Novel technology for preparing pentafluoroethyl iodide by one-step method

A technology for pentafluoroiodoethane and iodine pentafluoride is applied in the field of one-step preparation of pentafluoroiodoethane, and can solve the problems of easy oxidation or carbon deposition of catalyst carrier, difficult control of selectivity and yield, and unfavorable industrial production. , to save energy, prevent damage to equipment, and facilitate industrialization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

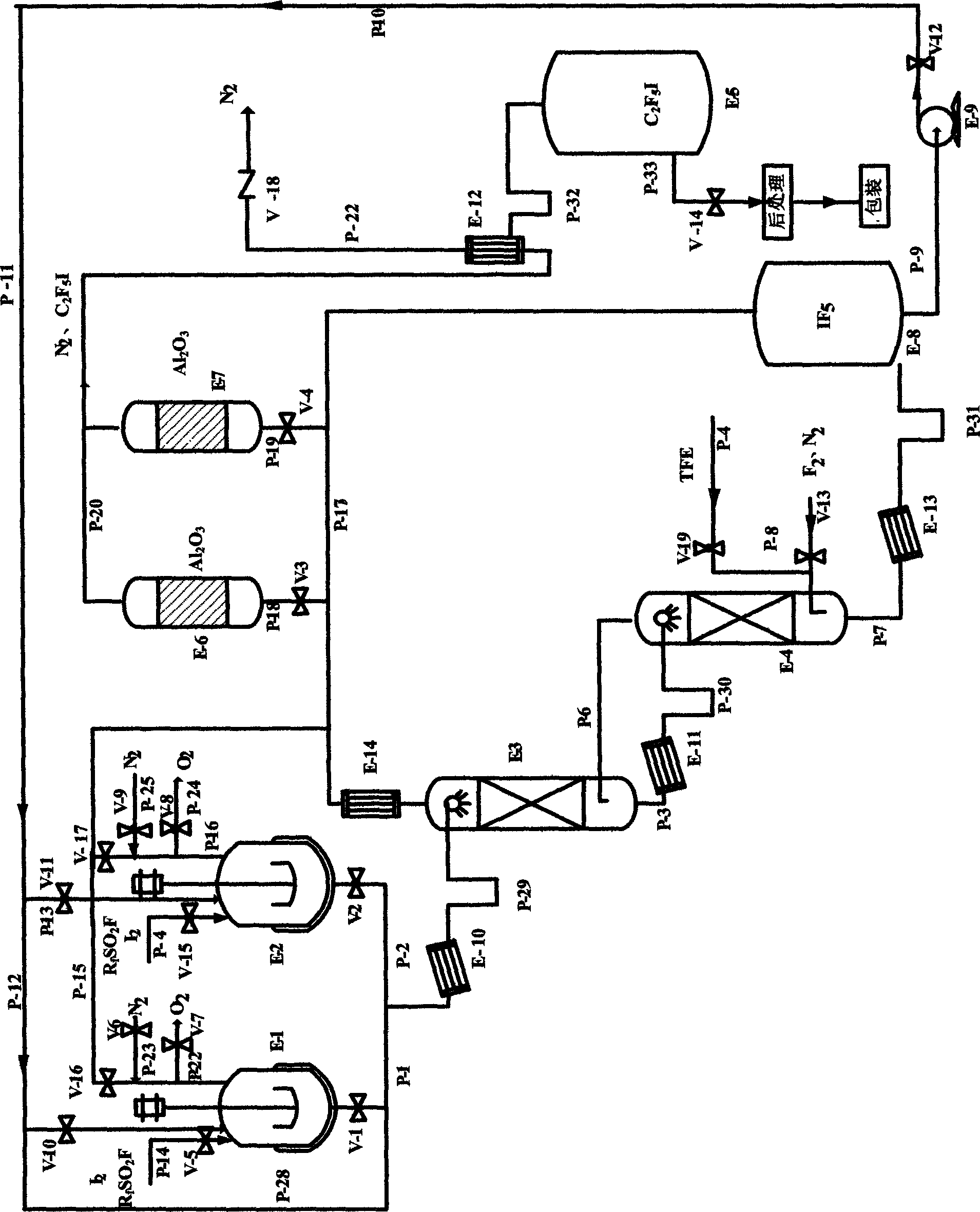

[0033] according to figure 1 Shown, the technique that the present invention one-step method prepares pentafluoroiodoethane adopts multi-stage tower reactor serial process flow, and according to technological needs, tower number can be 1~N level, N≥2; Iodine solution (pentafluoride iodine as a solvent), perfluoroalkylsulfonyl fluoride and fluorine-nitrogen mixed gas, and tetrafluoroethylene gas respectively enter the multi-stage reaction tower from both ends to react in reverse flow. The heat absorbed when dissolving iodine and the heat generated in the reaction are taken out through the condenser between the towers, and the reaction tower and the condenser are connected by a U-shaped tube. During the reaction, the U-shaped liquid-sealed tube is filled with iodine solution, thereby avoiding It prevents fluorine gas from entering the iodine solution pipeline, and achieves the effect of preventing pipeline short circuit. The concentration of iodine solution decreases step by st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com