High-efficiency flotation collecting agent for high-sulfur iron easily-argillized fine-grained complex embedded copper-molybdenum ore as well as preparation method and application thereof

A high-sulfur iron, copper-molybdenum ore technology, applied in flotation, process efficiency improvement, solid separation and other directions, can solve the problem of not being able to take into account the collection of copper and molybdenum, weak collection of target minerals, and insufficient adaptability and other problems, to achieve the effect of balanced collection of copper and molybdenum, small dosage of chemicals, and strong suitability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

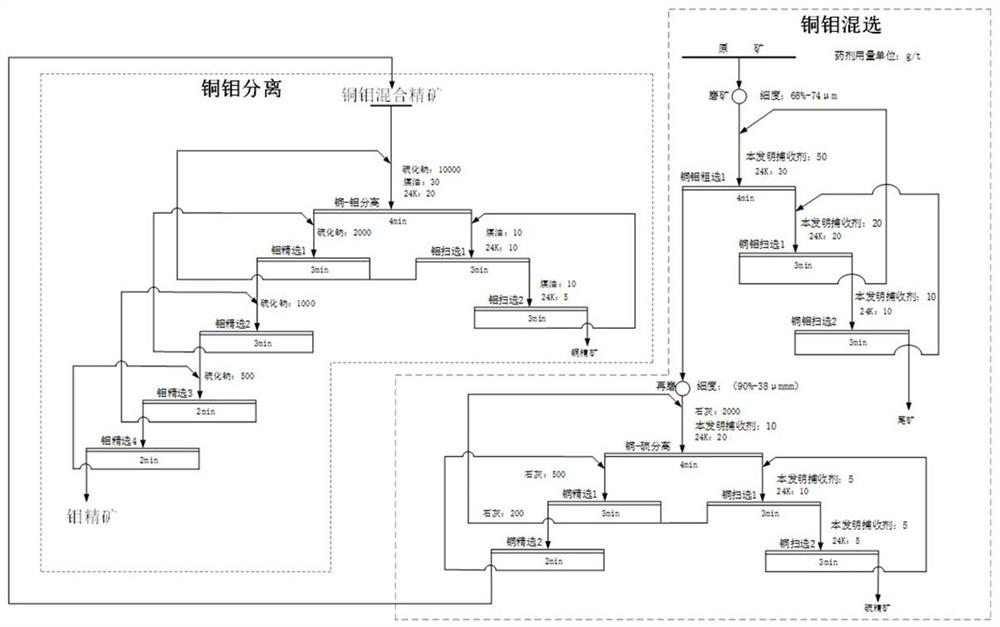

Image

Examples

preparation example Construction

[0039] The preparation method of the high-sulfur iron, easy mud, fine-grained and complex embedded copper-molybdenum ore high-efficiency flotation collector includes the steps of surfactant preparation, modified oil preparation and preparation steps, specifically including:

[0040] A. Preparation of surfactant: Weigh sodium dodecylbenzenecyclonate, sodium glycerol monolaurate monosulfate and sodium bis-2-hexyl ethyl sulfosuccinate according to the formula ratio, and add them to the ethanol solution in sequence , stir and mix to obtain the target surfactant;

[0041] B. Modified oil preparation: The target modified oil is obtained by high-speed stirring and shearing of the kerosene and neutral oil in the formula ratio;

[0042] C. Preparation:

[0043] 1) Add the modified oil to the surfactant and stir to obtain material a;

[0044] 2) Add the tartaric acid, xanthate and thiourethane in the formula ratio to the material a in sequence, stir and mix to obtain the target high-sul...

Embodiment 1

[0049] The composition of raw materials in this embodiment: the parts by weight of raw materials are 20 parts of isopentyl xanthate acrylonitrile ester, 20 parts of isopropyl allyl thiocarbamate, 8 parts of tartaric acid, 32 parts of modified oil, and 20 parts of surfactant .

[0050] The weight parts of the modified oil are specifically 19.2 parts of kerosene and 12.8 parts of phenol.

[0051] The parts by weight of the surfactant are specifically 10 parts of sodium dodecylbenzenesulfonate, 8 parts of sodium glycerol monolaurate monosulfate, and 2 parts of sodium bis-2-hexylethylsulfosuccinate.

[0052] The preparation method of a high-efficiency flotation collector for high-sulfur iron, which is easy to muddy and fine-grained, complexly embedded copper-molybdenum ore is as follows:

[0053] A. In a stirred tank, add the surfactant in parts by weight to equal parts of ethanol, and stir and mix thoroughly at 25° C. and a stirring speed of 1200 r / min to obtain solution a. The...

Embodiment 2

[0060] The raw material composition of the present embodiment: raw material parts by weight are 18 parts of sec-butyl xanthate propionitrile, 22 parts of n-butyl allyl thiocarbamate, 10 parts of tartaric acid, 25 parts of modified oil, 25 parts of surfactant .

[0061] The weight parts of the modified oil are specifically 15 parts of kerosene and 10 parts of phenol.

[0062] The parts by weight of the surfactant are specifically 12.5 parts of sodium dodecylbenzenesulfonate, 10 parts of sodium glycerol monolaurate monosulfate, and 2.5 parts of sodium bis-2-hexylethylsulfosuccinate.

[0063] The preparation method of a high-efficiency flotation collector for high-sulfur iron, which is easy to muddy and fine-grained, complexly embedded copper-molybdenum ore is as follows:

[0064] A. In a stirred tank, add the surfactant in parts by weight to equal parts of ethanol, and stir and mix thoroughly at 30° C. and a stirring speed of 1500 r / min to obtain solution a. The method of addi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com