Novel environment-friendly composite gold ore dressing collector

A collector and composite technology, applied in flotation, solid separation, etc., can solve the problems of low recovery rate of ore dressing, low recovery rate of gold-sulfur separation, and easy loss of fine-grained gold, so as to improve collection performance and select Good performance, enhance the effect of electrostatic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

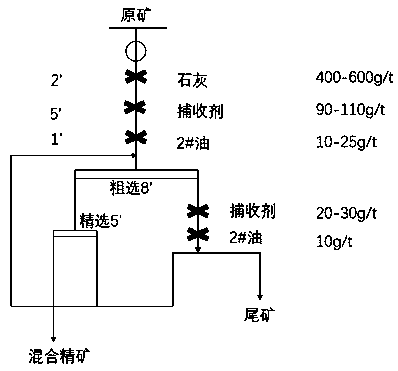

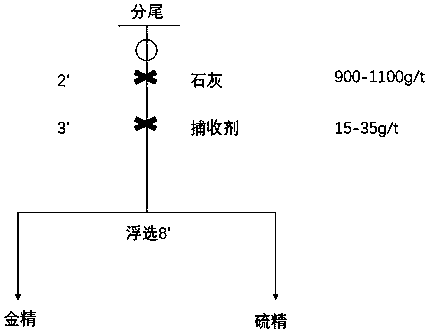

Method used

Image

Examples

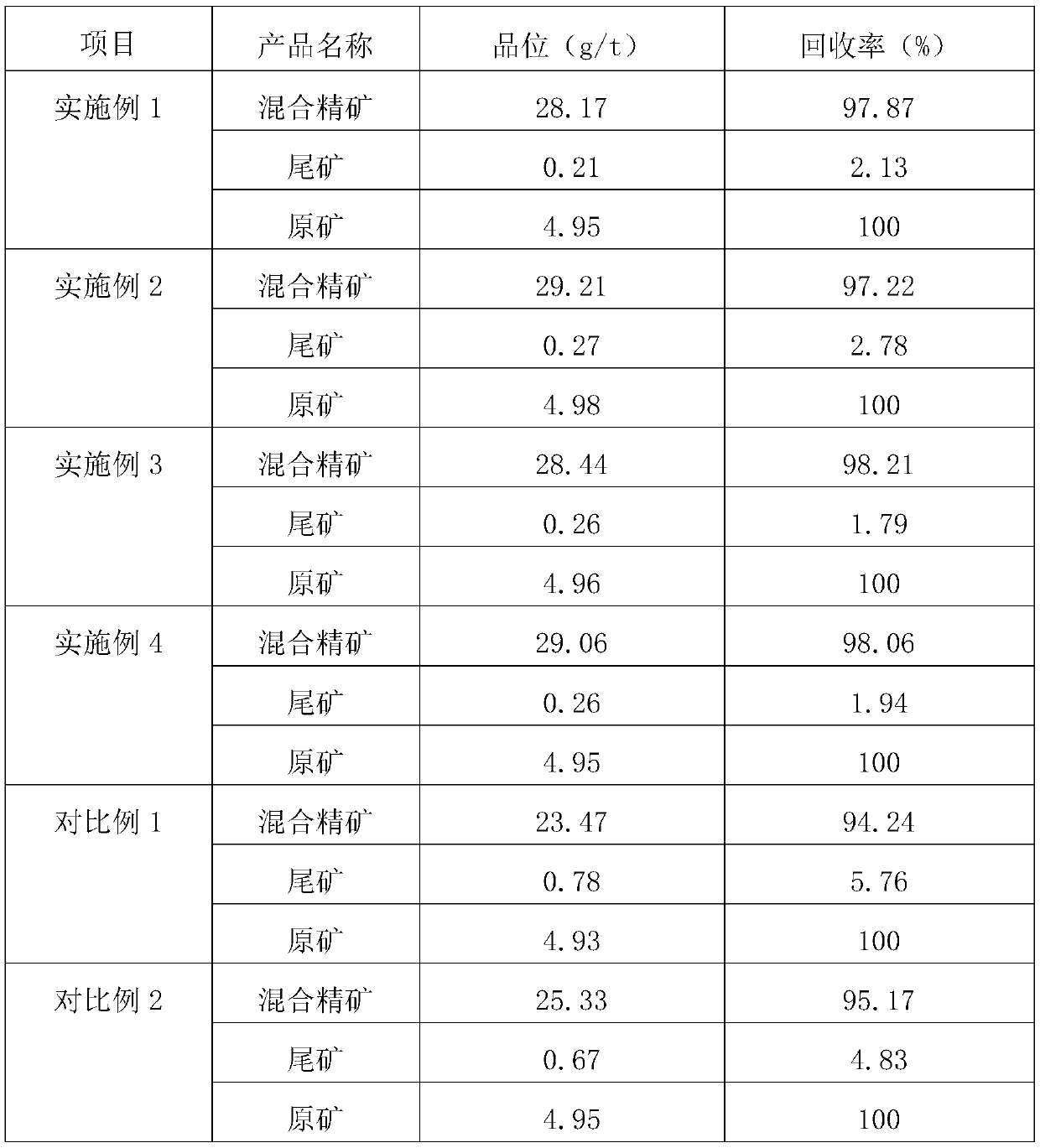

Embodiment 1

[0038] The novel environment-friendly compound gold mineral processing collector of the present embodiment comprises the following proportioning components in parts by weight: 35 parts of main collectors, 34 parts of secondary collectors, and 20 parts of water;

[0039] Wherein, the main collector is composed of the following raw materials in parts by weight: 45 parts of dibutyl dithiophosphate, 28 parts of isooctyl thioglycolate, 12 parts of ethyl thiocarbamate, 8 parts of sodium oleate, 9 parts of dihydrocarbyl thionocarbamate; Described secondary collector is made up of the raw material of following parts by weight: C 733 parts of hydroxamic acid, 28 parts of polyacrylamide, 13 parts of isooctyl phosphate.

[0040] The preparation method of collector in the present embodiment comprises the following steps:

[0041] ① Dissolve sodium oleate and dihydrocarbylthionocarbamate into the thiourethane solution in turn, and stir and react for 5.2 hours at a temperature of 70°C to p...

Embodiment 2

[0053] The new environment-friendly composite gold mineral processing collector of the present embodiment comprises the following proportioning components in parts by weight: 40 parts of main collector, 22 parts of secondary collector, and 15 parts of water;

[0054] Wherein, the main collector is composed of the following raw materials in parts by weight: 47 parts of diisopropyl dithiophosphate, 25 parts of isooctyl mercaptoacetate, 10 parts of ethyl thiocarbamate, 9 parts of sodium oleate , 8 parts of dihydrocarbylthionocarbamate; the secondary collector consists of the following raw materials in parts by weight: 35 parts of C8 hydroxamic acid, 27 parts of polyacrylamide, and 11 parts of isooctyl phosphate.

[0055] The preparation method of collector in the present embodiment comprises the following steps:

[0056] ① Dissolve sodium oleate and dihydrocarbylthionocarbamate into the thiourethane solution in sequence, and stir and react for 5 hours at a temperature of 71°C to ...

Embodiment 3

[0068] The novel environment-friendly composite gold mineral processing collector of the present embodiment comprises the following proportioning components in parts by weight: 42 parts of the main collector, 30 parts of the secondary collector, and 17 parts of water;

[0069] Wherein, the main collector is composed of the following raw materials in parts by weight: 50 parts of dibutyl dithiophosphate, 20 parts of isooctyl thioglycolate, 9 parts of ethyl thiocarbamate, 7 parts of sodium oleate, 9 parts of dihydrocarbylthionocarbamate; the secondary collector consists of the following raw materials in parts by weight: 31 parts of C9 hydroxamic acid, 27 parts of polyacrylamide, and 15 parts of isooctyl phosphate.

[0070] The preparation method of collector in the present embodiment comprises the following steps:

[0071] ① Dissolve sodium oleate and dihydrocarbylthionocarbamate into the thiourethane solution in turn, and stir and react for 5.5 hours at a temperature of 75°C to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com