Preparation method of gamma-C2S-based cementing material

A technology of base glue and raw material, which is applied in the field of preparation of γ-C2S base cementitious materials, can solve the problems of incapability of industrial production and application and high preparation cost, and achieve the effects of reducing energy consumption for grinding and reducing production costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

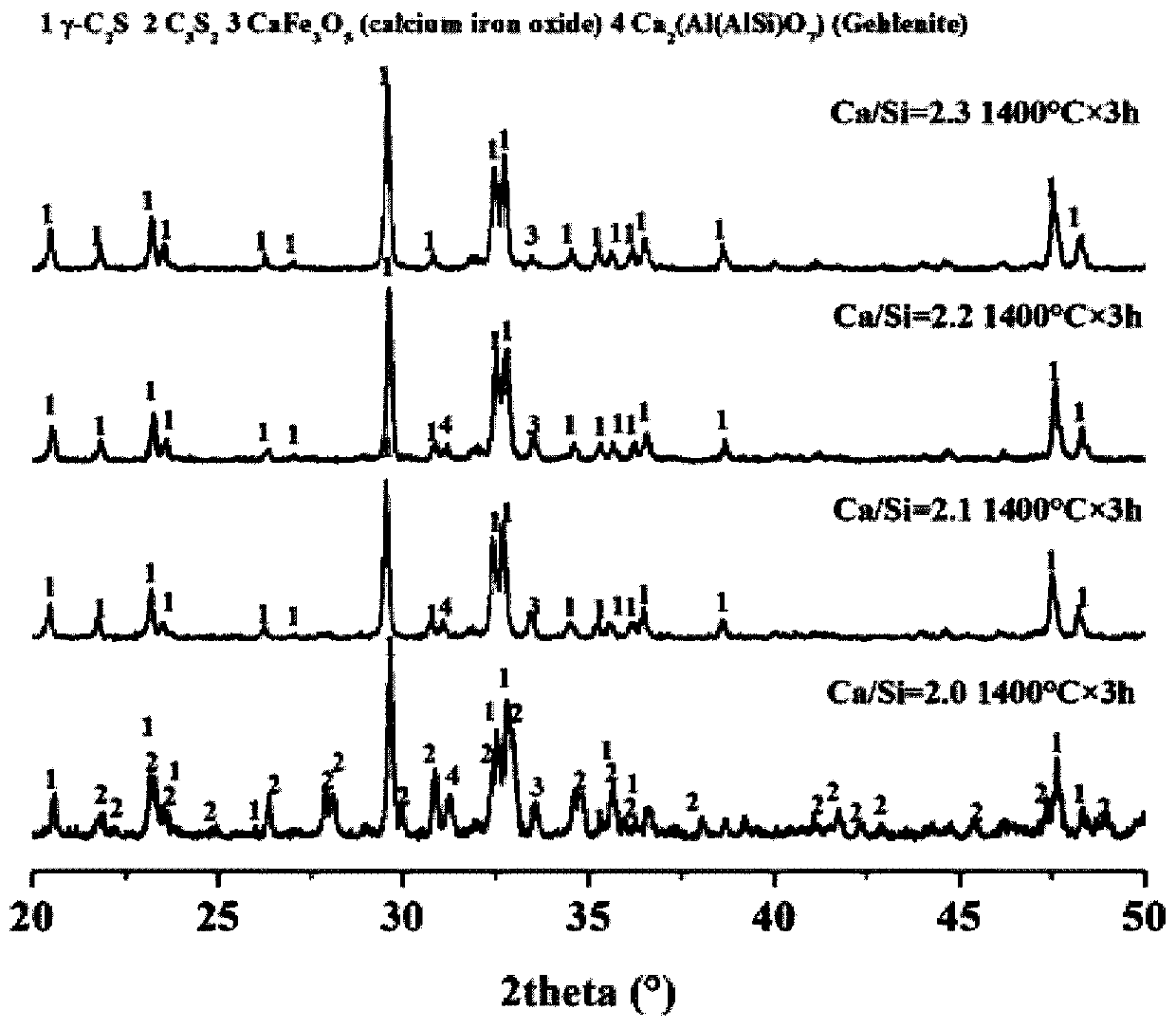

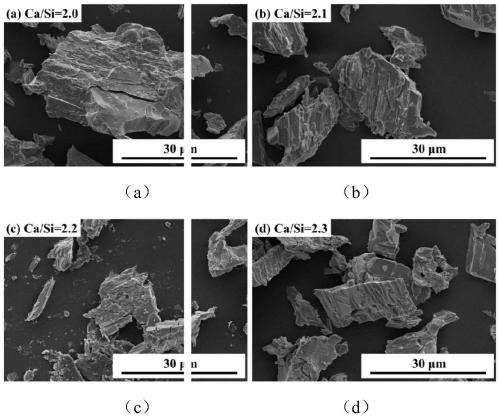

[0022] a gamma-C 2 The preparation method of S base cementitious material, comprises the following steps:

[0023] 1) According to the calcium-silicon molar ratio of 2.1, put limestone and sandstone into a ball mill and ball mill and mix them for 2 hours to obtain raw materials for firing, wherein the calcium oxide content in the limestone is ≥50%, and the silicon dioxide content in the sandstone is ≥85%;

[0024] 2) Mix the calcined raw material with 10% absolute ethanol evenly, press it into a green body under a molding pressure of 30MPa, then fully dry it at 60°C, and then put the dried green body into In the high-temperature furnace, raise the temperature to 800°C at a heating rate of 10°C / min, and keep it for 1 hour to ensure that the calcium carbonate in the raw material is fully decomposed, then continue to raise the temperature to 1350°C at a heating rate of 10°C / min, and keep it for 3 hours. Cool naturally to room temperature to obtain γ-C 2 S-based gelling material...

Embodiment 2

[0028] a gamma-C 2 The preparation method of S base cementitious material, comprises the following steps:

[0029] 1) According to the calcium-silicon molar ratio of 2.0, put steel slag and sandstone into a ball mill and ball mill and mix them for 2 hours to obtain raw materials for firing, wherein the content of calcium oxide in the limestone is ≥ 50%, and the content of silicon dioxide in the sandstone is ≥ 85%;

[0030] 2) Mix the calcined raw material with 10% absolute ethanol evenly, press it into a green body under a molding pressure of 20MPa, then fully dry it at 60°C, and then put the dried green body into In the high-temperature furnace, raise the temperature to 800°C at a heating rate of 10°C / min, and keep it warm for 0.5h to ensure that the calcium carbonate in the raw material is fully decomposed, then continue to raise the temperature to 1400°C at a heating rate of 10°C / min, and keep it for 3h. The furnace was naturally cooled to room temperature to obtain γ-C 2...

Embodiment 3

[0034] a gamma-C 2 The preparation method of S base cementitious material, comprises the following steps:

[0035] 1) According to the molar ratio of calcium to silicon of 2.3, limestone and silica are put into a ball mill and ball milled for 2 hours to obtain raw materials for firing, wherein the content of calcium oxide in the limestone is ≥ 50%, and the content of silicon dioxide in the sandstone is ≥ 85%;

[0036] 2) Mix the calcined raw material with 10% absolute ethanol evenly, press it into a green body under a molding pressure of 15MPa, then fully dry it at 60°C, and then put the dried green body into In the high-temperature furnace, raise the temperature to 800°C at a heating rate of 10°C / min and keep it warm for 1 hour to ensure that the calcium carbonate in the raw material is fully decomposed, then continue to raise the temperature to 1500°C at a heating rate of 10°C / min Cool naturally to room temperature to obtain γ-C 2 S-based gelling material.

[0037] The γ-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com