Amphoteric lignin-based surfactant and preparation method and application thereof

A surfactant and lignin-based technology, which is used in the preparation of amphoteric lignin-based surfactants, and in the field of amphoteric lignin-based surfactants, can solve the problem of reducing the surface tension of lignin salts, reducing the surface tension of aqueous solutions, and enhancing alkali lignin Solve the problems of water solubility and other problems, and achieve the effect of simple and controllable reaction process route, excellent surface activity and good degreasing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] (1) Dissolve 10g of alkali lignin in 100mL of deionized water, stir to fully dissolve the alkali lignin, and adjust the pH of the system to 10 with 1mol / L sodium hydroxide solution.

[0043] (2) Add lauryl glycidyl ether, the mass ratio of alkali lignin to lauryl glycidyl ether is 5:2, and react at 60°C for 2 hours under the protection of nitrogen to obtain the reaction product;

[0044] (3) The reaction product was distilled under reduced pressure at 60°C to remove the impurities remaining in the reaction. Measure 8g of amphoteric lignin-based surfactant to prepare a 10% aqueous solution, add 6mL of 30% hydrogen peroxide by volume to carry out bleaching treatment, control the treatment temperature at 40°C, and the treatment time is 30min, and obtain the color after vacuum drying at 60°C Pale yellow amphoteric lignin-based surfactant A.

Embodiment 2

[0046] (1) Dissolve 10 g of sodium lignosulfonate in 80 mL of deionized water, stir to fully dissolve the sodium lignosulfonate, and adjust the pH of the system to 11 with 1 mol / L sodium hydroxide solution.

[0047] (2) Add lauryl glycidyl ether, the mass ratio of sodium lignosulfonate to lauryl glycidyl ether is 5:3, and react at 60°C for 3 hours under the protection of nitrogen to obtain the reaction product;

[0048] (3) The reaction product was distilled and dried under reduced pressure at 60°C to remove the remaining impurities in the reaction, and 8g of amphoteric lignin-based surfactant was prepared to make a 10% aqueous solution, and 6mL of hydrogen peroxide with a concentration of 40% by volume was added for bleaching treatment. The temperature in the treatment process was controlled at 60° C., the treatment time was 40 minutes, and the light yellow amphoteric lignin-based surfactant B was obtained after vacuum drying at 60° C.

Embodiment 3

[0050] (1) Dissolve 10g of alkali lignin in 50mL of deionized water, stir to fully dissolve the alkali lignin, and adjust the pH of the system to 12 with 1.5mol / L sodium hydroxide solution.

[0051] (2) Add lauryl glycidyl ether, the mass ratio of alkali lignin to lauryl glycidyl ether is 5:4, and react at 80°C for 4 hours under the protection of nitrogen to obtain the reaction product;

[0052] (3) The reaction product was distilled and dried under reduced pressure at 60°C to remove the remaining impurities in the reaction, and 8g of amphoteric lignin-based surfactant was prepared to make a 10% aqueous solution, and 6mL of hydrogen peroxide with a concentration of 50% by volume was added for bleaching treatment. The temperature in the treatment process was controlled at 55° C., the treatment time was 60 minutes, and the amphoteric lignin-based surfactant C with light yellow color was obtained after vacuum drying at 60° C.

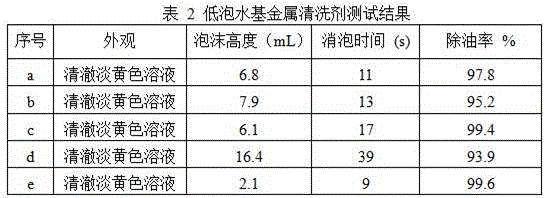

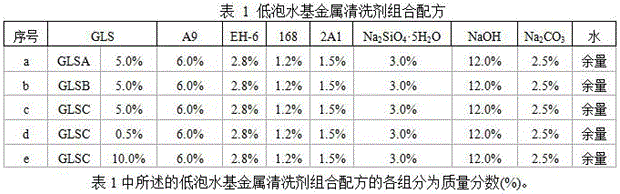

[0053] The amphoteric lignin-based surfactants of Ex...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com