A composite solid propellant with low burning rate, high energy and high mechanical properties

A solid propellant, burning rate technology, used in offensive equipment, compressed gas generation, explosives, etc., can solve problems such as difficult to dissolve, melting point exceeding 55 °C, etc., to meet the requirements of structural integrity, excellent and stable mechanical properties , the effect of large molecular weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] (1) Propellant composition

[0042] components PAO-PCL NG / BTTN AP HMX Al Content (%wt) 7 18.3 15 42 18 components TPB MNA NPBA TDI Content (%wt) 0.05 0.3 0.2 0.15

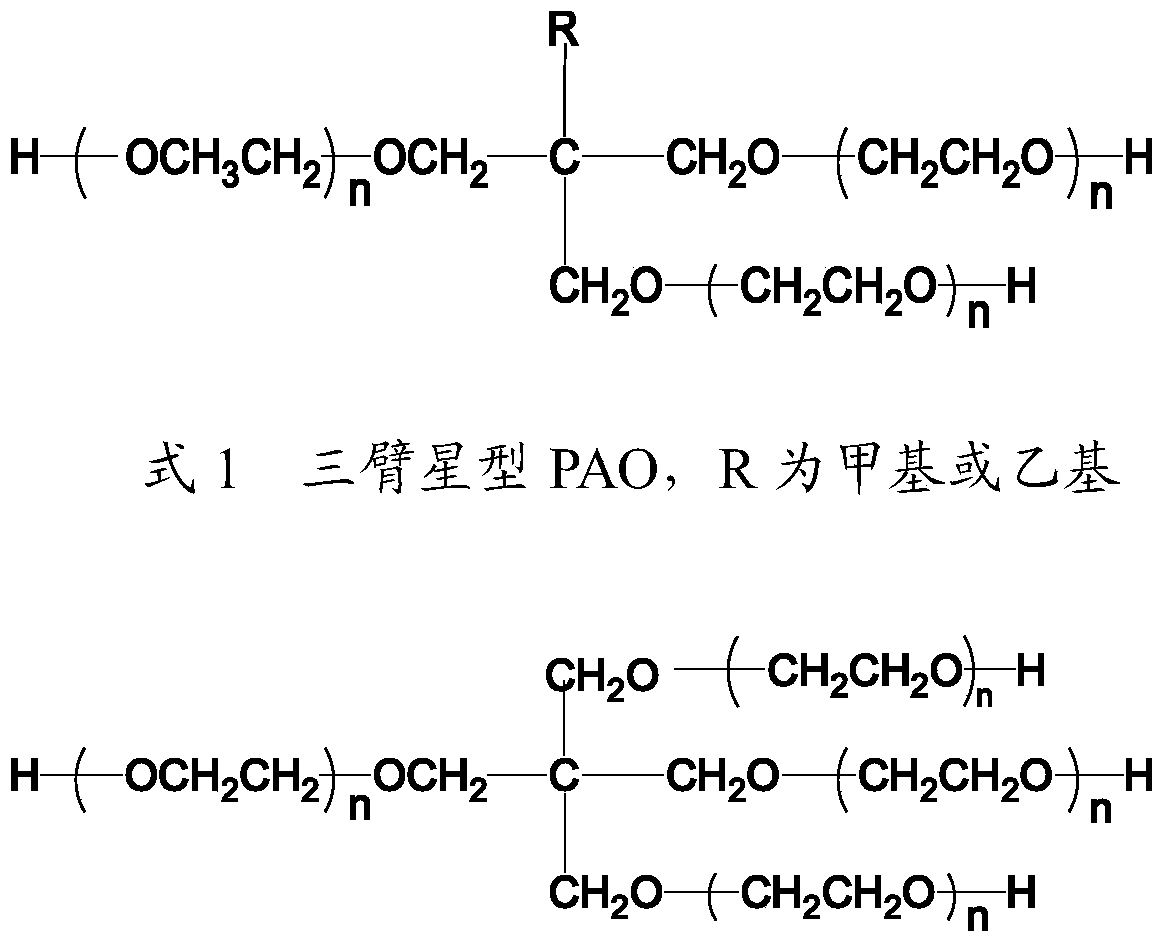

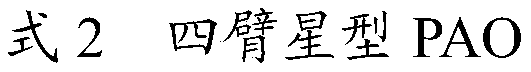

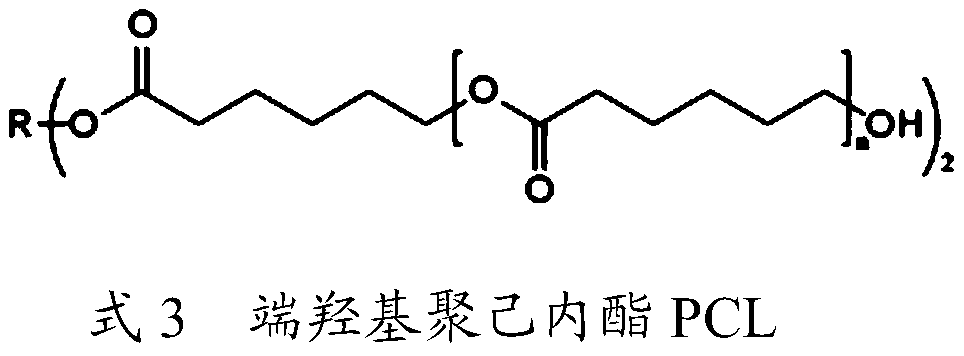

[0043] Among them: PAO-PCL is the PAO with f=3, Mn=10000 as the initiator, and the PAO-PCL adhesive with f=3, Mn=20000 is prepared according to the molar ratio PAO:PCL=1:1, and the melting point is 50.1°C .

[0044] (2) Propellant performance

[0045] Energy performance (6.86MPa measured specific impulse): 255.2s

[0046] Burning rate: r6.86MPa=7mm / s

[0047] Mechanical properties: 25℃ σ m =0.91MPa, ε m =115%

[0048] +70°C ε m =87%

[0049] -30℃ε m =92%

Embodiment 2

[0051] (1) Propellant composition

[0052] components PAO-PCL NG / BTTN AP HMX Al Content (%wt) 6 19 12.25 47 15 components TPB MNA NPBA HDI Content (%wt) 0.05 0.3 0.2 0.2

[0053] Wherein: PAO-PCL is to use the PAO of f=3, Mn=15000 as initiator, according to the molar ratio PAO:PCL=2:1 feeding intake, prepare f=3, the PAO-PCL adhesive of Mn=22500, melting point 50.2°C.

[0054] (2) Propellant performance

[0055] Energy performance (measured specific impulse of 6.86MPa): 255.3s

[0056] Burning rate: r6.86MPa=7.3mm / s

[0057] Mechanical properties: 25℃ σ m =0.91MPa, ε m =125%

[0058] +70°C ε m =97%

[0059] -30℃ε m =98%

Embodiment 3

[0061] (1) Propellant composition

[0062] components PAO-PCL NG / BTTN AP HMX Al Content (%wt) 6.3 19 12 46 16 components TPB MNA NPBA TDI Content (%wt) 0.05 0.3 0.2 0.15

[0063] Wherein: PAO-PCL is to use the PAO of f=3, Mn=20000 as initiator, according to molar ratio PAO:PCL=2:1 feeds intake, prepares f=3, the PAO-PCL adhesive of Mn=30000, melting point 51.2°C.

[0064] (2) Propellant performance

[0065] Energy performance (measured specific impulse of 6.86MPa): 255.3s

[0066] Burning rate: r6.86MPa=7.4mm / s

[0067] Mechanical properties: 25℃ σ m =0.91MPa, ε m =129%

[0068] +70°C ε m =102%

[0069] -30℃ε m =90%

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com