Conveyor belt longitudinal-tearing online monitoring early warning device

A monitoring and early warning, longitudinal tearing technology, applied in the conveyor control device, conveyor objects, transportation and packaging, etc., can solve the problems of poor reliability and poor real-time performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

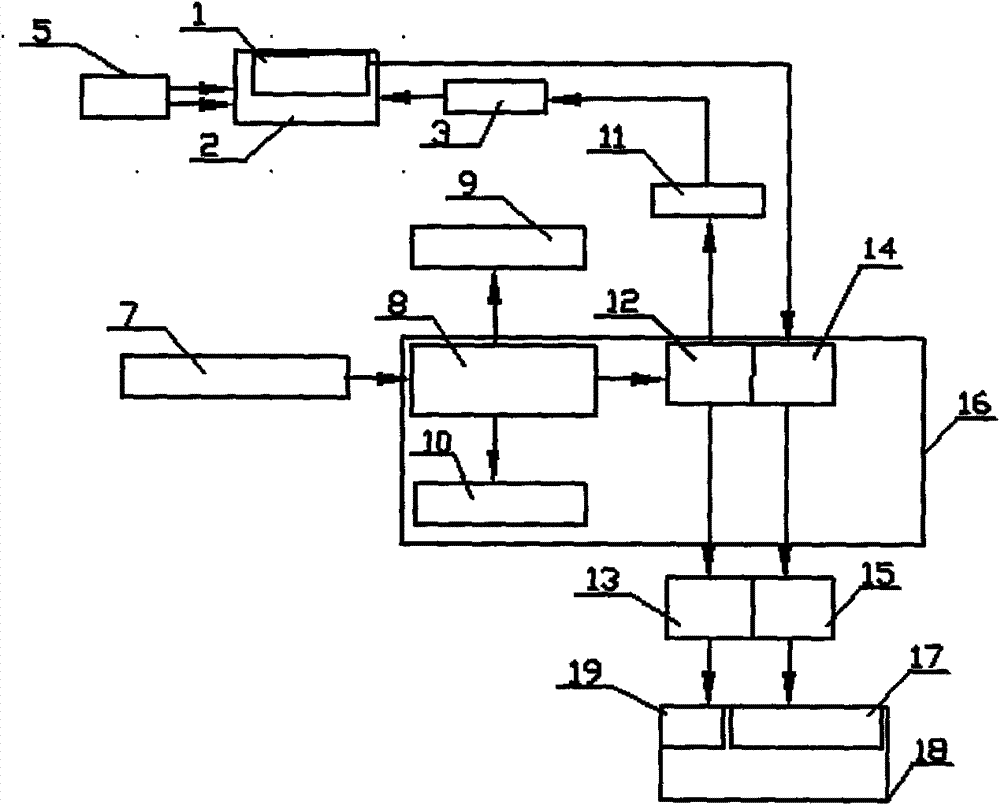

Embodiment approach 1

[0037] Embodiment 1: When the width of the belt conveyor belt is 2m and the conveyor belt speed is lower than 5m / s, the working process of the online monitoring and early warning device for longitudinal tear of the conveyor belt is: MV-VS200FM / installed under the conveyor belt C The 1394 signal output by the CCD infrared camera 1 is converted by the VS-IE200 1394 signal to optical fiber module 14 and then transmitted to the VS-IE200 optical fiber to 1394 signal module 15 in the central control room through the optical fiber, and then the 1394 signal is passed through the MV-1394 image capture card 17 Transmit to the upper computer 18, compare the processed image features through the image processing software system of the upper computer 18, realize the identification of the surface crack and tear image of the conveyor belt and calculate the crack length. When the crack length reaches the set first threshold, the upper computer 18 communicates with the programmable logic control...

Embodiment approach 2

[0056] Embodiment 2: When the width of the belt conveyor belt is less than 1m and the conveyor belt speed is lower than 3m / s, the main technical indicators of the device are:

[0057] Power supply: Inoue: ~220V±10%50HZ

[0058] Downhole: ~127V±10%50HZ

[0059] Signal transmission distance: PLC and host computer communication optical fiber transmission: 40Km

[0060] Infrared CCD camera output signal fiber transmission: 1Km

[0061] Working temperature: 30℃

[0062] Detection accuracy: 98%

[0063] Image detection resolution: 1.5mm

[0064] Imaging frame rate: 30 frames / s

[0065] Conveyor belt width: 0.9m

[0066] Check the running speed of the conveyor belt: 2m / s.

[0067] Explosion-proof standard: GB3836.2-2000 GB3836.4-2000

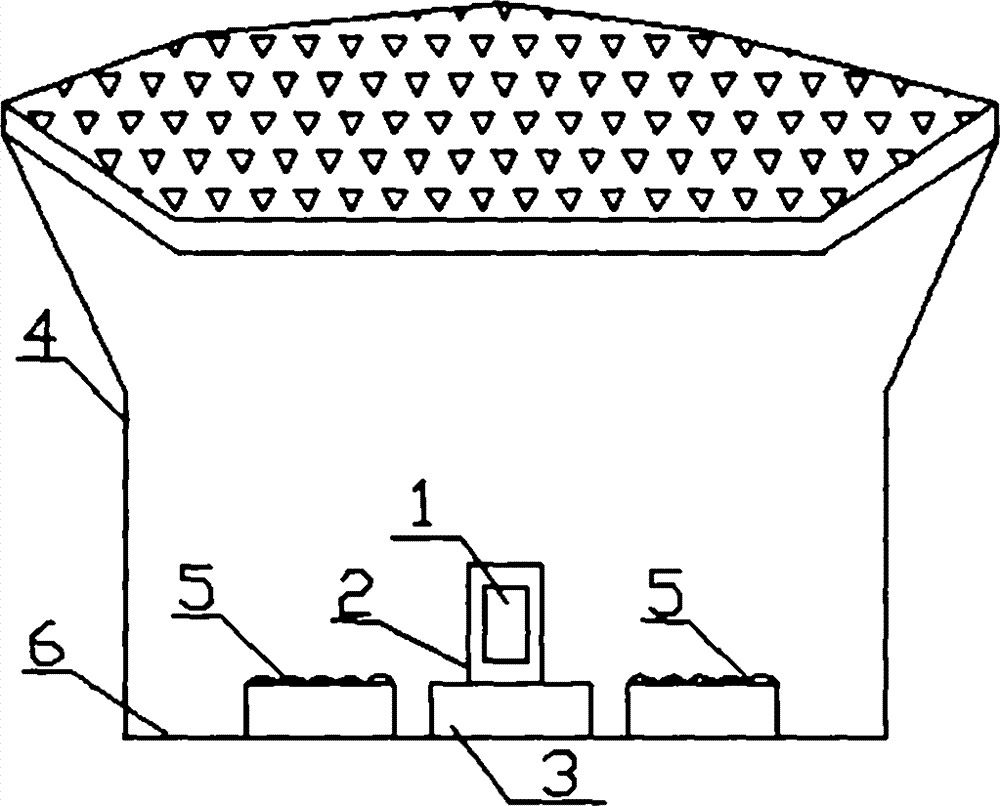

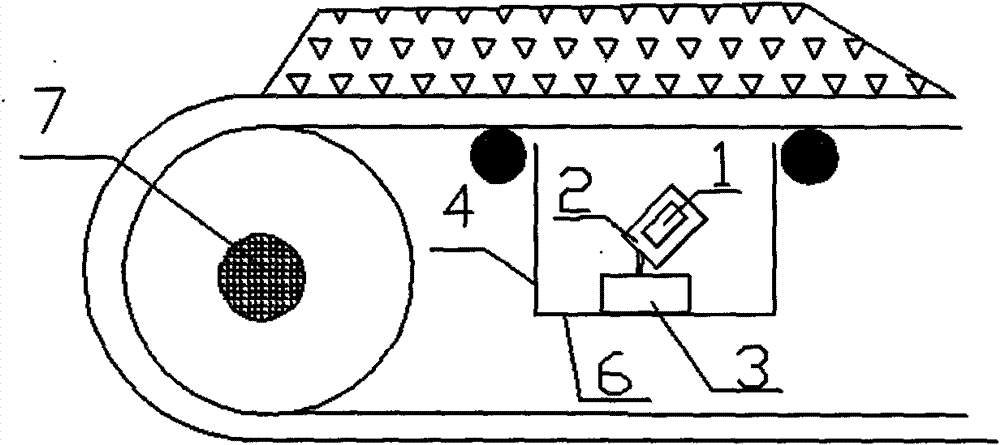

[0068] The sealed cabin 4 of the compensation device used to provide a stable light and dark environment for the detection device is formed by connecting a funnel body welded by steel plates and a rectangular cylinder body: a funnel body welded by f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com