Synthesizing method and device for high-silicon zeolite molecular sieve

A zeolite molecular sieve and synthesis device technology, applied in the direction of crystalline aluminosilicate zeolite, etc., can solve the problem that the shape of the product zeolite cannot be changed, and achieve the effects of convenient calculation, ensuring volatility, and reducing operation difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

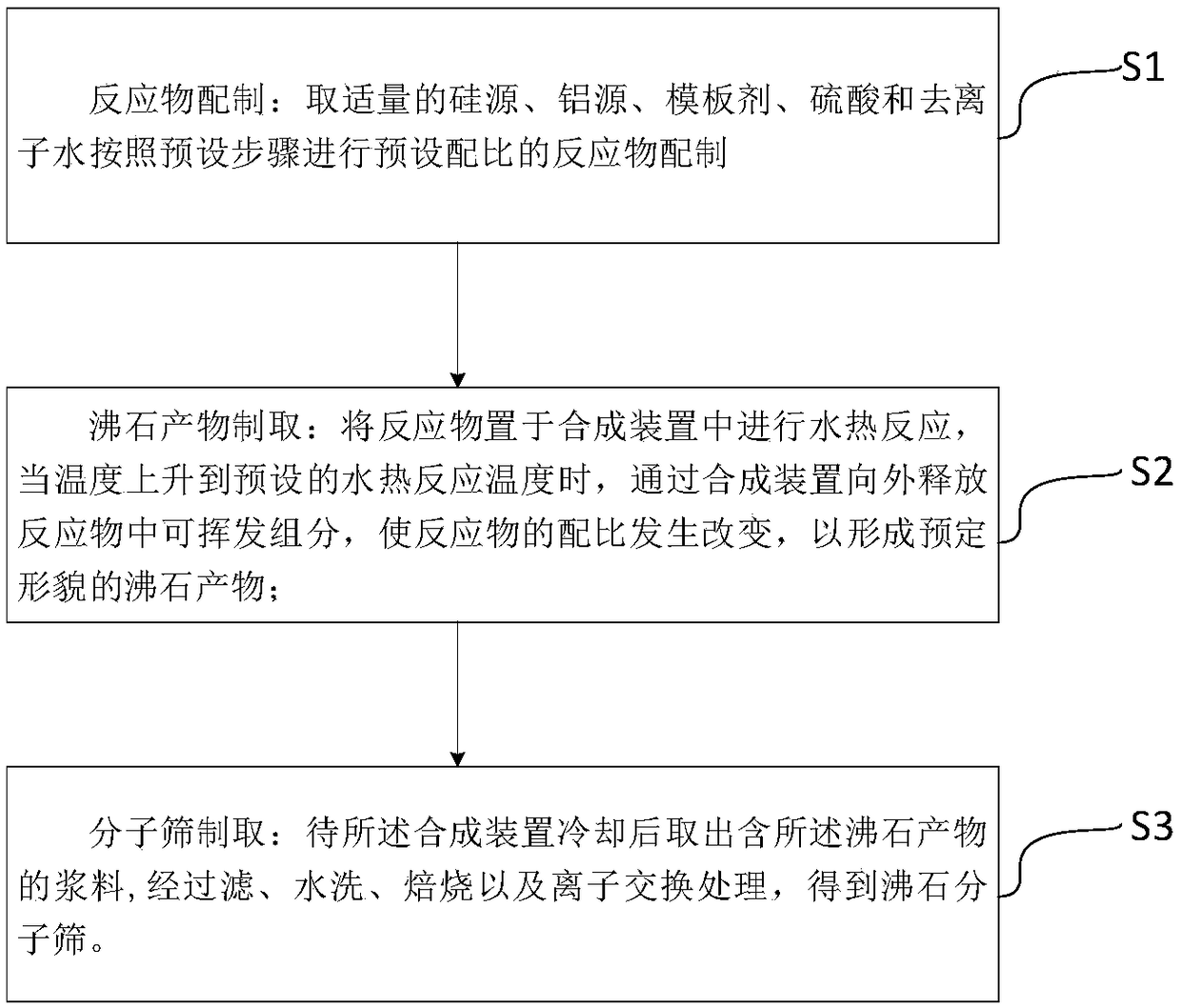

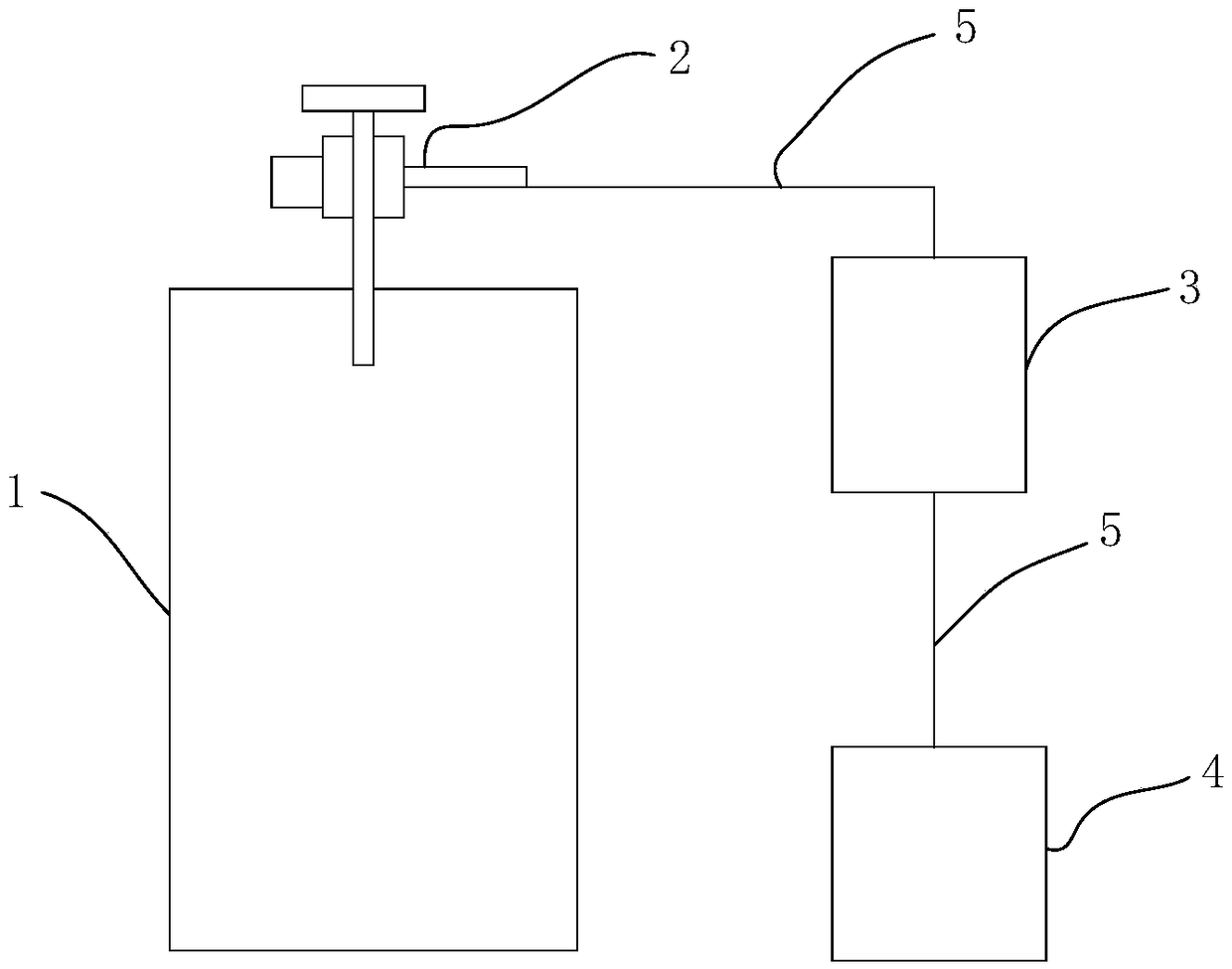

[0040] refer to figure 1 Shown, the synthetic method of the high silica zeolite molecular sieve provided for the embodiment of the present invention, it comprises:

[0041]Reactant preparation: Take appropriate amount of silicon source, aluminum source, template agent, sulfuric acid and deionized water to prepare the preset ratio of reactants according to the preset steps. Among them, the silicon source is industrial water glass (Na 2 O-7.5%; SiO 2 -28%) or silica sol; Aluminum source is aluminum sulfate; Template agent is tetrapropyl ammonium hydroxide (TPAOH) aqueous solution, and the content of preferred tetrapropyl ammonium hydroxide (TPAOH) is 20%; Regulate pH with industrial concentration sulfuric acid.

[0042] Specifically, first weigh aluminum sulfate solid and dissolve it in concentrated sulfuric acid diluted with deionized water to form liquid A; then weigh solid sodium hydroxide and add it to TPAOH solution to mix into liquid B; then slowly pour the liquid B int...

Embodiment 1

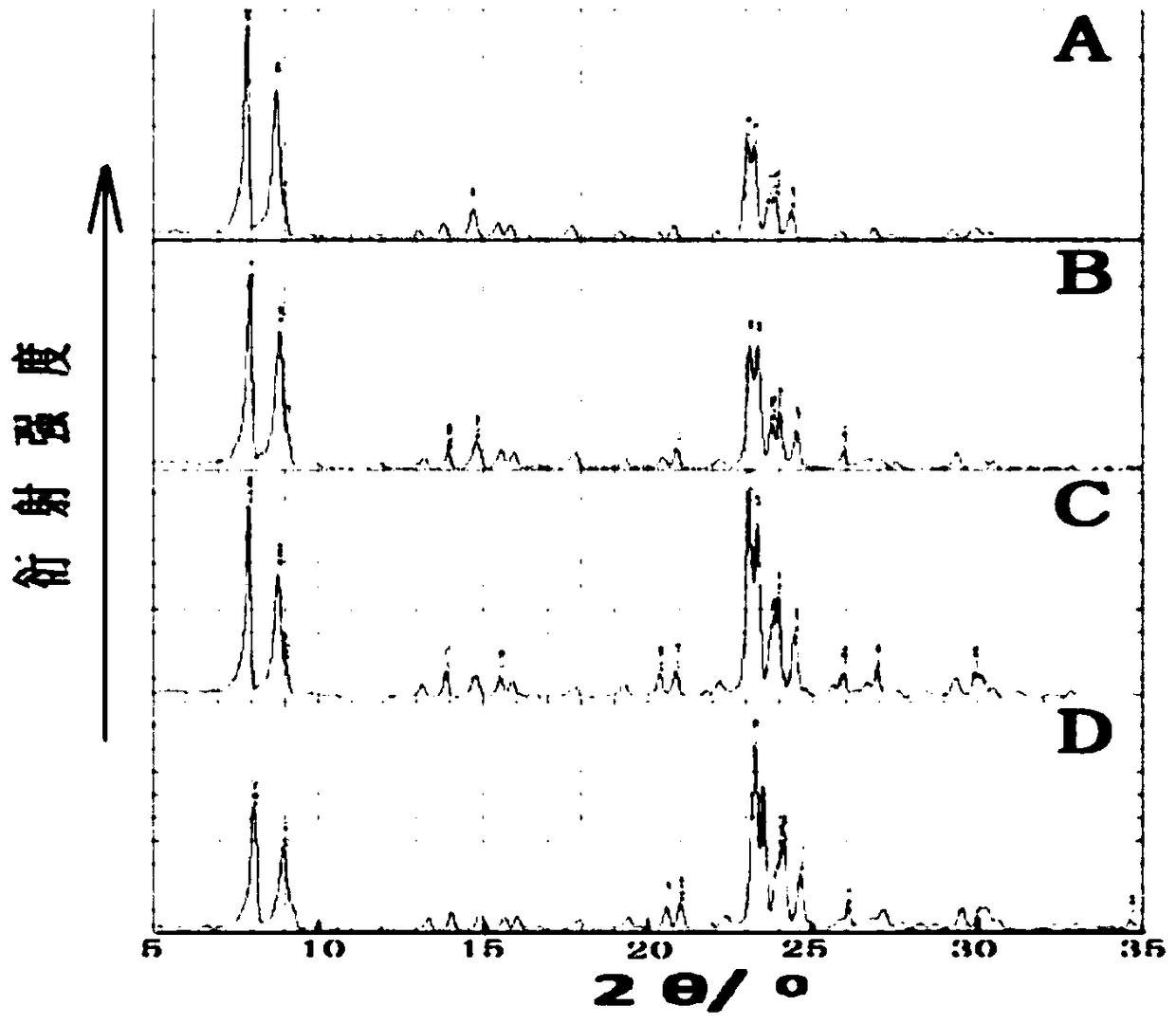

[0054] First, according to the preset ratio of reactants Na 2 O:TPA 2 O:SiO 2 :Al 2 o 3 :H 2 0=1.5:1.0:400:1.0:25, take quantitative silicon raw material water glass, aluminum raw material aluminum sulfate, template agent TPAOH solution, sulfuric acid and deionized water and other synthetic raw materials to prepare reactants; then, prepare The reactant is poured into the reaction kettle, the volume filling degree is 80%, and the reaction kettle is heated to 170°C, and the hydrothermal reaction is carried out for 48 hours; finally, the slurry containing the synthetic product zeolite is taken out after the reaction kettle is cooled, and the zeolite in the slurry is removed by filtration. The mother liquor and the solid product are washed with deionized water to PH = 6-8, dried at 120°C, and then placed in a muffle furnace at 600°C for 6-8 hours with air, and the organic matter TPA in the product is burned out and the product is cooled. Exchange with 0.5N hydrochloric acid, ...

Embodiment 2

[0056] First, according to the preset ratio of reactants Na 2 O:TPA 2 O:SiO 2 :Al 2 o 3 :H 2 0=1.5:1.0:400:1.0:25, take quantitative silicon raw material water glass, aluminum raw material aluminum sulfate, template agent TPAOH solution, sulfuric acid and deionized water and other synthetic raw materials to prepare reactants; then, prepare Pour the reactants into the reaction kettle with a volume filling degree of 80%, and heat the reaction kettle to 170°C, then open the high-pressure valve to relieve the pressure for 2 minutes, then close the valve, and conduct a hydrothermal reaction for 36 hours; finally, take out the reaction kettle after cooling The slurry containing the synthetic product zeolite is filtered to remove the mother liquor in the slurry, the solid product is washed with deionized water to PH=6-8, dried at 120°C, and then placed in a muffle furnace at 600°C for 6-8 hours of air roasting , After the organic matter TPA in the product was burned out, the pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com