Iodine pentafluoride production equipment and production method

A technology of iodine pentafluoride and production equipment, applied in the direction of inter-halogen compounds, etc., can solve the problems of easy formation of agglomerates of iodine, low iodine solubility, and inability to continuously perform production, and achieves good cooling and condensation effects and heat exchange efficiency. High and full use of energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] In order to describe the technical content, structural features, achieved goals and effects of the present invention in detail, the following will be described in detail in conjunction with the embodiments and accompanying drawings.

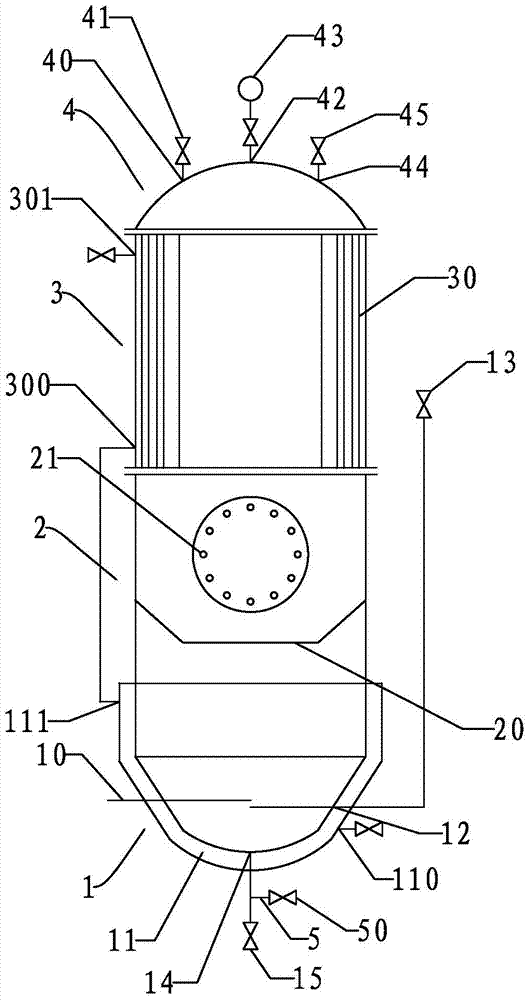

[0051] see figure 1As shown, the iodine pentafluoride production equipment of the present embodiment includes a closed reactor, and the reactor includes a liquid phase zone 1, a solid phase zone 2, a condensation zone 3 and an exhaust zone 4 from bottom to top; A temperature measuring rod 10 is arranged in the liquid phase area 1, and a cooling water jacket 11 is arranged outside the liquid phase area 1, and the water inlet 110 of the cooling water jacket 11 is located at the bottom of the cooling water jacket 11, so The water outlet 111 of the cooling water jacket 11 is located at the top of the cooling water jacket 11, and the side of the liquid phase region 1 is provided with a fluorine gas inlet 12, and the fluorine gas inlet 12 is con...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com