Surfacing repair method for dissimilar metal pipeline of safety end of voltage stabilizer in nuclear power station

A technology of dissimilar metals and voltage stabilizers, applied in metal processing, arc welding equipment, metal processing equipment, etc., can solve the problems of complex surfacing layer structure, unfavorable improvement of stress state, complex stress state of surfacing layer, etc. The effect of integrity and mechanical consistency, reducing the contact interface of dissimilar metals, and reducing the difficulty of on-site surfacing maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

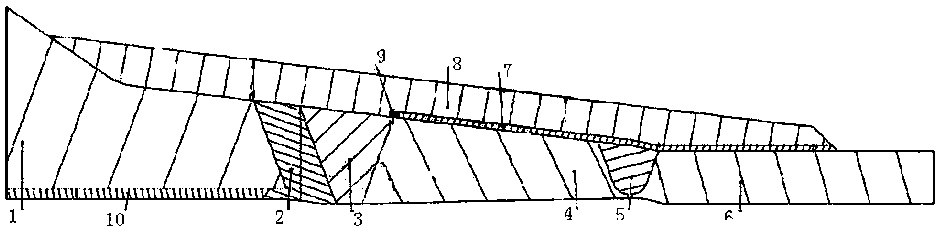

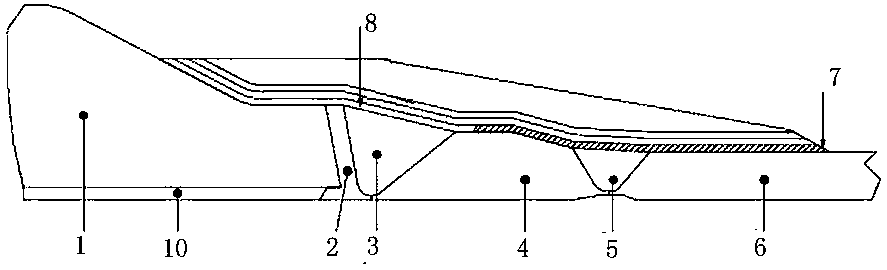

[0031] A method for repairing dissimilar metal pipelines on the safe end of a nuclear power regulator includes the following steps:

[0032] Excavate the stainless steel weld 5 on the weld between the transition pipe section 4 and the pipe section 6, and repair the stainless steel weld 5, and polish the repair weld to be flush with the pipe section 6;

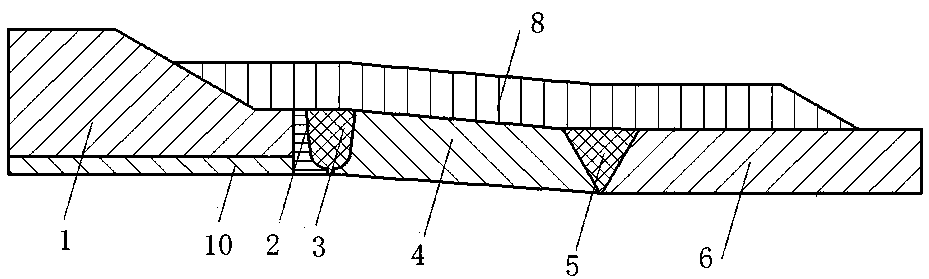

[0033] On the low-alloy steel pipe section 1, the pre-stacked edge 2, the pre-stacked edge weld 3, and the pipe section 6, the nickel-based alloy surfacing layer 8 is surfacing, and it becomes like image 3 The surfacing structure shown.

[0034] When digging out stainless steel welds, mechanical methods such as grinding wheels are used to polish the surface of the stainless steel welds and form a circumferential groove with a certain depth and width. The width is increased by 2mm to 4mm on the basis of the width of the stainless steel welds. The depth is 2mm~3mm.

[0035] Stainless steel weld groove repair welding process method: ado...

example

[0046] Example: The entire surfacing layer welding includes the following five steps:

[0047] Step 1: Stainless steel weld groove repair welding

[0048] Stainless steel weld groove repair welding adopts pulse automatic argon arc welding method, welding peak current is 250A, base current is 190A, pulse ratio is 0.2s:0.2s, arc voltage is 11.5V, rotation speed is 140mm / min, wire feeding speed The rotation is 2400mm / min, the welding gun gas is 0.35MPa, and the temperature between layers is controlled below 180℃.

[0049] Step 2: Stainless steel weld groove repair welding weld grinding

[0050] Using mechanical grinding method, the stainless steel weld groove repair welding seam is ground to be flush with the original base material.

[0051] Step 3: Weld the first three layers

[0052] The first three layers are welded using tempering welding technology, the peak current is 180A, the base current is 120A, the pulse ratio is 0.2s:0.2s, the arc voltage is 10.2V, the rotation speed is 140mm / m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Depth | aaaaa | aaaaa |

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com