Flotation method of calcium-oxide-inhibited pyrite

A technology of pyrite and calcium oxide, applied in flotation, solid separation and other directions, can solve the problems of high cost, insufficient environmental protection, poor activation effect, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

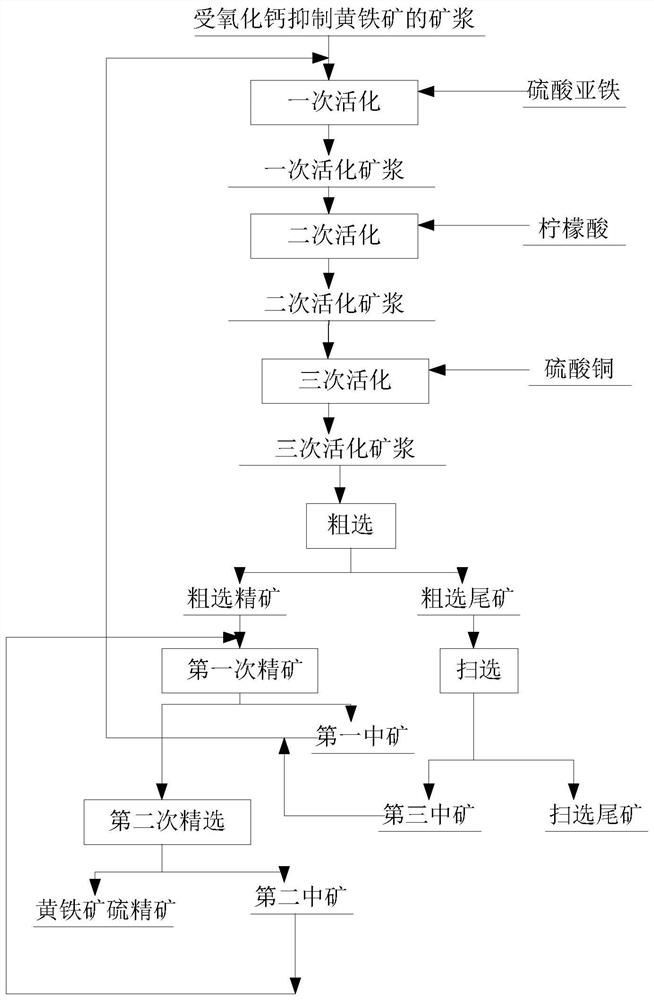

[0037] A copper-sulphur mine adopts a strong alkali process to separate copper and sulfur. The copper beneficiation tailings are suppressed pyrite pulp. The weight content of pyrite in the pulp is 15% (calculated as dry ore), and other gangue minerals mainly It is silicate minerals such as quartz and feldspar, and the pH value of the slurry is 12.1. as per figure 1 The flotation process shown is as follows:

[0038] Put the suppressed pyrite pulp in the first mixing tank, add ferrous sulfate to it, the addition amount is 5000g / t pulp dry weight, stir for 4min, the final pulp pH is 8.2, and form an activated pulp;

[0039] Put the primary activated pulp in the second mixing tank, add citric acid in the amount of 400g / t pulp dry weight, stir for 4min, and form the secondary activated pulp;

[0040] Put the secondary activated pulp in the third mixing tank, add copper sulfate to it, the addition amount is 50g / t of pulp dry weight, and add collector butyl xanthate, the addition ...

Embodiment 2

[0043] A lead-zinc-sulphide mine adopts a strong alkali process to suppress pyrite, and the tailings of zinc beneficiation are suppressed pyrite pulp. The content of pyrite in the pulp is 17% (calculated as dry ore), and other gangue minerals are mainly It is silicate minerals such as quartz, feldspar and pyroxene, and the pH value of the pulp is 11.8. as per figure 1 The flotation process shown is as follows:

[0044] Put the suppressed pyrite pulp in the first mixing tank, add ferrous sulfate to it, the addition amount is 4500g / t pulp dry weight, stir for 4min, the final pulp pH is 8.0, and form an activated pulp;

[0045] Put the primary activated pulp in the second mixing tank, add citric acid to it, the addition amount is 450g / t pulp dry weight, stir for 4min, and form the secondary activated pulp;

[0046] Put the secondary activated pulp in the third mixing tank, add copper sulfate to it, the addition amount is 50g / t of pulp dry weight, and add collector butyl xanthat...

Embodiment 3

[0049] A copper-lead-zinc-sulphide mine uses a strong alkali process to suppress pyrite, and the tailings of zinc dressing are suppressed pyrite pulp. The content of pyrite in the pulp is 11% (calculated as dry ore), and other gangue minerals It is mainly silicate minerals such as quartz, feldspar and pyroxene, and the pH value of the pulp is 11. as per figure 1 The flotation process shown is as follows:

[0050] Put the suppressed pyrite pulp in the first mixing tank, add ferrous sulfate to it, the addition amount is 2500g / t pulp dry weight, stir for 4min, the final pulp pH is 8.2, and form an activated pulp;

[0051] Put the primary activated pulp in the second mixing tank, add citric acid to it in an amount of 350g / t pulp dry weight, stir for 4min, and form the secondary activated pulp;

[0052] Put the secondary activated pulp in the third mixing tank, add copper sulfate to it, the addition amount is 50g / t dry weight of the pulp, add collector amyl xanthate, the addition...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com