Method for machining pyrrhotite containing nickel ore

A technology for pyrrhotite and nickel ore, which is applied in the field of processing nickel ore containing pyrrhotite, and can solve the problems of unutilization of low-grade nickel concentrate, corrosion of equipment by alkaline pulp, and the impact of pentlandite on the floatability and other problems, to achieve the effect of clean and pollution-free raw materials, stable and convenient operation, and improved quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

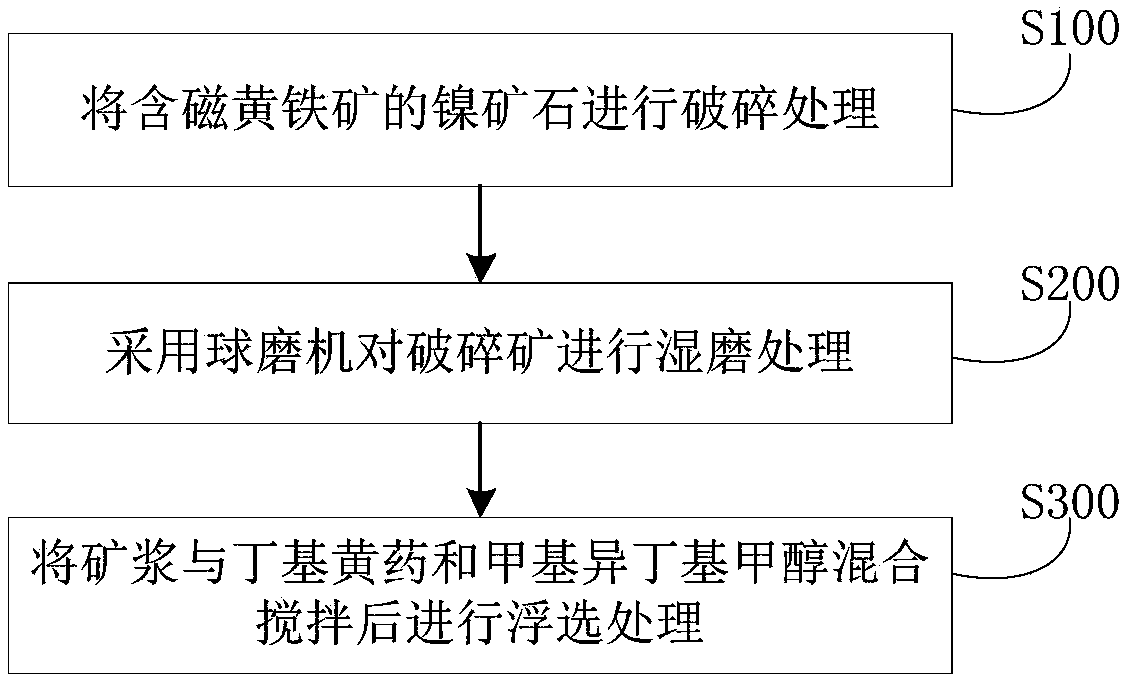

Method used

Image

Examples

Embodiment 1

[0036] Crushing a nickel ore containing pyrrhotite in South Africa, the content of pentlandite in the ore is 6.9wt%, and the content of pyrrhotite is 45wt%, to obtain a crushed ore with a particle size not greater than 2mm; then The crushed ore is wet-milled with a ball mill containing stainless steel liners and balls to obtain a slurry with a concentration of 35wt% and a particle size of not higher than 0.074mm, accounting for 80%; then the collector butyl xanthate and foaming agent Methyl isobutyl carbinol was added to the pulp at a mass ratio of 100000:6:2, stirred for 3 minutes, and the pH value of the pulp became 8.2; finally, nickel concentrate and pyrrhotite were obtained by flotation for 6 minutes. The nickel grade of the nickel concentrate is 9.58%, and the nickel recovery rate reaches 85.6%.

Embodiment 2

[0038] A certain nickel ore containing pyrrhotite in Canada was crushed, the content of pentlandite in the ore was 1.68wt%, and the content of pyrrhotite was 12.43wt%, to obtain a crushed ore with a particle size not greater than 2mm; Then use a ball mill containing stainless steel liners and balls to wet-grind the crushed ore to obtain a slurry with a concentration of 35wt% and a particle size of no more than 0.074mm, accounting for 75%; then the collector butyl xanthate and foaming The agent methyl isobutyl carbinol was added to the pulp according to the mass ratio of 100000:7:2.5, stirred for 3 minutes, and the pH value of the pulp became 8.1; finally, the nickel concentrate and pyrrhotite were obtained by flotation for 7 minutes. The nickel grade of the nickel concentrate is 10.62%, and the nickel recovery rate reaches 75.6%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com