Controllable flame burner and method for synthesizing carbon nano tubes

A technology of carbon nanotubes and flame combustion, applied in the direction of nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve the problems of product existence, poor controllability of heat source temperature, and the need to increase the output of carbon nanotubes, etc. problems, to achieve the effect of expanding the effective collection area, reducing impurities and increasing production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

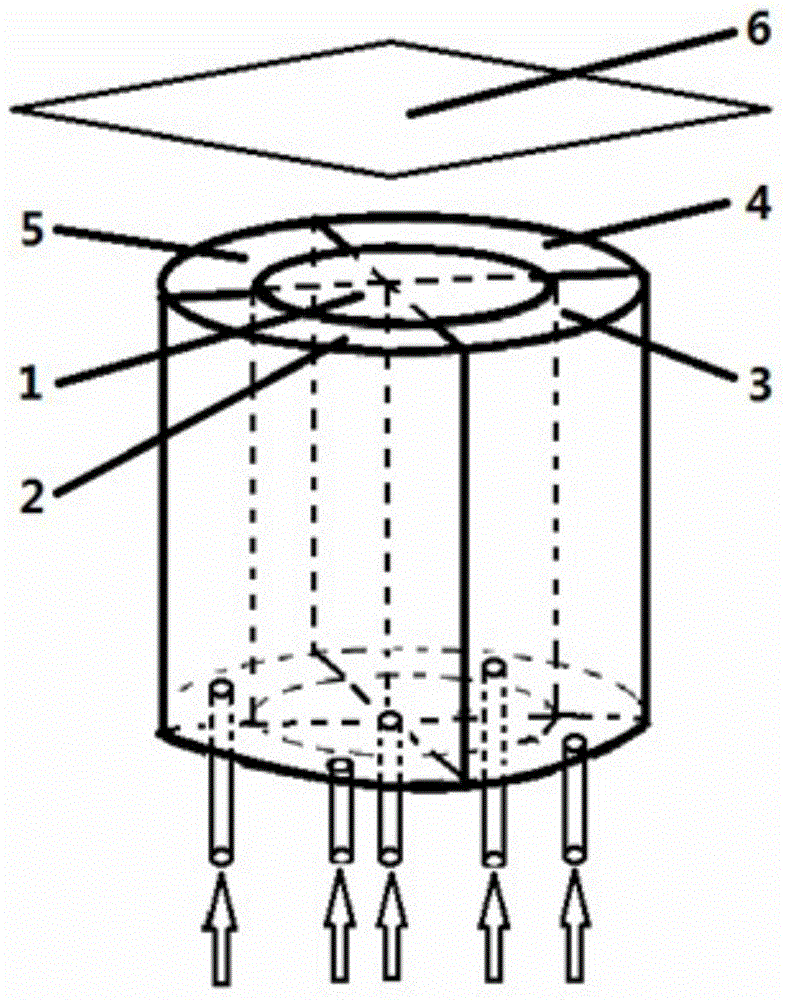

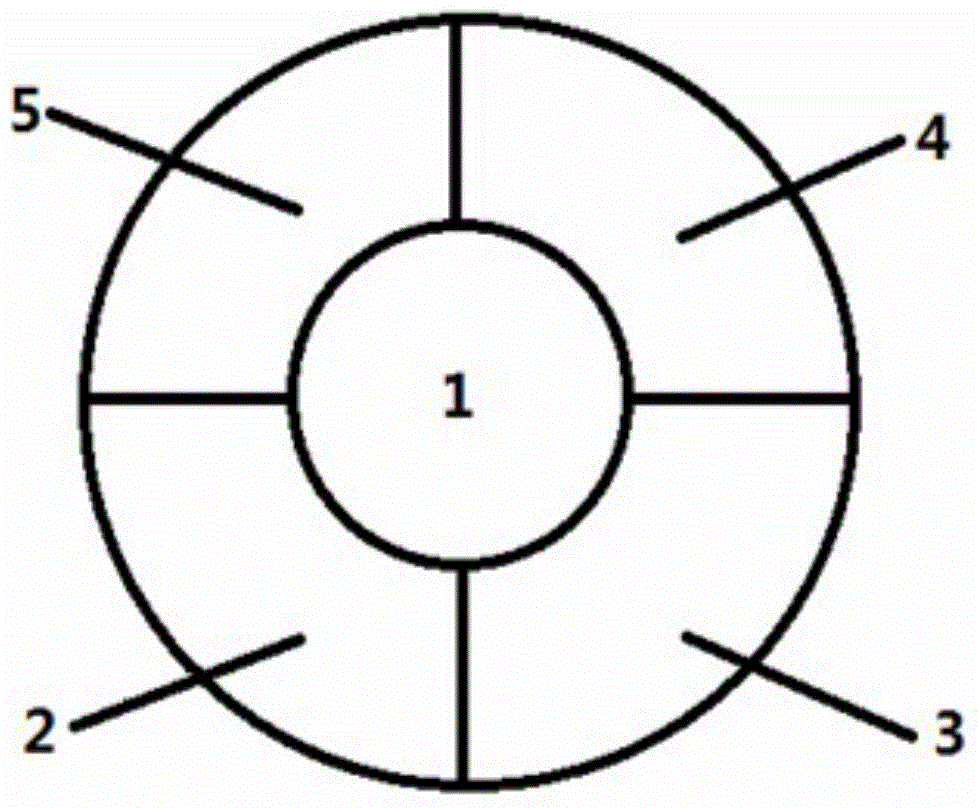

[0025] The controllable flame burner of synthetic carbon nanotube of the present invention, its preferred embodiment is:

[0026] It includes double-layered straight circular tubes nested up and down. The area surrounded by the inner straight circular tube is the central reaction synthesis area, and the area surrounded by the inner straight circular tube and the outer straight circular tube is divided into high-temperature heat source area and In the low-temperature cooling zone, the upper outlet of the double-layer straight circular tube is the carbon nanotube sampling zone, the lower opening of the central reaction synthesis zone is the inlet of reactant mixture gas, inert gas and nano-catalyst particles, and the high-temperature heat source zone The lower port of the low-temperature cooling zone is the inlet of the flammable premixed gas, and the lower port of the low-temperature cooling zone is the inlet of the cooling gas.

[0027] There are two high-temperature heat sour...

specific Embodiment

[0042] The present invention is illustrated by taking a specific method for synthesizing carbon nanotubes by a controlled flame burner as an example.

[0043] Such as figure 1 , figure 2 As shown, it consists of central reaction synthesis area 1, high-temperature heat source areas (combustion chamber) 2 and 4, low-temperature cooling areas 3 and 5, and carbon nanotube sampling area 6.

[0044] The reactant mixture gas, inert gas and nano-catalyst particles are introduced from the bottom of the central reaction synthesis area (central tube) 1, and the combustible premixed gas is introduced from the bottom of the high-temperature heat source area 2 and 4, and a high-temperature heat source can be provided through premixed combustion. Pass inert gas or nitrogen or air from the bottom of cryogenic cooling zones 3 and 5 to adjust the synthesis reaction temperature in the central tube. The synthesized carbon nanotube material is collected in the carbon nanotube sampling area 6 at...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com