Treatment process for garbage leachate

A technology for landfill leachate and a treatment method, which is applied in the field of landfill leachate treatment, can solve the problems of a drop in pH value of an anaerobic system, poor anaerobic reaction effect, large investment and operating costs, etc., so as to promote the hydrolysis and degradation process, avoid the The effect of biodegradable load and low investment and operation cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

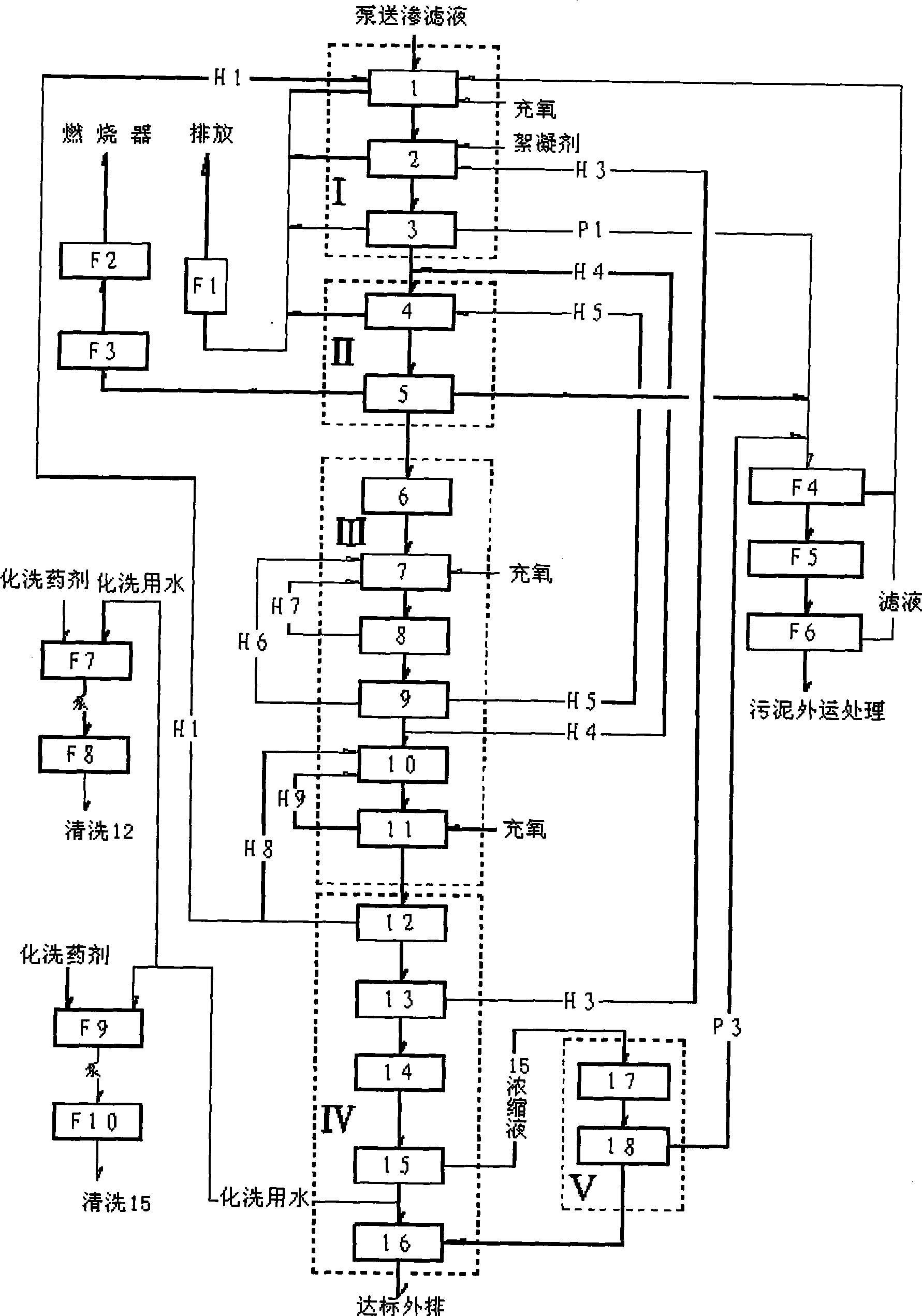

[0022] The present invention will be further described below in conjunction with accompanying drawing and specific embodiment:

[0023] As shown in the accompanying drawings, the landfill leachate treatment method of the present invention comprises the following steps:

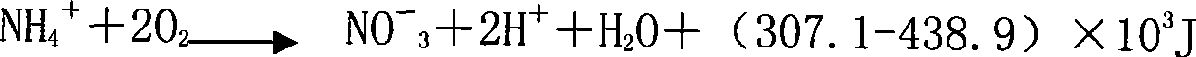

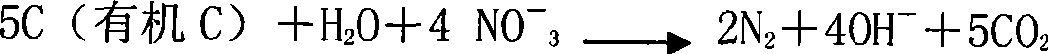

[0024] One. First, the present invention pumps leachate into the micro-aerobic biosorption pool 1 in the micro-aerobic biosorption system 1 through the lifting pump arranged in the garbage storage pit, and the micro-aerobic biosorption pool 1 is mixed with post-process The excess sludge H1 discharged from the MBR membrane separation unit 12 in the first section can absorb organic matter in the water while being slightly aerated and stirred, and the incoming water contains a large amount of easily biochemical substances, and the nitrification sludge is used for denitrification , to remove part of the nitrate nitrogen, the hydraulic retention of the landfill leachate in the microaerobic biosorption tank 1 is 1 t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com