Method for recovering fine mud cassiterite

A recovery method and technology of cassiterite, applied in chemical instruments and methods, wet separation, solid separation, etc., can solve the problems of large specific surface area, small collision probability of cassiterite particles, loss of cassiterite minerals, etc., and achieve process structure. Simple, low dosage, high recovery effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] 1. Mineral raw materials:

[0018] The mineral raw material used is tin tailings separated by shaking table, the particle size is 5-74 microns, the tin content is 0.37%, the gangue mineral silicon dioxide content is 29.84%, and the calcium carbonate content is 32.62%.

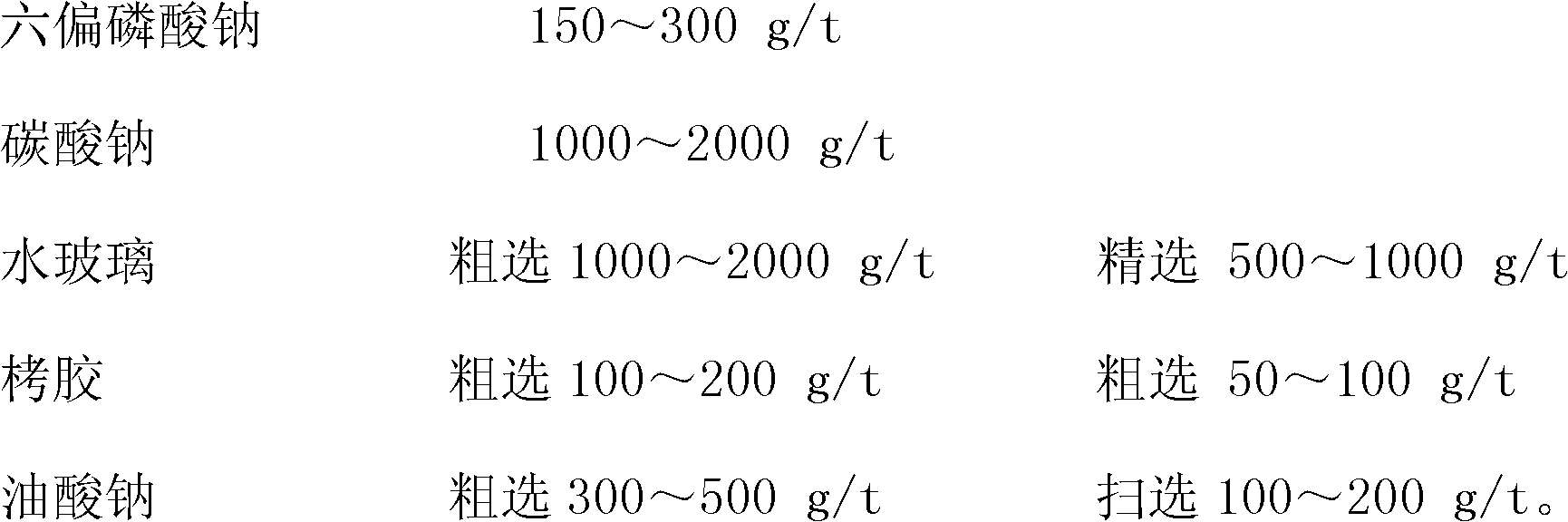

[0019] 2. Flotation agents and operating conditions:

[0020]

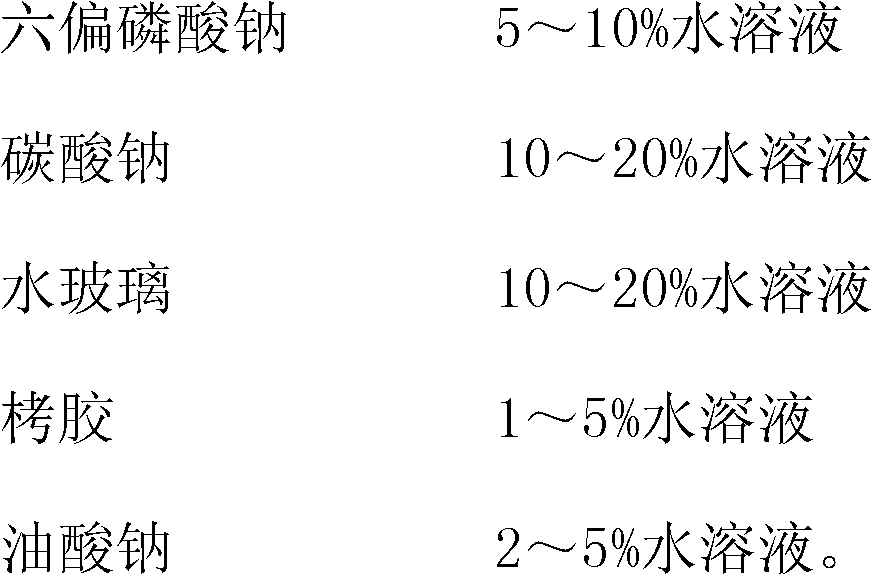

[0021] When in use, the medicament is first prepared into the following weight percent concentrations:

[0022]

[0023] After using sodium hexametaphosphate to disperse the fine stiltite minerals, the fine stiltite minerals are classified, and then the fine stiltite minerals of different particle sizes are used in a fine mud shaker with a stroke of 8 mm and a stroke rate of 320 times per minute. Separately carry out re-election to obtain fine ore concentrates of different particle sizes, and finally combine the fine ore concentrates of different particle sizes and then carry out flotation to recover the fine ores. During the flotatio...

Embodiment 2

[0025] 1. Mineral raw materials

[0026] The mineral raw material used is tin tailings separated by shaking table, the particle size is 5-74 microns, the tin content is 0.45%, the gangue mineral silicon dioxide content is 32.14%, and the calcium carbonate content is 36.59%.

[0027] 2. Flotation agents and operating conditions:

[0028]

[0029] When in use, the medicament is first prepared into the following weight percent concentrations:

[0030]

[0031] After using sodium hexametaphosphate to disperse the fine stiltite minerals, the fine stiltite minerals are classified, and then the fine stiltite minerals of different particle sizes are used in a fine mud shaker with a stroke of 11 mm and a stroke rate of 360 times per minute Separately carry out re-election to obtain fine ore concentrates of different particle sizes, and finally combine the fine ore concentrates of different particle sizes and then carry out flotation to recover the fine ores. During the flotation...

Embodiment 3

[0033] 1. Mineral raw materials

[0034] The mineral raw material used is tin tailings separated by shaking table, the particle size is 5-74 microns, the tin content is 0.40%, the gangue mineral silicon dioxide content is 34.48%, and the calcium carbonate content is 31.76%.

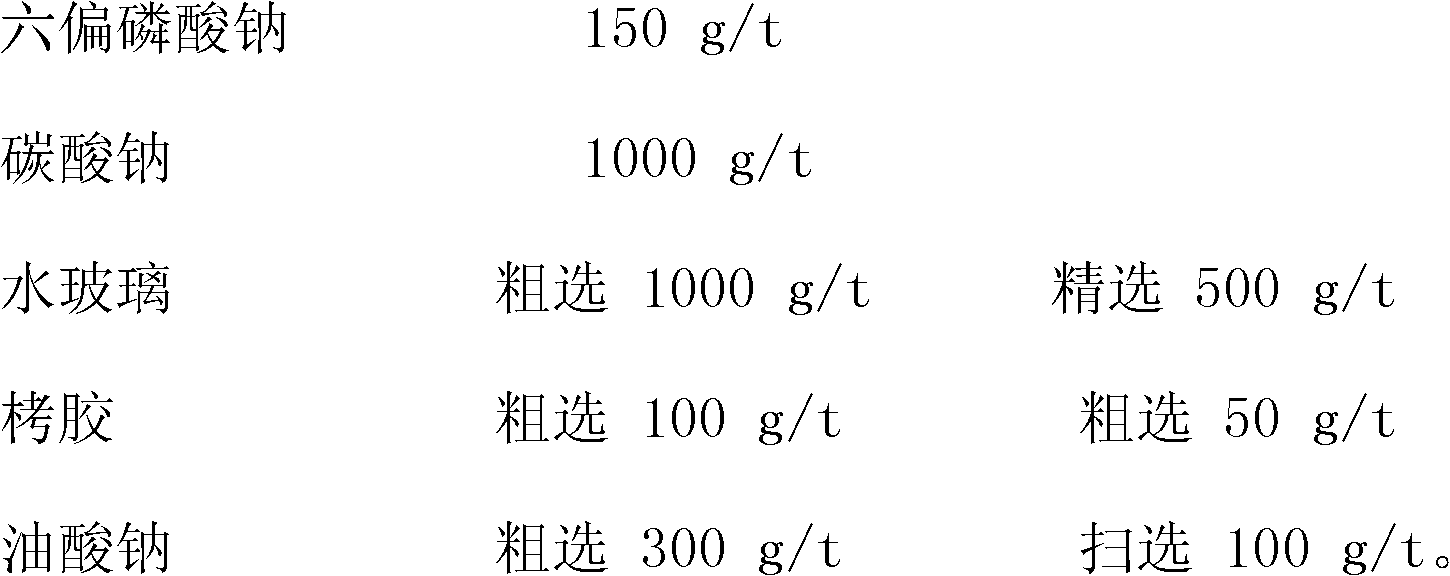

[0035] 2. Flotation agents and operating conditions:

[0036]

[0037] When in use, the medicament is first prepared into the following weight percent concentrations:

[0038]

[0039] After using sodium hexametaphosphate to disperse the fine stiltite minerals, the fine stiltite minerals are classified, and then the fine stiltite minerals of different particle sizes are used in a fine mud shaker with a stroke of 9 mm and a stroke rate of 340 times / min. Separately carry out re-election to obtain fine ore concentrates of different particle sizes, and finally combine the fine ore concentrates of different particle sizes and then carry out flotation to recover the fine ores. During the flotation proces...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com