A kind of synthesis method of γ-pga-bn with controllable degree of esterification

A synthesis method and technology of esterification degree, applied in the synthesis field of γ-PGA-Bn, can solve the problems of uncontrollable degree of esterification, waste of organic solvent, long reaction time, etc., to save reaction time, save resources, and facilitate follow-up processing easy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] A method of synthesizing γ-PGA-BN of esterification degree, including the following steps:

[0023] (1) γ-polyglycine raw material (molecular weight is above 700,000) Purification: Take γ-PGA in water, adjusting the pH of 1 by HCl, and then placed in dialysis bag 4 days after dialysis 4 days after lyophilization;

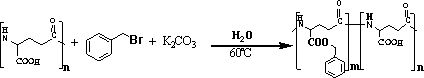

[0024] (2) Synthesis of γ-PGA-BN: Take step (1) Purification of γ-polyglymunine 0.43 ~ 1g in a 50 ml of Slack, add 10 ~ 20ml to ion, add K 2 CO 3 The solution, then placed in an oil bath at 60 ° C, stirred for 0.5 h, adding brominated, reactive 3 to 12 h to be reacted in the upper layer, and the lower layer has a large amount of white solids, the reaction reaches the end point, close the oil bath, cooling To room temperature, where γ-polyglutamic acid, K 2 CO 3 The mass ratio of the solution and bromide solution is 1: 0.53 ~ 5.35: 1.74 ~ 7.96;

[0025] (3) Wash: The solution obtained by step (2) was washed in an HCl aqueous solution of 0 ° C, pH = 1, and the soli...

Embodiment 2

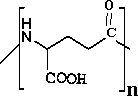

[0027] A method of synthesizing the γ-PGA-BN of esterification degree, including the steps of: (1) γ-polyglymine raw material (more than 700,000 molecular weight): Polyglatine structural formula as shown in :

[0028]

[0029] The γ-PGA40G was dissolved in water, and pH = 1 was adjusted with HCl. After 4 days of dialysis in the dialysis bag, 20.5 g of solid spare was obtained;

[0030] (2) Synthesis of γ-PGA-BN of esterification degree of esterification:

[0031] Weigh 0.43 g of lyophilized γ-PGA in 25ml Slack, add 10ml to ion water, add 0.23 GK 2 CO 3 The above solution was placed in an oil bath at 60 ° C, stirred for 0.5 h, adding 0.75 g of Brominated benz, reaction for about 3 h, and the upper layer is clarified, and there is a large number of white solids in the lower layer, the reaction reaches the end point, close the oil bath, Cool to room temperature.

[0032] The above solution was washed in an HCl aqueous HCl solution of 0 ° C, 100 mL, pH = 1, and the solid was washed ...

Embodiment 3

[0034] Synthesis of γ-PGA-BN of esterification of 28%:

[0035] Weigh 1 g γ-PGA in the 50ml Slack bottle, add 20ml to ion water, add 0.8 GK 2 CO 3 The above solution was placed in an oil bath at 60 ° C, stirred for 0.5 h, and 1.32 g of Brominated benzyl, the reaction time was about 4 h, and the upper layer was clarified in the upper layer, and the lower layer had a large number of white solids, and the reaction reached the end point, close the oil bath, Cool to room temperature.

[0036] The above solution was washed in an HCl aqueous HCl solution of 0 ° C, 200 mL, pH = 1, and the solid was washed 3 times in deionized water, and finally placed in the Sodet extractor, extract 48h with diethyl ether, dried and vacuum Dry, weighed 1.15 g, yield 96%, and migmetric, esterification degree of 28%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com