Degradable antibacterial film and preparation method thereof

A technology of antibacterial film and film-forming solution, which is applied in the field of film materials, can solve problems such as poor compatibility, and achieve the effects of no drug resistance, significant antibacterial performance, and excellent antibacterial effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0056] A kind of preparation method of degradable antibacterial film [recorded as: polycaprolactone / MOF-545 (3%)], comprises the following steps:

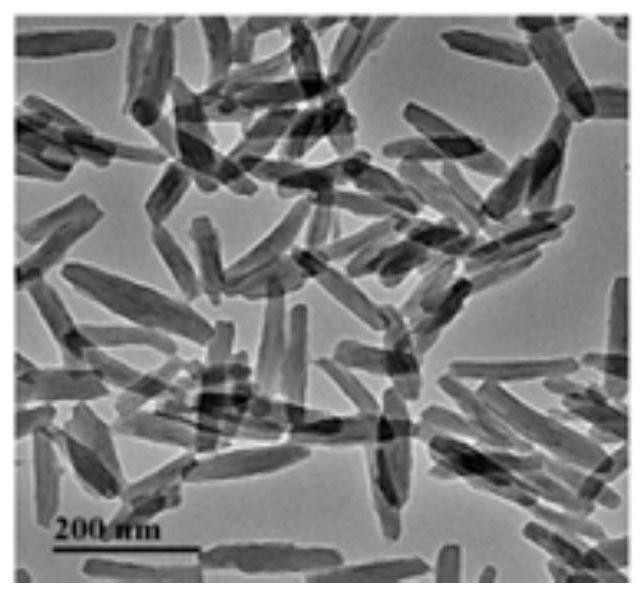

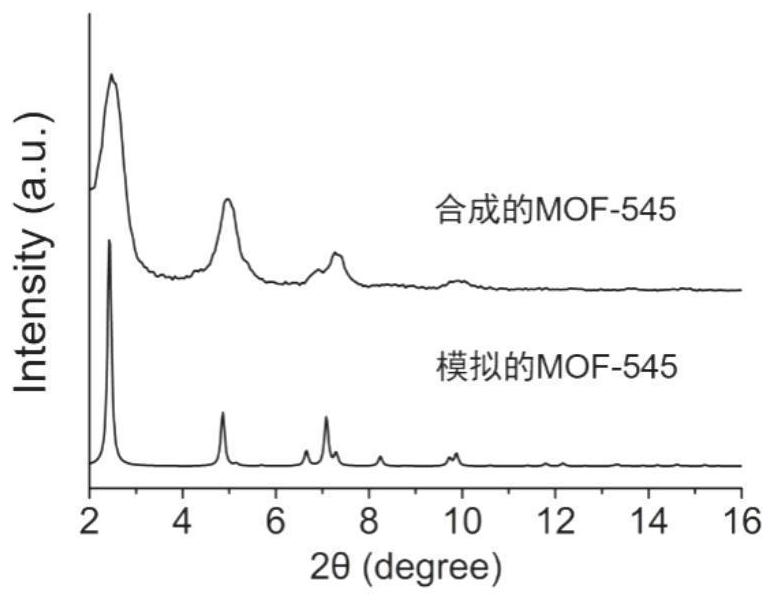

[0057] 1) Preparation of porphyrin metal-organic framework (MOF-545):

[0058] Weigh 12.5 mg of zirconium oxychloride octahydrate, add 10 mL of N,N-dimethylformamide, and sonicate for 30 min to dissolve it. Add 2.5 mg of tetra-carboxyphenylporphyrin, sonicate for 10 minutes, and finally add 0.6 mL of glacial acetic acid to mix well, transfer the mixed solution to a polytetrafluoroethylene autoclave, put it in an oven, and slowly raise the temperature to 65 ° C, react for 3 days, and react Slowly cool down to room temperature. The product was collected by centrifugation (12000rpm, 20min), and the obtained product was successively washed three times with N,N-dimethylformamide (12000rpm, 20min), washed three times with acetone (12000rpm, 20min), and finally dried in a vacuum oven at 60°C for 24h ;

[0059] 2) Preparation of degrada...

Embodiment 2

[0065] A kind of preparation method of degradable antimicrobial film [denoted as: polycaprolactone / MOF-545 (5%)], comprises the following steps:

[0066] 1) with embodiment 1;

[0067] 2) Preparation of degradable antibacterial film:

[0068] Solution A: Weigh 220mg of polycaprolactone and add 2.2mL of N,N-dimethylformamide, sonicate for 30min to dissolve completely, and obtain a mass concentration of 100mg mL -1 Polycaprolactone solution;

[0069] Dispersion B: Weigh 30mg MOF-545, add 3mL N,N-dimethylformamide and sonicate for 30min to obtain a mass concentration of 10mg mL -1 MOF-545 dispersion;

[0070] Take 655 μL of solution A and 345 μL of dispersion B, mix it, cast it on a glass mold and spread it evenly, place it in a constant temperature hot blast oven at 37°C, and slowly evaporate N,N-dimethylformamide. After about 3 hours, the solvent was completely evaporated, and a small amount of methanol was added to wet the mixed film and slowly peeled off, and dried in vac...

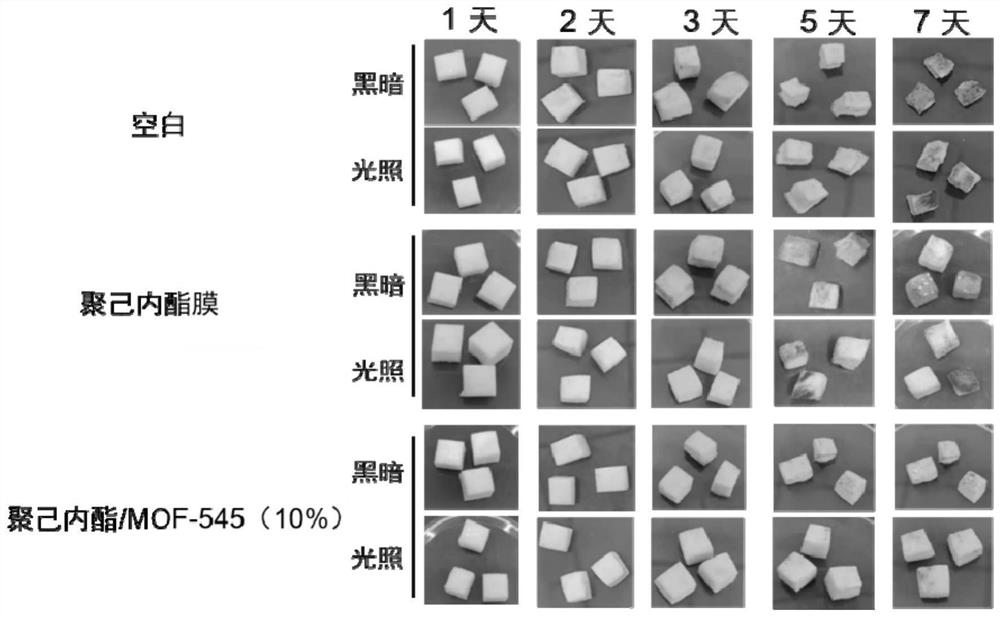

Embodiment 3

[0072] A kind of preparation method of degradable antimicrobial film [denoted as: polycaprolactone / MOF-545 (10%)], comprises the following steps:

[0073] 1) with embodiment 1;

[0074] 2) Preparation of degradable antibacterial film:

[0075] Solution A: Weigh 220mg of polycaprolactone and add 2.2mL of N,N-dimethylformamide, sonicate for 30min to dissolve completely, and obtain a mass concentration of 100mg mL -1 Polycaprolactone solution;

[0076] Dispersion B: Weigh 30mg MOF-545, add 3mL N,N-dimethylformamide and sonicate for 30min to obtain a mass concentration of 10mg mL -1 MOF-545 dispersion;

[0077] Take 621 μL of solution A and 690 μL of dispersion B, mix it, cast it on a glass mold and spread it evenly, place it in a constant temperature hot blast oven at 37°C, and slowly evaporate N,N-dimethylformamide. After about 3 hours, the solvent was completely evaporated, and a small amount of methanol was added to wet the mixed film and slowly peeled off, and dried in va...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Maximum stress | aaaaa | aaaaa |

| Stress | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com