Blended concentrate flotation technology

A mixed concentrate and flotation technology, applied in flotation, solid separation, etc., can solve the problems of poor separation effect, different effects, unfavorable mineral processing, etc., achieve fast flotation speed, improve hydrophilicity, and save the amount of chemicals Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

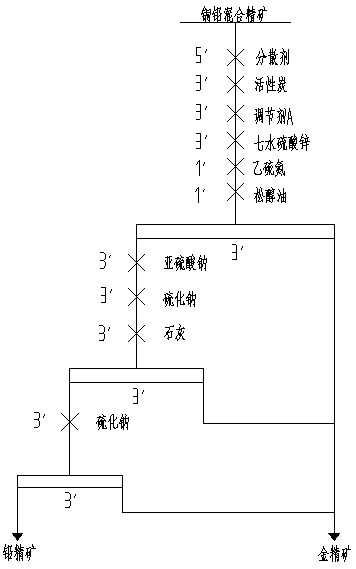

[0020] A mixed concentrate flotation process, the specific process is: the copper-lead mixed concentrate is sorted by an open-circuit process for one roughing and two beneficiation to obtain lead concentrate and gold concentrate;

[0021] The roughing process is as follows: adding sodium hexametaphosphate, activated carbon, lime, zinc sulfate heptahydrate, ethion and pinitol oil to the copper-lead mixed concentrate, and the concentration of each flotation agent is sodium hexametaphosphate 1000g / t, activated carbon 160g / t, lime 5000g / t, zinc sulfate heptahydrate 800g / t, ethyl disulfide 20g / t, terpineol oil 10g / t, the control roughing time is 3min;

[0022] The beneficiation includes primary beneficiation and secondary beneficiation, the primary beneficiation is: adding concentration of 1200g / t sodium sulfide, 450g / t sodium sulfite and 1500g / t lime to the roughing pulp; the secondary beneficiation is: adding Sodium sulfide with a concentration of 450g / t is added to the primary ...

Embodiment 2

[0024] A mixed concentrate flotation process, the specific process is: the copper-lead mixed concentrate is sorted by an open-circuit process for one roughing and two beneficiation to obtain lead concentrate and gold concentrate;

[0025] The roughing process is as follows: adding sodium hexametaphosphate, activated carbon, lime, zinc sulfate heptahydrate, ethion and pinitol oil to the copper-lead mixed concentrate, and the concentration of each flotation agent is sodium hexametaphosphate 200g / t, 60g / t of activated carbon, 1000g / t of lime, 200g / t of zinc sulfate heptahydrate, 5g / t of ethyl disulfide, 1g / t of pinitol oil, and the control roughing time is 3min;

[0026] The beneficiation includes primary beneficiation and secondary beneficiation. The primary beneficiation is: adding concentration of 500g / t sodium sulfide, 200g / t sodium sulfite and 1000g / t lime to the rough beneficiation pulp; the secondary beneficiation is: adding Sodium sulfide with a concentration of 150g / t i...

Embodiment 3

[0028] A mixed concentrate flotation process, the specific process is: the copper-lead mixed concentrate is sorted by an open-circuit process for one roughing and two beneficiation to obtain lead concentrate and gold concentrate;

[0029] The roughing process is: add sodium hexametaphosphate, activated carbon, lime, zinc sulfate heptahydrate, ethion and pine alcohol to the copper-lead mixed concentrate, and the concentration of each flotation agent is sodium hexametaphosphate 600g / t, activated carbon 100g / t, lime 2500g / t, zinc sulfate heptahydrate 500g / t, ethyl disulfide 15g / t, terpineol oil 5g / t, the control roughing time is 3min;

[0030] The beneficiation includes primary beneficiation and secondary beneficiation. The primary beneficiation is: adding concentration of 1000g / t sodium sulfide, 300g / t sodium sulfite and 1200g / t lime to the roughing pulp; the secondary beneficiation is: adding Sodium sulfide with a concentration of 400g / t is added to the primary beneficiation p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com