Copper-molybdenum separation method for low-grade copper-molybdenum ore with consideration of backwater utilization

A copper-molybdenum ore, low-grade technology, used in solid separation, flotation and other directions, can solve the problems of large process energy consumption, many chemical addition points, and large consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

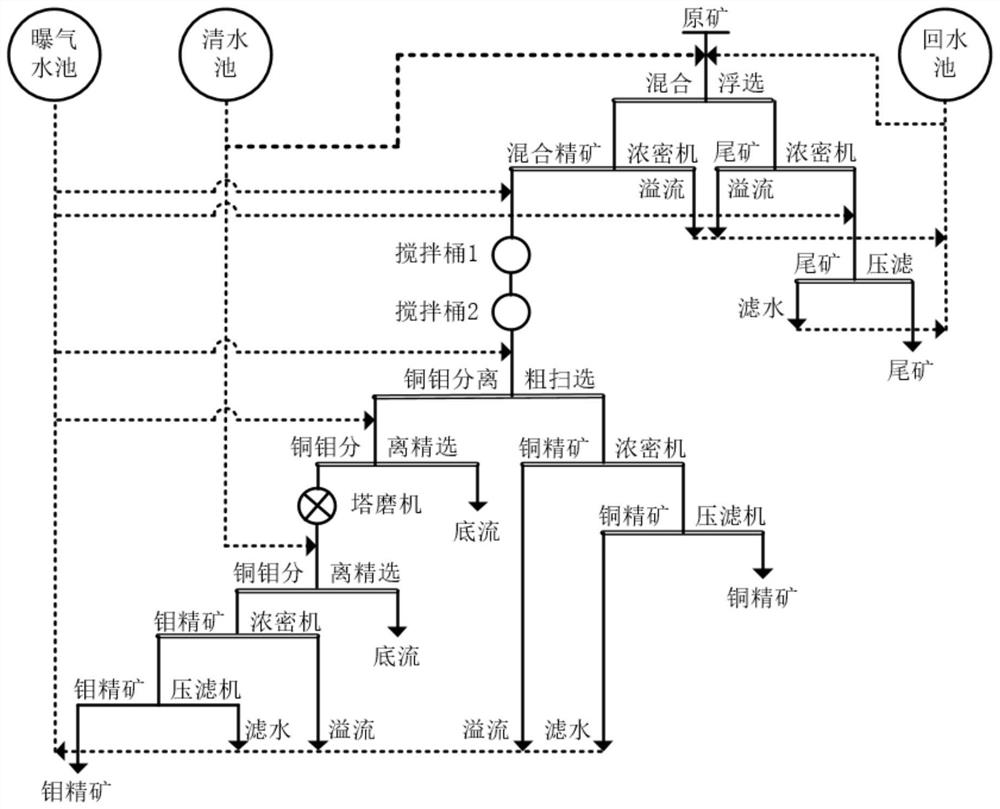

[0116] The copper-molybdenum ore is a porphyry-type copper-molybdenum ore in Tibet. The metal sulfides contained in the ore are mainly bornite, chalcopyrite, chalcocite, pyrite, and molybdenite; the gangue minerals are mainly garnet, Epidote, rhodoxene, wollastonite, diopside, calcite, plagioclase, quartz, etc.; copper molybdenum grade 0.95%, molybdenum grade 0.032%.

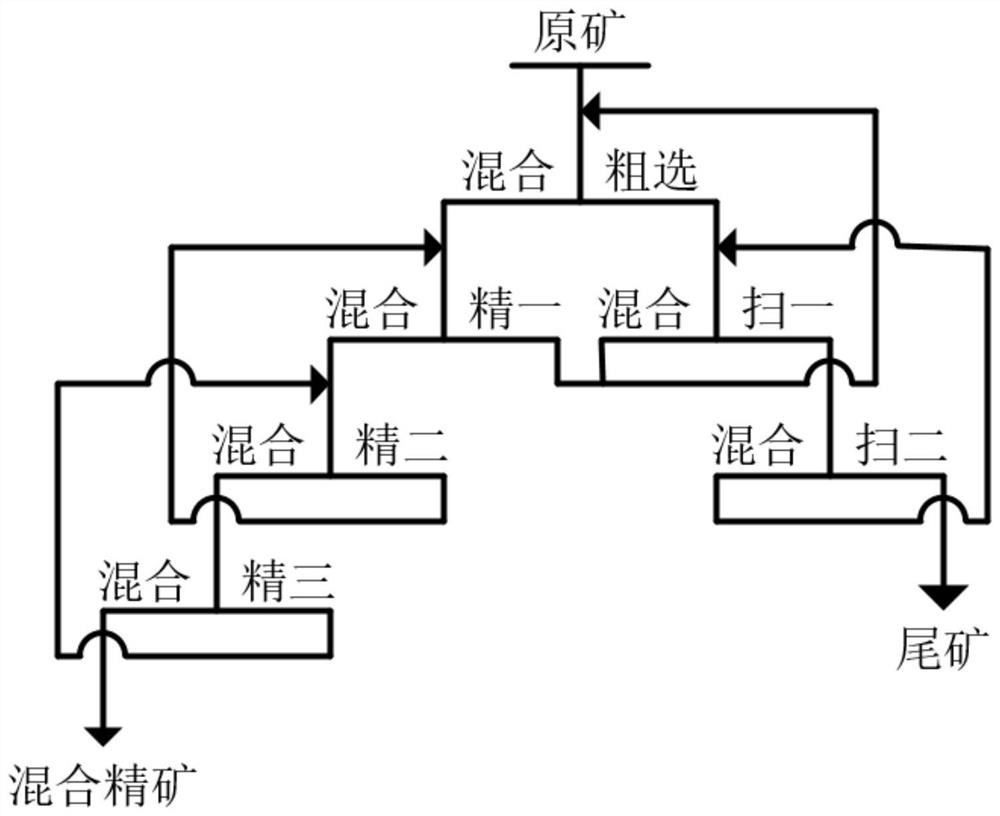

[0117] Copper-molybdenum ore undergoes copper-molybdenum mixed flotation (one-time roughing, two-time sweeping and three-time beneficiation) to obtain copper-molybdenum mixed concentrate; the copper grade in the copper-molybdenum mixed concentrate is 19.65%, and the molybdenum grade is 0.42%; The mixed concentrate yield was calculated to be 4.49%.

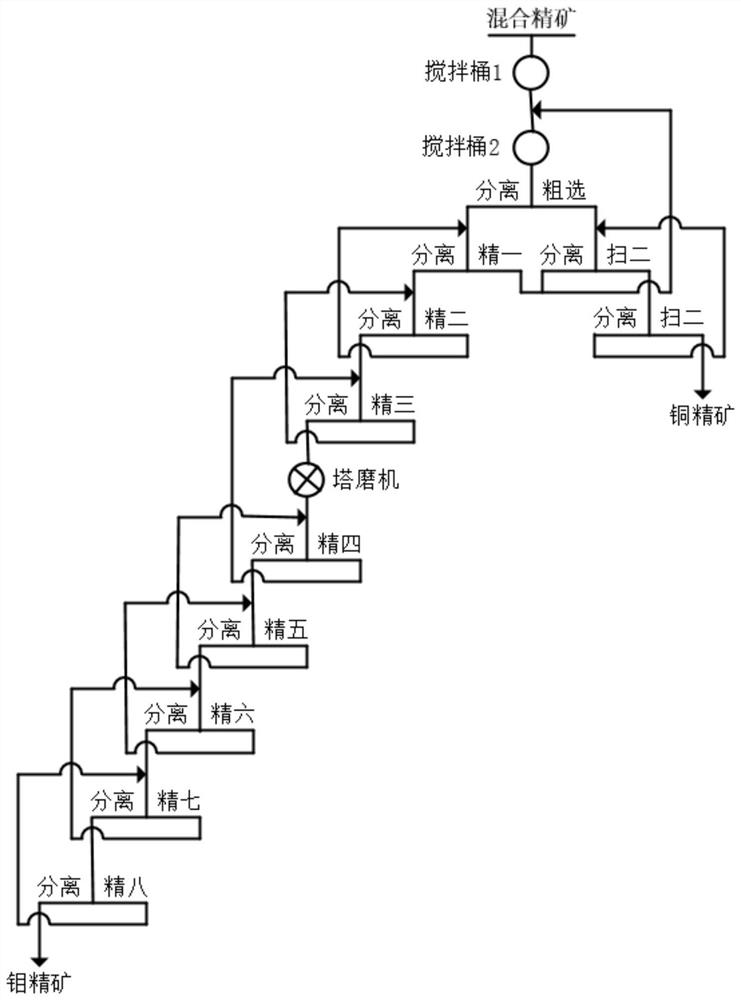

[0118] The copper-molybdenum mixed concentrate enters the thickener to concentrate, the concentrated concentration is 49%, and is pumped to the mixing tank 1 before the copper-molybdenum separation flotation, and the water in the aeration tank is used for pulping. Th...

Embodiment 2

[0138] A porphyry-type copper-molybdenum deposit in Tibet, the metal sulfides in the ore are mainly bornite, chalcopyrite, chalcocite, pyrite, molybdenite, and the gangue minerals are mainly garnet, epidote, rose Pyroxene, wollastonite, diopside, calcite, plagioclase, quartz, etc.; copper grade of copper molybdenum ore is 0.75%, and molybdenum grade is 0.026%.

[0139] Copper-molybdenum ore undergoes copper-molybdenum mixed flotation (one-time roughing, two-time sweeping and three-time beneficiation) to obtain copper-molybdenum mixed concentrate; the copper grade in the copper-molybdenum mixed concentrate is 18.12%, and the molybdenum grade is 0.37%; The mixed concentrate yield was calculated to be 3.77%.

[0140] The copper-molybdenum mixed concentrate enters the thickener to concentrate, the concentrated concentration is 48%, and is pumped to the mixing tank 1 before the copper-molybdenum separation flotation, and the water in the aeration tank is used for slurry adjustment....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com