Two-dimensional nano-molybdenum disulfide and preparation method thereof

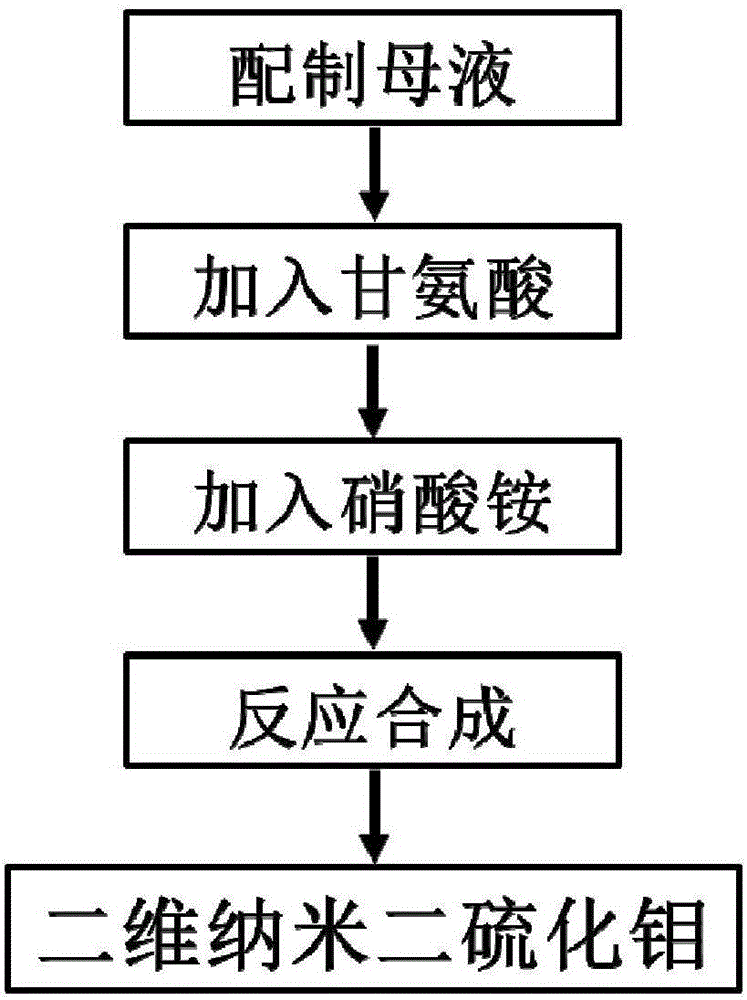

A molybdenum disulfide and two-dimensional nanotechnology are applied in the field of two-dimensional nano-layered structure molybdenum disulfide materials and their preparation fields, and can solve the problems of cumbersome preparation process, shortened preparation cycle, and disadvantageous mass production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] (1) Add 25g of ammonium paramolybdate tetrahydrate (also known as ammonium paramolybdate, ammonium heptamolybdate) into 60ml of concentrated ammonia water, stir until completely dissolved, then add 240ml of ammonium sulfide solution, and then place the mixed solution in a heating furnace Heating at 50~60°C for 20 minutes to form a dark red mother liquor.

[0028] (2) Use a 1000ml beaker to measure 100ml of the mother liquor, add 14g of glycine, wait for the glycine to fully dissolve and then stir for 10 minutes to form a mixed solution. The temperature of the mother liquor is always kept at 60~70°C during the above process.

[0029] (3) Add 24g of ammonium nitrate to the mixed solution containing the mother liquor and glycine, and stir until the ammonium nitrate is completely dissolved. During the above process, keep the temperature of the mixed solution at 60~70°C. After the ammonium nitrate is completely dissolved, raise the heating temperature To 200~230°C, continue ...

Embodiment 2

[0033] (1) Add 25g of ammonium paramolybdate tetrahydrate into 60ml of concentrated ammonia water, stir until completely dissolved, then add 240ml of ammonium sulfide solution, then place the mixed solution in a heating furnace and heat at 50~60°C for 20 minutes to form a deep red color mother liquor.

[0034] (2) Use a 1000ml beaker to measure 100ml of the mother liquor, add 10g of glycine, wait for the glycine to fully dissolve and then stir for 10 minutes to form a mixed solution. The temperature of the mother liquor is always kept at 60~70°C during the above process.

[0035] (3) Add 23g of ammonium nitrate to the above mixed solution containing mother liquor and glycine, and stir until the ammonium nitrate is completely dissolved. During the above process, keep the temperature of the mixed solution at 60~70°C. After the ammonium nitrate is completely dissolved, raise the heating temperature To 200~230°C, continue heating and stirring.

[0036](4) The above solution is co...

Embodiment 3

[0039] (1) Add 25g of ammonium paramolybdate tetrahydrate into 60ml of concentrated ammonia water, stir until completely dissolved, then add 240ml of ammonium sulfide solution, then place the mixed solution in a heating furnace and heat at 50~60°C for 20 minutes to form a deep red color mother liquor.

[0040] (2) Use a 1000ml beaker to measure 100ml of the mother liquor, add 8g of glycine, wait for the glycine to fully dissolve and then stir for 10 minutes to form a mixed solution. The temperature of the mother liquor is always kept at 60~70°C during the above process.

[0041] (3) Add 18g of ammonium nitrate to the above mixed solution containing mother liquor and glycine, and stir until the ammonium nitrate is completely dissolved. During the above process, keep the temperature of the mixed solution at 60~70°C. After the ammonium nitrate is completely dissolved, raise the heating temperature To 200~230°C, continue heating and stirring.

[0042] (4) The above solution is co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com