Electromagnetic actuator for active noise control for amorphous alloy transformers

An electromagnetic actuator, active control technology, applied in transformer/inductor noise damping, electromagnet and other directions, can solve the problems of inability to adjust the mode, fixed structure, etc., to achieve low manufacturing cost, noise elimination, simple process structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

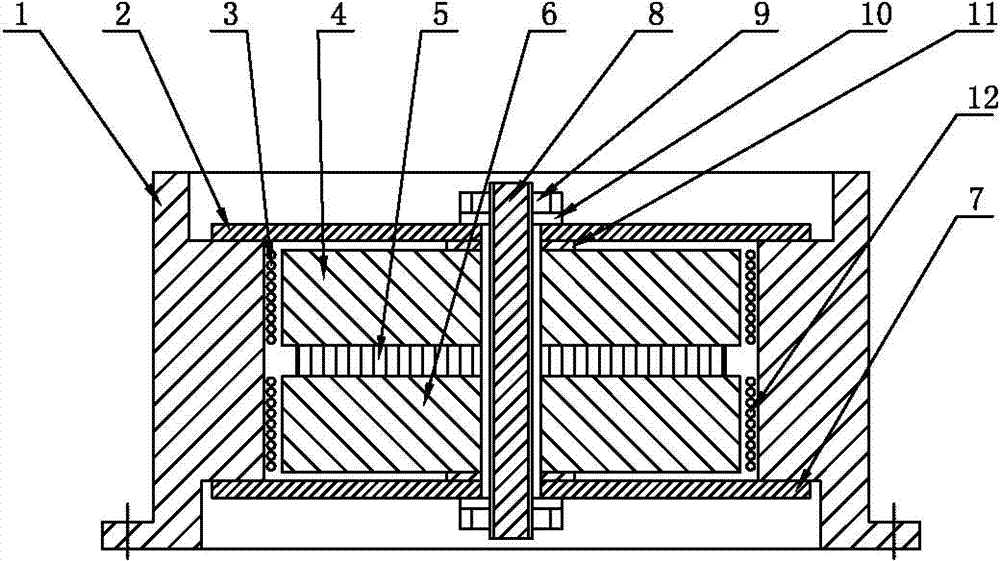

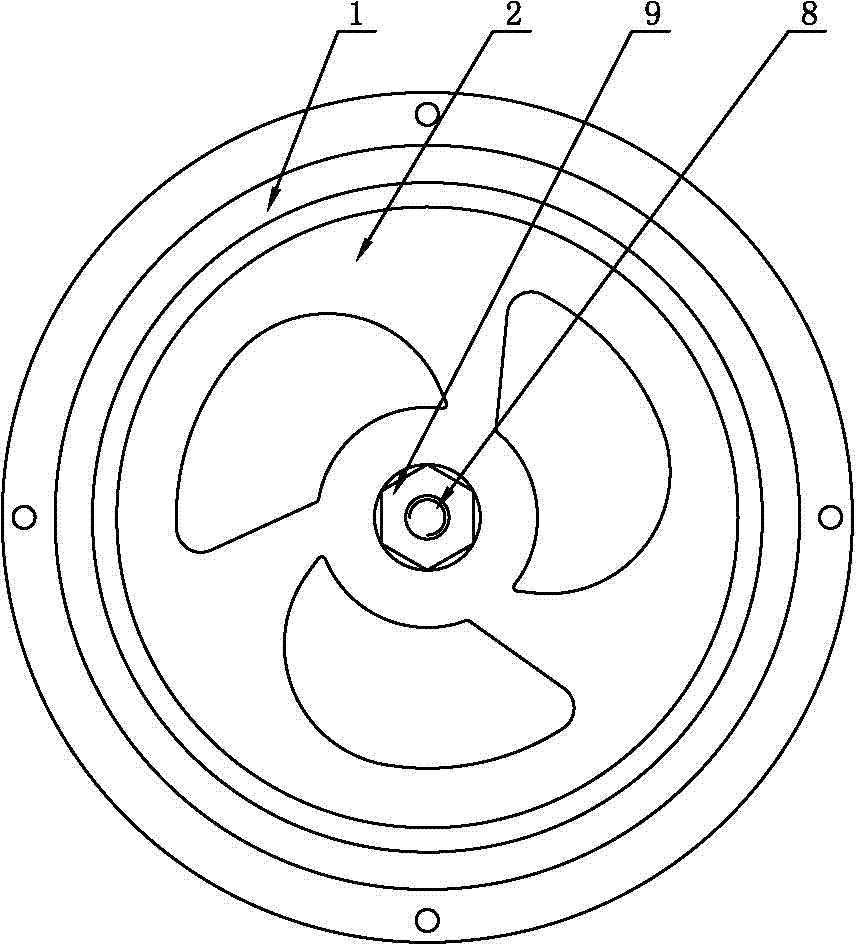

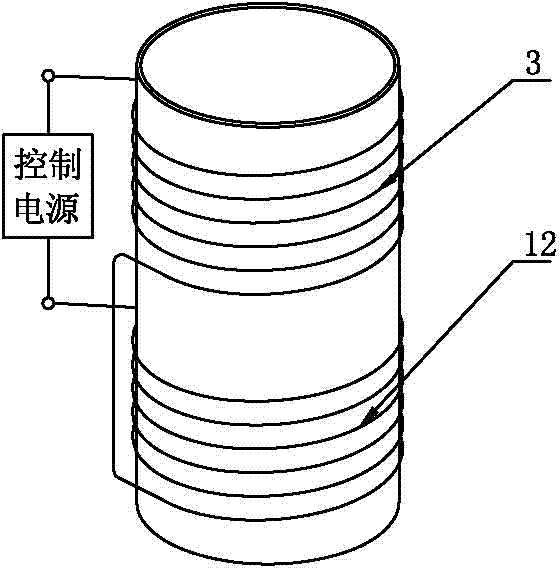

[0021] Such as Figure 1-3 An electromagnetic actuator for active noise control of an amorphous alloy transformer shown includes a support 1 installed on the surface of the transformer. The top and bottom of the support 1 are provided with corresponding annular inner steps, and the two inner steps are respectively provided There are an upper spring plate 2 and a lower spring plate 7. Between the upper spring plate 2 and the lower spring plate 7, an upper moving iron core 4, a permanent magnetic steel 5 and a lower moving iron core 6 are arranged from top to bottom. The upper spring plate 2. The upper moving iron core 4, the permanent magnetic steel 5, the lower moving iron core 6 and the lower spring plate 7 are connected in series by the screw 8 and fixed together by the nuts 9 at both ends of the screw 8. The upper moving iron core 4 and the lower The outer circumference of the moving iron core 6 is respectively wound with an upper coil 3 and a lower coil 12, the upper coil 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com