Method for controllably preparing aluminum oxide powder with multiple morphologies

A technology of alumina powder and aluminum powder, which is applied in chemical instruments and methods, preparation of alumina/hydroxide, inorganic chemistry, etc., can solve problems such as pollution, long process time, and complicated operation, so as to promote development and solve The effect of heavy pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0018] A controllable Al with various morphologies 2 o 3 The method of powder, its step is:

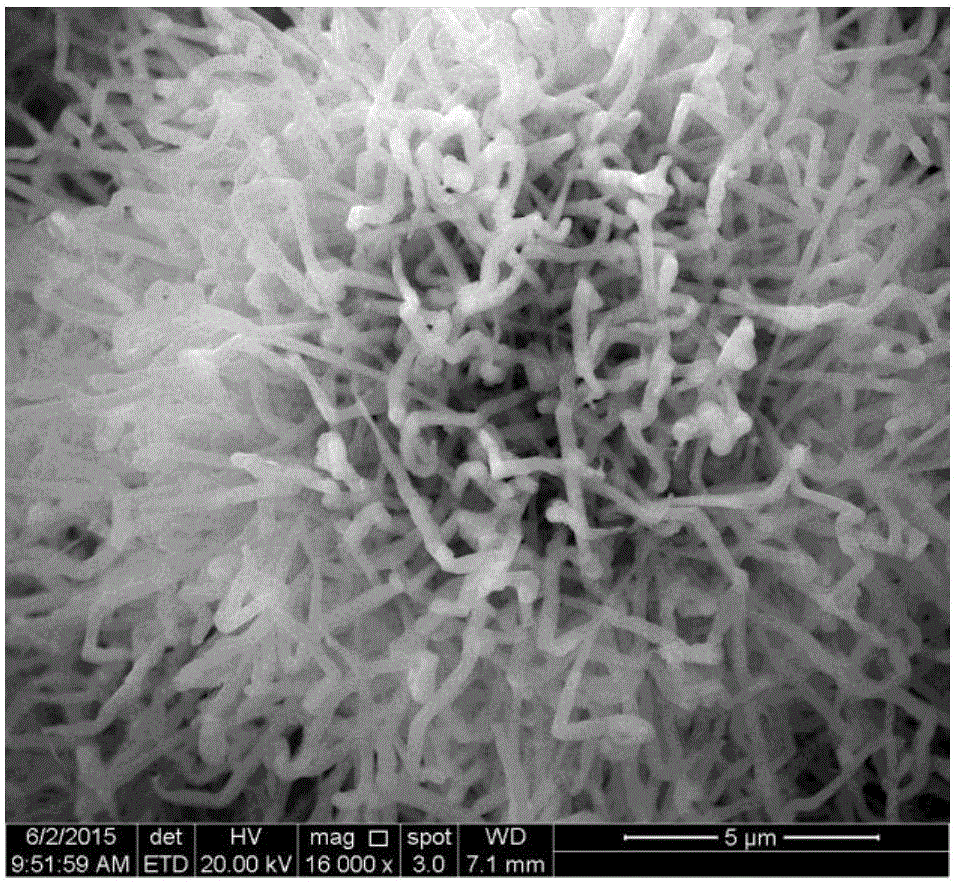

[0019] Select aluminum powder with a particle size of 53 microns and high-purity graphite with a particle size of 30 microns as raw materials, weigh the aluminum powder and graphite powder according to the Al / C mass ratio of 2:1, and then mix and ball mill them in a ball mill for 5 hours to make them fully well mixed. The prepared raw materials were placed in a microwave tube furnace for reaction synthesis. Both ends of the quartz tube were open, the heating rate was 100°C / min, the synthesis temperature was 1100°C, and the temperature was kept for 1 hour. The obtained product was alumina whiskers after cooling.

example 2

[0021] A controllable Al with various morphologies 2 o 3 The method of powder, its step is:

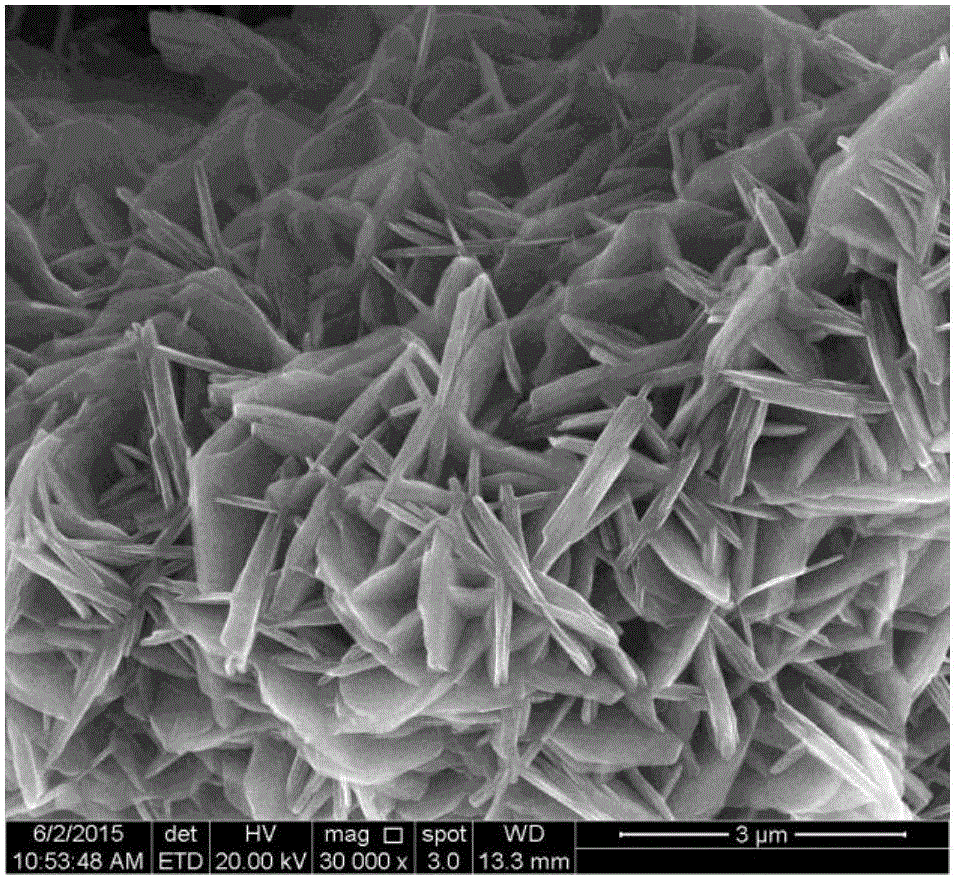

[0022] Select aluminum powder with a particle size of 10 microns and activated carbon with an average particle size of 10 microns as raw materials, weigh the aluminum powder and activated carbon source powder according to the Al / C mass ratio of 3:1, and then mix and ball mill them in a ball mill for 5 hours to make It is well mixed and homogeneous. The prepared raw materials were placed in a microwave tube furnace for reaction synthesis. Both ends of the quartz tube were open, the heating rate was 100°C / min, the synthesis temperature was 1000°C, and the heat preservation was carried out for 1 hour. The obtained product was alumina nanosheets after cooling.

example 3

[0024] A controllable Al with various morphologies 2 o 3 The method of powder, its step is:

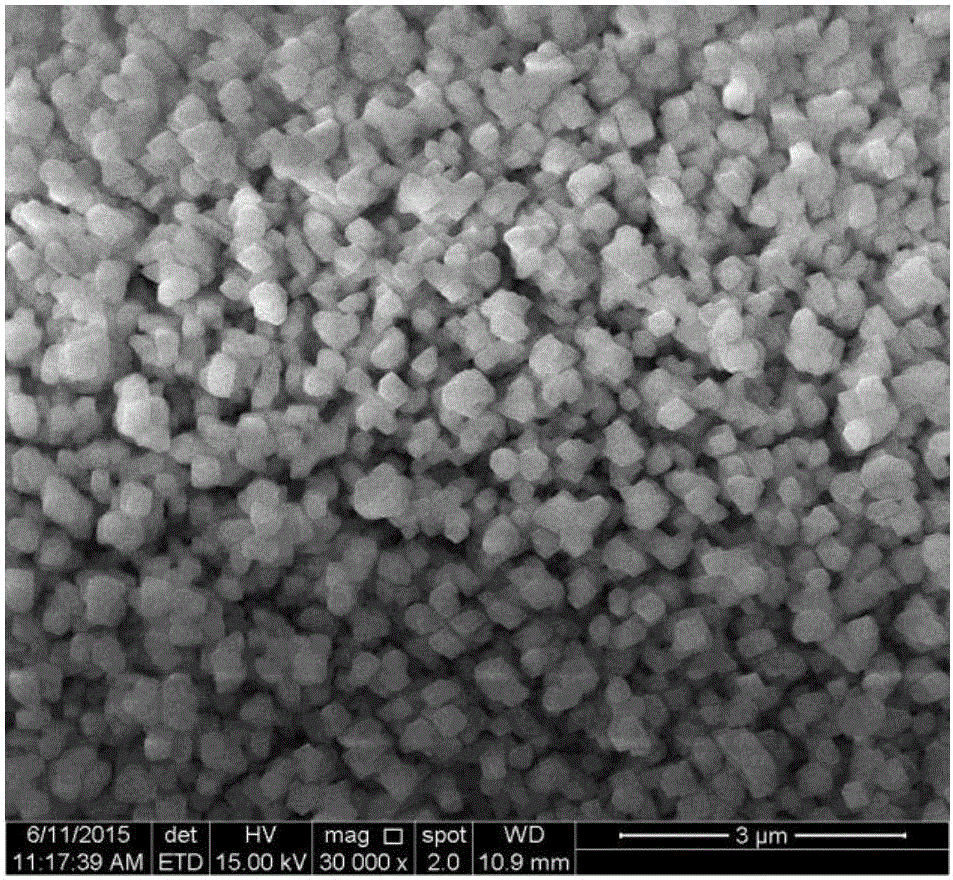

[0025] Select aluminum powder with a particle size of 30 microns and carbon black with an average particle size of 30nm as raw materials, weigh the aluminum powder and carbon black powder according to the Al / C mass ratio of 7:3, and then mix and ball mill them in a ball mill for 5 hours to make them fully well mixed. Put the prepared raw materials in a microwave tube furnace for reaction synthesis. The two ends of the quartz tube are open. The heating rate is 100°C / min. The synthesis temperature is 1000°C, and the temperature is kept for 2 hours. The obtained product is fine-grained alumina after cooling. particles.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com