Two segment type biological fuel cell

A technology of fuel cells and microorganisms, applied in the field of two-stage microbial fuel cells, can solve the problems of ineffective degradation of sewage, inability to reduce the construction cost of microbial fuel cells, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

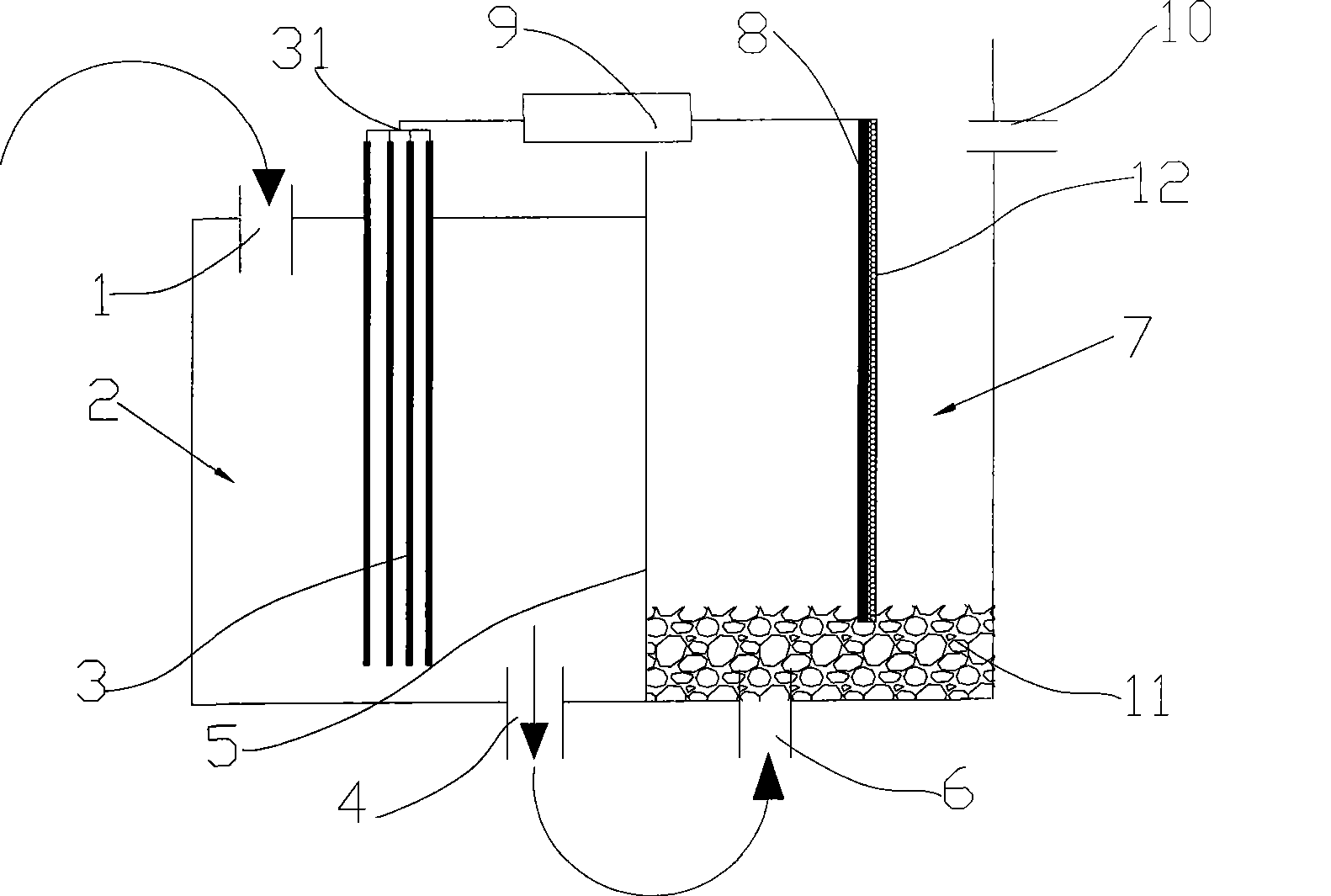

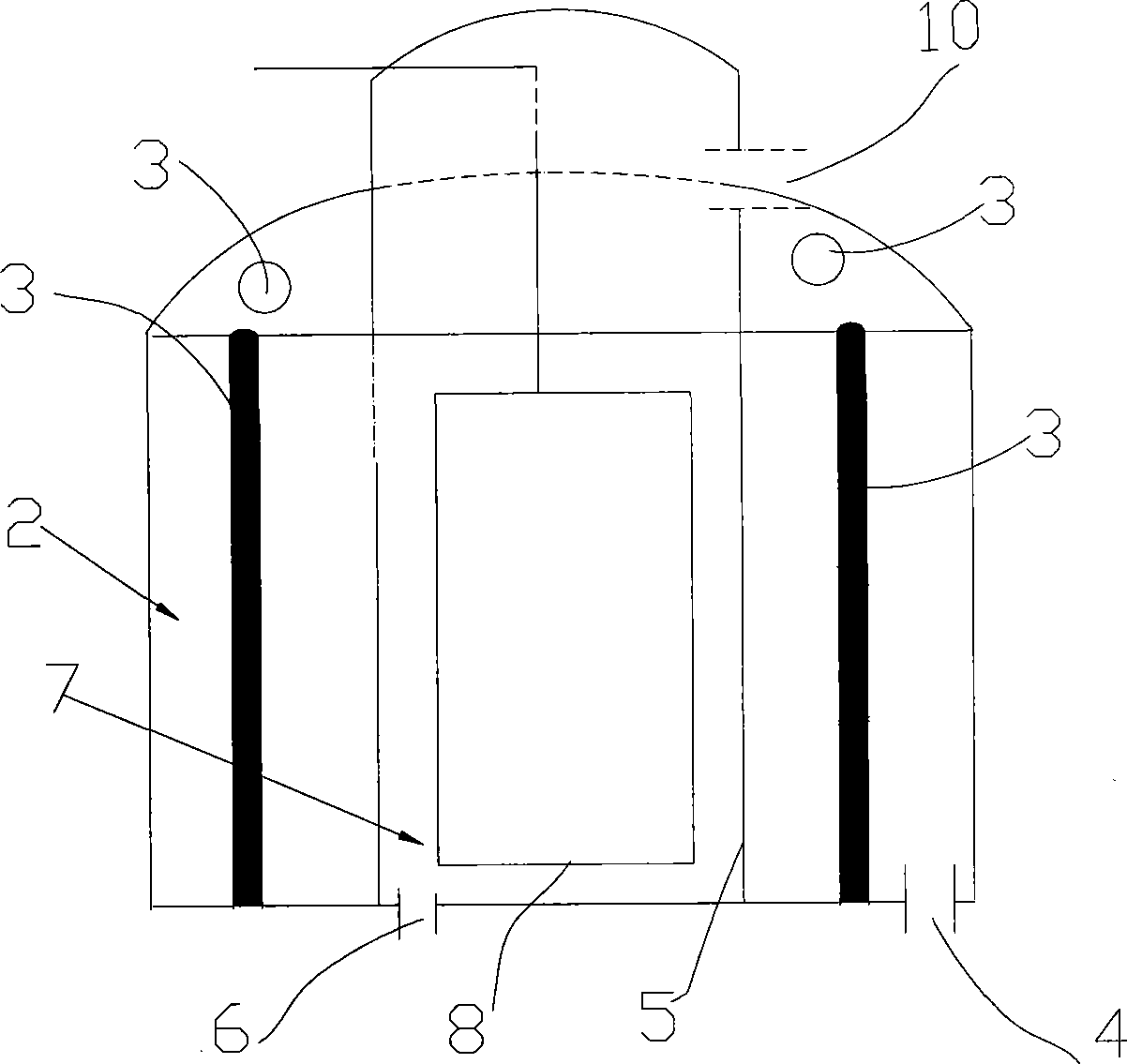

[0016] see figure 1 and figure 2 As shown, a two-stage microbial fuel cell includes a cathode chamber 7 and an anode chamber 2 separated by a proton exchange membrane 5. Only proton hydrogen can pass through the anode chamber 2 and the cathode chamber 7, and the cathode chamber 7 is connected to the atmosphere. The cathode chamber 7 is higher than the anode chamber 2, and an overflow port 10 is provided at the upper end of the cathode chamber 7; an anode 3 is inserted in the anode chamber 2, and a cathode 8 is inserted in the cathode chamber 7 , the electrode material is made of carbon cloth or carbon sticky with a large specific surface area, anaerobic microorganisms are used as an anode catalyst in the anode chamber 2, so that the anode chamber 2 is completely anaerobic, and the cathode chamber 7 is made of electrochemically active microbes. The aerobic microorganisms are used as the cathode catalyst. Specifically, an aerobic microorganism culture medium 11 is provided in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com