Magnesium-aluminum-zirconium solid catalyst for embedded synthesis of alkoxy alcohol ether ester in one step

A technology for synthesizing alkoxy alcohol ethers and solid catalysts, applied in physical/chemical process catalysts, preparation of organic compounds, organic chemistry, etc., can solve problems such as poor product performance, high energy consumption, high material consumption, and long process flow. Achieve the effects of easy separation, high selectivity, and easy separation and recovery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] In a three-necked flask equipped with a stirrer, a reflux condenser was installed. Dissolve 9.3g of magnesium chloride hexahydrate, 10.8g of aluminum nitrate nonahydrate, and 1.2g of zirconium nitrate pentahydrate with 41.2g of deionized water, and add them to a three-necked flask. Dissolve 3.2g of potassium hydroxide, 7.8g of Dissolve potassium carbonate, quickly add potassium hydroxide and potassium carbonate solution into the three-necked flask, and stir vigorously. After reacting for half an hour, crystallize at 70°C for 6 hours, then suction filter to obtain a solid precipitate, and wash with deionized water 4 times, each water consumption is 100mL, placed in a constant temperature drying oven at 100 ℃ and dried until constant weight. The dried solid was ground and calcined in a muffle furnace at 500° C. for 5 h to obtain a magnesium-aluminum-based composite metal oxide solid catalyst.

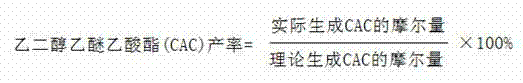

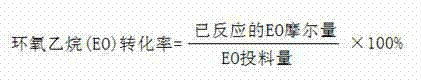

[0018] This catalyst is used to catalyze the ethoxylation reaction of ethyl a...

Embodiment 2

[0020] The basic preparation method is the same as in Example 1, except that the salt solution added to the three-necked flask has only magnesium chloride and aluminum nitrate.

[0021] This catalyst is used to catalyze the ethoxylation reaction of ethyl acetate with raw material ratio EA:EO=3:1, the conversion rate of ethylene oxide is 50.92%, the yield rate of CAC is 23.12%, and the yield rate of DCAC is 14.70%. .

Embodiment 3

[0023] The basic preparation method is the same as in Example 1, except that the mixed salt solution added to the three-necked flask is magnesium chloride, aluminum nitrate and zinc nitrate.

[0024] This catalyst is used to catalyze the ethoxylation reaction of ethyl acetate with a molar ratio of raw materials EA:EO=2:1, the conversion rate of ethylene oxide is 39.36%, the yield rate of CAC is 18.64%, and the yield rate of DCAC is 11.33% %.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com