Patents

Literature

54results about How to "Fast flotation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Gastric retention controlled drug delivery system

ActiveUS7776345B2Fast flotationMaintain physical integrityOrganic active ingredientsNervous disorderControlled releaseExcipient

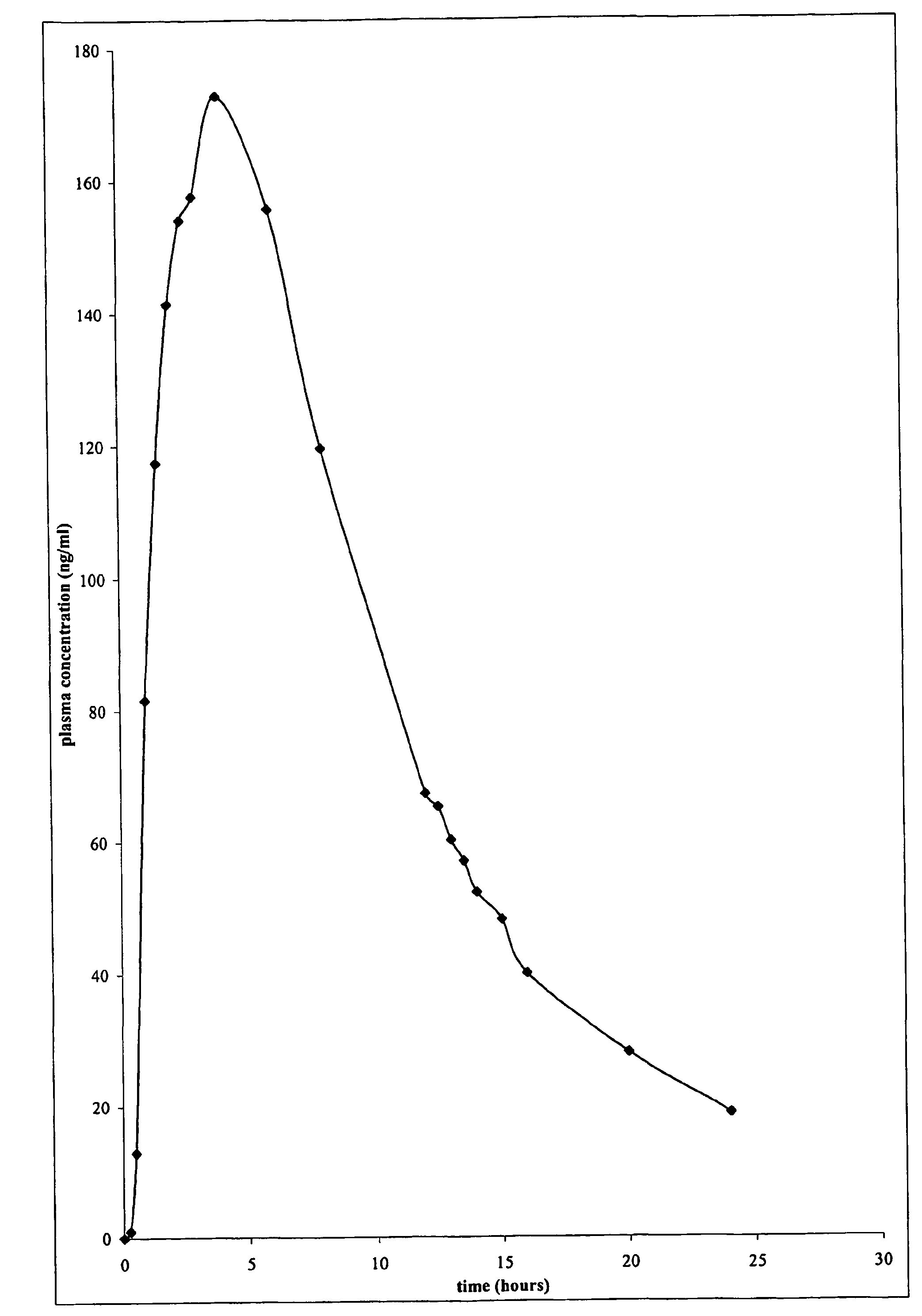

The present invention provides a gastric retention controlled drug delivery system comprising: (a) a controlled release core comprising a drug, a highly swellable polymer and a gas generating agent, said core being capable of swelling and achieving floatation rapidly while maintaining its physical integrity in gastrointestinal fluids for prolonged periods, and (b) a rapidly releasing coat composition comprising the same drug as in the core and pharmaceutically acceptable excipients, wherein the coating composition surrounds the core such that the system provides a biphasic release of the drug in gastrointestinal fluids.

Owner:SUN PHARMA INDS

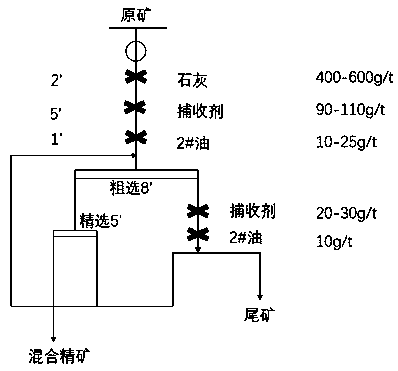

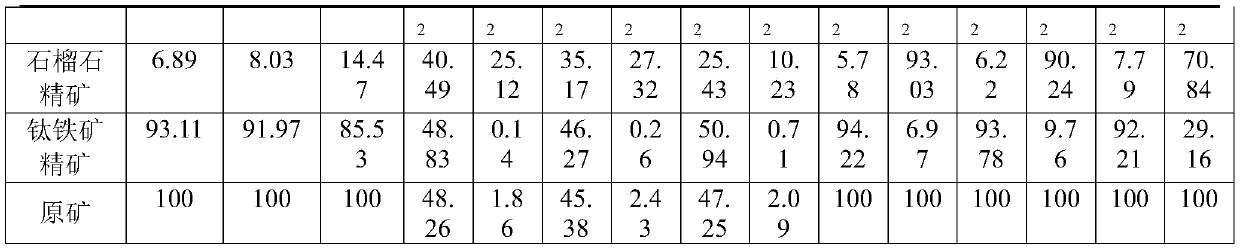

Comprehensive recovery process of intense-weathering poor vanadium titano-magnetite

InactiveCN103157551AImproved flotation indicatorsHigh yieldFlotationWet separationMagnetiteProduct base

The invention provides a comprehensive recovery process of intense-weathering poor vanadium titano-magnetite. The comprehensive recovery process of the intense-weathering poor vanadium titano-magnetite comprises the steps of prescreening, crushing, dry separation, primary grinding, primary magnetic separation, secondary grinding, secondary magnetic separation, strong magnetic separation, floating separation and syrup mixing, and titanium floating separation. The process of titanium floating separation comprises the steps of rough separation, scavenging for two times, and fine separation for four times. According to the comprehensive recovery process of the intense-weathering poor vanadium titano-magnetite, the problems that a throwing tail is high in grade and recovery rate of titanium concentrate is low when an existing process and an existing device are used for processing the intense-weathering poor vanadium titano-magnetite are solved. The index of finished products based on the comprehensive recovery process is that the grade of iron ore concentrate is 64% and yield of the iron ore concentrate is 37%, the grade of the titanium concentrate is 42% and the yield of the titanium concentrate is 41%, and the grade of fine-grain gangue iron is lower than 7% and the grade of titanium is lower than 1%.

Owner:SHANDONG QIANSHUN MINING & METALLURGY SCI

Collecting agent for floating cupric sulfide ore

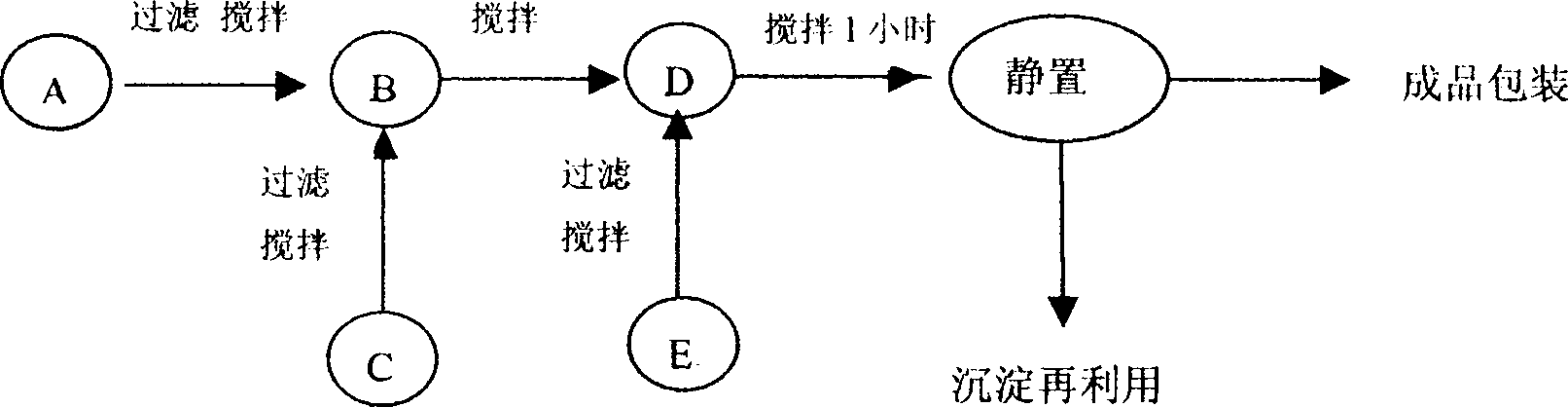

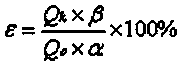

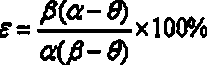

The collecting agent for floatation of copper sulfide ore is prepared by using thionocarbamate, diethylthionitrogen ester, 730A, dialkyl phosphorodithioate and propenyl butyl sulfonate according to the ratio of 0.6-0:0-0.06:0.2-0.1:0.1: 0.1-0.2, and its preparation method includes the following steps: respectively filtering thionocarbamate and 730A; under the condition of normal temp. and normal pressure slowly adding diethylthionitrogen ester while stirring, uniformly stirring them, then adding it and propenyl butyl sulfonate into dialkyl phosphorodithioate, stirring for 1 hr. then standing still for 2 hr. and removing precipitate so as to obtain the invented collecting agent with good selectivity and strong collecting power, and it can effectively separate copper-sulfur, copper-in and copper-arsenic, etc.

Owner:YUNNAN KEENLY NEW MATERIAL

Integrated utilization method of ironmaking dust removal ash

InactiveCN103131861AUse to achieveAchieve recyclingSolid waste managementSolid waste disposalBrickSlag

The invention provides an integrated utilization method of ironmaking dust removal ash, which comprises the following steps: (1) pulping; (2) carbon extraction by floatation; (3) reduction of zinc and iron; (4) water quenching and hot closed slag technique; (5) screening and crushing; (6) magnetic separation of iron; and (7) preparation of water-permeable bricks. The grade of the regenerated carbon powder of the recovered product is 66%, and the recovery rate is 90.75%; the grade of zinc oxide is 51%, and the recovery rate is up to 76.7%; the grade of iron concentrate is 67%, and the recovery rate is 31.4%; and the grade of iron coarse ore is 36%, and the recovery rate is 14.6%. The invention can implement complete reutilization of ironmaking dust removal ash.

Owner:SHANDONG QIANSHUN MINING & METALLURGY SCI

Beneficiation method of sulphide ore

ActiveCN103736569AIncrease productivityIncrease production costFlotationGrain treatmentsMining engineeringSulfidation

A beneficiation method of sulphide ore relates to improvement of a beneficiation method of sulphide ore, and especially adopts a combined flotation method with a cylindrical grinder. The beneficiation process comprises the steps of performing first-stage screening of sulphide ore to obtain a first-stage coarse particle concentrate A1 and a first-stage tailing product A2; and the beneficiation process is characterized in that the first-stage tailing product A2 is subjected to a combined screening process by a cylindrical grinder. The method of the invention can effectively overcome the problem that sulphide ore with a small disseminated grain size and complex material composition cannot be recovered effectively with routine flotation methods in a flotation process, adopts a combined screening process of first-stage tailings by using a cylindrical grinder, and achieves satisfied metal recovery effect on ultrafine particle fractions in the ore by beneficiation with a cylindrical grinder.

Owner:JINCHUAN GROUP LIMITED

GH coal collector and preparation method thereof

The invention discloses a GH coal collector and a preparation method thereof, and the collector comprises the following components by weight percent: 3-12% of mixed surfactant, 1-5% of cosolvent, 3-8% of ordinary kerosene, 5-17% of No.0 national standard diesel oil and 45-60% of deionized water. The preparation method comprises the following steps: adding 3-12% of the mixed surfactant and 1-5% of the cosolvent into 5-17% of the No.0 national standard diesel oil and 3-8% of the ordinary kerosene at the temperature of 40-65 DEG C and the normal pressure, stirring for 10 minutes, then adding 45-60% of the deionized water, cooling and performing high-speed shearing and stirring for 0.5 hour. The cost is low, the process is simple and the operation is convenient. The GH coal collector and the preparation method thereof are widely suitable for the field of mineral processing engineering.

Owner:高露

Brown coal reverse-flotation medicament combination use method

InactiveCN102773168AImproved floating speedImprove settlement performanceFlotationMineral flotationSlurry

A brown coal reverse-flotation medicament combination use method belongs to a fine particle coal separate method. The method comprises the following steps of: mixing brown coal which is finely ground so that the monomer granularity achieves basic dissociation into ore slurry with preference concentration; firstly adding soluble salt (sodium chloride) to stir; adding an inhibiting agent (causticizing corn starch) to stir; then adding a collecting agent (dodecyl amine-hydrochloride) to stir; and finally adding a foaming agent (methyl isobutyl carbinol) to stir; and the brown coal reverse-flotation medicament combination use method is characterized in that the soluble salt is added in the brown coal reverse-flotation, and four medicaments are combined for use. The brown coal reverse-flotation medicament combination use method has the advantages that the conventional floating agent is used, and the flotation of thin brown coal granules without modification is realized by using a reverse-flotation method through the combination of medicaments, namely, mineral granules with high ash float out from foams as a goal object; and simultaneously, according to the method, the flotation rate of mineral is increased, the separating effect is improved, the sedimentation rate of ore slurry is quickened, and the sedimentation of separated ore slurry is facilitated. Compared with the direct flotation, the stronger the hydrophilicity of the surface of brown coal is, the better the reverse-flotation effect is; and therefore, the disadvantages are changed into the advantages.

Owner:CHINA UNIV OF MINING & TECH

Copper-nickel sulphide ore floatation collector

The invention relates to a copper-nickel sulphide ore floatation collector, which is prepared from isobutanol, phosphorus pentasulfide, ammonia water, hydroximic acid and ethionine ester. A preparation method comprises the following steps of: adding the isobutanol into a kettle, adding the phosphorus pentasulfide with stirring, introducing steam to heat to the temperature of the between 70 and 80 DEG C, performing reaction for 2 hours, injecting water into a jacket until the temperature is reduced to 40 DEG C, adding into an ammoniation kettle, injecting water for dilution with stirring, introducing the ammonia water for ammoniation when the concentration is diluted to 70 percent, controlling the ammoniation temperature to be 45 DEG C, and stopping introducing the ammonia water when the pH value reaches 8-9; continuously stirring for 20 minutes to obtain a substance for later use; weighing the substance for later use, the hydroximic acid and the ethionine ester based on weight part; and putting into the kettle sequentially, stirring at normal temperature for 1 hour, and discharging when the pH value is over 7 to obtain the finished product. The copper-nickel sulphide ore floatation collector has the advantages of strong selectivity and high recovery rate.

Owner:磐石市鑫达化工有限责任公司

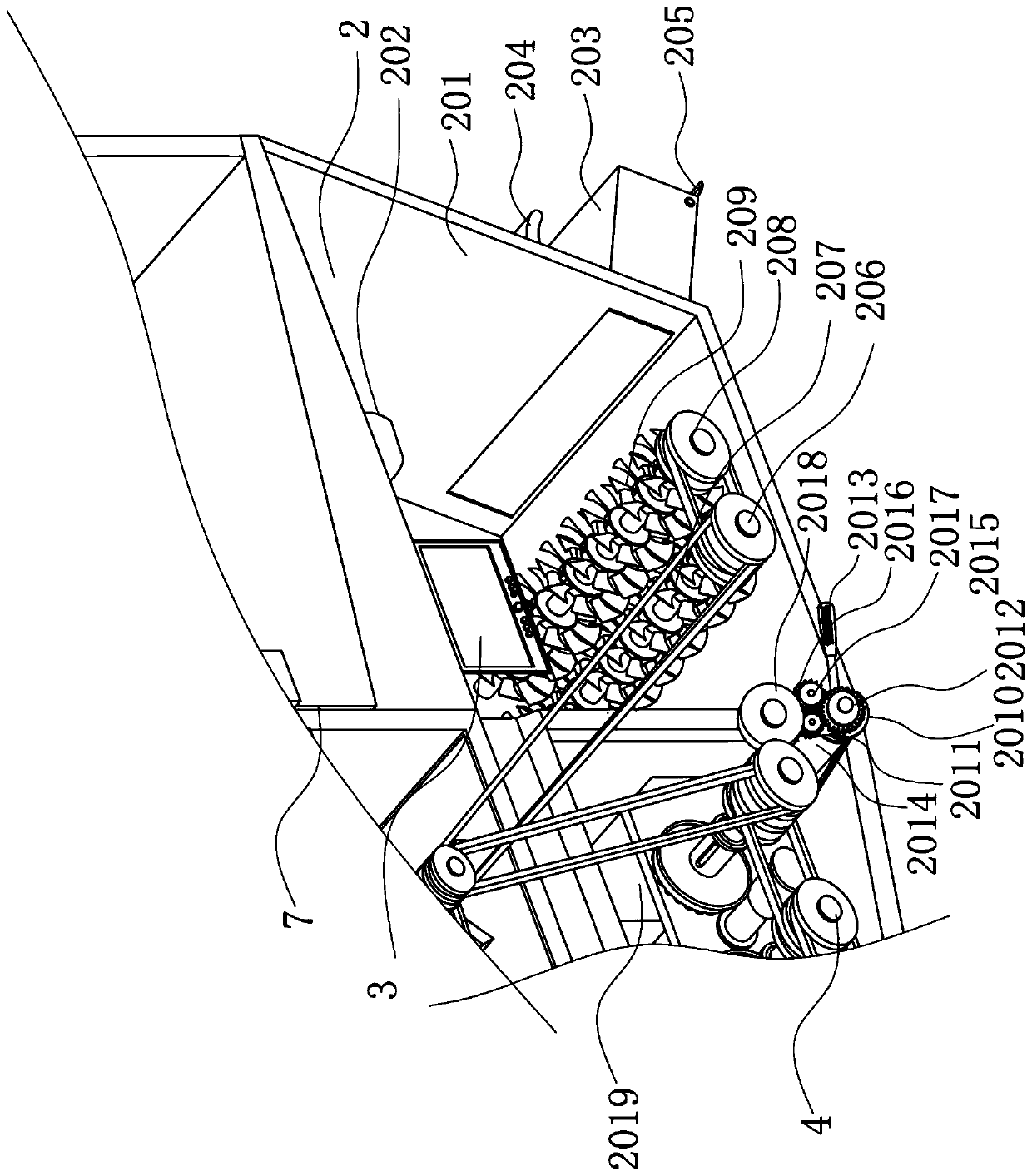

Rubber recycling device

ActiveCN111016008AFast flotationEasy to break laterPlastic recyclingMechanical material recoveryWaste rubberProcess engineering

The invention relates to the field of waste rubber recovery, in particular to a rubber recycling device. The technical problem to be solved by the invention is to provide a rubber recycling device. The rubber recycling device comprises a bottom frame, an automatic feeding, drying and crushing mechanism, a control screen, a rubbing mechanism, a first connecting pipe, a second connecting pipe, an active flotation mechanism, a third connecting pipe and a fourth connecting pipe. The automatic feeding, drying and crushing mechanism is arranged on the right side of the top of the bottom frame. Therubbing mechanism is arranged on the top left of the bottom frame. According to the rubber recycling device, garbage attached to the surfaces of nipples is subjected to flotation and collection, andmeanwhile, rapid flotation is achieved; garbage can be floated through active cooperation and stirring; milk powder agglomeration in the nipple are rapidly removed, and meanwhile, later crushing is facilitated; and the surface of the nipple is subjected to rough machining, so that the slipping phenomenon cannot be generated during crushing, and crushing is uniform.

Owner:宁波北仑广盈胶业有限公司

Method for reclaiming gold and silver by ultrasonic treatment and flotation of gold and silver containing tailings

InactiveCN102133556AFast flotationHigh recovery rateFlotationProcess efficiency improvementLower gradeLow graded

The invention discloses a method for reclaiming gold and silver by ultrasonic treatment and flotation of gold and silver containing tailings. According to the method for flotation after the gold and silver containing tailings are treated by adopting a high sound intensity ultrasonic processor for mine, due to the action of power ultrasonic, the oxide film on the surface of the gold and silver containing tailings in the high sound intensity ultrasonic processor for mine is quickly removed, and the mineral monomer is dissociated. The low-grade gold and silver tailings can be treated, the speed of clearing the oxide film and crushing mineral coenobiums is high, the energy consumption is low, the agent consumption is low, the production cost is low, the flotation speed of the ultrasonic treated gold and silver tailings is high, and particularly the reclamation rate of gold and silver in the gold and silver tailings can be improved.

Owner:古晓跃

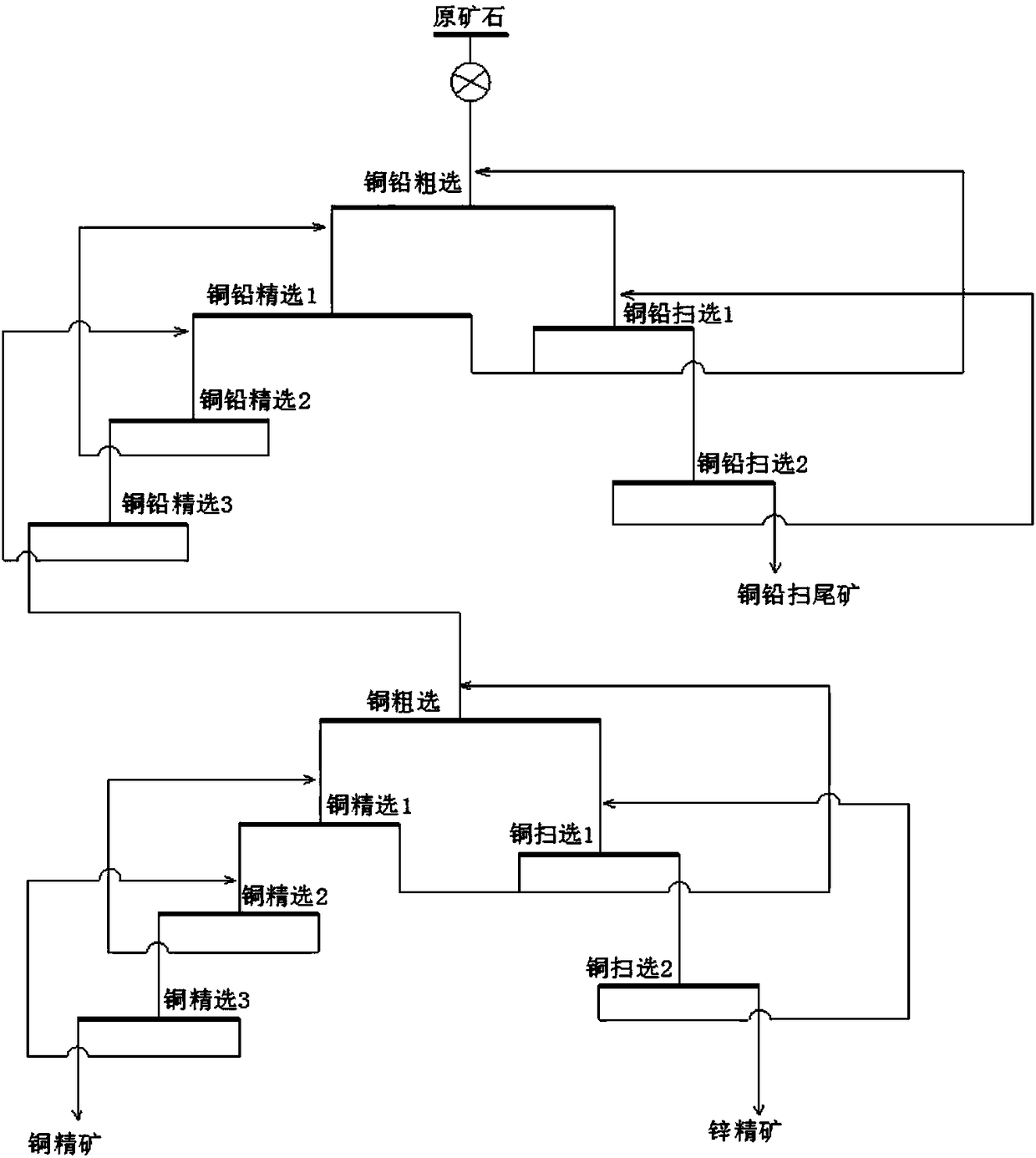

Beneficiation method for copper-lead sulphide ore

ActiveCN108405189APromote separationImprove recovery rate and gradeFlotationCitrate sodiumCalcium hypochlorite

The invention discloses a beneficiation method for copper-lead sulphide ore, and belongs to the technical field of beneficiation. The method comprises raw ore grinding, copper-lead mixing flotation and copper-lead separation. Copper-lead mixing flotation comprises primary copper-lead roughing, tertiary copper-lead fine selecting and secondary copper-lead scavenging. Copper-lead separation comprises primary copper roughing, tertiary copper fine selecting and secondary copper scavenging. Lime, calcium hypochlorite, zinc sulfate, sodium sulfite, sodium sulphide, dimethyl dicarbonate, sodium pyrophosphate, sodium citrate, ethionine ester, ethyl thio carbamate, sodium n-butylxanthate, aniline aerofloat, diphenyl amino phosphorodithioic acid and sodium carbonate are added in the copper-lead roughing and copper-lead scavenging processes. Lime, water glass, sodium phosphate starch, carboxymethyl starch, phthalic acid, thiosalicylic acid, ethionine ester and sodium ethylxanthate are added in the copper roughing and copper scavenging processes. The beneficiation method solves the problem that in the process of beneficiation of the copper-lead sulphide ore through a traditional flotation method, the copper and lead recycling rate is low.

Owner:广西华洋矿源材料有限公司

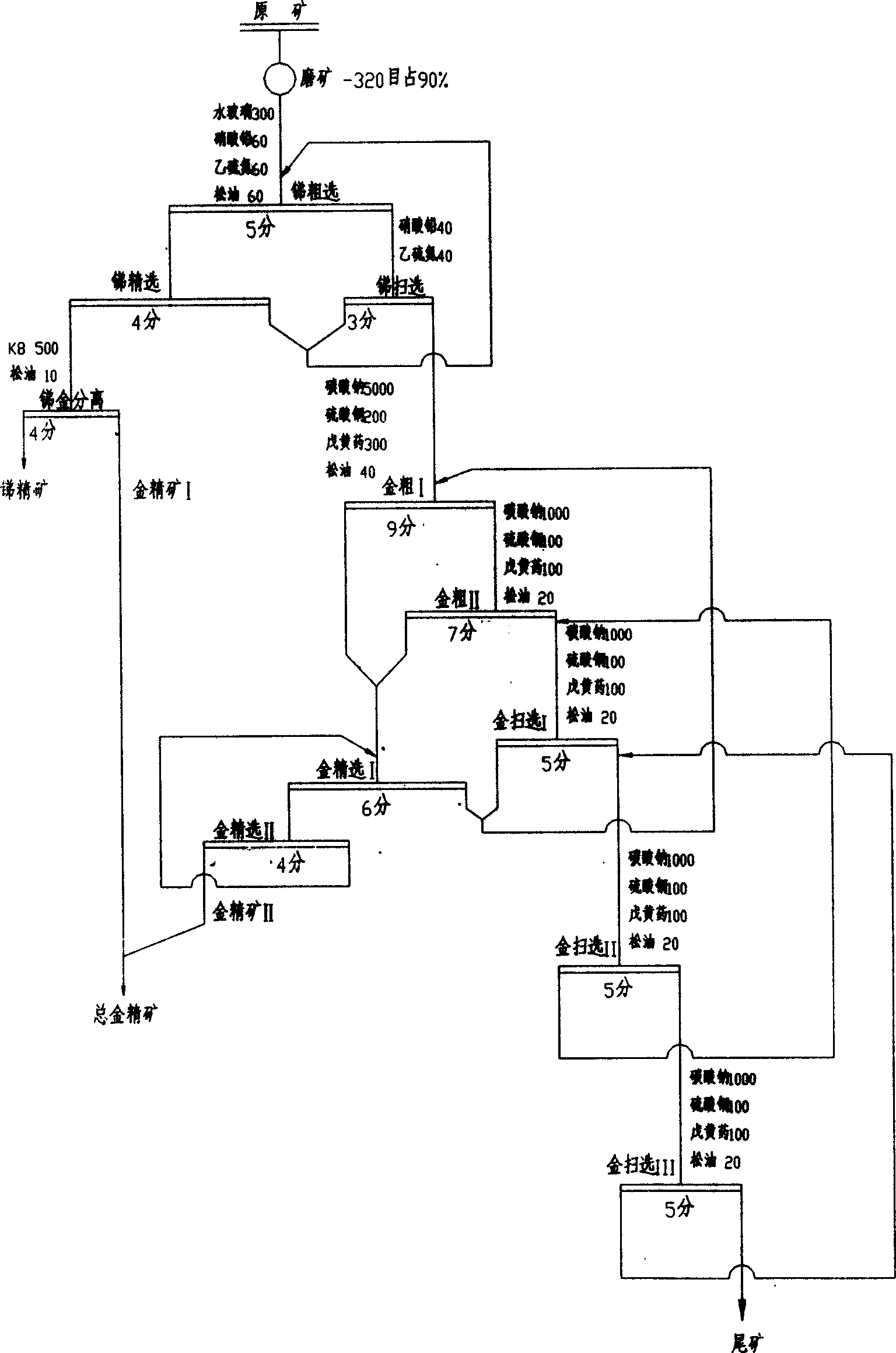

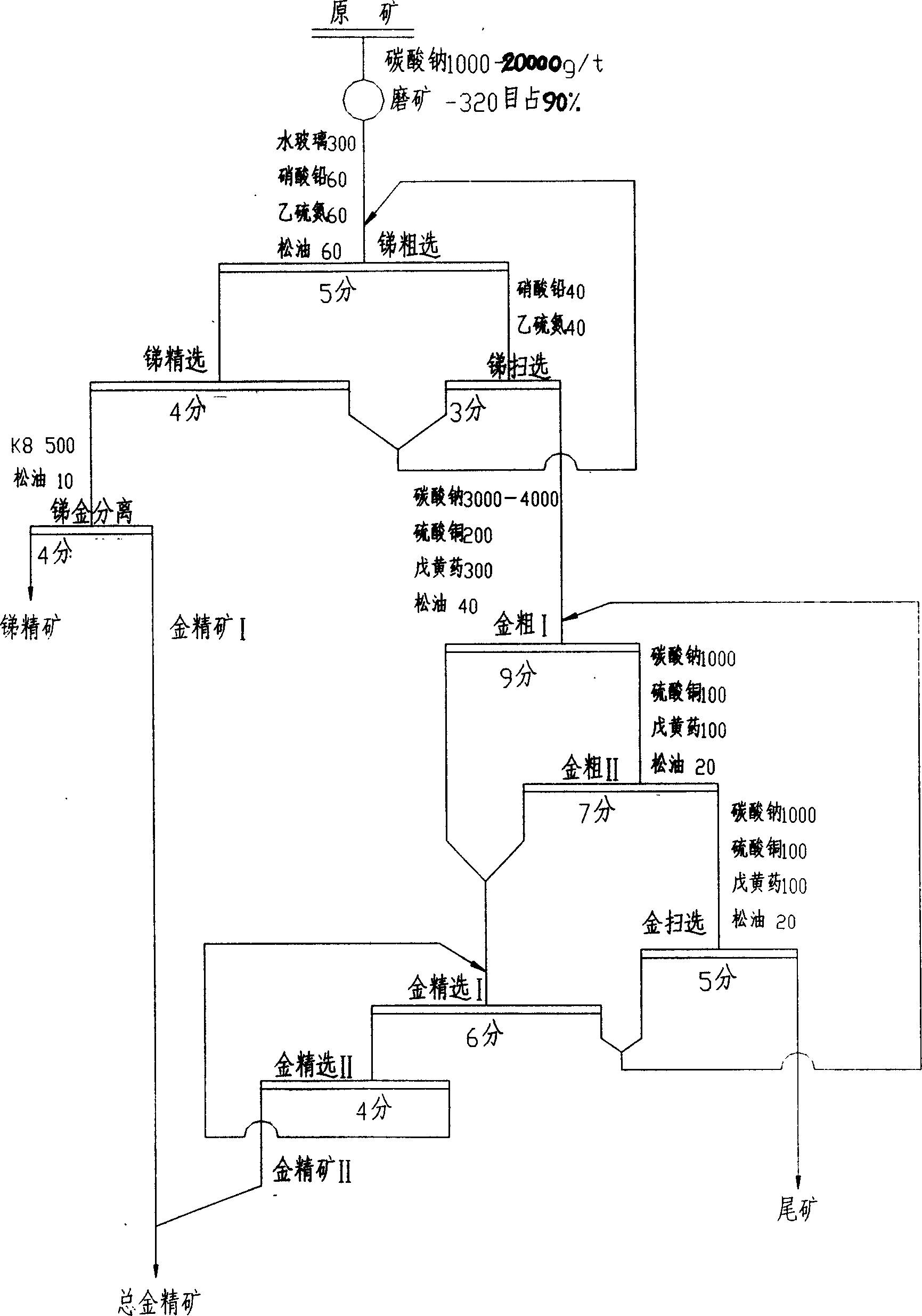

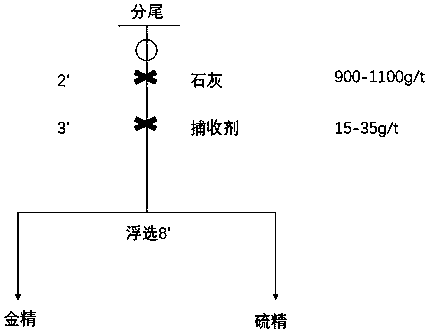

New technology for flashing speed activation flotation of Carin type gold mine

InactiveCN1544155AFloating speed is fastPromote differentiationFlotationGrain treatmentsPyriteEconomic benefits

The invention is a new technique of flash activation select flotation of Carlin-type gold ore, during the grinding course of Carlin-type gold ore at a 320-eye grinding fineness accounting for 85-90%, preadding sodium carbonate at 1000-2000g / t. as regulating agent, to make golden arsenical pyrite and pyrite able to firstly absorb activating agent sodium carbonate at the first time of dissociating a fresh surface, accelerating floatation of the gold ore and promoting differentiation of medium ore to make total recovery of gold selection reach 81% and the recovery show a net increase of 7-11 percents; at the same time, omitting complex technique of eliminating mud, reducing the loss caused by fine mud containing gold, reducing number of times of finely selection and scan-selection, simplifying technical flow and largely heightening economic benefits.

Owner:KUNMING METALLURGY INST

Direct flotation method of zinc sulfide ore

The invention relates to a direct flotation method of zinc sulfide ore. The method includes the steps of grinding the zinc sulfide ore to form ore pulp, adjusting the PH value of the ore pulp to reach 6-11, adding N-alkyl dithiocarbamic acid sodium as a collecting agent and terpenic oil as a foaming agent into the ore pulp, adding zero or little copper sulfate as an activating agent and carrying out flotation. According to the method, copper activation-free direct flotation of the zinc sulfide ore can be realized, the use amount of copper sulfate can be remarkably lowered, and subsequent flotation separation of zinc sulfide and other metal sulfide ore can be promoted.

Owner:KUNMING UNIV OF SCI & TECH

High-mud high secondary copper ore mineral dressing method and combined modifier applied to method

ActiveCN107350083AEliminate the effects ofInhibition effectFlotationMineral flotationMaterials science

The invention belongs to the technical field of the ore flotation process and particularly relates to a high-mud high secondary copper ore mineral dressing method and a combined modifier applied to the method. The combined modifier comprises, by weight, sodium sulfide, sodium metabisulfite, sodium hydrosulfite and sodium carbonate dry powder in proportion of 4-5:1:1-2:1-2. The combined modifier is applied to the high-mud high secondary copper ore mineral dressing method. Lime, the combined modifier and water with the same mass as raw ores are added into the raw ores and then are subjected to grinding and flotation. Copper concentrates and flotation tailings are obtained after two times of concentration and two times of scavenging. The combined modifier effectively eliminates flotation environment deterioration caused by secondary copper ions in flotation pulp through full utilization of the synergic effect of chemicals. The use amount of flotation collectors is reduced. The ore dressing cost is saved. Floating of floatable gangue minerals is effectively suppressed. The electric potential of copper ore flotation pulp is optimized. The flotation speed of copper ores is increased.

Owner:NORTHWEST RES INST OF MINING & METALLURGY INST

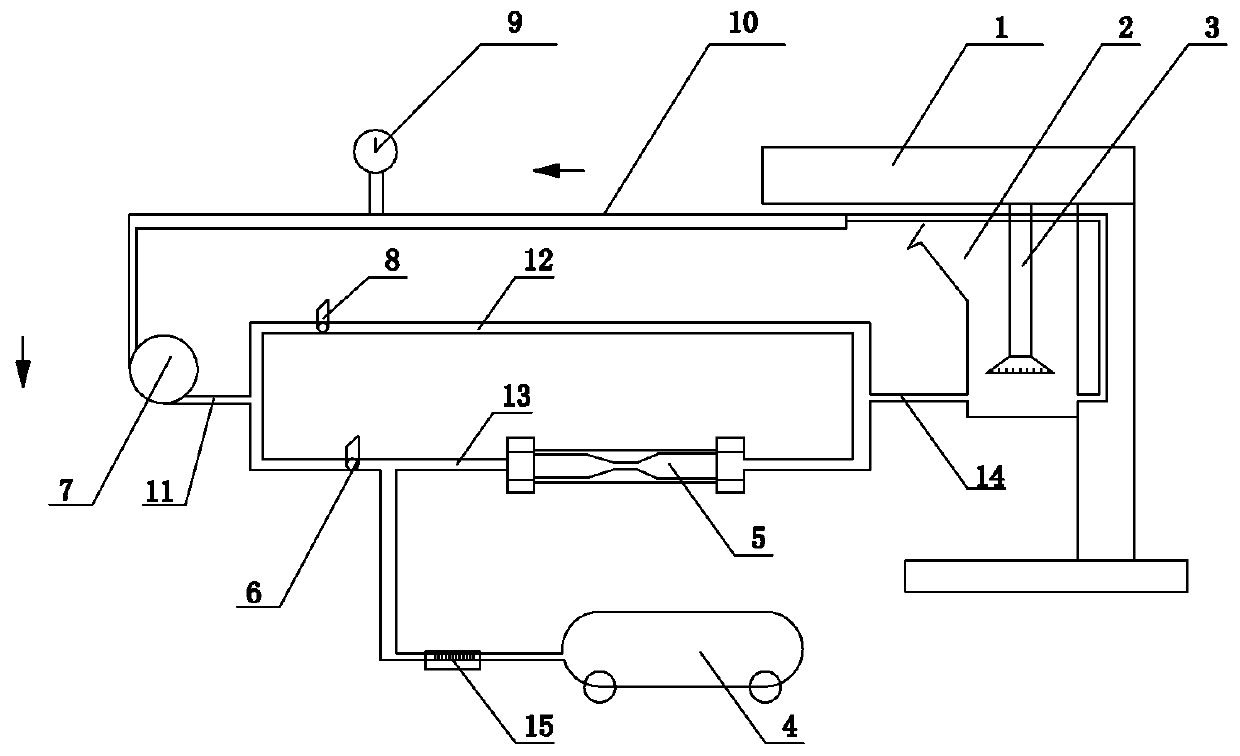

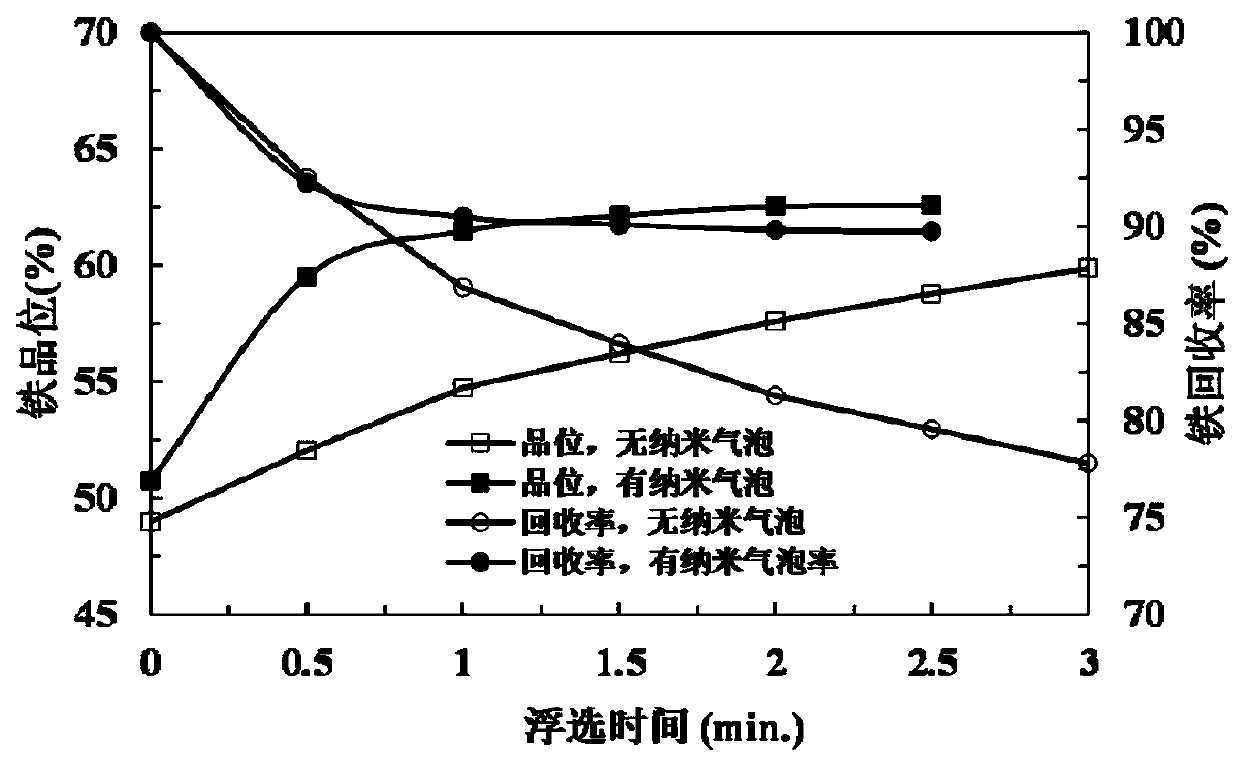

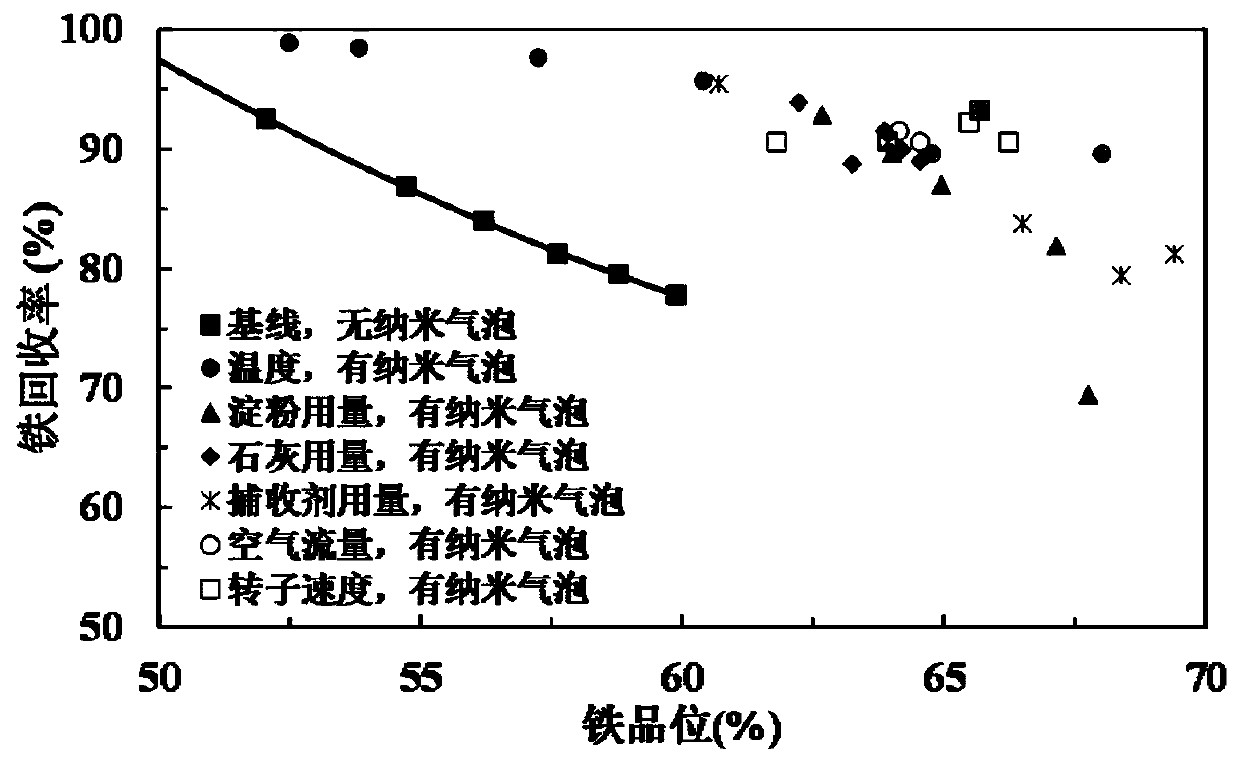

Micro-fine particle nano-bubble flotation method and system

InactiveCN110479501AImprove flotation efficiencyIncrease the probability of collisionFlotationClosed loopMineral flotation

The invention relates to micro-fine particle nano-bubble flotation method and system. The fine particle nano-bubble flotation system comprises a flotation machine, a flotation tank and a stirrer, andis characterized in that the lower parts of the front wall and the rear wall of the flotation tank are communicated with an ore pulp nano-bubble inflation system, and the system is also externally connected with an air compressor; the system comprises a circulating pump, a nano-bubble generator, a pipeline and a valve, a feed port of the circulating pump is communicated with the lower part of therear wall of the flotation tank, a discharge port of the circulating pump is connected with two pipelines, one pipeline is provided with a valve, the other pipeline is provided with a valve and a nano-bubble generator, and the tail ends of the two pipelines are combined into one pipeline, which is communicated with the lower part of the front wall of the flotation tank to form a closed loop; the air compressor is connected with a pipeline positioned between the valve and the nano-bubble generator through an air conveying pipeline; the method has the advantages that 1) nano bubbles are used forultrafine mineral flotation to open up a new way, and 2) hematite flotation contrast test results show that under the same iron ore concentrate grade condition, the iron recovery rate of the iron oreconcentrate can be increased by at most 18%, and the flotation time is shortened by more than 2 / 3.

Owner:ANSTEEL GRP MINING CO LTD

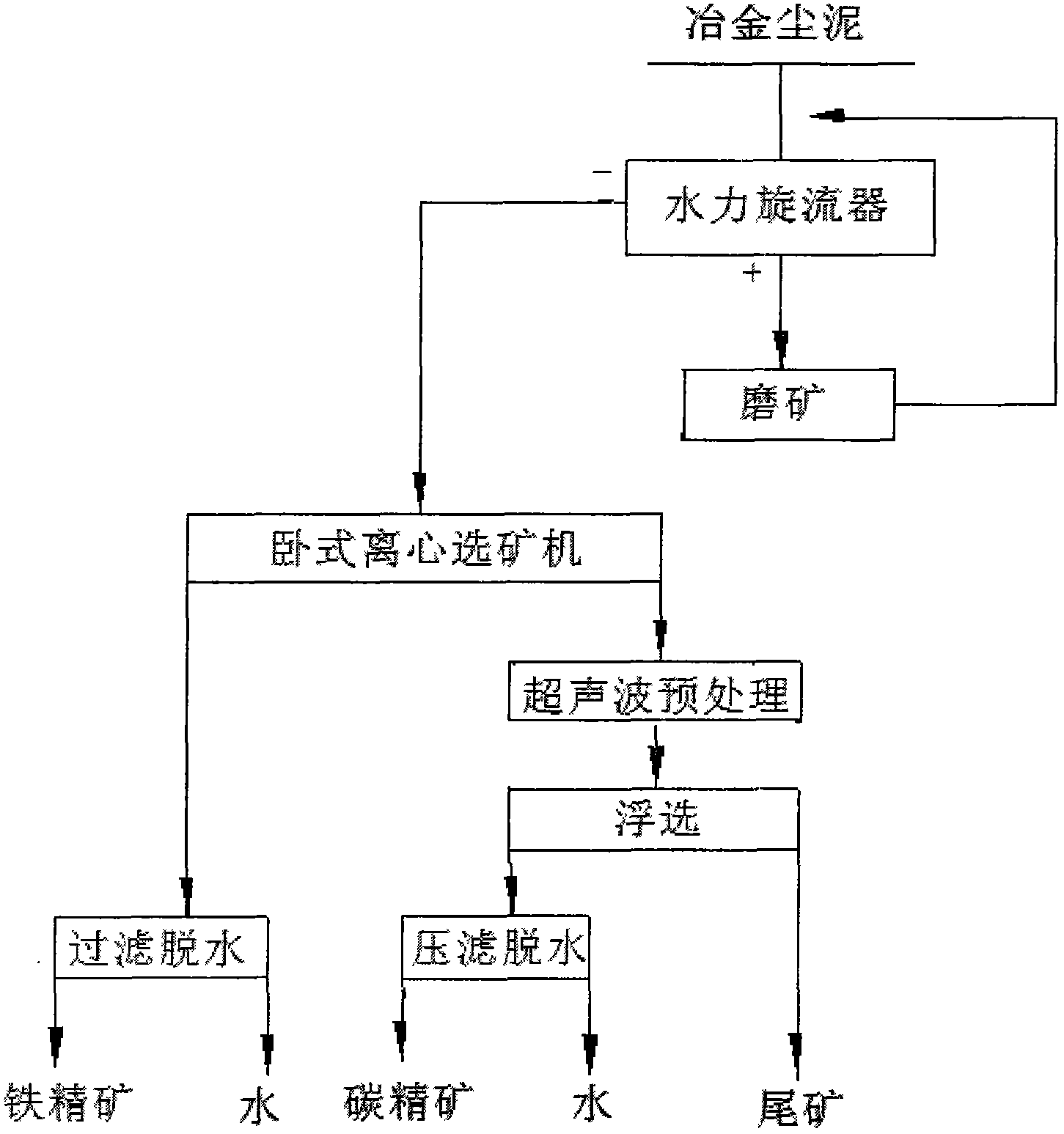

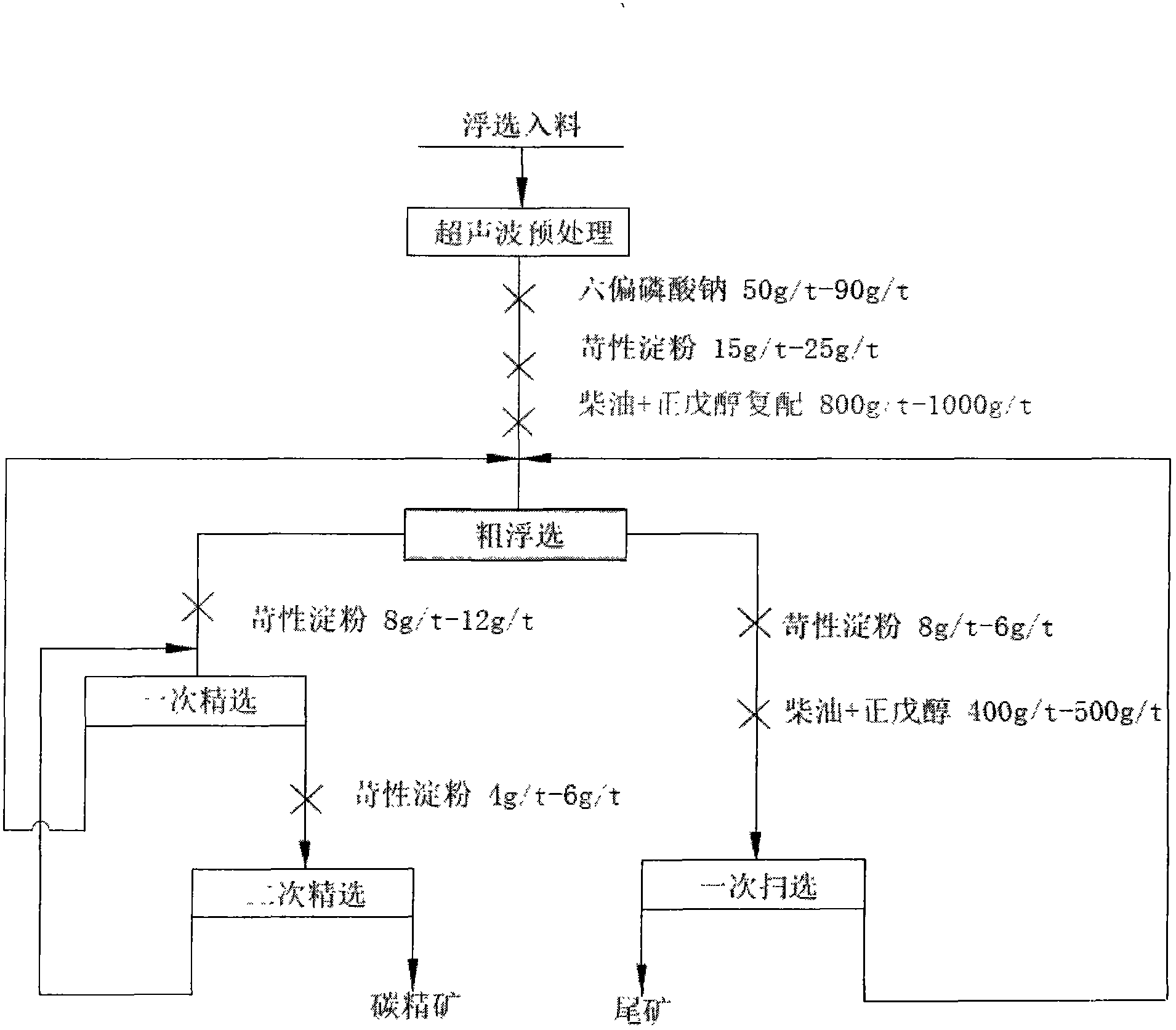

Processing and utilizing method for extracting carbon and iron from blast furnace metallurgy dust and sludge

InactiveCN103230831AGood for opening and dispersingImprove sorting effectRotary centrifugesFlotationSludgePolyacrylamide

A processing and utilizing method for extracting carbon and iron from blast furnace metallurgy dust and sludge belongs to the technical field of mineral processing. The method is characterized by including the steps that metallurgy dust and sludge containing polyacrylamide flocculant is processed, the metallurgy dust and sludge is graded through a hydrocyclone, coarse fraction products are ground and returned to grading operation, fine fraction products are subjected to once roughing and once fine selection through a horizontal centrifugal separator, and iron ore concentrate for metallurgy is obtained through filtering and dehydration operation. Ore pulp of tailing products of the horizontal centrifugal separator is processed through ultrasonic wave and dispersed by adding sodium hexametaphosphate, selective flocculant caustic starch is added, carbon is selected in a floatation mode under the effect of diesel and an n-amyl alcohol compound collecting agent, and carbon concentrate can be obtained through operation of once roughing, twice fine selection and once scavenging. The tailing products selected in the floatation mode are used as the final tailing products. The processing method for utilizing secondary resources of the blast furnace metallurgy dust and sludge containing the flocculant efficiently is provided and has important practical significance on cleaner production, recycling economy and energy saving and emission reduction in iron and steel industry.

Owner:NORTH CHINA UNIVERSITY OF SCIENCE AND TECHNOLOGY

Ore flotation activator and its preparation method

InactiveCN1911528ARaise the gradeIncrease the error rate of beneficiationFlotationFoaming agentFish oil

The present invention relates to one kind of mineral floating activating agent and its preparation. The mineral floating activating agent is prepared with the materials including water, gypsum, animal oil, fish oil and sodium carbonate in the weight ratio of 0.2-2 to 0.2-0.5 to 0.1-1.0 to 0.2-2.0 to 0.1-1.0 and through several technological steps. It is white water soluble powder of grain size 0.02 mm. The mineral floating activating agent is used as catalyst in sulfide mineral floating operation, and can activate collecting agent and foaming agent to reach effective separation of adhered gangue and non-sulfide mineral and ensure high floating effect.

Owner:BEIJING WUTAI HUANQIU SCI & TECH DEV

Jet-type short-column flotation machine

The invention discloses a jet-type short column flotation machine. The jet-type short column flotation machine comprises a flotation column assembly. The upper end of the flotation column is a cylinder, the lower end of the flotation column is a cone, and a concentrate collecting tank, a concentrate converging tank and an outlet are formed in the periphery. An inner conical cylinder and a dispersion plate which are used for reflection and dispersion are arranged inside, a tailing collecting tank is arranged between the inner conical cylinder and an outer conical cylinder, and a secondary circulating collecting port and a circulating pipe are arranged at the lower end. A feeding device is automatically controlled, and a feeding pipe is installed in the center of the flotation column cylinder from bottom to top and connected to an ore pulp dispersing bag. A jet nozzle, an air suction mechanism and a diffusion port are installed in an ore pulp jet device, a tailing confluence bin is arranged at the bottom of the outer conical barrel, a gate valve and a tailing discharge port are formed in a tailing barrel, and a chemical adding mechanism and two defoaming devices are arranged. The jet-type short column flotation machine is mainly used for flotation of coal slime and nonferrous ores, and has the advantages of sufficient ore pulp mineralization, high separation efficiency, low flotation concentrate ash content, high control precision, stable operation and low operation cost due to no operation parts.

Owner:湖南长欣博远工程技术有限公司

Novel environment-friendly composite gold ore dressing collector

ActiveCN110064524AOvercoming selectivityOvercoming the problem of poor harvesting abilityFlotationCarbamatePhosphate

The invention relates to a novel environment-friendly composite gold ore dressing collector. The novel environment-friendly composite gold ore dressing collector comprises, by weight, the following components: 35-45 parts of a main collector, 20-35 parts of an auxiliary collector and 15-20 parts of water; wherein the main collector comprises, by weight, the following raw materials: 45-50 parts ofdihydrocarbyl dithiophosphate, 20-28 parts of isooctyl thioglycolate, 8-12 parts of thiourethane, 5-9 parts of sodium oleate and 8-10 parts of dihydrocarbyl thiocarbonyl carbamate; the auxiliary collector comprises, by weight, the following raw materials: 30-35 parts of alkyl hydroxamic acid, 26-28 parts of polyacrylamide and 10-15 parts of isooctanol phosphate. The novel environment-friendly composite gold ore dressing collector has the advantages of strong collecting capacity, good selectivity, small dosage and foaming property for gold ore, and effectively solves the problems that the ore dressing recovery rate of fine grains and micro fine grains is low, the fine-grained gold is easy to lose when gold with high sulfur content is separated, and the gold-sulfur separation recovery rate is low.

Owner:YANTAI MOUJIN MINING

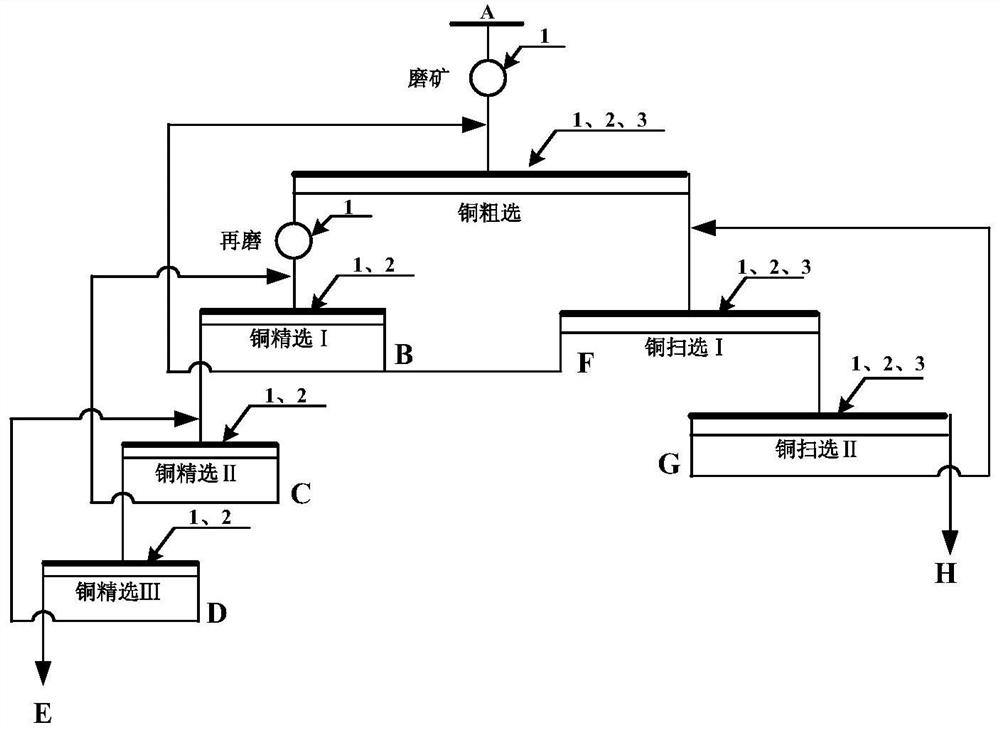

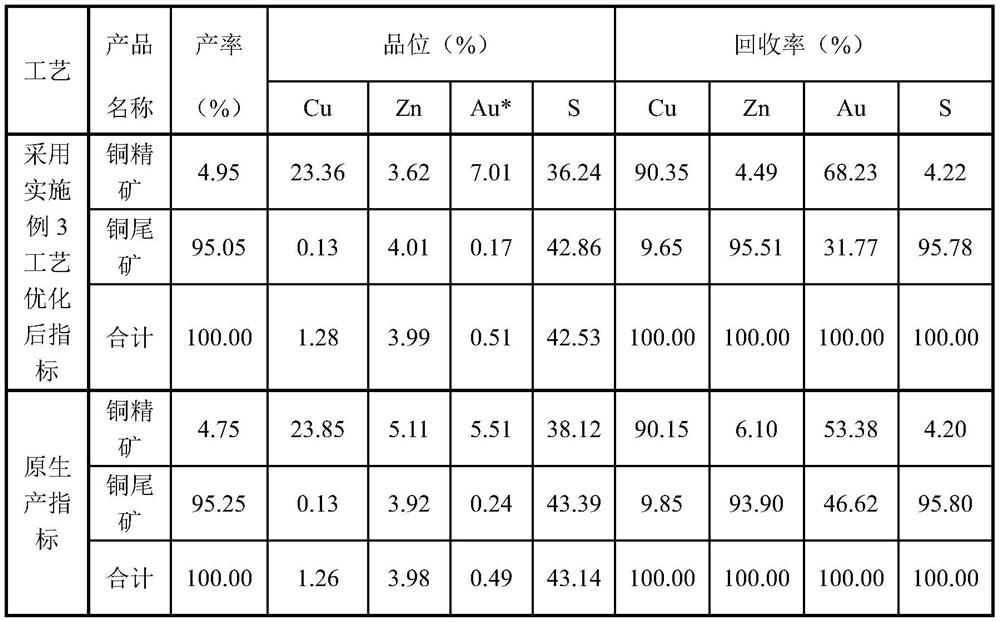

Low-alkali separation method for high-sulfur copper-zinc ore

The invention discloses a low-alkali separation method for high-sulfur copper-zinc ore. The low-alkali separation method comprises the following steps: grinding of raw ore; copper roughing, wherein dry calcium oxide powder, a zinc inhibitor, namely solid sodium pyrosulfite powder and an efficient copper collecting agent are added in the process of copper roughing, and rough copper concentrate andcopper roughing tailings are obtained; multi-stage copper scavenging, wherein the dry calcium oxide powder, the zinc inhibitor solid sodium metabisulfite powder and the efficient copper collecting agent are added in each stage of scavenging operation; regrinding of the rough copper concentrate; and copper concentration, wherein the reground rough copper concentrate is subjected to multi-section concentration operation, and the dry calcium oxide powder and the zinc inhibitor solid sodium metabisulfite powder are added in each section of concentration operation. The method can overcome the defects of existing high-alkali copper-zinc separation processes for the high-sulfur copper-zinc ore and solve the problem of low recovery rate of associated noble metals.

Owner:厦门紫金矿冶技术有限公司

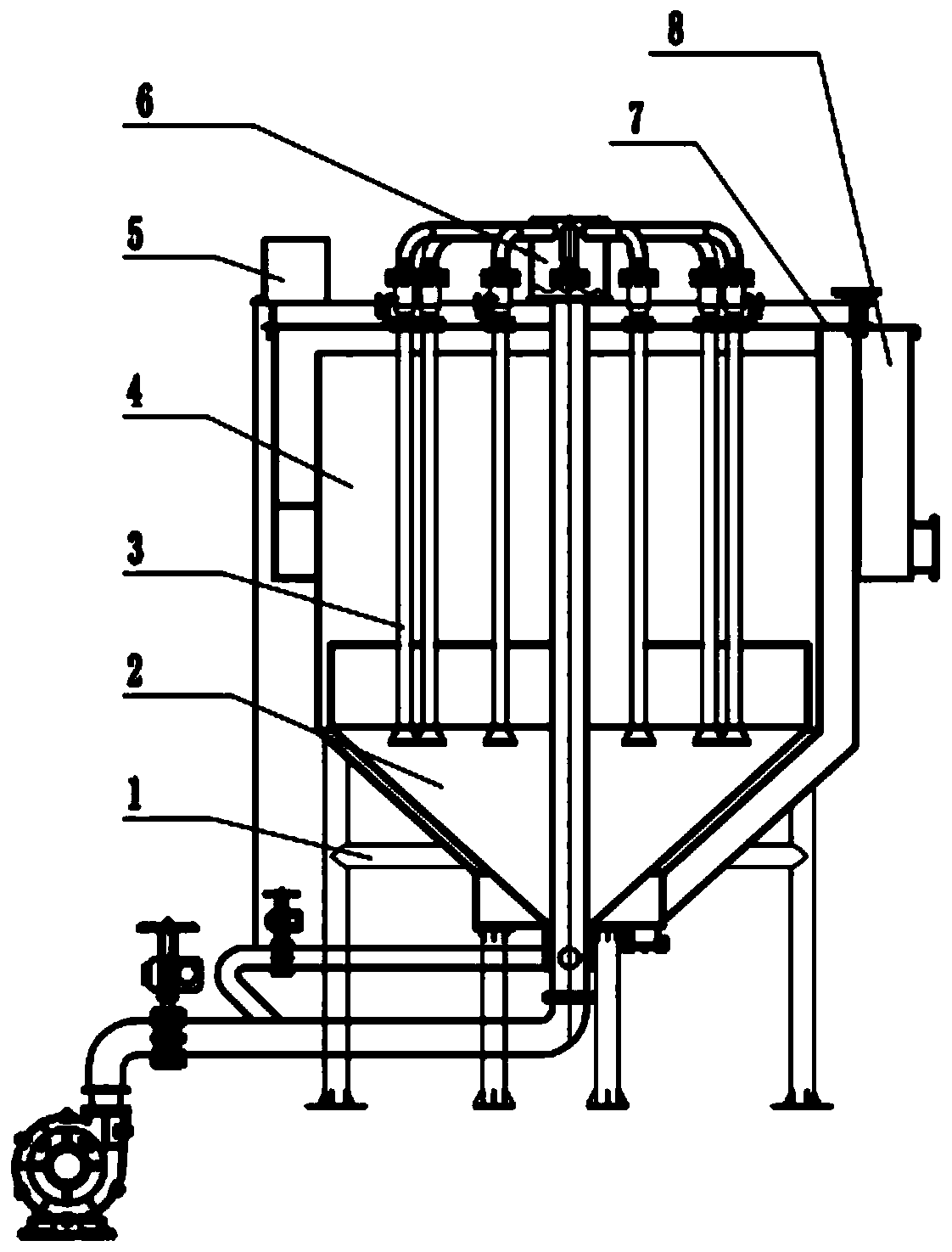

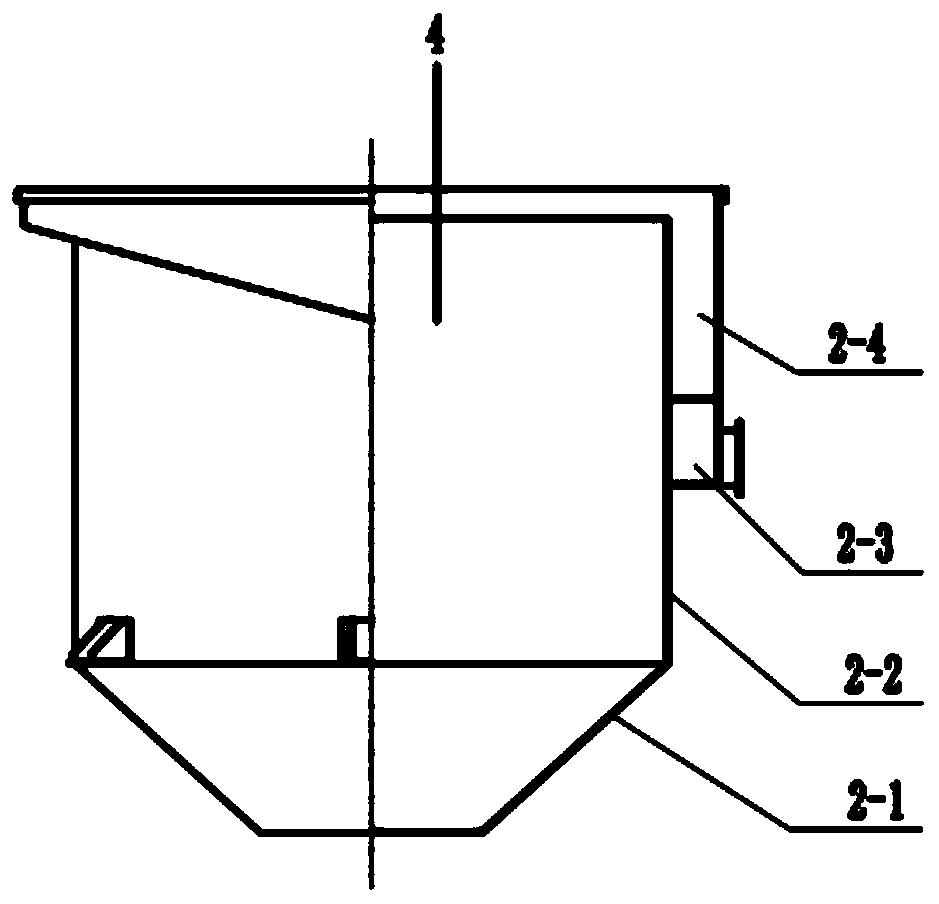

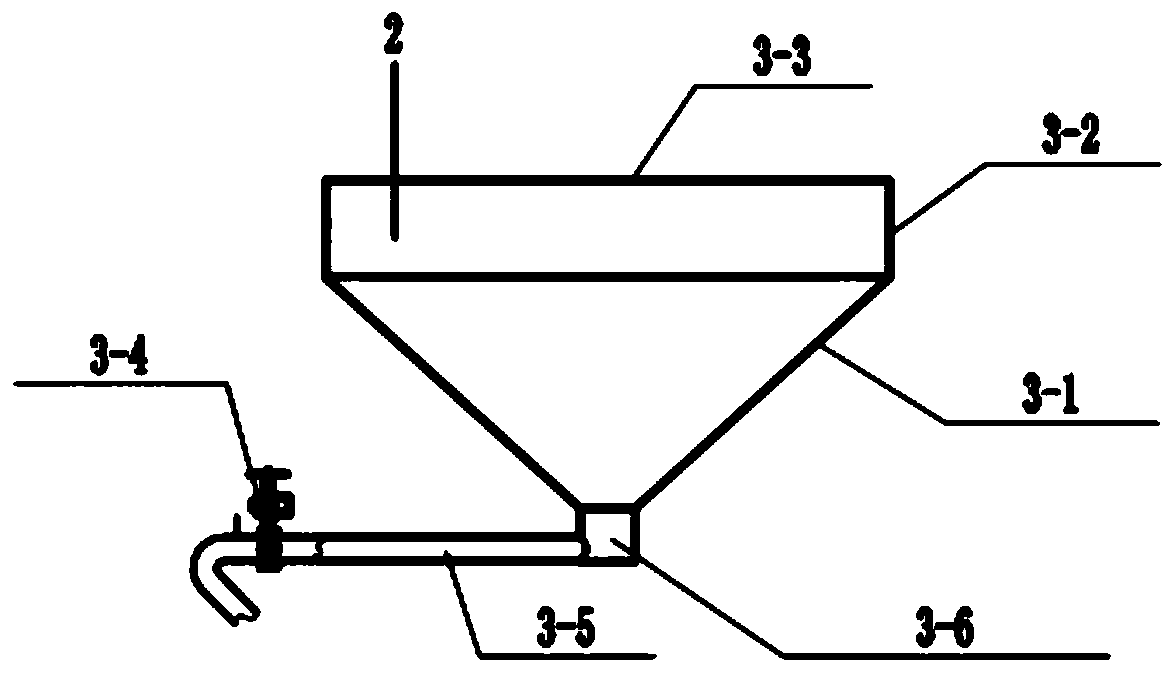

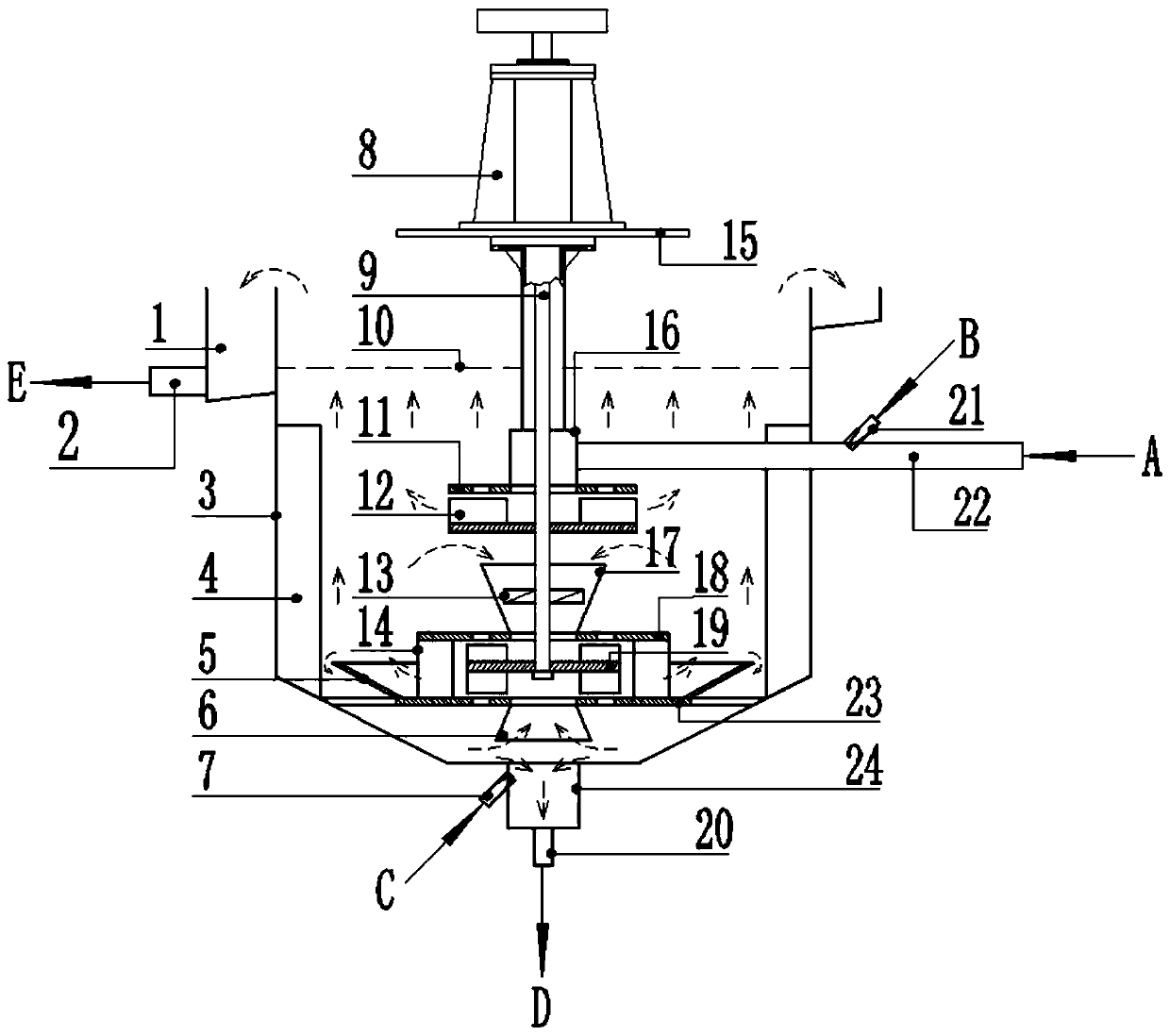

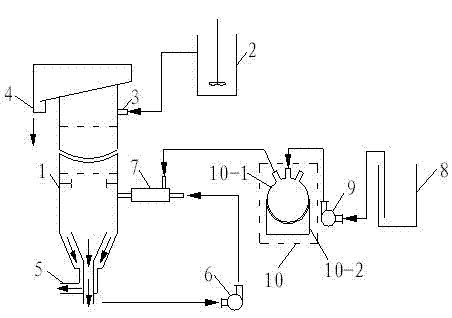

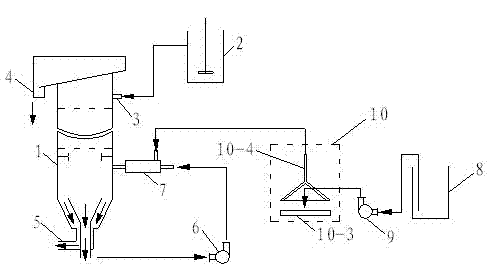

Forced circulation and fast flotation separation device and method

A forced circulation and fast flotation separation device and method is suitable for flotation of easily floating coarse particle minerals or coal. The device comprises a transmission mechanism, a flotation tank body, a fast flotation system and a forced circulation system. An inverted trapezoid platform is arranged below the flotation tank body, a foam tank is arranged at the top of the invertedtrapezoid platform, a concentrate discharging pipe is arranged at the lowest position of the foam tank, a sieve plate is arranged at the foam tank in the cylinder, the forced circulation system is arranged in the inverted trapezoid platform of the flotation tank body, a plurality of guide plates are arranged between the forced circulation system and the sieve plate, the transmission mechanism is arranged at the top of the flotation tank body, and the forced circulation system comprises an upper guide cylinder, a propelling wheel, a dispersing stator, a centrifugal mineralizing wheel and a lower guide device arranged below the centrifugal mineralizing wheel and fixed at the bottom of the tank body. The device is simple in structure and high in separation efficiency.

Owner:CHINA UNIV OF MINING & TECH

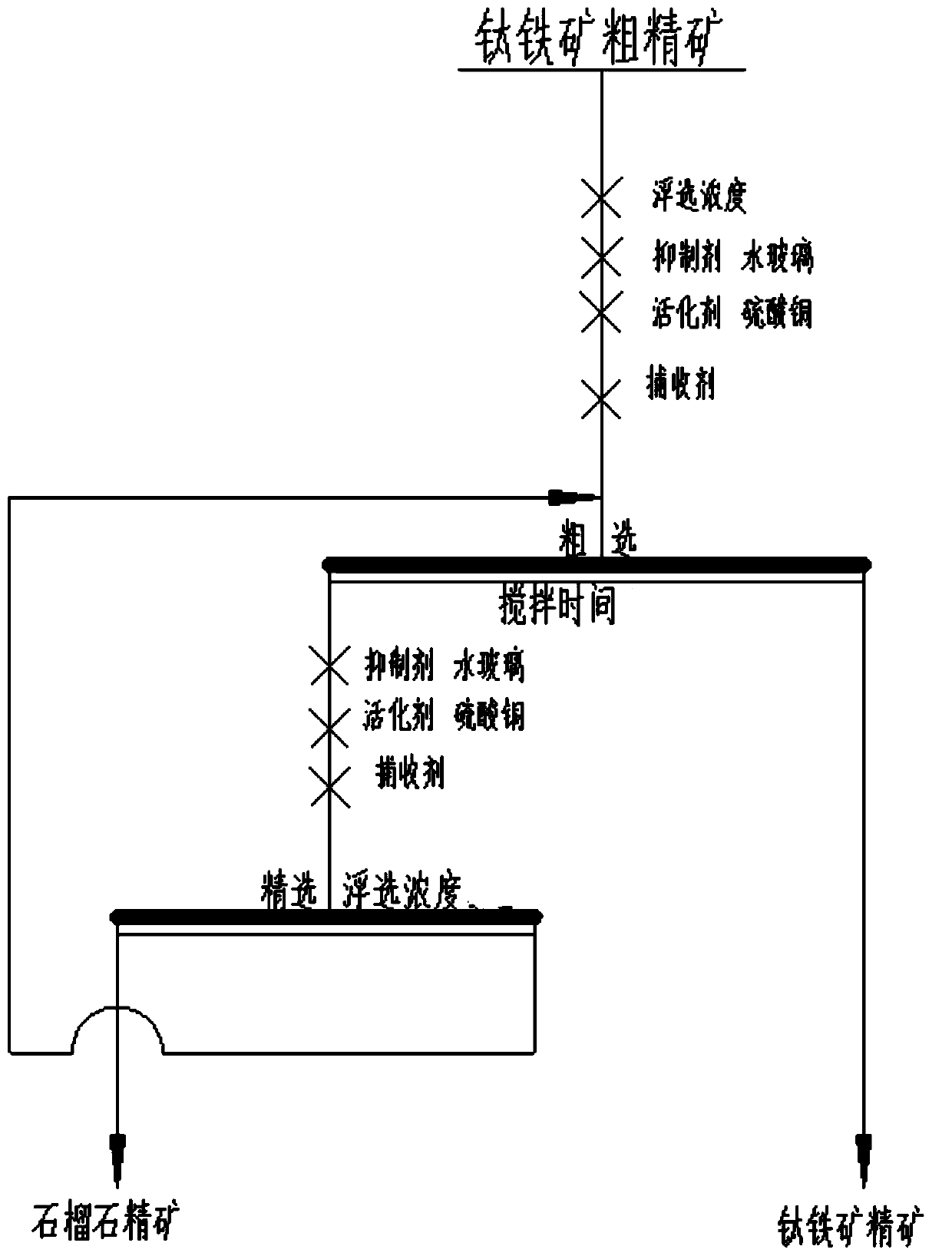

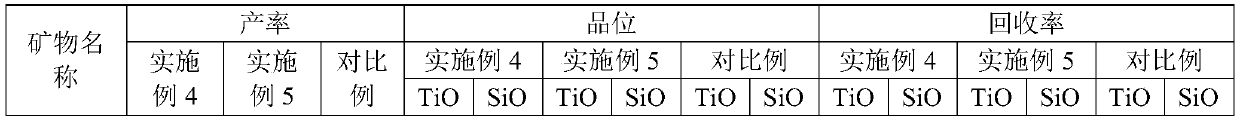

Collecting agent for separating garnet and ilmenite and flotation process of collecting agent

The invention provides a collecting agent for separating garnet and ilmenite and a flotation process of the collecting agent. The collecting agent is composed of the following raw materials in parts by weight: 10-15 parts of tall oil, 25-35 parts of oxidized paraffin soap, 40-50 parts of palm oil, 10-15 parts of sodium fatty acid methyl ester sulfonate and 10-15 parts of sodium hydroxide. The collecting agent provided by the invention is used for flotation of garnet and ilmenite; high selectivity and collecting performance are realized; the collecting effect is improved, the collecting dosageis reduced, the stability is good, the flotation speed is high, the grade of garnet is comprehensively improved, the impurity content in a concentrate product is reduced, the operation recovery rate of garnet concentrate is increased by 10-20%, the grade of garnet is increased by 10-20%, and good economic benefits are achieved.

Owner:HAINAN WENSHENG HIGH TECH MATERIALS +3

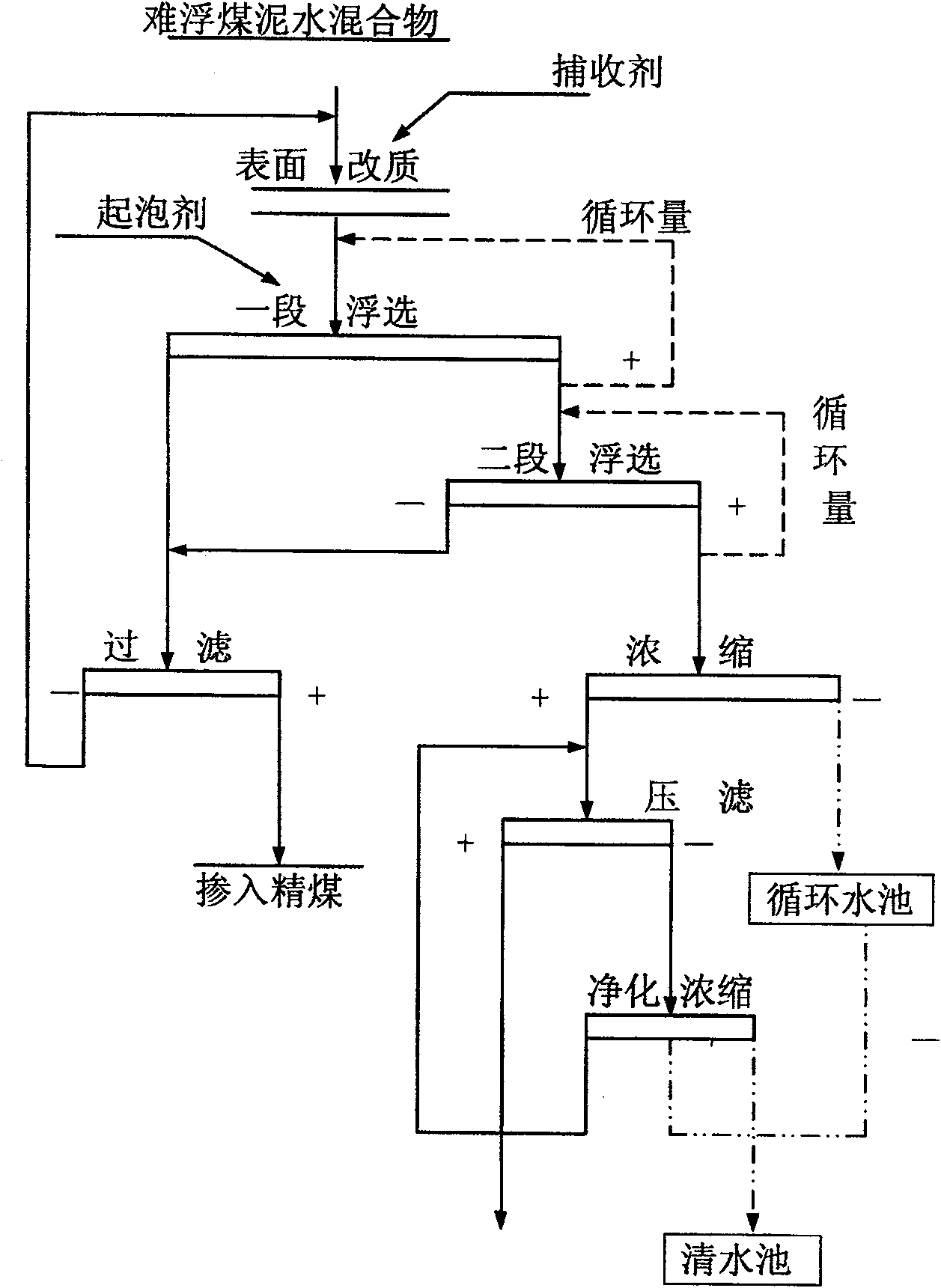

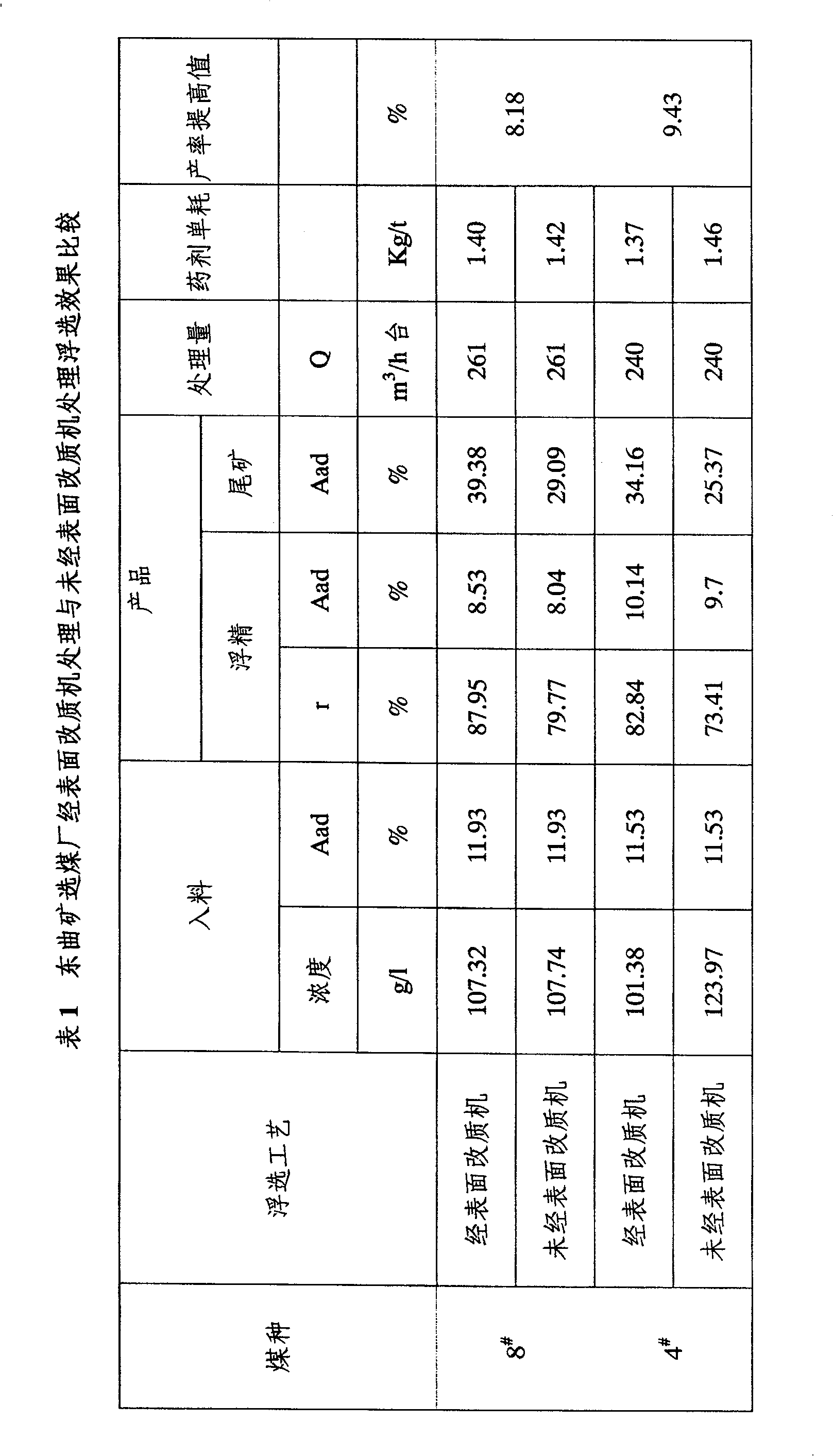

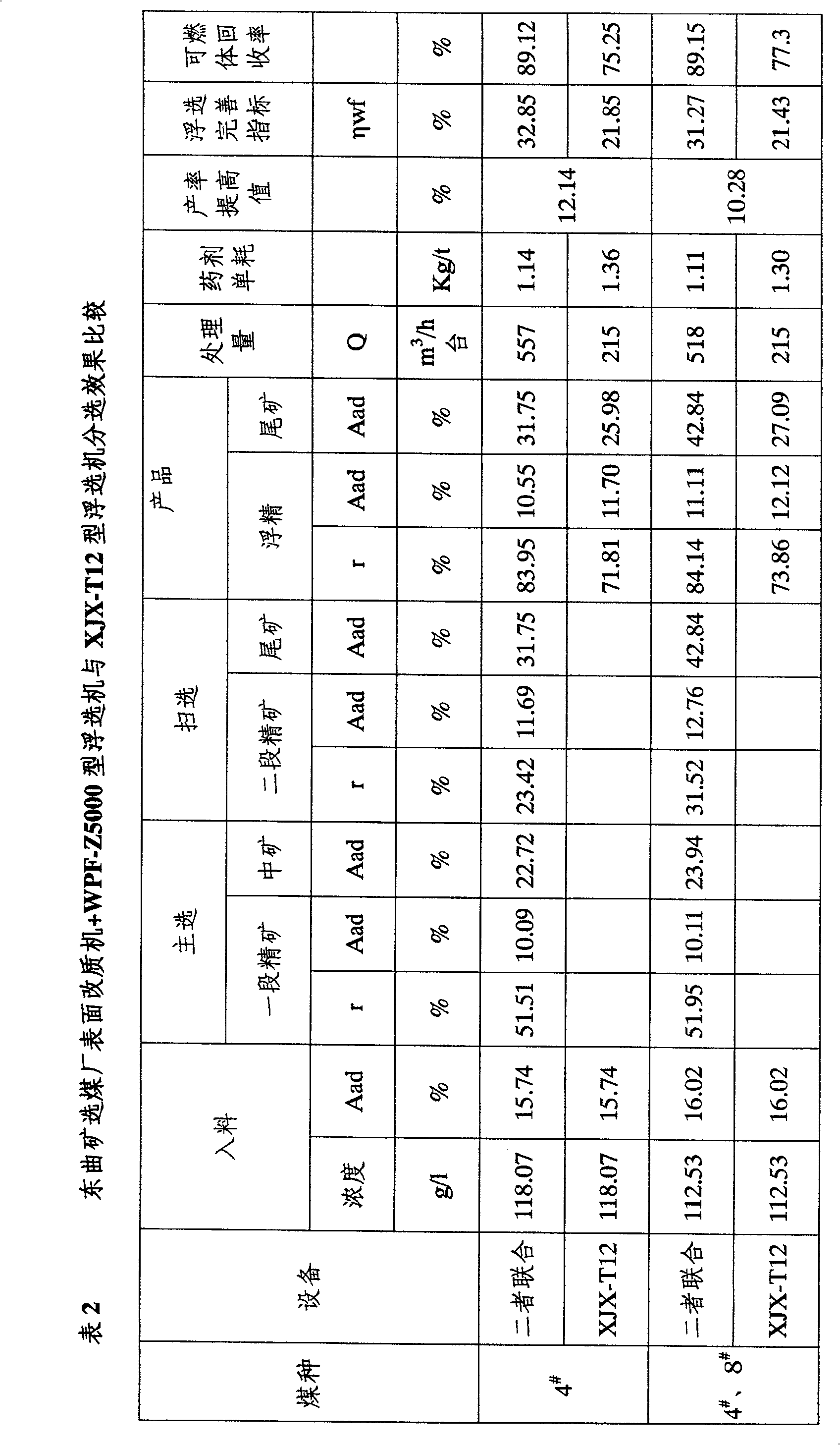

Floatation method of difficult-to-float coal

The invention provides a flotation method for difficult-to-float coal slime, which uses a surface modifier combined with a micro-bubble flotation machine. Both the flotation and flotation effects can be effectively guaranteed, which solves the problem that the difficult-to-float slime cannot wash out qualified float products and the float yield is low. Since the two mechanisms have some similarities, after joint use, they can guarantee On the basis of ash content, the unit consumption of chemicals (collectors and foaming agents) is reduced by 20%, and the extraction rate of floating semen is increased by more than 10%.

Owner:SHANXI COKING COAL GROUP

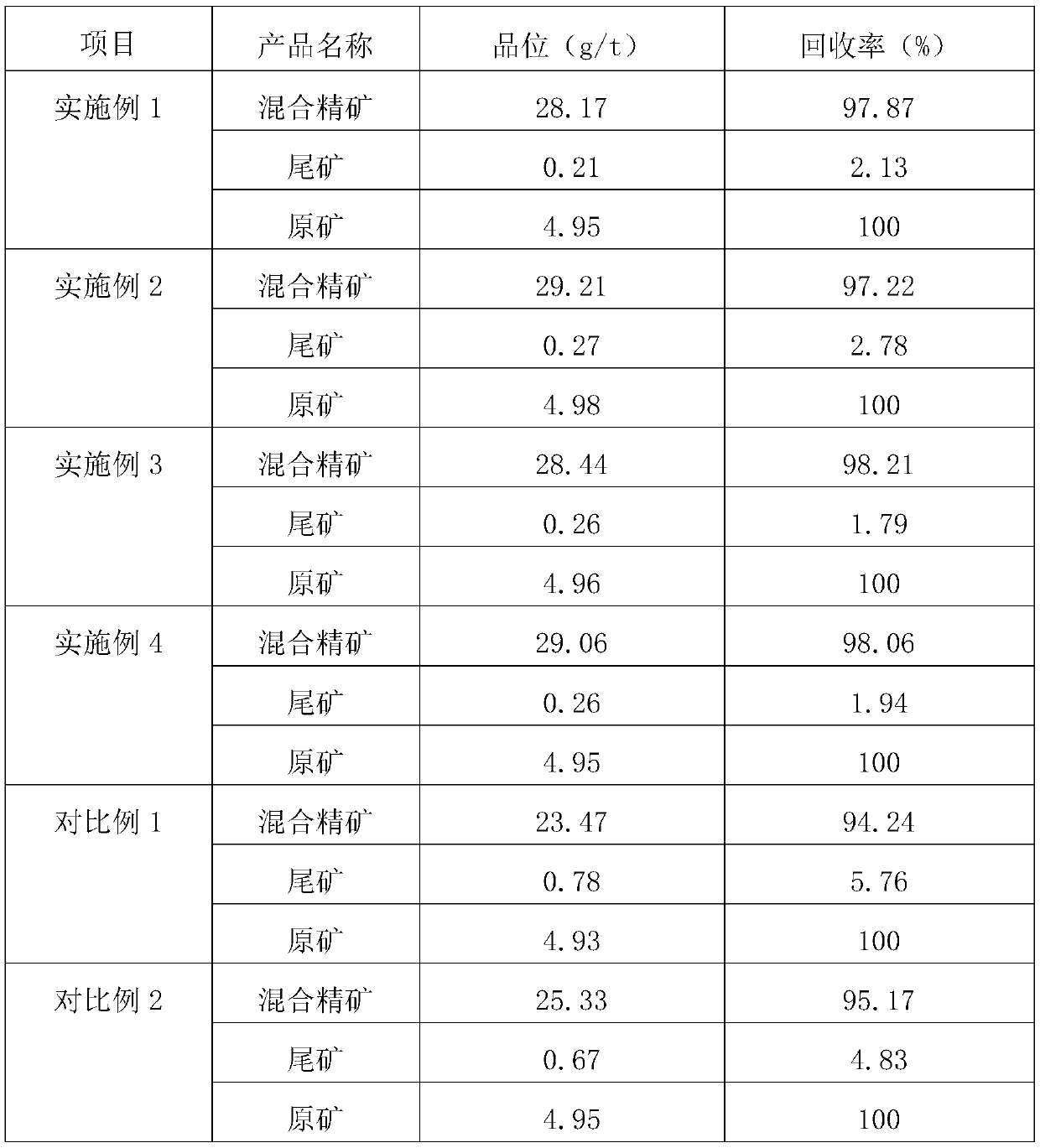

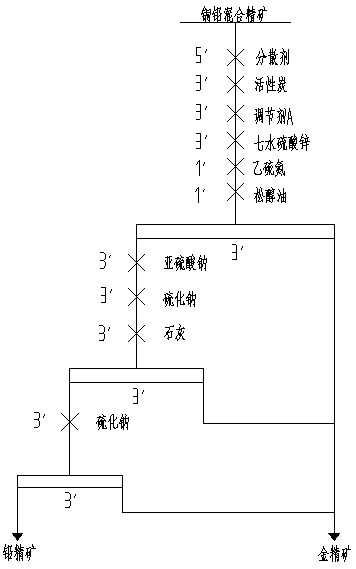

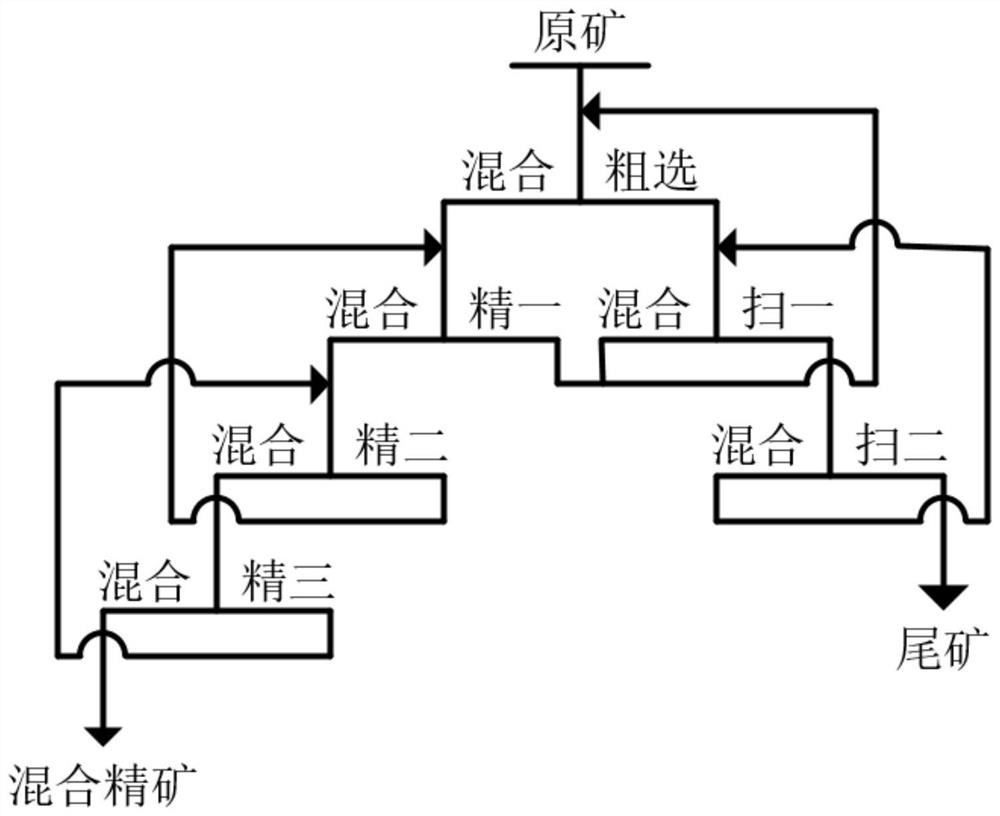

Blended concentrate flotation technology

InactiveCN109731694AFlotation Process ImprovementGuaranteed RecoveryFlotationActivated carbonCarbamate

The invention belongs to the technical field of beneficiation, particularly relates to a blended concentrate flotation technology and aims to provide a blended concentrate flotation separation technology which is a flotation separation method which can effectively increase gold and lead recovery rate, has fewer process steps and saves cost. The technical scheme includes that copper-lead blended concentrate is roughed once and concentrated twice by an open process and separated to obtain lead concentrate and gold lead concentrate. The roughing technology is characterized in that dispersing agents, activated carbon, regulators A, zinc sulfate heptahydrate, ethyl thio carbamate and terpenic oil are added into the copper-lead blended concentrate, and roughing time is controlled to be 3 minutes. Concentration includes primary concentration and secondary concentration, primary concentration includes adding inhibitors A, auxiliary inhibitors and regulators B into rough ore pulp, secondary concentration includes adding inhibitors B into primary ore concentrate pulp to finish the flotation technology, and the primary ore concentrate pulp is separated to obtain the lead concentrate and the gold lead concentrate. The blended concentrate flotation technology is widely applied to the technical field of blended concentrate flotation.

Owner:山西紫金矿业有限公司

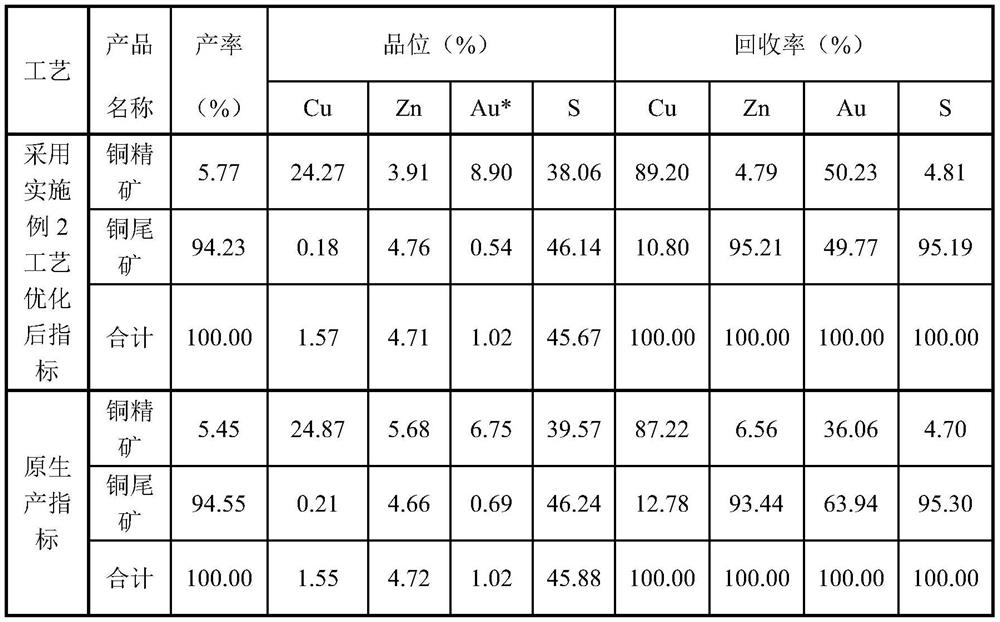

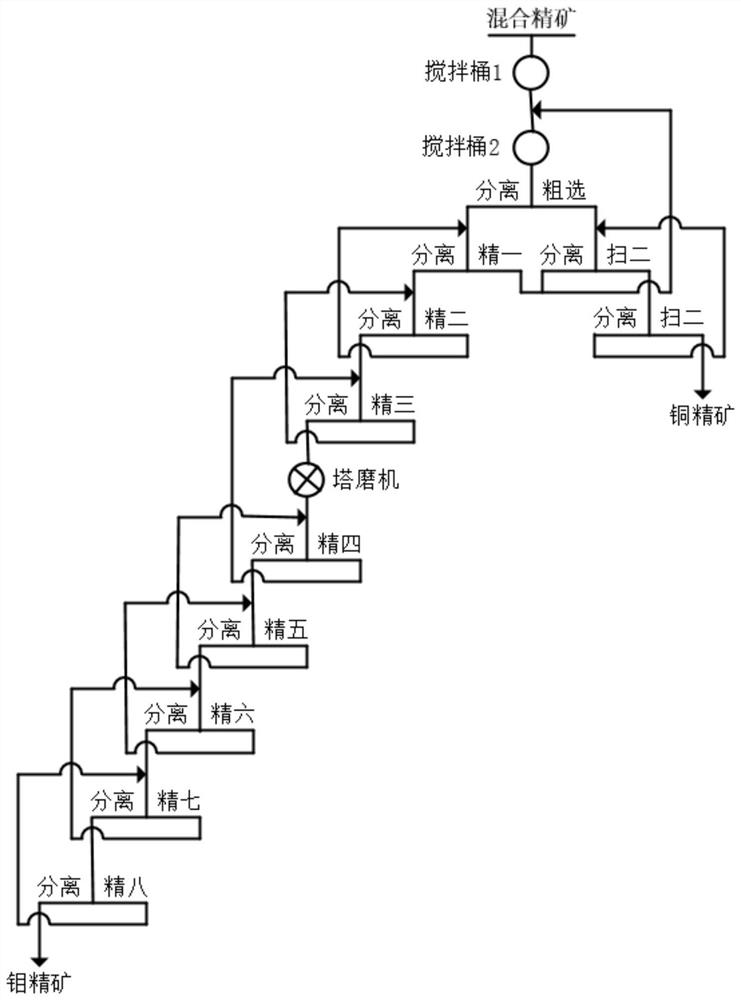

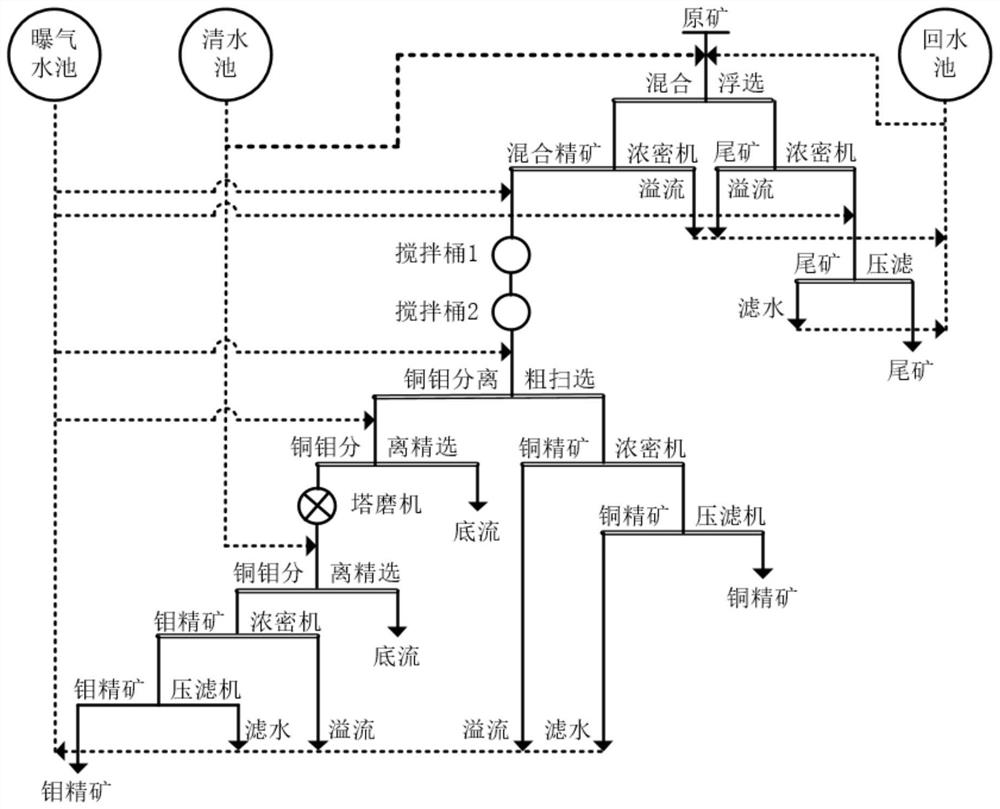

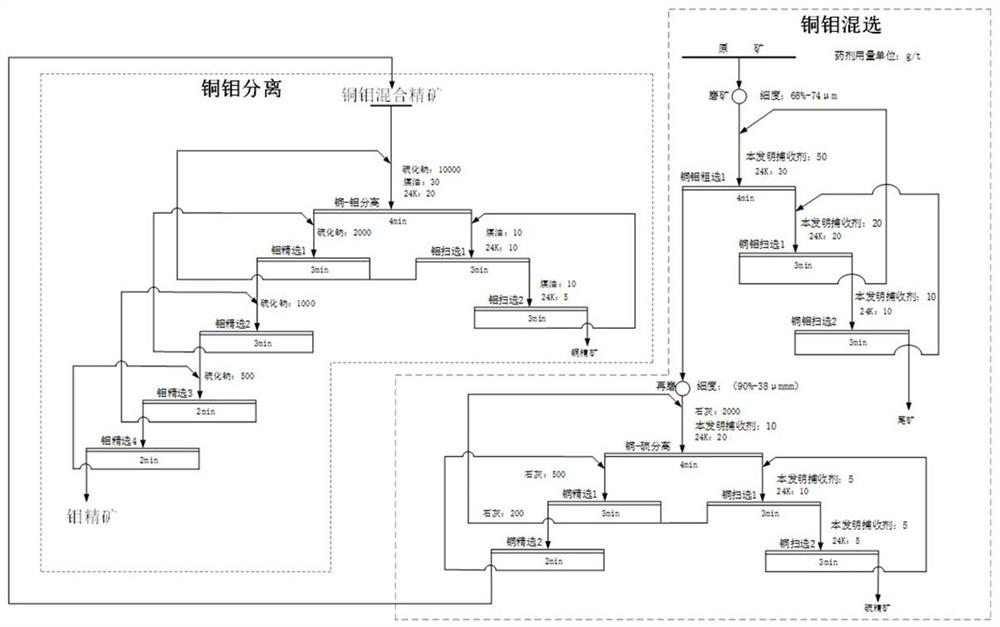

Copper-molybdenum separation method for low-grade copper-molybdenum ore with consideration of backwater utilization

The invention provides a low-grade copper-molybdenum ore copper-molybdenum separation method giving consideration to backwater utilization, which comprises the following steps: carrying out copper-molybdenum bulk flotation on copper-molybdenum ore to obtain copper-molybdenum bulk concentrate and tailings; the tailings are subjected to concentration and filter pressing, and low-water-content tailings are obtained; and the copper-molybdenum bulk concentrate is concentrated, pulp mixing is conducted, then copper-molybdenum separation operation is conducted, and molybdenum concentrate and copper concentrate are obtained. According to the invention, sodium hydrosulfide and sodium thioglycollate are combined for use, so that the use amount of sodium hydrosulfide is greatly reduced; a pulp mixing and stirring barrel is arranged before the copper-molybdenum separation operation, the concentration of floating pulp is stabilized, meanwhile, sodium hydrosulfide is adopted for adjusting the potential of the pulp, and through the modes of sodium hydrosulfide reagent removal, high-concentration concentration reagent removal, aeration reagent removal, stirring friction washing and the like, residual reagents in the copper-molybdenum mixing operation in the pulp are reduced. According to the method provided by the invention, copper and molybdenum can be well separated.

Owner:TIBET HUATAILONG MINING DEV

Emulsified diesel oil collector and preparation method thereof

InactiveCN101982241BWill not affect operating proceduresImprove sorting effectFlotationEmulsionHardness

The invention provides an industrial coal slime emulsified diesel oil collector and a preparation method thereof. The collector comprises LAE9, sodium petroleum sulfonate, 8-DEG C oleic acid, sesame oil sodium soap, dodecylbenzenesulfonic acid, diesel oil and water. The diesel emulsion prepared by the method has high stability, selectivity and yield, solves the problem of low emulsion stability caused by the water hardness, can be industrially applied and has the characteristic of saving diesel oil resources; and moreover, the invention can improve the flotation selectivity and yield of the coal slime, has low cost and high efficiency and meets the requirements of energy conservation and environmental protection.

Owner:杨青松

Cellulose-based derivatives as chemical aids for mineral enrichment in froth flotation

PendingUS20200391223A1High recovery levelIncrease production capacitySilicaFlotationActive agentPolythylene glycol

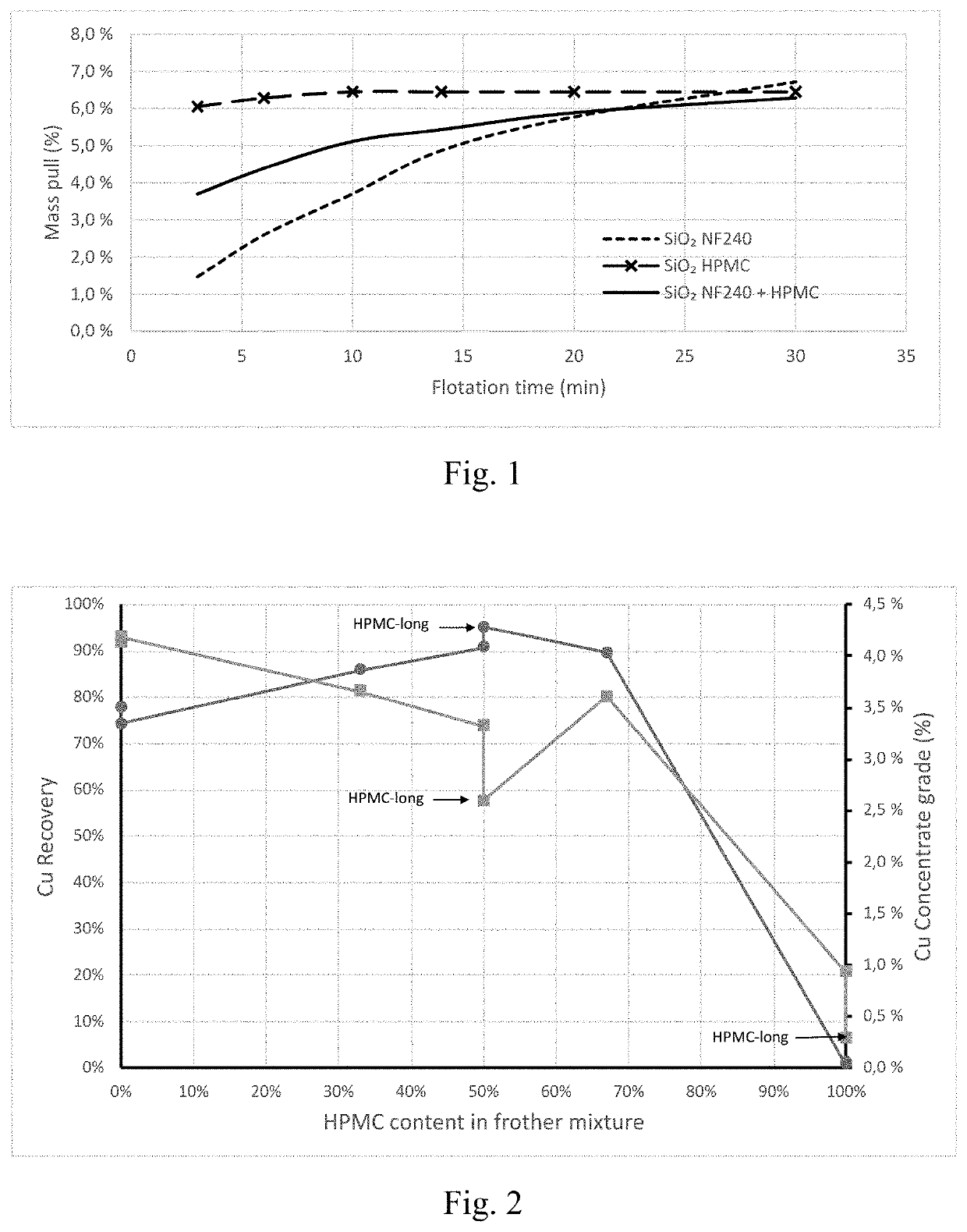

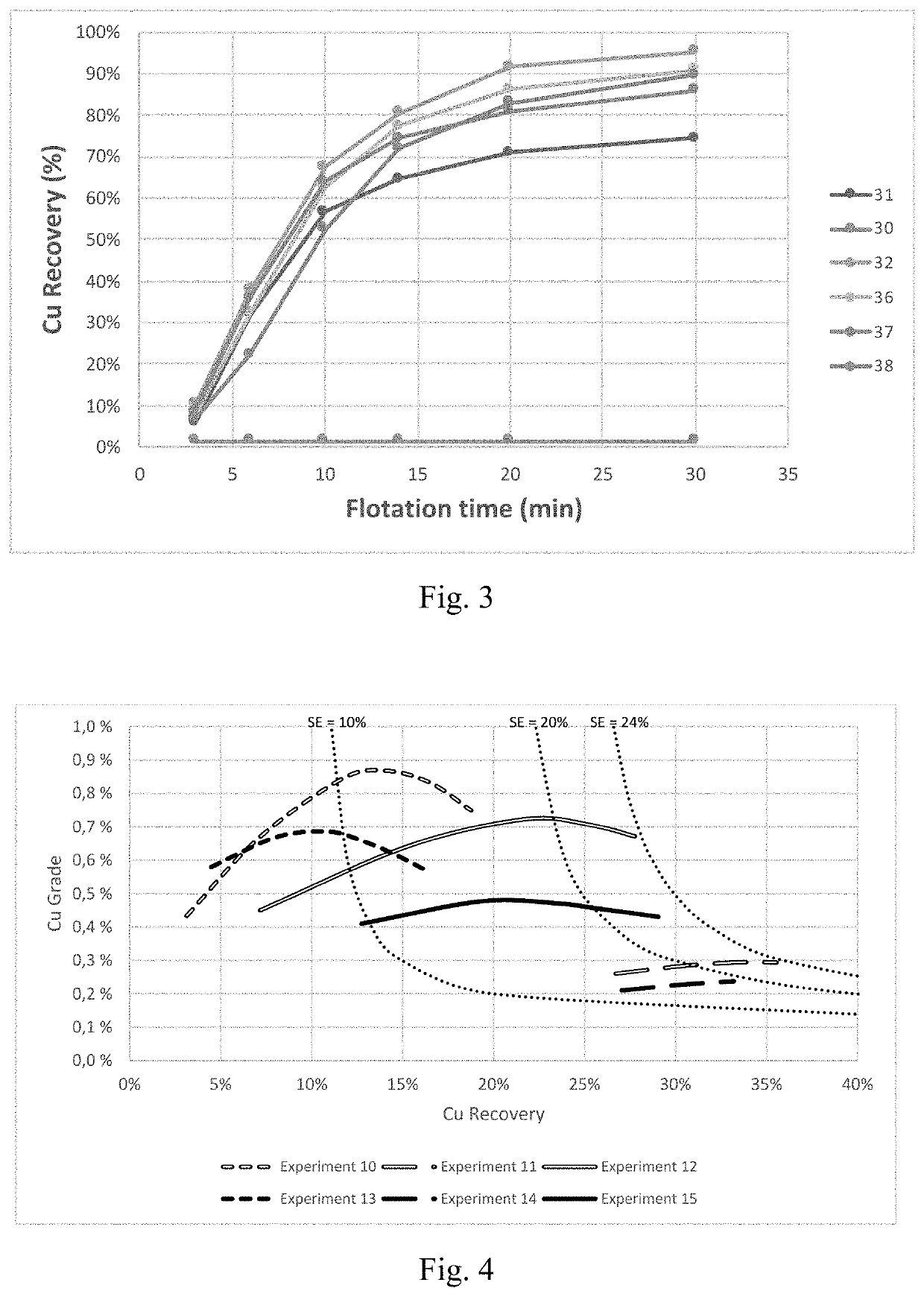

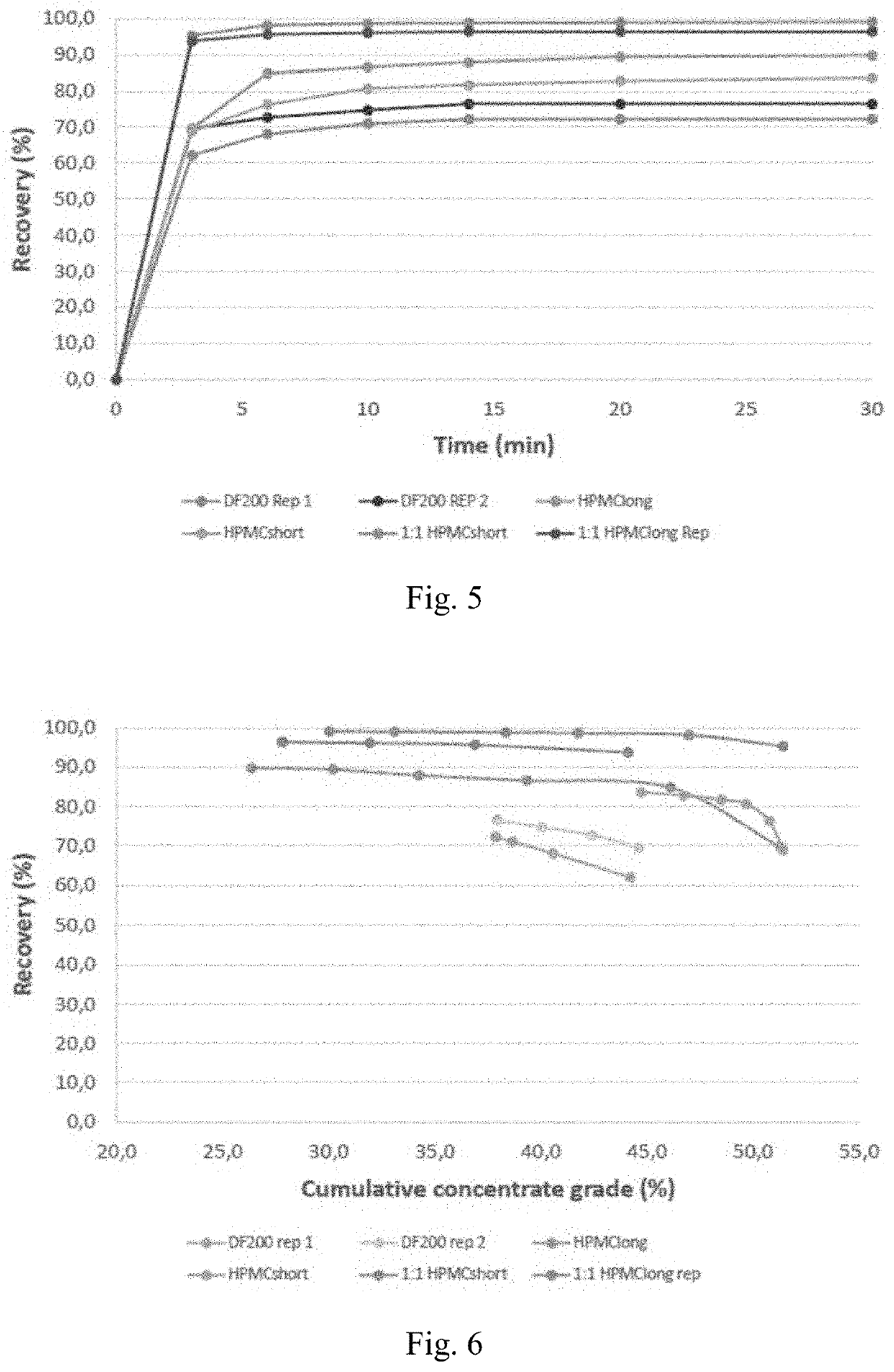

Frother composition and method of concentrating minerals by flotation. The method comprises providing an aqueous slurry formed by the minerals in finely divided form in water; optionally adding a collector to render the mineral hydrophobic; subjecting the slurry thus obtained to flotation in a flotation cell aerated to form bubbles; and recovering the hydrophobic mineral particles together with the froth to form a concentrate. In the method an amphiphilic cellulose derivative, such as and a second surfactant as a frother to promote the formation of a stable froth on top of the slurry in the flotation cell. Hydroxypropyl methyl cellulose or hydroxyethyl methyl cellulose are combined with at least one non-ionic organic surfactant or polyglycol esters, for providing a frother. The novel cellulose-based frothers can be used in mineral processing plants to allow for processing of larger quantities of minerals without significant modification of existing facilities.

Owner:AALTO UNIV FOUND

High-efficiency flotation collecting agent for high-sulfur iron easily-argillized fine-grained complex embedded copper-molybdenum ore as well as preparation method and application thereof

ActiveCN112264194ASimple and fast manufacturing methodLow toxicityFlotationProcess efficiency improvementActive agentSurface-active agents

The invention discloses high-efficiency flotation collecting agent for high-sulfur iron easily-argillized fine-grained complex embedded copper-molybdenum ore and a preparation method and application thereof. The efficient flotation collecting agent for the high-sulfur iron easily-argillized refined fine-grained complex embedded copper-molybdenum ore is prepared from, by weight, 15-25 parts of xanthate, 15-25 parts of thionocarbamate, 6-10 parts of tartaric acid, 23-35 parts of modified oil and 20-30 parts of surfactant. The collecting agent is small in agent dosage, high in flotation speed, stable and non-sticky in foam property, balanced in copper-molybdenum collecting property and high in adaptability to high-sulfur iron and silicate gangue prone to argillization, the hydrophobic property of micro-fine particle copper-molybdenum ore products can be aggregated, the loss of micro-fine particle copper-molybdenum in sulfur in the copper-sulfur separation process is effectively reduced, and compared with a traditional xanthate collecting agent, subsequent copper-molybdenum separation operation is facilitated, and the high molybdenum concentrate grade can be obtained.

Owner:KUNMING METALLURGY INST

System and method for deeply purifying coal

The invention relates to a system and a method for deeply purifying coal. The system is composed of a flotation column, a mixing tank, a circulating pump, a bubble generator, an oil storage barrel, a gasoline pump and an oil gas generator. The method comprises the following steps: adding kerosene or diesel oil into the oil gas generator and then heating and evaporating the kerosene or diesel oil,thereby generating kerosene or diesel oil steam; introducing the kerosene or diesel oil steam together with air into a floatation device, thereby generating oil bubbles; and promoting the wetting property of the bubbles under the condition of maintaining the floatation of a mineral main body, thereby achieving the purpose of promoting the floatability of the mineral. The problem of difficulty in flotation of low-rank coals can be solved, the rate of multipurpose utilization of the coal can be increased and the economic value can be promoted. The system and method provided by the invention aresuitable for deeply purifying the low-rank coals with low metamorphic grade, such as brown coal, long flame coal, non-caking coal, weakly caking coal, gas coal, and the like, can be used for greatly promoting the yield of clean coal and can be used for obviously reducing the dosage of the kerosene or diesel oil used as a collecting agent. The system has the advantages that the structure is simple, the operation is convenient, the floatation index of the low-rank coals is excellent and the dosage is small.

Owner:CHINA UNIV OF MINING & TECH

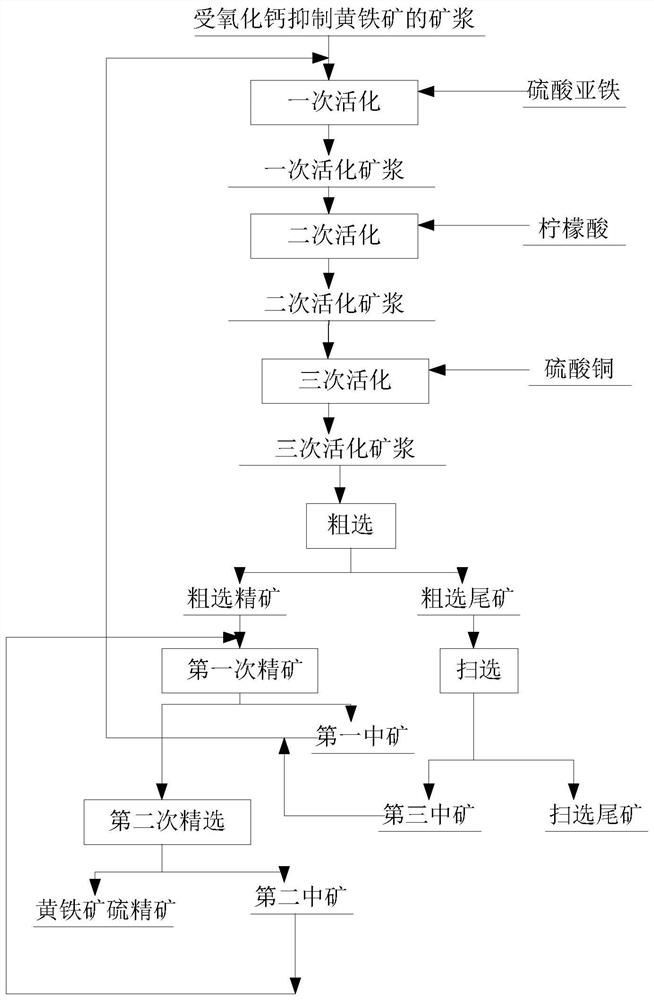

Flotation method of calcium-oxide-inhibited pyrite

The invention provides a flotation method of calcium-oxide-inhibited pyrite. The method comprises the following steps: S1, adding ferrous sulfate into ore pulp of pyrite inhibited by calcium oxide for primary activation to obtain primary activated ore pulp; S2, adding citric acid into the primary activated ore pulp for secondary activation to obtain secondary activated ore pulp; S3, adding copper sulfate into the secondary activated ore pulp for tertiary activation to obtain tertiary activated ore pulp; and S4, performing flotation on the third-time activated ore pulp to obtain pyrite sulfur concentrate. According to the method, the ferrous sulfate, citric acid and copper sulfate composite agents are adopted as activating agents for combined use, and the activating effect is enhanced through sequential adding and step-by-step activation, so that the flotation speed can be effectively increased, and the grade and the recovery rate of the sulfur concentrate are improved. Meanwhile, by selecting the composite agents, the cost is relatively low, ammonia gas and the like are not released, and the environmental protection property is higher.

Owner:CHINA ENFI ENGINEERING CORPORATION

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com