Washing and direct flotation method of low-grade refractory argillaceous phosphorite

A low-grade, positive flotation technology, used in flotation, phosphate material treatment, solid separation, etc., can solve the problems of difficult industrial application, high beneficiation cost, poor separation effect, etc. The effect of good selection index and low residual phosphorus in tailings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

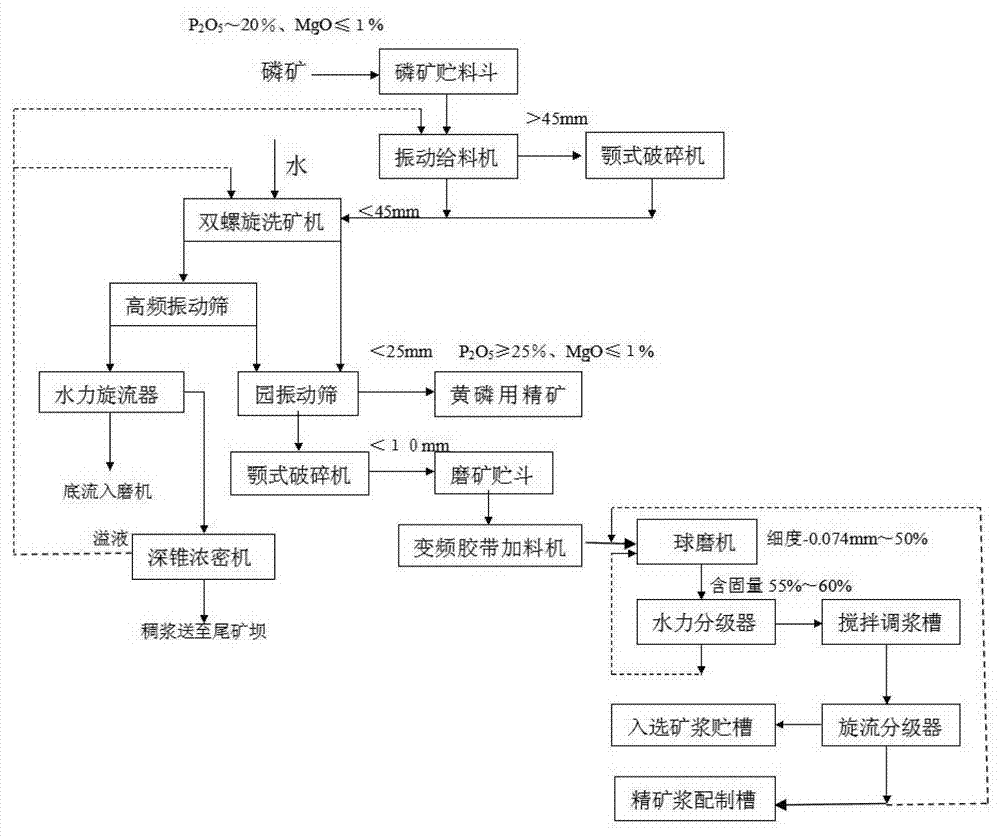

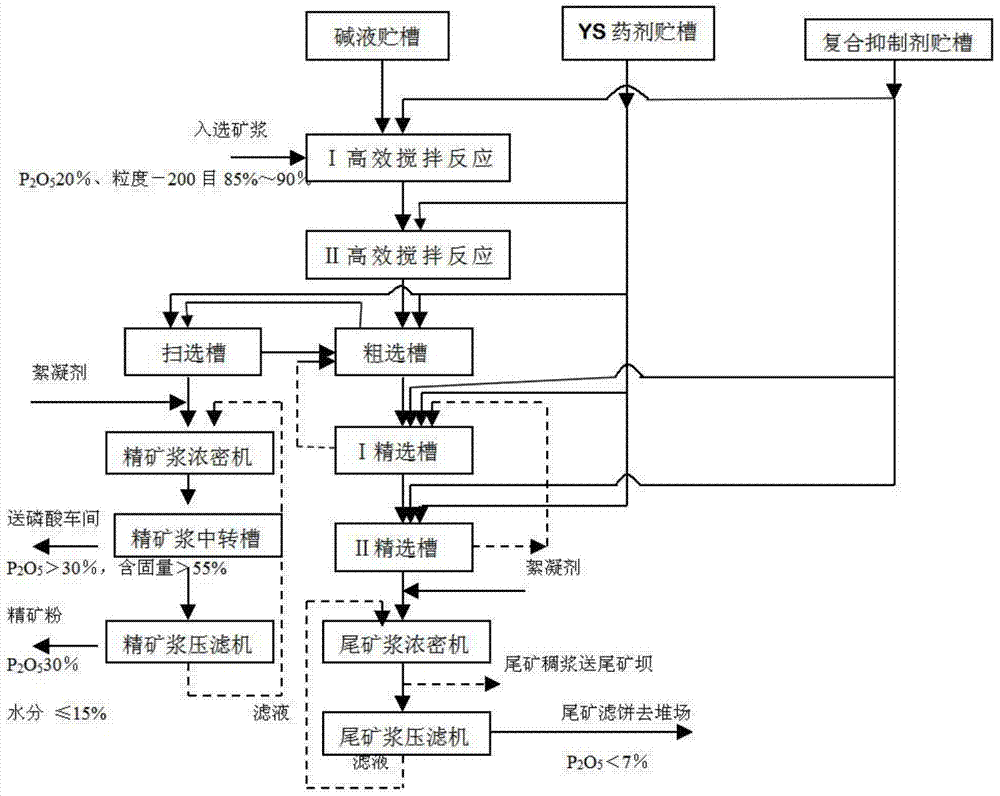

[0048] See figure 1 , figure 2 , a low-grade refractory argillaceous phosphate ore washing positive flotation method, the present invention is characterized in that the process steps include: a. phosphate rock closed-circuit coarse crushing-fine crushing-screening-washing, fine ore closed-circuit wet grinding and classification process ; b. Phosphate ore roughing - double beneficiation - one sweep positive flotation - dense - press filter positive flotation process; where:

[0049] a. Phosphate rock closed-circuit coarse crushing-fine crushing-screening-water washing, fine ore closed-circuit wet grinding and classification process, the obtained mass percentage is P 2 o 5 Phosphorus concentrate ≥25%, particle size ≤25mm for yellow phosphorus production, prepared without flotation, used for phosphoric acid production, extraction and pulping particle size -100 mesh > 85%, mass percentage is P 2 o 5 28.5% phosphate slurry; figure 2 The shown technological process specifical...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com