Method for producing and purifying sulfur hexafluoride

A technology of sulfur hexafluoride and fluorine gas, applied in the direction of sulfur and halogen compounds, etc., can solve the problem of not being able to obtain sulfur hexafluoride and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

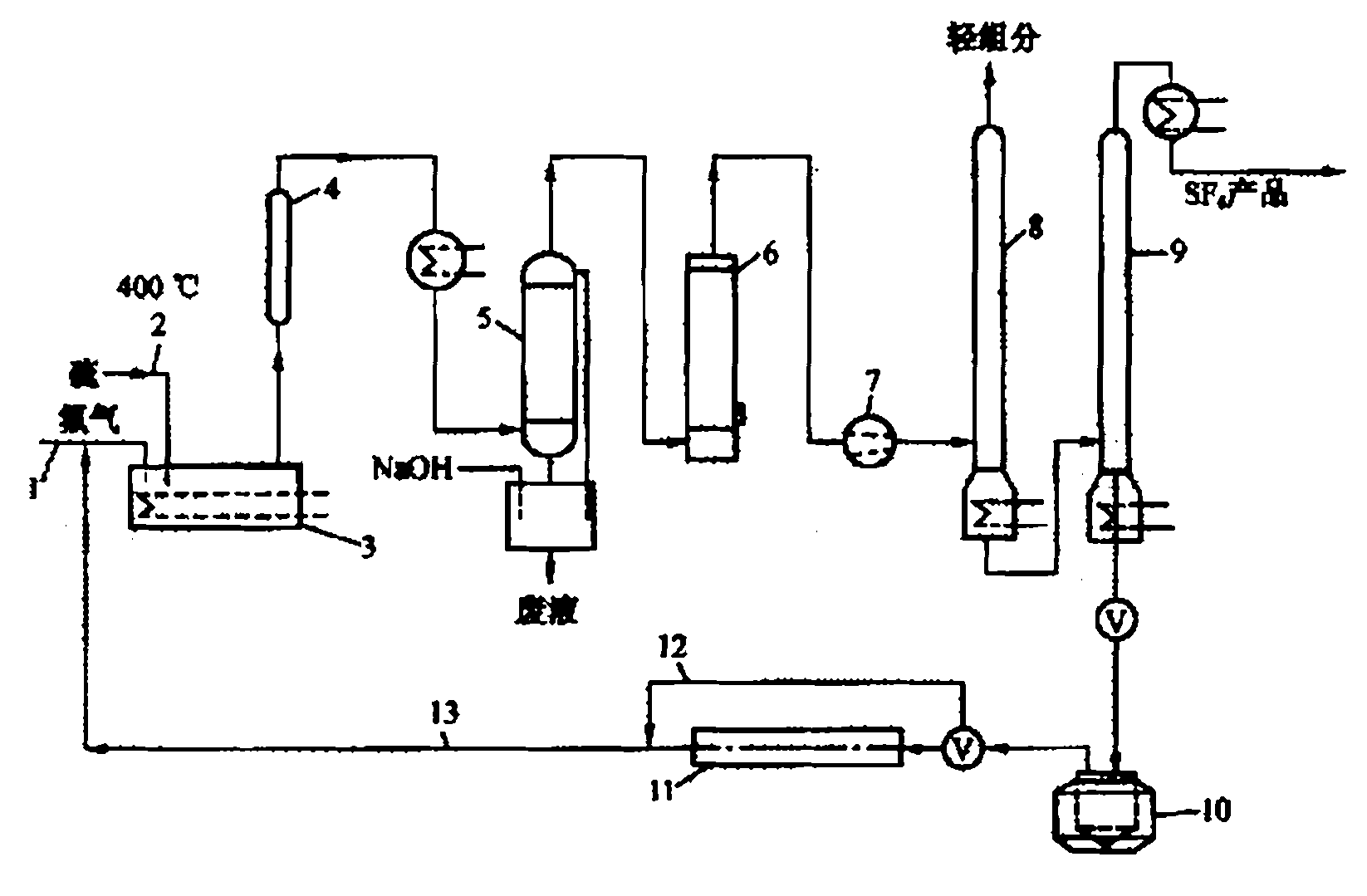

[0014] Fluorine and sulfur (1:1) reaction This process is composed of reaction synthesis, pyrolysis, alkali washing, adsorption, rectification, vaporization and impurity circulation treatment and other units. First, fluorine gas and molten sulfur react in reactor 3 to synthesize crude sulfur hexafluoride; then, the crude sulfur hexafluoride passes through pyrolysis tower 4 at 400°C to decompose S2F10 and S2F10O at high temperature; the third step is to pass through washing tower 5 , to remove acidic and hydrolyzable impurities such as HF, SF4, etc.; the fourth step, enter the adsorption drying tower 6 to remove water and some low-fluorine sulfur compounds; the fifth step, use two-stage pressurized rectification towers 8 and 9 to remove light Component impurities CF4, THC, O2, N2 and heavy impurities SO2F2, CO2, N2O, ClO3F, SF5OCF3, etc., get the sulfur hexafluoride product that reaches the purity requirement of at least 99.8% content from the top of the secondary rectification ...

Embodiment 2

[0016] Fluorine and sulfur reaction (1:0.5) This process is composed of reaction synthesis, pyrolysis, alkali washing, adsorption, rectification, vaporization and impurity circulation treatment and other units. First, fluorine gas and molten sulfur react in reactor 3 to synthesize crude sulfur hexafluoride; then, the crude sulfur hexafluoride passes through pyrolysis tower 4 at 400°C to decompose S2F10 and S2F10O at high temperature; the third step is to pass through washing tower 5 , to remove acidic and hydrolyzable impurities such as HF, SF4, etc.; the fourth step, enter the adsorption drying tower 6 to remove water and some low-fluorine sulfur compounds; the fifth step, use two-stage pressurized rectification towers 8 and 9 to remove light Component impurities CF4, THC, O2, N2 and heavy impurities SO2F2, CO2, N2O, ClO3F, SF5OCF3, etc., get the sulfur hexafluoride product that reaches the purity requirement of at least 99.8% content from the top of the secondary rectificatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com