Method and equipment for distilling and purifying iodine pentafluoride

A technology of iodine pentafluoride and rectification, applied in the direction of interhalogen compounds, etc., can solve problems such as inability to separate hydrogen fluoride, blockage of valves and pipelines, high viscosity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

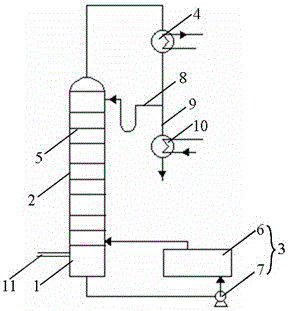

Image

Examples

Embodiment 1

[0059] The equipment and method of the present invention are used to separate the crude product with a mass fraction of iodine pentafluoride of 98%. The rectification device has a column diameter of φ20mm, a built-in tray, and the number of trays is 20. The feeding position is the tower kettle. Control the temperature at the bottom of the tower to 130°C, the temperature at the top of the tower to 115°C, and the reflux ratio to 5. Among them, the gas phase product from the gas phase extraction outlet at the top of the tower is cooled to a liquid phase product (colorless), with a content of 99.8%, and a metal ion content of 40ppm (total).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com