Beneficiation method of iron pyrite in lead-zinc flotation tailings

A mineral processing method and flotation tailings technology, applied in flotation, solid separation, etc., can solve the problems of high energy consumption of mineral processing, corrosion of equipment and pipelines, long flotation process, etc., achieve long flotation time, reduce sulfuric acid The amount and power consumption, and the effect of improving the sulfur recovery rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

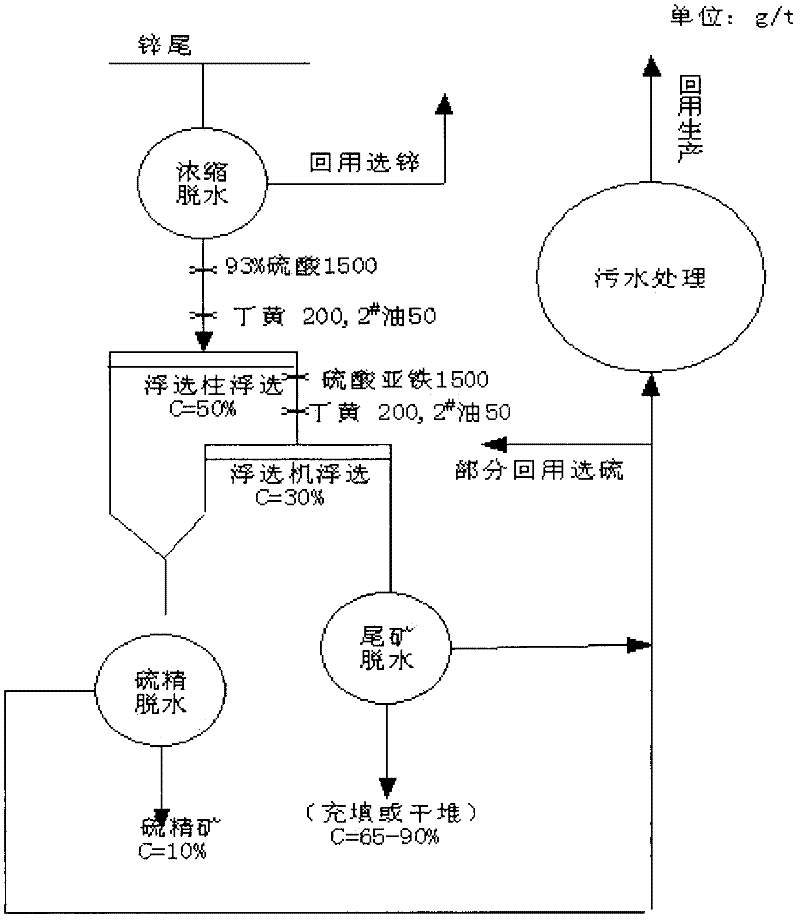

Method used

Image

Examples

Embodiment 1

[0012] In a lead-zinc sulfide ore mine, the raw ore of the lead-zinc sulfide ore contains multiple genera (wt%): Pb 1.5, Zn 2.5, S 31, Fe 25, Ag 88g / t. The sulfur element in the ore mainly exists in the form of pyrite. The flotation process of the concentrator adopts the priority flotation process of lead, zinc and sulfur in sequence. The concentration of sulfur in the lead-zinc floating tailings is about 30%, and the sulfur content is about 31%.

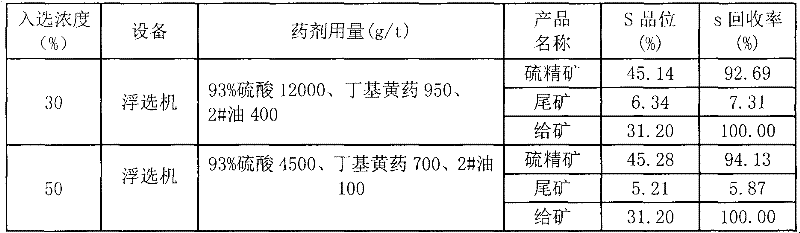

[0013] Take the production lead-zinc flotation tailings sample to do the concentration comparison test, see Table 1, the mass concentration of the lead-zinc flotation tailings is 30% and 50% respectively, add different doses of chemicals, all use the flotation machine for flotation, after A small closed-circuit test was carried out in the laboratory, and the comparison results are shown in Table 1:

[0014] Table 1: Comparative results of selected concentration tests

[0015]

[0016] It can be seen from Table 1 that after conce...

Embodiment 2

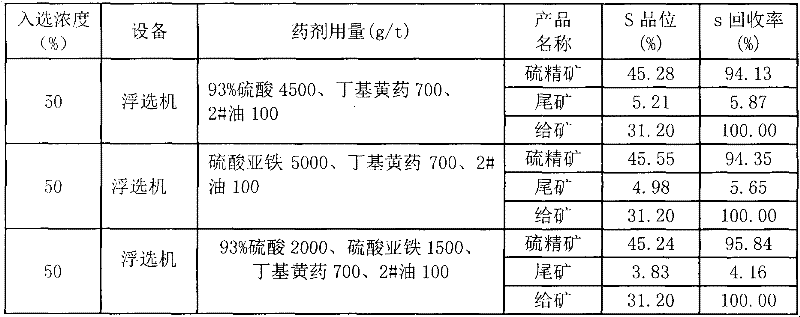

[0018] Embodiment 2 selects the ore sample identical with embodiment 1, gets the production lead-zinc flotation tailings sample to do regulator contrast test, see table 2, lead-zinc flotation tailings mass concentration is all 50%, adds different medicaments, all Flotation was carried out by using a flotation machine, and after a small closed-circuit test in the laboratory, the comparison results are shown in Table 2:

[0019] Table 2: Comparative results of modifier tests

[0020]

[0021] It can be seen from Table 2 that for the high-concentration sulfur separation of lead-zinc flotation tailings, the combination of sulfuric acid and ferrous sulfate as a regulator is better than the flotation index of using sulfuric acid or ferrous sulfate alone as a regulator, and can further reduce the amount of sulfuric acid used.

Embodiment 3

[0023] Embodiment 3 selects the ore sample identical with embodiment 1, gets the production lead-zinc flotation tailings sample to do flotation equipment comparative test, see table 3, lead-zinc flotation tailings mass concentration is all 50%, adds identical medicament, The flotation machine and the flotation column were used for flotation respectively. After a small closed-circuit test in the laboratory, the comparison results are shown in Table 3:

[0024] Table 3: Comparison results of flotation equipment tests

[0025]

[0026] It can be seen from Table 3 that compared with the flotation machine, the flotation column produces higher concentrate grades, but the tailings are also high, which has certain limitations.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com