A kind of preparation method and production equipment of iodine pentafluoride

A technology of iodine pentafluoride, fluorine-nitrogen mixed gas, applied in the direction of inter-halogen compounds, etc., can solve the problems of difficult continuous production, low product yield, unstable product quality, etc., and achieves easy automatic control and high product yield. , suitable for large-scale industrial production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

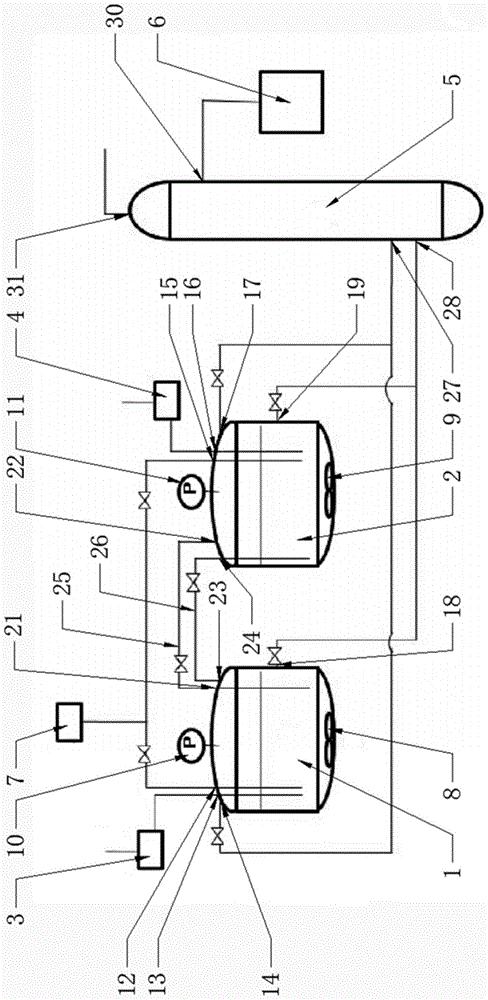

[0037] The production equipment of the iodine pentafluoride of the present embodiment, as figure 1As shown, it comprises a first reactor 1, a second reactor 2, a separation and rectification device 5, a first iodine heating device 3 and a second iodine heating device 4; the top of the first reactor 1 is provided with the first iodine Feeding pipe 13 and the first fluorine nitrogen inlet pipe 12, one end of the first iodine feeding pipe 13 communicates with the first iodine heating device 3, and the other end (end) goes deep into the bottom of the first reaction kettle 1 inner cavity, and the One end of the first fluorine-nitrogen inlet pipe 12 is communicated with the gas supply system 7, and the other end (end) goes deep into the bottom of the first reactor 1 inner chamber; the top of the second reactor 2 is provided with a second iodine feed pipe 16 With the second fluorine nitrogen inlet pipe 15, one end of the second iodine feeding pipe 16 communicates with the second iodi...

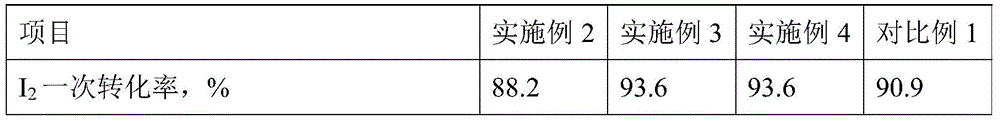

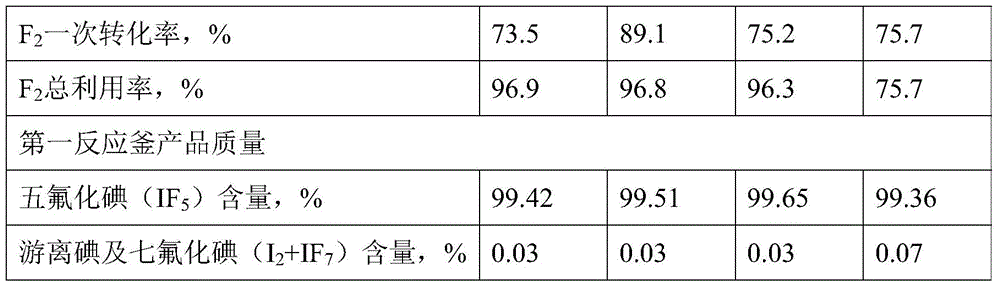

Embodiment 2

[0041] The preparation method of the iodine pentafluoride of the present embodiment uses the production equipment of embodiment 1, specifically comprises the following steps:

[0042] 1) The reactor is vacuumized, and 100kg iodine pentafluoride is added respectively in the first reactor and the second reactor, and solid iodine is added to the first and second iodine heating devices for melting respectively, and the molten iodine passes through the first and second iodine heating devices. One, the second iodine feeding pipe flows into the reactor under the iodine pentafluoride liquid level, the add-on of molten iodine is 10kg (10% of the iodine pentafluoride quality) in each reactor, in the first reactor and the second A mixed system of iodine-containing iodine pentafluoride solution and slurry-like iodine pentafluoride is formed in the reaction kettle, and the temperature of the mixed system is controlled to be 70°C;

[0043] 2) Through the gas supply system and the first fluo...

Embodiment 3

[0050] The preparation method of the iodine pentafluoride of the present embodiment uses the production equipment of embodiment 1, specifically comprises the following steps:

[0051] 1) The reactor is vacuumized, and 100kg iodine pentafluoride is added respectively in the first reactor and the second reactor, and solid iodine is added to the first and second iodine heating devices for melting respectively, and the molten iodine passes through the first and second iodine heating devices. One, the second iodine feeding pipe flows into the reactor under the iodine pentafluoride liquid level, the add-on of molten iodine is 5kg (5% of the iodine pentafluoride quality) in each reactor, in the first reactor and the second A mixed system of iodine-containing iodine pentafluoride solution and slurry-like iodine pentafluoride is formed in the reaction kettle, and the temperature of the mixed system is controlled to be 50°C;

[0052] 2) Through the gas supply system and the first fluori...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com