Phosphorous boron doped lithium manganese phosphate/carbon composite material and preparation method thereof

A carbon composite material, lithium manganese phosphate technology, applied in phosphorus compounds, chemical instruments and methods, inorganic chemistry, etc., can solve problems such as low activity, improve discharge capacity, improve electrochemical response speed, and reduce material polarization Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

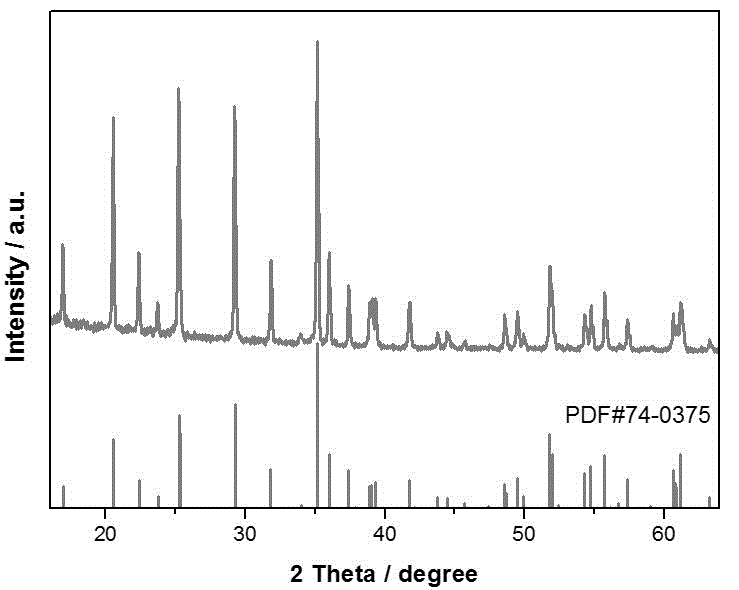

[0021] Lithium carbonate, manganese carbonate, ammonium dihydrogen phosphate and boric acid were prepared according to the molar ratio of Li: Mn: P: B at 1: 1: 0.95: 0.05, added with 10 wt.% carbon black, mixed and ball milled for 4 hours, the powder obtained was 700 Calcined in an argon atmosphere at ℃ for 5 hours, and then cooled in the furnace to obtain a boron-doped lithium manganese phosphate / carbon composite material LiMnP 0.95 B 0.05 O 4-δ / C, figure 1 It is the XRD pattern of the material.

Embodiment 2

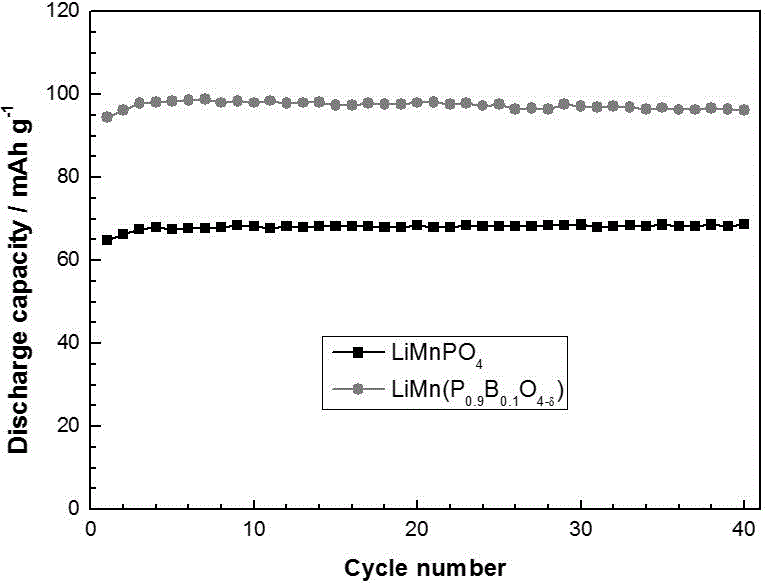

[0023] Lithium dihydrogen phosphate, manganese acetate and lithium borate were prepared according to the molar ratio of Li: Mn: P: B 1: 1: 0.9: 0.1, 15 wt.% sucrose was added, and the mixture was ball milled for 6 hours. The powder obtained was argon at 600 ℃ Calcined in an atmosphere for 10 hours, after cooling in the furnace, the boron-doped lithium manganese phosphate / carbon composite material LiMnP 0.9 B 0.1 O 4-δ / C. The electrochemical performance test method is as follows: mix the obtained composite material, binder (polyvinylidene fluoride), and conductive agent (acetylene black) in a mass ratio of 9:1:1, and add 10 wt.% N- The methyl pyrrolidone solvent is made into a slurry, and then coated on an aluminum foil with a thickness of 15 microns, and dried under vacuum to remove the solvent. Then use a sampler to cut a disc with a radius of 1 cm and place it in an anhydrous and oxygen-free glove box. The wafer was used as the working electrode, the metal lithium was the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com