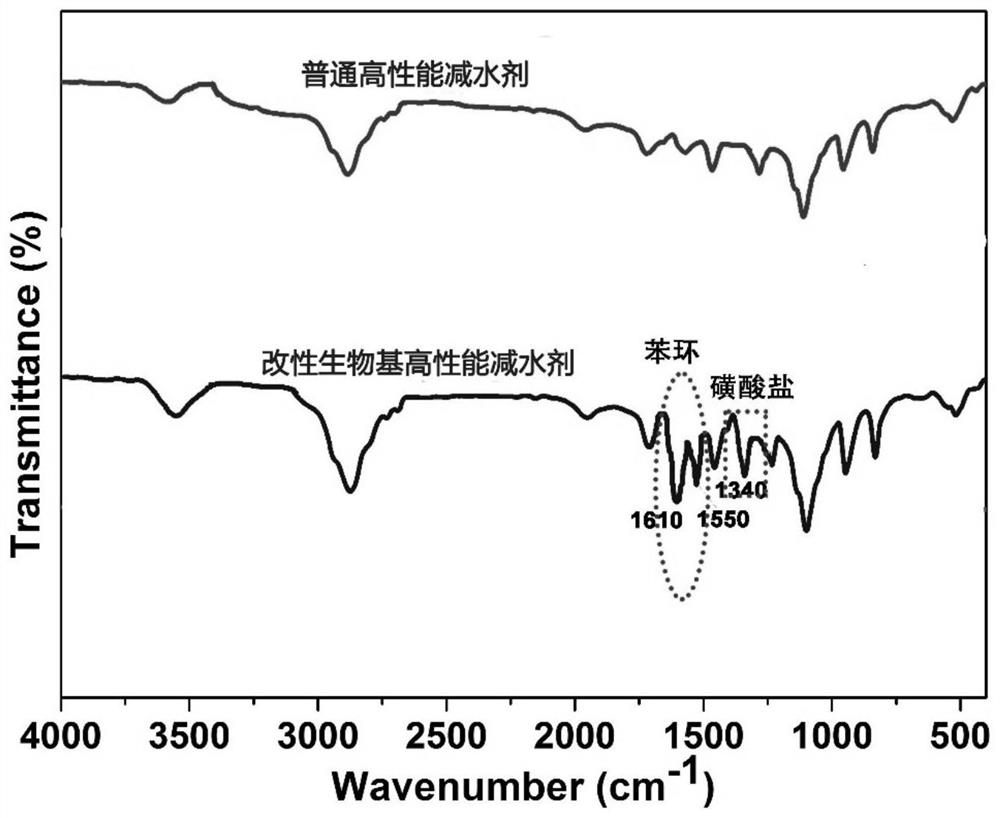

Image

Examples

Embodiment 1

[0040] A preparation method of a modified bio-based high-performance water reducer, the steps are as follows:

[0041] S1. Preparation of double bond-activated lignin derivatives:

[0042] S11. Weigh 250g of alkali lignin and 750g of deionized water in a container, raise the temperature to 50°C, continue to stir and dissolve, use an ultrafiltration membrane with a molecular weight cut-off of 2500 to separate, and then perform rotary evaporation and concentration to obtain a concentration of 40.5%. Purified alkali lignin solution. Weigh 250 g of the purified alkali lignin solution, add 3.2 g of acetic acid, and adjust the pH value of the filtrate to about 2 to prepare an acidic alkali lignin solution.

[0043] S12. Add 200 g of acidic alkali lignin solution and 1.5 g of hexamethylenetetramine into a reaction vessel with a reflux condensing device, keep stirring, control the reaction temperature at 75° C., and react for 6 hours to obtain alkylamino-modified Alkali lignin.

[00...

Embodiment 2

[0049] A preparation method of a modified bio-based high-performance water reducer, the steps are as follows:

[0050] S1. Preparation of double bond-activated lignin derivatives:

[0051] S11. Weigh 200g of sodium alkali lignin carboxylate and 800g of deionized water in a container, raise the temperature to 40°C, continue to stir and dissolve, use an ultrafiltration membrane with a molecular weight cut-off of 3000 to separate, and then perform rotary evaporation and concentration to obtain the concentration A 35.6% solution of purified alkali lignin sodium carboxylate. Weigh 500 g of purified alkali lignin sodium carboxylate solution, add 3.5 g of hydrochloric acid, adjust the pH value of the filtrate to about 1, and prepare an acidic alkali lignin sodium carboxylate solution.

[0052] S12. Add 300g of acidic alkali lignin sodium carboxylate solution and 1.0g of hexamethylenetetramine into a reaction vessel with a reflux condensing device, keep stirring, control the reaction...

Embodiment 3

[0058] A preparation method of a modified bio-based high-performance water reducer, the steps are as follows:

[0059] S1. Preparation of double bond-activated lignin derivatives:

[0060] S11. Weigh 300g of alkali lignin potassium carboxylate and 700g of deionized water in a container, raise the temperature to 50°C, continue to stir and dissolve, use an ultrafiltration membrane with a molecular weight cut-off of 3500 to separate, and then perform rotary evaporation and concentration to obtain the concentration A 50.3% solution of purified alkali lignin potassium carboxylate. Weigh 400 g of purified alkali lignin potassium carboxylate solution, add 1.8 g of sulfuric acid, and adjust the pH value of the filtrate to about 1 to prepare an acidic alkali lignin potassium carboxylate solution.

[0061] S12. Add 200g of acidic alkali lignin potassium carboxylate solution and 2.0g of hexamethylenetetramine into a reaction vessel with a reflux condensation device, keep stirring, contr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com